AirCom Pneumatic

Videos

Loading the player ...

- Offer Profile

- AirCom Pneumatic GmbH is a

long-standing specialist in control, measurement and switching of air, gases

and fluids. The product range includes a large variety of valves and

regulators which are in use worldwide in many industry sectors and branches

– from mechanical and medicine engineering, chemical and pharmaceutical

industries to test engineering and laboratory techniques.

AirCom’s team of experts in pneumatic systems, fluid technology and electronics is at your service to help you find the right instrument for your application and task.

Product Portfolio

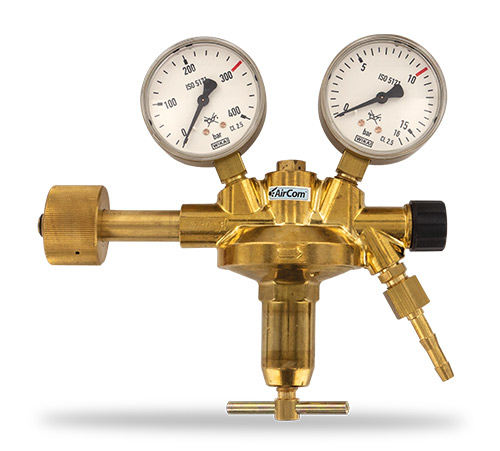

Pressure Regulators

Miniature

Standard

Low Pressure

High Pressure

Precision

Vacuum

Differential Pressure

mechanically operated

Cylinder

Water

Steam/RU

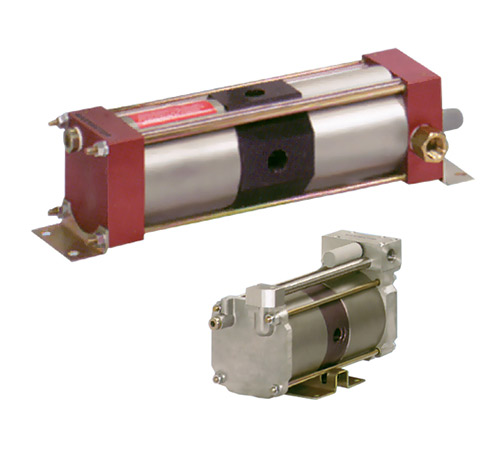

Volume Boosters

R119-J

-

Description:

Pilot-operated regulator adapted for control by small remote

pilot regulator or by proportional pressure valve. Ideal for

continuous high-capacity requirements where reduced pressure

must be held constant over wide variations in flow. Booster

with diaphragm up to regulator size G11/2, with piston from

regulator size G2 on. The booster is silicone-free.

Media: compressed air or non-corrosive gases

Supply_pressure: max. 21 bar

Ratio: 1:1

Pilot_pressure: max. 18 bar

Pilot_port: G1/8 at regulator size G1/4 and G3/8, G1/4 from regulator size G1/2 on

Air_consumption: approx. 1.0 l/min of pilot signal

Relieving_function: relieving, optionally non-relieving

Gauge_port: G1/4 on both sides of the body

Mounting_position: any

Temperature_range:

0 °C to 50 °C / 32 °F to 122 °F

up to 80 °C / 176 °F at G3

Body: zinc die-cast, aluminium at G3

Inner_valve: brass

Diaphragm: NBR/Buna-N, optionally FKM

Bottom_screw: reinforced nylon

R03-J

-

Description:

Pilot-operated volume booster with positive bias designed to supply outlet pressure equal to signal pressure plus an adjustable preset spring constant. With very high forward and reverse flow characteristics and excellent sensitivity. A typical application is balancing or regulating pressure in tanks.

Media: oil-free and 5 µm filtered compressed air or non-corrosive gases

Supply_pressure: max. 16 bar

Ratio: 1:1

Pilot_pressure:

max. 10 bar, accordingly lower in the case of manual pre-pressure setting, pilot port G1/8

Accuracy:

at supply pressure change from 2 bar to 7 bar

= < 6 mbar pressure deviation

at flow rate change from 0 l/min to 20 l/min

= < 20 mbar pressure deviation

response sensitivity = < 2 mbar

Air_consumption:

1.5 l/min at P1= 5 bar,

2 l/min at P1= 7 bar,

4 l/min at P1= 10 bar, < 1% of volume flow

Relieving_function: relieving

Relief_capacity: 700 l/min at 6 bar outlet and 0.35 bar overpressure above setpoint

Gauge_port: G1/4 on both sides of the body, one screw plug supplied

Mounting_position: any

Temperature_range:

0 °C to 60 °C / 32 °F to 140 °F, for appropriately conditioned compressed air down to -30 °C / -22 °F

Body: zinc die-cast

Elastomer: NBR/Buna-N

R208

-

Description:

The volume booster amplifies the volume at a 1 to 1 ratio of pilot pressure to outlet pressure.

The pilot pressure has no constant bleed and shows the same

function as a spring in a common regulator. Generating counter

pressure on the diaphragm.

Media: compressed air or non-corrosive gases

Supply_pressure: max. 17 bar

Pilot_port: G1/4

Accuracy:

at supply pressure variation of 7 bar = < 7 mbar pressure deviation

Transmission_error:

1% from 1 to 1 to 1 to 3 ratio, 2% at greater or inverse transmission

Response_sensitivity:

1 mbar at 1 to 1, 2 mbar at 1 to 2,

3 mbar at 1 to 3 and at inverse transmission

Air_consumption: max. 3 l/min, subject to outlet pressure

Relieving_function: relieving

Relief_capacity: 310 l/min at 1.5 bar outlet and 0.35 bar overpressure above setpoint

Gauge_port: G1/4 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 80 °C / 32 °F to 176 °F, NBR,

for appropriately conditioned compr. air down to -40 °C / -40 °F

0 °C to 90 °C / 32 °F to 194 °F, FKM,

for appropriately conditioned compr. air down to -40 °C / -40 °F

Body: aluminium die-cast

Elastomer: NBR/Buna-N, optionally FKM

Inner_valve: brass and zinc-plated steel

R750

-

Description:

The volume booster with transmission ratio amplifies the outlet

pressure at a 1 to 1 up to 1 to 6 ratio by a pneumatic pilot

pressure, which has no constant bleed. That signal pressure

has the same function as a spring in a common regulator.

Generating counter pressure on the diaphragm. This force is

compensated by the outlet pressure on the diaphragm's bottom side.

The ratio of pilot pressure to outlet pressure depends on the size

of the operating diaphragms.

Media: compressed air or non-corrosive gases

Supply_pressure: max. 17 bar

Pilot_port: G1/4

Accuracy:

at supply variation of 3.5 bar =

< 7 mbar at 1 to 1, < 10 mbar at 1 to 2,

< 21 mbar at 1 to 3, < 41 mbar at 1 to 6

Response_sensitivity:

< 2 mbar at 1 to 1, < 3 mbar at 1 to 2,

< 17 mbar at 1 to 3, < 23 mbar at 1 to 6

Air_consumption: max. 3 l/min, subject to outlet pressure

Relieving_function: relieving

Relief_capacity: 170 l/min at 1.5 bar outlet and 0.7 bar overpressure above setpoint

Gauge_port: on both sides of the body, thread equal to regulator thread

Mounting_position: any

Temperature_range:

0 °C to 70 °C / 32 °F to 158 °F, for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: zinc die-cast

Elastomer: NBR/Buna-N

Inner_valve: brass and stainless steel

R450

-

Description:

The volume booster amplifies the volume at a 1 to 1 ratio of

pilot pressure to outlet pressure. The pilot pressure has no

constant bleed and shows the same function as a spring in a

common regulator, generating counter pressure on the diaphragm.

This force is compensated by the outlet pressure on the

diaphragm's bottom side. The ratio of pilot pressure to outlet

pressure depends on the size of the operating diaphragms.

Media: compressed air or non-corrosive gases

Supply_pressure: max. 17 bar

Pilot_port: G1/4

Accuracy: at supply pressure variation of 7 bar = < 7 mbar pressure deviation

Response_sensitivity: 2.5 mbar

Air_consumption: without constant bleed

Relieving_function: relieving

Relief_capacity: 1100 l/min at 0.35 bar overpressure above setpoint

Gauge_port: G1/4 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C/-40 °F

Body: aluminium die-cast

Elastomer: NBR/Buna-N,optionally FKM

Inner_valve: brass and aluminium

R116

-

Description:

Pilot-operated regulator adapted for control by small remote

pilot regulator or by proportional pressure valve. Ideal for

continuous high-capacity requirements where reduced pressure

must be held constant over wide variations in flow.

The booster is equipped with a diaphragm.

Transmission ratio 1 to 1 (pilot pressure to outlet pressure).

Media: compressed air or non-corrosive gases

Mounting_position: any

Supply_pressure: max. 28 bar

Ratio: 1:1

Pilot_pressure: max. 18 bar

Outlet_pressure: 0.2 ... 18 bar

Air_consumption: without constant bleed

Relieving_function: 6500 l/min at 6 bar, see diagram

Ports: inlet / outlet = see chart

exhaust:

G1/2 (up to overall size G1/2),

G3/4 (from size G3/4 on)

gauge_P2: G1/4

gauge_P1: G1/8 (from size G3/4 on)

Temperature_range: -18 °C to 70 °C / 0 °F to 158 °F

Body: zinc die-cast

Inner_valve: brass

Elastomer: NBR/Buna-N

Bottom_screw: reinforced nylon

R200,R201

-

Description:

The volume booster amplifies the volume at a 1 to 1 ratio of

pilot pressure to outlet pressure.

The pilot pressure has no constant bleed. The bias spring at

booster R200 generates a positive shift of the pressure range

between pilot pressure and outlet pressure.

Booster R201 with great relief capacity is a combination of

two R200 boosters.

Media: compressed air or non-corrosive gases

Supply_pressure: max. 17 bar

Pilot_pressure: max. 10 bar

Pilot_port: G1/4 at R200, 1/4"NPT at R201

Accuracy: at supply pressure variation of 7 bar = < 20 mbar pressure deviation

Response_sensitivity: 30 mbar

Air_consumption: without constant bleed

Relieving_function: relieving, optionally non-relieving

Relief_capacity:

1800 l/min at 0.3 bar overpressure above setpoint at R200,

9000 l/min at R201

Gauge_port: G1/4 on both sides of the body at R200, 1/4"NPT at R201

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: aluminium die-cast

Elastomer: NBR/Buna-N on Polyester, optionally FKM

Inner_valve: stainless steel, cadmium-plated steel and brass

RGDJ-J/RGB4-J

-

Description:

Highly sensitive low pressure volume booster with diaphragm

and a 1 to 1 transmission ratio.

Zero shut-off prevents the outlet pressure from increasing

when there is no flow circulating.

Media: compressed air or non-corrosive gases

Supply_pressure_RGDJ-J: max. 400 mbar

Supply_pressure_RGB4-J: max. 4 bar

Pilot_pressure_RGDJ-J: max. 100 mbar

Pilop_pressure_RGB4-J: mac. 350 mbar

Pilot_port: G1/4

Air_consumption: without constant bleed

Relieving_function: non-relieving

Accuracy_at_maximum_volume_flow:

< 20% pressure deviation of full scale

Gauge_port: not available,

optionally G1/4 on one side of the body from regulator size R3/4" on

Mounting_position: any

Temperature_range_RGDJ-J: -20 °C to 70 °C / -4 °F to 158 °F

Temperature_range_RGB4-J: -15 °C to 60 °C / 5 °F to 140 °F

Body: aluminium

Inner_valve: aluminium and plastic

Elastomer: NBR/Buna

RZ-J

-

Description:

Highly sensitive diaphragm low pressure volume booster with excellent regulating characteristics.

Media: compressed air or non-corrosive gases

Supply_pressure:

max. 20 bar depending on the accuracy, the smaller P1 the higher the accuracy max. 10 bar at pressure range < 150 mbar

Accuracy:

at max. flow rate, < e.g. 10% pressure deviation of full scale

Air_consumption: without constant bleed

Adjustment: manual by turning the spindle under the cover of the spring cage

Relieving_function: non-relieving, optionally relieving

Gauge_port: not available

Mounting_position: any

Temperature_range: -20 °C bis 60 °C / -4 °F to 140 °F

Body: SG cast iron GGG50, GGG40 at G2

Elastomer: NBR/Buna-N, optionally FKM

Spring_cage: aluminium

Inner_valve: brass and stainless steel

R650

-

Description:

Signal-operated regulator designed to provide outlet pressure

which is the sum of the input signal pressure plus a preset bias.

As an option, the relay can start with bias range -0.3 bar / -4 psi.

The relay can also be used as a differential pressure regulator.

Media: compressed air or non-corrosive gases

Supply_pressure: max. 17 bar

Pilot_pressure: max. 10 bar, pilot port G1/4

Ratio: 1:1

Accuracy: response sensitivity < 1 mbar

Air_consumption: without constant bleed

Relieving_function: relieving

b Relief_capacity: 110 l/min at 1.5 bar outlet and 0.35 bar overpressure above setpoint

Gauge_port: G1/4 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: aluminium die-cast

Elastomer: NBR/Buna-N

Inner_valve: brass

R3000-J

-

Description:

Volume booster made of stainless steel throughout, without constant bleed, transmission ratio 1 to 1.

Media: compressed air, gases or liquids

Supply_pressure:

max. 60 bar for R3000-06J/-08J, all others 50 bar,

for liquids Δp max. = 25 bar

Pilot_pressure:

max. 15 bar for R3000-..J2,

max. 50 bar for R3000-..J5,

Control_port: G¼

Relieving_function: non-relieving, optionally relieving

Exhaust: DN 2, optionally DN 4

Gauge_port:

G¼ on both sides of the body, one screw plug supplied

Mounting_position: any

Temperature_range:

0 °C to 80 °C / 32 °C to 176 °F for FKM or EPDM

0 °C to 130 °C / 32 °C to 266 °F for high temperature version

for appropriately conditioned compressed air down to -20 °C / -4 °F or low temperature version down to -40 °C / -40 °F

Body: stainless steel 316L, material no. 1.4404

O-rings: FKM, optionally EPDM

Diaphragm: NBR/Buna-N with PTFE coating, optionally SST

Inner_valve: SST 316L, W.-Nr. 1.4404

R120-J

-

Description:

Solid volume booster made of brass or bronze throughout with

a 1 to 1 transmission ratio.

R120-02J2 to R120-08J2 are diaphragm-operated.

R120-12J, R120-16J and R120-..J5 are piston-operated.

Media: compressed air, non-corrosive gases or liquids

Supply_pressure: max. 50 bar, for liquids Delta p max = 25 bar

Pilot_pressure:

max. 15 bar for R120-..J2,

max. 50 bar for R120-..J5

Ratio: 1:1

Pilot_port: G1/4

Air_consumption: without constant bleed

Relieving_function: non-relieving, optionally relieving

Relief_size: DN2 mm, optionally DN4 mm

Gauge_port: G1/4 on both sides of the body, one screw plug supplied

Mounting_position: any

Temperature_range:

0 °C to 80 °C / 32 °F to 176 °F, FKM or EPDM

0 °C to 130 °C / 32 °F to 266 °F high temperature version,

for appropriately conditioned compressed air down to -20 °C / -4 °F, optionally low temperature version down to -400 °C / -40 °F

Body: brass up to G1/2, bronze from G3/4 on

O-rings: FKM or optionally EPDM

Diaphragm: NBR/Buna-N with PTFE coating

Inner_valve: brass

RLM,RLE

-

Description:

The pilot pressure regulator/booster regulates the outlet

pressure through a signal pressure at ratio of 1 to 1.

Functioning as a pressure regulator the pilot pressure may

either be internally inducted from the inlet pressure or

externally. The dome chamber is closed by a needle valve.

Functioning as a volume booster the dome is controlled by

a proportional pressure regulator or a pilot pressure regulator.

Media: compressed air, non-corrosive gases or liquids

Supply_pressure:

max. 25 bar for RL.-0.J1,

max. 100 bar for RL.-0.J2,

max. 40 bar for oxygen,

max. 1.5 bar for acetylene

Pilot_pressure:

max. 24 bar for RL.-0.J1,

max. 99 bar for RL.-0.J2

Pilot_port: G1/4

Accuracy:

at supply pressure variation of 10 bar = 0.1 bar pressure deviation

at temperature variation of 3 °C / K = 1% pressure deviation at internal pilot pressure

Air_consumption: without constant bleed

Relieving_function: non-relieving

Gauge_port: not available

Mounting_position: any, dome preferably mounted up

Temperature_range:

-20 °C to 100 °C / -4 °F to 212 °F for FKM,

-40 °C to 130 °C / -4 °F to 266 °F for EPDM

Body: brass or stainless steel 1.4571

Inner_valve: brass or stainless steel 1.4571

Elastomer: FKM, optionally EPDM

RH3-J

-

Description:

Highly reliable high pressure volume booster with diaphragm and high flow.

In addition, the booster features high sensitivity and excellent regulating characteristics.

Media: compressed air, non-corrosive gases or liquids

Supply_pressure: max. 260 bar, optionally 345 bar or 310 bar

Test_pressure: 150% of maximum supply pressure according to regulations ANSI / ASME B31.3

Pilot_pressure: see chart, pilot port G1/8

Leakage_rate: < 1x 10-4 mbar l/s He

Air_consumption: without constant bleed

Relieving_function: non-relieving

Gauge_port: not available, optionally 1/4"NPT at inlet and outlet

Mounting_postition: any

Temperature_range: -25 °C to 100 °C / -13 °F to 212 °F

Body: brass, optionally stainless steel

Elastomer: FKM

Inner_valve: PTFE, brass or optionally stainless steel

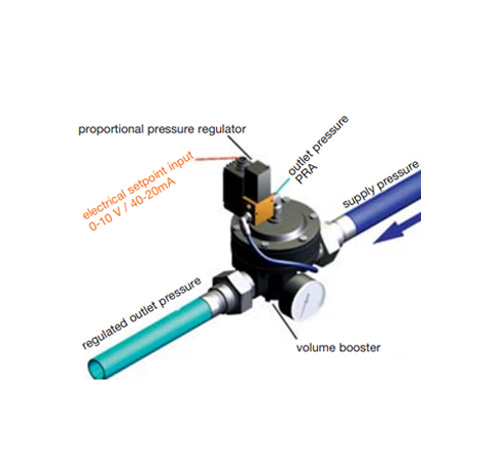

BP1

-

Description:

General_operational_description:

The volume booster and proportional valve are fed by the supply

pressure. When no command signal is applied the outlet pressure

behind the booster is zero. When the command signal is increased the outlet pressure rises in proportion to it.

Since the transmission ratio is not exactly 1 to 1, a slight

pressure difference occurs between the outlet pressure of the

proportional valve and the booster’s outlet on single loop systems.

This can be balanced by a feedback signal (double loop), though.

At single loop combinations the pressure difference between command signal and outlet pressure is being ignored because the proportional valve only refers to its own outlet pressure within the pilot chamber.

The outlet pressure performance is dependent of the volume booster’s accuracy.

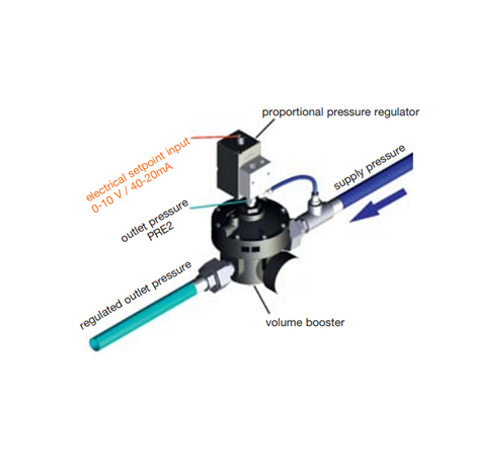

BP2

-

Description:

General_operational-description:

The volume booster and proportional valve are fed by the supply pressure. When no command signal is applied the outlet pressure behind the booster is zero. When the command signal is increased the outlet pressure rises in proportion to it. Since the transmission ratio is not exactly 1:1, a slight pressure difference occurs between the outlet pressure of the proportional valve and the booster’s outlet on single loop systems. This can be balanced by a feedback signal (double loop), though. Combinations with a second feedback have the possibility to balance pressure differences. For this a pressure transducer is installed in the outlet line of the booster. The electrical signal of the transducer is applied as a feedback signal onto the proportional valve. The valve detects any pressure differences and compensates them automatically. In high flow applications a pressure drop at the outlet of the pilot regulator is thus minimised.

Proportional Regulators

PQ1

-

Description:

The pneumatic proportional valve produces outlet pressure in

proportion to an electrical command input signal. It comprises

a complete closed loop servo system consisting of valves,

manifold, housing and electronic controls.

Single_loop:

Pressure is controlled by two solenoid valves. One valve

functions as inlet control, the other as exhaust. The pressure

outlet is measured by an internal pressure transducer which

provides a feedback signal to the electronic controls. This

feedback signal is compared with the command input signal.

Any difference between the two signals causes one of the two

solenoid valves to open, allowing flow into or out of the system.

Accurate pressure is maintained by these two valves.

Accuracy:

Linearity / Hysteresis = ± 0.15 % FS

Response sensitivity = < 0.1% FS

Repeatability = ± 0.02% v.E

Total accuracy = ± 0.2 % V.E.

Supply_voltage: 15...24 V DC, residual ripple < 10%, with reverse voltage protection

Command signal: 0-10V, 4-20mA as an option

PQ2

-

Description:

The pneumatic proportional valve produces outlet pressure in

proportion to an electrical command input signal. It comprises

a complete closed loop servo system consisting of valves,

manifold, housing and electronic controls.

Double_loop:

The servo valve expands in single loop operation by combining

an additional feedback from an external sensing device with the

internal transducer. The external sensor provides information

on the control status.

The PQ2 then compares the command signal with the second loop feedback signal. Should there be a difference in the signal

comparisons, the servo valve will make adjustments to the

internal loop to bring the system into balance. This provides

accurate final outlet. The acceptance of electrical feedback from

an external sensor enables precise control of conditions such as

pressure, force, torque, position or flow.

External_pressure_transducer:

Any pressure transducer for 0-10 V and 4-20 mA output signal and

suitable for 15-24V DC supply voltage can be applied.

An appropriate coupling socket plus cable is required.

Supply_voltage: 15...24 V DC, residual ripple < 10%, with reverse voltage protection

Command signal: 0-10V, 4-20mA as an option

PQ3-PQ6

-

Description:

Closed loop electronic pressure regulator consisting of two

solenoid valves, an internal pressure transducer, and an

electronic control circuit mounted to an integral volume

booster. The pressure is controlled by activating the

solenoid valves, which apply pressure to the pilot side of

the volume booster.

Single_loop:

Pressure is controlled by two solenoid valves. One valve

functions as inlet control, the other as exhaust. The pressure

outlet is measured by an internal pressure transducer which

provides a feedback signal to the electronic controls.

This feedback signal is compared with the command input signal.

Any difference between the two signals causes one of the two

solenoid valves to open, allowing flow into or out of the system.

Accurate pressure is maintained by these two valves.

Media: dry, unlubricated and 5 μm filtered compressed air or non-corrosive gases

Pressure_range: -1... 35 bar

Accuracy: +/- 0.4%

Input_signal: 0-10 V; 4-20 mA as an option

Mounting_position: any

Protection_class: IP65

Adjustment: zero point, span, hysteresis

Response_time: 15 ... 20 ms

Air_consumption: without constant bleed

Power_consumption: 6 W

Temperature_range: 0 °C to 70 °C / 32 °F to 158 °F

Booster_body: nickel-plated aluminium

Elastomer: FKM, NBR/Buna-N

Transducer: aluminium and silicon

Valves: nickel-plated brass

PM

-

Description:

Proportional control valves with closed loop control

technology for better control of pressurised gases.

The instruments can be built as single closed loop or

dual closed loop control valves.

Media: dry, lubricated or unlubricated and 5 µm filtered

compressed air or non-corrosive gases

Fail_freeze: constant outlet pressure at voltage drop

Second_loop: 0...10 V, impedance 4.7 kΩ, ratio of internal to external relationship is 10% to 90%

Supply_voltage: 15...24 V DC, residual ripple < 10%, with reverse voltage protection

Command signal: 0-10V, 4-20mA as an option

Impedance:

0...10 V / 4.7 kΩ,

4...20 mA / 100 Ω,

jumper selectable command

Monitor_signal: 0...10 V at max. 10 mA

Electrical_ports: terminal strip for 2.5 mm2

Power_consumption: 3.6 W regulating, 0.5 W non-regulating

Air_consumption: without constant bleed

Linearity/Hysteresis: < 0.15% FS

Repeatability: < 0.02 FS

Temperature_influence: < 1% FS at 0 °C to 50 °C / 32 °F to 122 °F

Adjustment: zero point and span

Temperature_range: 0 °C to 70 °C / 32 °F to 158 °F

Mounting_position: any, vibration-resistant

Ports: brass

Elastomer: FKM

Transducer: aluminium and silicon

Valves: nickel-plated brass

PRE

-

Description:

Piezo-operated proportional pressure valve based on the

principle of a piezo element which bends when voltage is

applied. At the end of the piezo element is a flapper valve,

which operates against a precision nozzle to create back

pressure on the control diaphragm of a booster relay.

A pressure transducer provides feedback of the outlet

pressure compared with the setpoint value with correction by

the electronic control system if necessary.

Minimal_power_consumption:

- no self-heating, even none at pressure absence

- safe battery operation over a long period

Piezo_element:

- almost no power consumption necessary for regulation

- extremely quick regulating operations

- low-noise regulation especially for medical and laboratory technology

Small_and_light_design:

- particularly suitable for portable devices in conjunction wi700th battery operation

- ideal for limited space conditions

Supply_voltage: 24 V DC +/- 10%

PRE1:

DN 2.5, 350 l/min, coupling socket M8x1, 3-pin, monitor signal, 4-pin monitor signal optionally 0...P2max, = 0...10 V, max. 1 mA, Ra > 1kΩ

PRE2:

DN 6, 1600 l/min, coupling socket M12x1.5, 5-pin

monitor signal standard 0...P2max, = 0...10 V, max. 1 mA, Ra > 1kΩ

PR

-

Description:

The pneumatic proportional valve controls the outlet pressure

in proportion to an electrical command input signal.

It comprises a complete closed loop servo system in a compact

monoblock assembly with proportional solenoid valve, electronic

regulator and internal pressure transducer.

In the process, the outlet pressure is transformed into a

proportional electrical signal and compared with the input signal.

If the outlet pressure exceeds the preset setpoint, the valve

exhausts down to the pressure desired.

The valve has no constant bleed.

At absence of input signal or supply voltage the valve exhausts.

The power supply of the setpoint potentiometer is provided by the

proportional valve via connector pin number 5.

Pressure_transducer:

Open transducers = 100 mbar, 500 mbar, 1 bar and vacuum

Application_examples:

Proportional pressure regulators are being used for blowing machines, ultrasonic equipments, testing machines, painting systems, contouring systems, laser welding machines, textile machines, cheese presses, pneumatic brakes, clamping devices and medical engineering.

PP

-

Description:

The pneumatic proportional valve controls the outlet

pressure in proportion to an electrical command input signal.

It comprises a complete closed loop servo system in a compact

mono block assembly with proportional solenoid valve, electronic

regulatior and internal pressure transducer. The valve works

as a 3-port/2-way valve with proportional magnet. The digital

control system offers advantages at installation and commissioning for adapting the valve to special applications. The regulator can be set and optimised using a PC, RS232 adapter and software. Data record can be saved and used for further valves. The valve has no constant bleed. At absence of input signal or supply voltage the valve exhausts.

Software:

Display: signal, outlet pressure, parameter, pressure switch signal etc.

Scope_function: view setpoint, outlet pressure, internal signals from PID control

Parameters: command signal, zero point, overload threshold, ramp

Valve_diagnosis: parameters factory set or customised, optimization of the valve

Technical features- Pressure range 0...-0.1 bar bis 0...50 bar

- Command signal 0-10 V, 0-20 mA, 4-20 mA

- Output signal 0-10 V, 0-20 mA, 4-20 mA

- Adjustment zero point, range

- Pressure sensor 100 / 500 mbar, 1 / 5 / 10 / 16 / 20 / 30 / 50 bar

- Flow rate 250 / 820 / 1700 / 6500 l/min

- Linearity / Hysteresis ± 0.5% FS

- Response sensitivity < 0.5% v.FS

- Repeatability < 0.5% FS

- Regulating time < 1 s

- Rated input 12 / 22 / 30 / 44 W

- Relief capacity full nominal size

PF

-

Description:

The pneumatic proportional valve controls the outlet pressure

in proportion to an electrical command input signal. It comprises

a complete closed loop servo system in a compact mono block

assembly with proportional solenoid valve, electronic regulatior

and internal pressure transducer. The valve works as a slide valve

and is designed for flow applications such as thermal cutting.

The digital control system offers advantages at installation and

commissioning for adapting the valve to special applications.

The regulator can be set and optimised using a PC, RS232 adapter and software. Data record can be saved and used for further valves.

The valve has no constant bleed. At absence of input signal or

supply voltage the valve exhausts.

Software_Display: signal, outlet pressure, PID parameters, pressure switch signal etc.

Scope_function: view setpoint, outlet pressure, internal signals from PID control

Media: dry, lubricated, unlubricated and 50 μm filtered compressed air or non-corrosive gases

Supply_voltage: 24 V DC ± 10 V, residual ripple < 10%

Power_consumption: 14 W (810mA current consumption)

Signal_range: 0-10 V, 100 kΩ impedance 0/4-20 mA, 250 Ω impedance

Electr._connection: plug M12x1, 5-pin (protection class IP65)

Mounting_position: any, preferably solenoid on top

Accuracy: hysteresis 0.5% FS

Linearity_repeatability: < ± 0.5% FS

Temp._range: fluid / ambient 0 °C to 60 °C / 32 °F to 140 °F

Body: aluminium

Elastomer: NBR/Buna-N

PT6

-

Description:

The proportional pressure transducer translates a direct current

or voltage input signal into a proportional pneumatic outlet

signal. The valve uses proven moving coil and flapper nozzle

technology with a built-in pneumatic relay with slight

amplification and positive bias. Additional supply voltage is

not necessary. The device has to be protected against vibration.

Media: 5 µm filtered compressed air or non-corrosive gases

Supply_voltage: not required

Electrical_connector:

plug according to DIN 43650A, contact gap 18 mm,

3-pin, with coupling socket 30 x 30 mm

Command_signal:

0 … 10 V / 1.1 kΩ at PT6..-B,

otherwise 900 Ω 4 … 20 mA / 200 Ω at PT6..-B, otherwise 260 Ω

Failsafe: exhaust at power breakdown

Response_sensitivity: < 0.2% FS

Linearity: < 0.5 % FS at 0.2…2 bar, otherwise < 1% FS

Repeatability: < 0.1% FS

Hysteresis: < 0.25% FS at 0.2…2 bar, otherwise < 1% FS

Vibration_sensitivity: < 2% FS, for 10 g and 15 … 500 Hz

Adjustment:

Zero_point = by 0.3 bar

Range = 40% FS

Mounting_position: upright ± 15°

Temperature_range: -30 °C to 65 °C / -22 °F to 149 °F

Protection_class: IP 65

Body: chromated aluminium

Elastomer: NBR/Buna-N

Nozzle: sapphire in nickel-plated brass plate

Inner_valve: stainless steel, brass, zinc-plated steel

PPB

-

Description:

The series line of potentiometers are designed for use as a command signal for control valves. A 10 volt reference is used to provide excitation to the potentiometer. An op-amp measures the output on the wiper of the potentiometer and provides buffering to eliminate external components from affecting the linearity of the potentiometer.

A three wire cord is provided and is attached to the pc board to make necessary power signal and common connections

Field_of_application:

0-10 V version PPB-U is compatible with all proportional pressure regulators.

4-20 mA version PPB-I is compatible with all valves of Series PQ and PM.

For all other valves, e.g Series PP, PR, PRE, a setpoint of 4.1 ... 18.5 mA is generated.

Measuring_range: 0 ... 999

Supply_voltage: 15 - 24 V DC

Current_consumption: max. 30 mA

Linearity/Hysteresis: ± 0.25% FS

Mounting_position: any

Temperature_range: 0 °C to 70 °C / 32 °F to 158 °F

PT7

-

Description:

The proportional valve translates a direct current or voltage

signal into a linear proportional pneumatic outlet signal. With

rapid response controls using low-powered piezo microelectronics, flapper nozzle and solid state control circuit. The proportional valve has internal electronic with an electrical feedback sensor and is housed in NEMA4X (IP65) enclosure with six outlet ranges, jumper selectable. Input and outlet ports on both ends of the body simplify pneumatic piping.

Media: 5 µm filtered compressed air or non-corrosive gases

Supply_voltage:

7…30 V DC, 90 mW, required for 0…10 V setpoint input only,

with reverse voltage protection

Electrical_connector:

plug according to DIN 43650A, contact gap 18 mm, 3-pin,

with coupling socket 30 x 30 mm

Command_signal:

0 … 10 V/ 10 kΩ, 3-pin, 24 V DC supply voltage,

4 … 20 mA / 330 Ω, two-wire, min. 7 V DC on input

Failsafe: exhaust at power breakdown

Response_sensitivity: < 0.2% FS

Linearity: < 0.25% FS

Repeatability: < 0.1% FS

Hysteresis: < 0.1% FS at 0.2…0.5 bar, otherwise < 0.25% FS

Vibration_sensitivity: < 1% FS, for 10 g and 15 … 500 Hz

Adjustment:

Zero point = by 0.3 bar

Range = 40% FS

Mounting_position: any

Temperature_range: -40 °C to 70 °C / -40 °F to 158 °F

Protection_class: IP 65

Body: chromated aluminium

Elastomer: NBR/Buna-N

Nozzle: sapphire in nickel-plated brass plate

Inner_valve: stainless steel, brass, zinc-plated steel

PD

-

Description:

The proportional pressure regulator is digitally controlled and

works as a 3/2 valve with proportional magnet and closed loop.

The digital control system offers advantages at installation and

commissioning for adapting the valve to special applications. The

regulator can be set and optimised using a PC, RS232 adapter and software.

Software:

Display: signal, outlet pressure, PID parameters, pressure switch signal etc.

Scope_function: view setpoint, outlet pressure, internal signals from PID control

Parameters: range, zero, amplification and ramp

Valve_diagnosis: parameters factory-set or customised, optimization of the valve.

Media: dry, lubricated or unlubricated and 50 µm filtered compressed air or non-corrosive gases

Supply_voltage: 24 V DC ± 10 V, residual ripple < 10%

Command_signal: 0 … 10 V / 100 kΩ impedance, 0/4-20 mA / 250 Ω impedance

Electrical_connector: plug M12x1, 5-pin, with coupling socket

Pressure_switch: PNP outlet, accurate to ± 5%

Power_consumption: 21 W at DN 4, 40 W at DN 8

Linearity/Hysteresis: < 0.5% FS / < 1% FS

Repeatability: < 0.5% FS

Mounting_position: any

Protection_class: IP 65

Temperature_range:

Medium: 0 °C to 60 °C / 32 °F to 140 °F

Ambience: 0 °C to 50 °C / 32 °F to 122 °F

Body: aluminium

Elastomer: NBR/Buna-N

Inner_valve: POM

PQH

-

Description:

Proportional control valve with closed loop control technology

for better control of pressurised gases. The instrument can be

built as single closed loop or dual closed loop control valve.

Media: dry, lubricated or unlubricated and

20 µm filtered compressed air or non-corrosive gases

Fail_freeze: constant outlet pressure at voltage drop

Second_loop: 0-10 V, impedance 4.7 kΩ, ratio of internal to

external relationship is 10% to 90%

Supply_voltage: 15-24 V DC, residual ripple < 10%,

with reverse voltage protection

Impedance: 0-10 V/10 kΩ, 4-20 mA/100 Ω

Protection_class: IP65

Electrical_connector: M12, 6-pin

Power_consumption: 24 W ( 985mA) regulating, 2.4W (100mA) non-regulating

Linearity_Hysteresis: < 0.5% FS

Repeatability: < 0.5% FS

Adjustment: zero, span, hysteresis

Temperature_range: 0 °C to 70 °C / 32 °F to 158 °F

Mounting_position: any, vibration-resistant

Ports: brass

Elastomer: FKM

Transducer: silicon

Valves: stainless steel

PCEX

-

Description:

Piezo-operated proportional pressure valve with closed loop in a

two-wire system. Outlet pressure is proportional to an electrical

input signal. The valve can be mounted in any position and is

immune to shock or vibration. It is pilot-controlled to reach a

higher flow rate.

Media: lubricated or unlubricated and 50 μm filtered compressed air or non-corrosive gases

Supply_voltage:

not necessary due to two-wire system

(supply through 4...20 mA command signal)

Electrical_connector: coupling socket, 4-pin according to DIN 43651, size 15 x 15 mm connector turnable in 90° steps

ATEX_classification: Compliance with directive 94/9/EC for use in

potentially explosive atmosphere of group IIC,

temperature classification T4.

Ignition protection type: II1G Ex ia IIC T4; II1D Ex D20 T135°C

Power_consumption: < 200 mW

Failsafe feature exhaust at power breakdown

Linearity/Hysteresis: < 1% FS Repeatability < 0.5% FS

Mounting_position: any

Protection_class: IP 65

Air_consumption: The pilot valve has an air consumption of 1.6 l/min

Temperature_range:

Media = 0 °C to 60 °C / 32 °F to 140 °F

Ambient = 0 °C to 60 °C / 32 °F to 140 °F

Body: aluminium and plastic

Elastomer: NBR/Buna-N and FKM

Inner_valve: stainless steel and plastic

P180

-

Description:

Motorised air pressure regulator designed for precise pneumatic

control using an electrical signal from a remote location. A slip

clutch prevents from motor damages at overload or end position

limitations.

Media: dry, oil-free and 5 µm filtered compressed air or non-corrosive

Operation:

With no electrical power the regulator maintains a precise setpoint

despite variable supply pressure and flow rates. When power is

applied to the motor the pressure outlet changes.

Power_consumption: 6 W for 6 rpm motor as standard, 4 W for 2 rpm motor

Control_signal: 220 V AC, optionally 24 V DC, 24 V AC or 110 V AC

Electrical_connector:

4 single wires, optionally plug according to DIN 43650A,

contact gap 18 mm, 3-pin with coupling socket

Accuracy: at varying supply pressures = < 1 mbar pressure deviation

Air_consumption: max. 2.3 l/min, subject to outlet pressure,

< 1% of volume flow

Relieving_function: relieving

Mounting_position: any, preferably upright

Relief_capacity: 140 l/min at 1.5 bar outlet and 0.35 bar overpressure above setpoint, optionally 280 l/min

Gauge_port: 1/4" NPT on both sides of the body

Temperature_range: -18 °C to 60 °C / 0 °F to 140 °F

Body: zinc die-cast

Elastomer: NBR/Buna-N

Inner_valve: stainless steel and brass

Mounting_bracket: black-coated steel

Prop. Flow Regulation

PV202 - 3

- Your are now in the overview of an article: PV202-3

Choose a version from the table underneath, please.Description:

The proportional flow valve can be controlled either by 24 V DC

or optionally by a plug amplifier with switchable signals.

Media: 50 µm filtered compressed air, vacuum or non-corrosive gases

Plug_amplifier: Conversion of the analogue signal into a pulse-wide modulated current.

Supply_voltage: 24 V DC, max. 1.1 A

Adjustment: zero point and range

Switchable_signal: 0...10 V, 0...20 mA, 4...20 mA

Time_ramp: 0.1 to 3 s selectable

Close_function: < 2% of max. signal

Hum_frequency: 40 to 700 Hz selectable

Electrical_connector: plug, 3-pin, with coupling socket (Pg 9P or PG 11P)

Operating_pressure: see chart, max. 12 bar

Protection_class: IP 65 with coupling socket

Mounting_position: any

PVK

-

Description:

Small proportional flow valve for regulating both air and non-corrosive gases.

Voltage signal 10 V as standard or optionally 5 V or 20 V DC.

Media: 50 µm filtered compressed air or non-corrosive gases

Operating_pressure: see chart, max. 7 bar

Electrical_specification:

1.

command signal 0-5 V DC

max. voltage 0-6.2 V DC

resistance 13 Ω

current consumption 0-370 mA

power consumption 1.9 W

2.

command signal 0-10 V DC

max. voltage 0-12.4 V DC

resistance 54 Ω

current consumption 0-185 mA

power consumption 1.9 W

3.

command signal 0-20 V DC

max. voltage 0-24.8 V DC

resistance 218 Ω

current consumption 0-92 mA

power consumption 1.9 W

Electrical_connection: solder lug or terminal lug, 2.5 x 0.5 mm

Mounting_position: any

Hysteresis: ± 10% FS

Repeatability: ± 3% FS

Temperature_range: 0 °C to 60 °C / 32 °F to 140 °F

Body: nickel-plated brass

Elastomer: NBR/Buna-N, optionally FKM or EPDM

Inner_valve: stainless steel and brass

PV21-PV40

-

Description:

2-way proportional flow valve controls the volume flow of

maximum 1185 l/min for air in proportion to the input signal

of 0 to 10 V or 0/4 to 20 mA. The proportional valve and the

electronic control unit are ordered separately.

Product_selection:

To achieve the best linear flow characteristics, it is advisable

not to reduce the flow too much and to have enough pressure drop

at the valve for good control.

Reference_value: ∆p at the valve > 30% of the total pressure drop.

Installation_hint:

The nominal width of the orifice following the proportional valve

should not be smaller than the nominal width of the valve.

A constriction of the cross-section after the valve should be

categorically avoided!

Design:

2-way proportional flow valve, normally closed during absence of

current, with additional control module PVY in cable plug or

- PVX in housing for DIN rail mounting

- PV1, PV2 and PV3 are directly acting solenoid control valves

- PV40, PV50 and PV60 are servo-assisted solenoid control valves

Mounting_position: any, but preferably with coil upright

Protection_class: IP 65 with coupling socket, IP 40 for DIN rail version

Temperature_range:

-10 °C to 90 °C / 14 °F to 194 °F for medium

-10 °C to 55 °C / 14 °F to 131 °F for electronics

Body: brass

Inner_valve: brass and stainless steel

Elastomer: FKM

Control_housing: plastic

PVE

-

Description:

Compact positioner with analogue control. Compressed air for

remote control necessary. The stroke is made proportional to the

flow through the parabolic contour of the piston. The valve shuts

tight and is of anti-water hammer design.

Media: compressed air, vacuum up to 10-2 mbar or liquids up to

viscosity of max. 600 CST (mm2/s)

Control:

1. pneumatic

- lubricated and unlubricated and 50 µm filtered compressed air

- 4...8 bar

- port G1/8

2. electrical

- 0-10 V, optionally 4-20 mA, supply 24 V DC ± 10%,

- power consumption 150 mA/3.6 W

- analog position feedback signal 0-10 V / 4-20 mA (after automatic balance)

Control_element:

2-port/2-way valve, NC (normally closed) as standard,

as option 3-port/2-way valve for mixing different media,

with standard piston

Electrical_connection: cable gland, optionally M12

Mounting_position: any

Protection_Class: IP 66

Linearity/Hysteresis: < 2% FS

Repeatability: < 1.0% FS

Failsafe: valve closes (NC) in the event of voltage failure, optionally outlet fail freeze feature

Temperature_range:

Ambiance: 0 °C to 50 °C / 32 °F to 122 °F

Medium: -10 °C to 180 °C / 14 °F to 356 °F

Control_valve_body: bronze, optionally SST 316L

Cone_seal: PTFE

Proportional_valve_body: aluminium, PA and FV

P8

-

Description:

Motorised proportional flow valve with low power consumption

and resistance to contamination. Throttle setting by wear-

resistant control drives made of oxide ceramic. Throttling occurs

with drip-tight zero shut-off but no gas tightness.

Media: compressed air, vacuum or liquids up to viscosity of 40 mm²/s Hysteresis: ± 4%

Operation:

DC, synchronous or stepping motor with standard voltage of 24 V DC or AC ±10% residual ripple and IP 54.

All motors fulfil standards EN50.081-1, EN50.082-2 and 89/336/EEC.

DC_motor_(15/24):

Motor with feedback potentiometer for servo-amplifier.

Resistor 1kΩ Â± 20 %, control e.g. by servo-amplifier.

Only part of potentiometer range is used.

Voltage for potentiometer 12 V, max. 10 mA.

DC_motor_(50/51):

With integrated position controller.

Setpoint input using jumpers = 0...10 V, 0/4...20 mA.

Input resistance 200 kΩ at voltage signal, 500 Ω at current signal.

Stepper_motor_(38):

Bipolar, by means of SAA1042A (Motorola) with drop resistance of

44 Ω per phase at a driver (full-step).

operating voltage of 24 V ± 5%. 2028 steps for 90° control disc turn,

200 Hz nominal step frequency.

Temperature_range: 10 °C to 90 °C / 14 °F to 194 °F

Protection_class: IP 54

Body: brass

Control_discs: oxide ceramic

Elastomer: NBR/Buna-N, optionally FKM or EPDM

VGM

-

Description:

Thermal mass flow meter based on high precision MEMS technology (CMOS sensor). Pressure and temperature insensitive

according to the CTA constant temperature principle. Also insensitive to pressure surges.

Media: compressed air or non-corrosive gases

Operating_pressure: max. 10 bar

Supply_voltage: Standard AA battery or Micro-USB power supply

(DIN62684), optionally external power +12 ...+30 V DC (max. 200 mA)

Display: Touch-display 128 x 64 px, blacklighted only with external

power supply (Micro-USB or 24 V DC)

Electrical_connector: optionally length 2.0 m, with free ends at 24 V DC

Function: totalisator included, physical units can be changed

Alarm_functions: 3 configurable alarms,

programmable as = low alarm, high alarm, window alarm and totalizer alarm.

The alarms can be configured with different parameters as delay and alarm duration.

Relais: switching current up to 1A, switching voltage 30 V DC

Accuracy: ± 2% FS, from 200 l/min ± 3% FS

Response_time: 500 ms at 99% accuracy

Turndown_ratio: 1 to 50 (Eco) or 1 to 1000 (Special)

Protection_class: IP 50

Flow_regulation: manual fine adjustment by 15 turns

Mounting position: any, horizontal from 5 bar on

Temperature_range: 0 °C to 50 °C / 32 °F to 122 °F

Warm-up_time: < 1 sec. for full accuracy

Body: aluminium, optionally electropolished stainless steel 316

Elastomer: FKM, optionally EPDM

VGR

-

Description:

Thermal mass flow meter based on high precision MEMS technology (CMOS sensor).

Pressure and temperature insensitive according to the CTA constant temperature principle. Also insensitive to pressure surges.

Media: compressed air or non-corrosive gases

Operating_pressure: max. 10 bar

Supply_voltage: Standard AA battery or Micro-USB power supply

(DIN62684), optionally external power +12 ...+30 V DC (max. 200 mA)

Display :Touch-display 128 x 64 px, blacklighted only with external

power supply (Micro-USB or 24 V DC)

Electrical_connector: optionally length 2.0 m, with free ends at 24 V DC

Alarm_functions: 3 configurable alarms,

programmable as = low alarm, high alarm, window alarm and totalizer alarm.

The alarms can be configured with different parameters as delay and alarm duration.

Relais: switching current up to 1A, switching voltage 30 V DC

Accuracy: ± 2% FS, from 200 l/min ± 3% FS

Response_time: 500 ms at 99% accuracy

Turndown_ratio: 1 to 50 (Eco) or 1 to 1000 (Special)

Protection_class: IP 50

Flow_regulation: manual fine adjustment by 15 turns

Mounting_position: any, horizontal from 5 bar on

Temperature_range 0 °C to 50 °C / 32 °F to 122 °F

Warm-up_time: < 1 sec. for full accuracy

Body: aluminium, optionally electropolished stainless steel 316

Elastomer: FKM, optionally EPDM

VR6

-

Description:

The modular, compact micro needle valve is for fine-flow

adjustment of gases and liquids. It consists of an inner valve

and body with straight or angle connector. The valve is free

from oil and grease.

Media: 5 µm filtered compressed air, non-corrosive gases or liquids

Operating_pressure: vacuum up to positive pressure of max. 20 bar

Adjustment:

The micro valve has a 15-turn spindle to fully open from a closed

condition. It operates with virtually no hysteresis and closes

clockwise or optionally counterclockwise. The valve needle is

non-rotating and thus provides a stable adjustment.

Panel_mounting: borehole 15 mm, mounting through two screws M4x10

Temperature_range:

-20 °C to 150 °C / -4 °F to 302 °F for FKM,

-40 °C to 150 °C / -40 °F to 302 °F for EPDM

Body: anodized aluminium, optionally stainless steel

Elastomer: FKM, optionally EPDM

Inner_valve: nickel-plated brass, optionally stainless steel

Knob: plastic

RF

-

Description:

Precision sapphire restrictor for reducing the flow of air or gas.

Fixed flow restrictors are used in back pressure and air jet sensing circuits.

Media: 5 µm filtered compressed air, non-corrosive gases or liquids

Diameter_tolerances: -3% to +10% of nominal diameter

Operating_pressure: vacuum up to positive pressure of max. 12 bar

Temperature_range: 5 °C to 50 °C / 41 °F to 122 °F

Body: brass

Restrictor: sapphire

R-0,F950

-

Description:

Precision sapphire restrictor for reducing the flow

Medium: compressed air or non-corrosive gases

Ã-Tolerance: ± 0.005 mm, respectively ± 3% of volume flow

Filter_element: 5 μm for DN0.08 up to DN0.23, from DN0.25 on 100 μm

Operating_pressure: vacuum up to max. 7 bar

Temperature_range: 5 °C to 50 °C / 41 °F to 122 °F

Body: polycarbonate, FDA-approved

Restrictor: sapphire

Filter_element: stainless steel fabric

F9

-

Description:

Compact in-line filter with fittings or threaded connection.

Flow direction and filter size in µm are clearly marked.

Media: compressed air or non-corrosive gases

Diameter_tolerances: -3% to +10% of nominal diameter

Filter_element: 5 µm, 25 µm, 43 µm or 73 µm

Operating_pressure: max. 8.6 bar

Temperature_range: 5 °C to 50 °C / 41 °F to 122 °F

Body: polysulphone

Filter_element: Dutch weave stainless steel

F2804

-

Description:

Check_valve:

The check valve permits flow in one direction only.

A small check disc within the housing ensures free flow in

one direction and at the same time seals off on the other side.

Restrictor_check_valve:

The restrictor check valve provides a constant flow in one

direction, defined through the orifice size, and a flow of the

full nominal size towards the other direction.

Media: 5 µm filtered compressed air or non-corrosive gases

Diameter_tolerance: -3% to +10% of nominal diameter

Operating_pressure:

max. 0.7 bar at F2804-400/1/2/3,

max. 5.2 bar at F2804-404

Cracking_pressure:

< 20 mbar at F2804-400/1/2/3,

< 25 mbar at F2804-404

Temperature_range: 5 °C to 50 °C / 41 °F to 122 °F

Body: polysulphone at F2804-400/1/2/3, polypropylene at F2804-404

Check_disc: Celcon at F2804-401/2, silicone at F2804-400/3/4

QE

-

Description:

The flow control valve functions as a pinch valve in a new design

of housing with full flow cross-section. Since the straight valve

passage has neither constrictions nor back-points, there is no danger of clogging or blockage. Frictional loss is at a minimum.

Media:

compressed air, gases, liquids or other paste-like or powdery media

Solids are enclosed by the flexible sleeve at shut-off.

Sleeve: Highly flexible with double woven reinforcement in eight

different grades. Sleeve simple to change.

Pressures:

Operating pressure = max. 4.0 bar

Pilot pressure = max. 6.5

Differential pressure = max. 2.5 bar

Closing pressure = P1 + 2.5 bar to DN 32, P1 + 2 bar from DN 40 on

Vacuum: If vacuum is greater than -100 mbar, vacuum compensation should be provided on the control side.

Accuracy: In the flow range of 0 to 70% the linearity of

pilot pressure to flow is about 10% accurate.

Mounting_position: any, at horizontal mounting pilot port

preferably at the top

Temperature_range: 0 °C to max. 100 °C / 32 °F to max. 212 °F,

subject to sleeve material

Body: stainless steel 316L, material no. 1.4435

Sleeve: depending on selected version

Q

-

Description:

The flow control valve functions as a pinch valve in a new

design of housing with full flow cross-section. Since the

straight valve passage has neither constrictions nor back-points,

there is no danger of clogging or blockage. Frictional loss is

at a minimum.

Media:

Compressed air, non-corrosive gases, liquids or other paste-like

or powdery media. Solids are enclosed by the flexible sleeve at

shut-off.

Sleeve:

Highly flexible with double-woven reinforcement in eight different

grades. Sleeve simple to change.

Pressures:

- Operating pressure = max. 4.0 bar

- Pilot pressure = max. 6.5 bar

- Differential pressure = max. 2.5 bar

- Closing pressure = P1 + 2.5 bar to DN32, P1 + 2 bar from DN40 on

Vacuum:

If vacuum is greater than -100 mbar, vacuum compensation should be provided on the control side.

Accuracy:

In the flow range of 0 to 70% the accuracy of the linearity of pilot

pressure to flow is approx. 10%.

Mounting_position: any

Temperature_range: 0 °C to max. 100 °C / 32 °F to max. 212 °F,

subject to sleeve material

Body: POM at QP or aluminium die-cast at QS

Sleeve: depending on selected version

Back Pressure Valves

59,130,134

-

Description:

Pressure relief valve for protecting compressed air devices from overpressure. If the pressure setpoint is exceeded, overpressure is vented into the atmosphere until the setpoint is reached again. It is recommended to choose a pressure range as low as possible.

Model59: Low-cost piston-operated valve of small size and high relief capacity.

Model130/134: Small, sensitive diaphragm-type valve made to screw in. Relief flow is proportional to overpressure. Model 134 features a tapped exhaust.

Media: compressed air or non-corrosive gases, model 134 also for liquids

Overpressure: max. 21 bar

Adjustment: by knurled screw at model 59 by plastic knob with snap-lock at model 130 and 134

Gauge port:

model 134 for inlet pressure G1∕8 on both sides of the body

model 59/130 not available

Temperature range: 0 °C to 50 °C / 32 °F to 132 °F

Mounting_position: any

Body: aluminium at model 59 and 130, brass at model 134

Elastomer: NBR/Buna-N at model 130 and 134

Seal: silicone at model 59

Spring_cage: plastic at type 130 and 134

Inner_valve: brass

10BP

-

Description:

The back pressure regulator is a high-flow, high-precision

pneumatic relief valve with adjustable setpoint. It provides

protection against overpressure in the downstream section of

pneumatic systems. A convoluted diaphragm provides the

sensitivity for venting to the atmosphere in response to the

slightest upstream change.

Media: compressed air or non-corrosive gases

Overpressure: max. 21 bar up to pressure range of 14 bar, max. 35 bar beyond

Adjustment: by handwheel with locknut

Gauge_port: G1/4 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: aluminium die-cast

Elastomer: NBR/Buna-N, optionally FKM

Inner_valve: stainless steel and brass

DB240

-

Description:

The back pressure regulator is a high-flow, high-precision

pneumatic relief valve with adjustable setpoint. It provides

protection against overpressure in the downstream section of

pneumatic systems. A convoluted diaphragm provides the

sensitivity for venting to the atmosphere in response to the

slightest upstream change.

Media: compressed air or non-corrosive gases

Overpressure: max. 17 bar

Adjustment: by handwheel with locknut

Gauge_port: G¼ on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 70 °C / 32 °F to 158 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Material_Body: aluminium

die-cast_Elastomer: NBR/Buna-N

Inner_valve: stainless steel and brass

DB300

-

Description:

Diaphragm back pressure regulators protect pneumatic devices

against overpressure. If the pressure exceeds the setpoint,

the pressure valve exhausts to the atmosphere until the

pressure level is below the setpoint. It is advisable to select

the pressure range as near as possible to the maximum setpoint.

Media: compressed air or non-corrosive gases

Overpressure: max. 10 bar

Accuracy: response sensitivity Adjustment: by handwheel with locknut

Gauge_port: G1⁄8 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

db4 Body: aluminium die-cast

Elastomer: NBR/Buna-N, optionally FKM

Inner_valve: brass

DB400

-

Description:

Diaphragm back pressure regulators protect pneumatic devices

against overpressure. If the pressure exceeds the setpoint,

the pressure valve exhausts to the atmosphere until the pressure

level is below the setpoint. It is advisable to select the

pressure range as near as possible to the maximum setpoint.

Media: compressed air or non-corrosive gases

Overpressure: max. 17 bar

Adjustment: by handwheel with locknut

Gauge_port: G¼ on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: aluminium die-cast

Elastomer: NBR/Buna-N, optionally FKM

Inner_valve: stainless steel, brass, aluminium and cadmium-plated steel

DBM

-

Description:

Back pressure regulators protect pneumatic devices against

overpressure. If the pressure exceeds the setpoint,the pressure

valve exhausts to the atmosphere until the pressure level is

below the setpoint.

It is advisable to select the pressure range

as near as possible to the maximum setpoint.

Media: compressed air, non-corrosive gases or liquids

Overpressure: see chart, max. 65 bar

Adjustment:

by spindle with locknut for DBM-01

by black plastic knob with snap-lock for DBM-02

by T-handle with locknut for DBM-04 / -08

by hexagonal spindle (spanner size 24 mm) with locknut for DBC-12 / -16

Gauge_port:

G1/8 at DBM-01 on both sides of the body,

G1/4 from DBC-02 on, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 80 °C / 32 °F to 176 °F for FKM or EPDM

0 °C to 130 °C / 32 °F to 266 °F high temperature version,

for appropriately conditioned compressed air down to -20 °C / -4 °F, or low temperature version down to -40 °C / -40 °F

Body: brass

O-rings: NBR/Buna-N, optionally FKM or EPDM

Inner_valve: brass

Diaphragm: NBR/Buna-N with PTFE coating

DBC

-

Description:

Back pressure regulators protect pneumatic devices against

overpressure. If the pressure exceeds the setpoint, the

pressure valve exhausts to the atmosphere until the pressure

level is below the setpoint. It is advisable to select the

pressure range as near as possible to the maximum setpoint.

Media: compressed air or non-corrosive gases

Overpressure: max. 30 bar

Adjustment:

- by plastic knob with snap-lock for DBC-01,

- by handwheel for DBC-02 to -A6

- by T-handle with locknut for DBC-06 to -16

Gauge_port: G1∕8 at DBC-01, G1/4 from DBC-02 on,

on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range: 0 °C to 60 °C / 32 °F to 140 °F,

for appropriately conditioned compressed air down to -20 °C / -4 °F

Body: aluminium

O-rings: NBR/Buna-N, optionally FKM or EPDM

Diaphragm: NBR/Buna-N with PTFE coating

Inner_valve: brass

DB110

-

Description:

Diaphragm back pressure regulators protect pneumatic devices

against overpressure. If the pressure exceeds the setpoint,

the pressure valve exhausts to the atmosphere until the

pressure level is below the setpoint. It is advisable to select

the pressure range as near as possible to the maximum setpoint.

Media: compressed air or non-corrosive gases

Recommendation:

connection thread G½ for pressure range 0...35 / 140 / 280 mbar

Overpressure: max. 10 bar

Accuracy: response sensitivity Adjustment: by handwheel with locknut

Gauge_port: G1/4 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: aluminium die-cast

Elastomer: NBR/Buna-N, optionally FKM

Inner_valve: stainless steel and brass

D3100

-

Description:

The diaphragm back pressure regulator protects compressed air devices from excessive pressure. If the pressure setpoint is exceeded, overpressure is vented into the atmosphere until the setpoint is reached again. It is recommended to choose a pressure range as low as possible.

Media: compressed air, gases

System_pressure: max. 6 bar

Adjustment:

by adjusting screw for D3100-04 to - 1A, with locknut

by T-handle for D3100-12 and -16, with locknut

Gauge_port: G1/4 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 80 °C / 32 °F to 176 °F, FKM or EPDM

0 °C to 130 °C / 32 °F to 266 °F, high temperature version

for appropriately conditioned compressed air down to -20 °C / -4 °F

or low temperature version down to -40 °C / -40 °F

Body: stainless steel 316L, material no. 1.4404

Diaphragm: NBR/Buna-N with PTFE coating

O-rings: FKM, optionally EPDM

Inner valve: stainless steel 316L, material no. 1.4404

DB208

-

Description:

Diaphragm back pressure regulators protect pneumatic devices

against overpressure. If the pressure exceeds the setpoint, the

pressure valve exhausts to the atmosphere until the pressure

level is below the setpoint. It is advisable to select the

pressure range as near as possible to the maximum setpoint.

Media: compressed air or non-corrosive gases

Overpressure: max. 17 bar

Pilot_pressure: 0 ... 10 bar

Accurcay: 1% at 7 bar pilot pressure

Response_sensitivity 1 mbar

Adjustment: depending on the level of signal pressure the response value will change accordingly

Gauge_port: G1/4 on both sides of the body, screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: aluminium die casting

Elastomer: NBR/Buna-N

O-rings: NBR/Buna-N, optionally FKM

Inner_valve: brass and zinc-plated steel

DB450

-

Description:

Diaphragm back pressure regulators protect pneumatic devices

against overpressure. If the pressure exceeds the setpoint,

the pressure valve exhausts to the atmosphere until the

pressure level is below the setpoint. It is advisable to

select the pressure range as near as possible to the maximum

setpoint.

Media: compressed air or non-corrosive gases

Overpressure: max. 17 bar

Pilot_pressure: 0 ... 10 bar

Accurcay: 3% at 7 bar pilot pressure

Response_sensitivity: 2.5 mbar

Adjustment: depending on the level of signal pressure the response value will change accordingly

Gauge_port: G1/4 on both sides of the body,

screw plugs supplied

Mounting_position: any

Temperature_range:

0 °C to 90 °C / 32 °F to 194 °F,

for appropriately conditioned compressed air down to -40 °C / -40 °F

Body: aluminium die casting

Elastomer: NBR/Buna-N

O-rings: NBR/Buna-N, optionally FKM

Inner_valve: brass and aluminium

Pressure Switches

DSP,DSQ

-

Description:

Adjustable pressure switch for monitoring pressure, vacuum and

differential pressure. From the 6 bar device on two turns of

the adjusting knob are necessary for the whole adjustment range,

so the scale on the knob is inappropriate.

Media: compressed air, non-corrosive gases or liquids

Overpressure: see chart

Switch_contact: SPDT switch with silver contact,

optionally gold contact

Contact_load: 2 A at 24 V DC, 6 A at 250 V AC

Electrical_connector: AMP spade terminal, 6.3 x 8 mm,

according to DIN 46244

Hysteresis: see chart

Life_cycle: 1E7 switching cycles

Vibration_resistance: 20 g

Certifications: VDE, TÃV design test, optionally Atex

Switching_time: 30 ms

Mounting_position: any, but indication needed for

switch point < 100 mbar

Protection_class: IP 65 w/ coupling socket

Temperature_range:

-20 °C to 85 °C / -4 °F to 185 °F for NBR/Buna-N, EPDM and polyamide, up to 130 °C / 266 °F for FKM

Body: Zytel, a high-quality polyamide

Elastomer: NBR/Buna-N, optionally EPDM, FKM or special FKM

(saturated steam-resistant)

Pressure_connection: brass, at DSP-W polyamide,

optionally stainless steel or PVDF

F4200

-

Description:

High-precision pressure and vacuum switch with electrical outlet signal.

The microswitch satisfies UL and CSA regulations. Polysulphone of the body approved by National Sanitation Foundation. The switch also complies with FDA regulations and is suitable for water and food products.

Media: compressed air, non-corrosive gases or liquids

Switch_contact: micro SPDT switch, covered by plastic cap

Contact_load:

3 A at 230 V AC, 1.2 A at 125 V DC or

10 A at 230 V AC, 0.5 A at 125 V DC

Electrical_connector: 0.187" (4.75 mm) quick connector for Molex connector

Repeatability: ± 2% FS

Certifications: CSA-certified and UL-listed

Switching_time: 25 ms

Mounting_position: any

4 Temperature_range: 4 °C to 66 °C / 40 °F to 150 °F

Body: polysulphone

Spring: stainless steel

Diaphragm: polyurethane

Media_non-contact_parts: nylon, carbon fibre nylon, acetal

F4300

-

Description:

Pressure and vacuum switch with electrical outlet signal and low hysteresis.

The microswitch satisfies UL and CSA regulations. Polysulphone of the body approved by National Sanitation Foundation. The switch also complies with FDA regulations and is suitable for water and food products.

Media: compressed air, non-corrosive gases or liquids

Switch_contact: micro SPDT switch, covered by plastic cap

Contact_load: 3 A or 4 A at 230 V AC, see chart

Electrical_connector: 0.110" (2.8 mm) quick connector for Molex/ETC connector

Repeatability: ± 2% FS

Certifications: CSA-certified and UL-listed

Switching_time: 25 ms

Mounting_position: any

Temperature_range: 4 °C to 66 °C / 40 °F to 150 °F

Body: polysulphone

Spring: stainless steel

Diaphragm: polyurethane

Media_non-contact_parts: nylon, carbon fibre nylon, acetal

DSB,DSC

-

Description:

Pressure to the unit is continuously monitored by a

piezo-resistive sensor and converted into a proportional

voltage signal. The signal is then amplified and delivered

as a PNP signal.

Media: dry, lubricated or unlubricated compressed air or

non-corrosive gases

Supply_voltage:

12...30 V DC, reverse voltage protection,

current consumption max. 30 mA,

output current max. 250 mA

Adjustment_DSB_Mode:

hysteresis or window, switching point and hysteresis, NO or NC,

closing or opening time, bar, psi, MPa, kg/cm² etc.

Display = current pressure, highest pressure, measurement errors

Switching_output_DSB:

2x PNP freely programmable as NO or NC, max. contact load 250 mA, short-circuit-proof

Switching_output_DSC:

1x PNP as at DSB and 1x analogue output signal 1…5 V,

output impedance < 500 Ω

Hysteresis: adjustable from 0% to 100% of set switching point

Linearity: < 1% FS

Repeatability: Switching_frequency: 200 Hz

LED_display: 3-digit, red 7-segment display on DSB, no display on DSC

Mounting_position: any

Error_display: via 7-segment display on DSB, via multicolour LED on DSC

Certifications: CSA-compliant, UL-listed

Shock_resistance: 10 g

Protection_class: IP 65

Temperature_range:-1 °C to 50 °C / 30.2 °F to 122 °F

Body: ABS-PC plastic, shockproof

Connection_thread: nickel-plated brass

PP700,VP700

-

Description:

Pilot-actuated pressure valve with precisely adjustable pilot

setpoint. Perfect for applications which require intrinsic

safety, pneumatic sequencing or pressure relief. Valves are

normally opened or closed. The switch complies with

FDA regulations and is suitable for water and food products.

Media: 5 µm filtered compressed air

Pressure_valve:

3-port/2-way air-assisted servo valve with exhaust to atmosphere,

NO or NC, made of nylon

Supply_pressure: 1.4...8 bar, untapped exhaust

Air_consumption: max. 0.3 l/min at 2 bar supply pressure or

max. 0.7 l/min at 7 bar

Pneumatic_connection: quick connector for hose external diameter

of 4 mm (5/32")

Flow_rate: 70 l/min at 7 bar, nominal size DN 0.2, Kv = 0.05

Switching_time: 64 ms at 6 bar supply pressure

Accuracy_pressure_switch:

at supply pressure variation of 0.7 bar =

Accuracy_vacuum_switch:

at supply pressure variation of 0.3 bar =

Repeatability: ± 2% FS

Temperature_range: 4 °C to 60 °C / 40 °F to 140 °F

Mounting_position: any

Body: polysulphone

Spring: stainless steel

Diaphragm: polyurethane

Media_non-contact_parts: nylon, carbon fibre nylon, acetal

Pressure Transducers

D9

-

Description:

The operating pressure is converted into a proportional, electrical

signal by a silicon pressure transducer. After amplification, the signal is monitored as an analogue voltage or current signal.

Media: all media compatible with stainless steel 316L, material no. 1.4404

Supply_voltage 12…32 V DC, residual ripple 5%,

reverse voltage protection, max. current consumption 4 mA

Electrical_connection: plug M12x1, 4-pins, with coupling socket

Outlet_signal:

4…20 mA = max. power consumption 260 mW

0…10 V = max. power consumption 50 mW

Linearity/Hysteresis: < 0.1 % FS typ.; < 0.3 % FS

Repeatability: < 0.1 % FS typ.; < 0.3 % FS

Long-term_stability: < 0.1 % FS typ.; < 0.3 % FS

Temperature_sensitivity:

< 0.03% FS typical per °C / K

< 0.05% FS typical per °C / K

at 0 °C to 70 °C / 32 °F to 158 °F

Response_time: 5 ms at 10…90% of measuring range

Shock_resistance: 50 g (11 ms)

Vibration_sensitivity: 10 g at 5…500 Hz

Protection_class: IP 67 according to DIN EN60529

Mounting_position: any

Temperature_range: -20 °C to 85 °C / -13 °F to 185 °F

Body/Diaphragm: stainless steel 316L, material no. 1.4404

D7

-

Description:

The operating pressure is converted into a proportional, electrical

signal by a ceramics pressure transducer. After amplification, the signal is monitored as an analogue voltage or current signal.

Media: all non-corrosive media compatible with stainless steel, nylon, silicon, silicone and epoxy

Supply_voltage: 12…32 V DC, residual ripple 5%,

with reverse voltage protection, max. current consumption 4 mA

Electrical_connector: plug M12x1, 4-pin, with coupling socket

Protection_class: IP67 according to DIN EN60529

Output_signal:

4…20 mA = max. power consumption 260 mW

0…10 V = max. power consumption 50 mW

Linearity/Hysteresis: < 0.2 % FS typ.; < 0.5 % FS

Repeatability: < 0.2 % FS typ.; < 0.3 % FS

Long-term_stability: < 0.5 % FS typ.; < 1 % FS

Temperature_sensitivity: < 0.03% FS typ./°C; < 0.08% FS/°C (0…50 °C)

Vibration_resistance: 2 g at 5…500 Hz

Temperature_range: -25 °C to 85 °C / -13 °F to 185 °F

Response_time: 5 ms for 10…90% of pressure range

Shock_resistance: 50 g (11ms)

Body: stainless steel 316L, mat. no. 1.4404

Measuring_cell: silicone and NBR/Buna-N o-ring

D8

-

Description:

The operating pressure is converted into a proportional, electrical

signal by a ceramics pressure transducer. After amplification, the signal is monitored as an analogue voltage or current signal.

Media: compressed air, non-corrosive gases or liquids compatible with ceramics and NBR/Buna-N

Supply_voltage:

12…32 V DC, residual ripple 5%,

with reverse voltage protection, max. current consumption 4 mA

Electrical_connector: plug M12x1, 4-pin, with coupling socket

Protection_class: IP67 according to DIN EN60529

Output_signal:

4…20 mA = max. power consumption 260 mW

0…10 V = max. power consumption 50 mW

Linearity/Hysteresis: < 0.1 % FS typ.; < 0.2 % FS

Repeatability: < 0.1 % FS typ.; < 0.2 % FS

Long-term_stability: < 0.1 % FS typ.; < 0.3 % FS

Temperature_sensitivity: < 0.03% FS typ./°C < 0.06% FS/°C (0…70 °C)

Vibration_resistance: 10 g at 5…500 Hz

Temperature_range: -25 °C to 85 °C / -13 °F to 185 °F

Response_time: 5 ms for 10…90% of pressure range

Shock_resistance: 50 g (11ms)

Body: stainless steel 316L, mat. no. 1.4404

Measuring_cell: ceramics AL2O3 and NBR/Buna-N o-ring

DA

-

Description:

Pressure transducer in compact and robust stainless steel

housing with piezo-resistive measuring element.

Factory-made calibration of zero point and range is possible.

Media: compressed air, non-corrosive gases or liquids

Overpressure:

max. 3x full scale, min. 3 bar,

for DAA-D6 and DAA-E1 max. 1500 bar

Supply_voltage:

9...33 V DC at current signal,

15...30 V DC at voltage signal,

residual ripple 5%, reverse voltage protection,

short-circuit-proof

Ex_Atex_version:

only current signal 10...30 V DC, max. 1 W,

as per EN 50.014 / EN 50.020 - 1974 A1…A5, Atex 2640-1

Electrical_connector: plug according to DIN 43650,

with coupling socket

Output_signal:

4...20 mA = max. power consumption 260 mW

0...10 V = max. power consumption 50 mW

Linearity/Hysteresis: < 0.5 FS

Repeatability: < 0.1 FS

Long-term_stability: < 0.2 FS, < 0.9 FS at version up to 500 mbar

Temperature_sensitivity:

< 0.02% FS per °C / K,

< 0.06% FS at version up to 2 bar per °C / K,

< 0.1% FS at version up to 500 mbar per °C / K,

at range of 0 °C to 70 °C / 32 °F to 158 °F

Response_time: 1 ms for 10...90% of pressure range

Shock_resistance: 50 g

Vibration_resistance: 10 g at 5...500 Hz

Protection_class: IP 65

Mounting_position: any

Temperature_range: 0 °C to 70 °C / 32 °F to 158 °F

Body/Diaphragm: stainless steel 316L, mat. no. 1.4435

O-rings: FKM, optionally EPDM

Measuring Devices

MA

-

Description:

Pressure gauge with Bourdon tube or capsule, dust-protected,

splash-proof, antirust, oil-resistant and silicone-free.

The capsule type gauge features an integrated restrictor

against pressure peaks.

Media: all media compliant with brass,

e.g. compressed air, non-corrosive gases or fluids

Scale:

Bourdon_tube_gauge: white background with black bar scale and red psi scale