- Offer Profile

-

AMSYS is a provider of advanced micromechanical sensors and sensor systems. With pressure measurement as its chief focus, the company supplies the entire spectrum of products in this field – from sensing elements to ready-to-use transmitters. Its largest range consists of OEM products which customers can use to configure their own sensors for all pressure measurement versions. Customized modifications are also possible above and beyond the standard product range.

Besides the pressure sensors AMSYS also supplies inclinometer, humidity sensors, temperature sensors and magnetic encoders

to complete the product range of micromechanical sensors.

pressure sensors

-

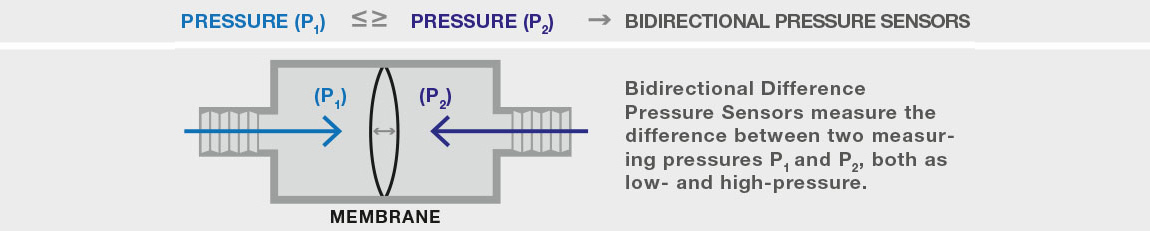

For all pressure measuring methods (absolute pressure, relative pressure, differential pressure, bidirectional differential pressure und barometric pressure) AMSYS offers a wide range of pressure sensors* for different pressure ranges and in different variants (balanced / not balanced / amplified / ready-to-use) and with analog and / or digital output signal.

The sensors are available in a variety of forms as an OEM pressure sensor (for PCB mounting), as a PCB pressure sensor module (pre-mounted on a printed circuit board), or as a pressure transmitter (for immediate use).

absolute pressure sensors

-

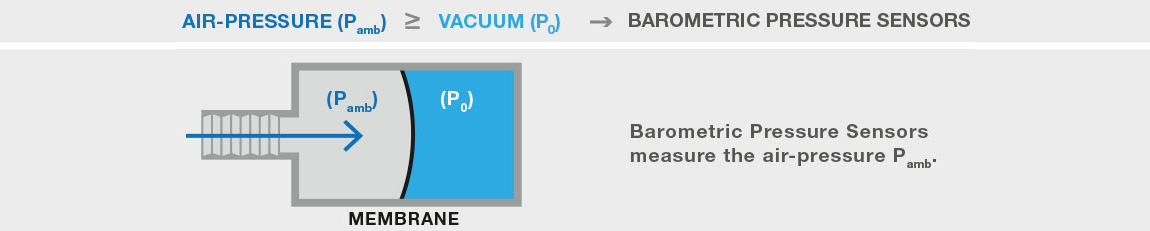

Absolute pressure sensors are used for pressure measurement against a reference pressure of 0 bar (vacuum). This can be used e.g. to determine the pressure in a closed system independent of the atmospheric pressure. They are suitable for measuring the negative pressure relative to the external pressure. In particular, it is possible to measure the ambient pressure against the vacuum, which is used for the barometric pressure measurement.

The range of AMSYS absolute pressure sensors extends from simple OEM sensors without amplification to high-precision amplified transmitters with adjusted standard output values.

Analog OEM sensors: MS5212 – analog absolute pressure sensor not compensated

-

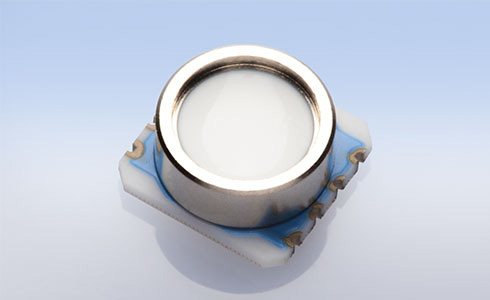

The MS5212 is part of the MS52XX series and is an analog OEM absolute pressure sensor that is neither compensated nor amplified. It has the characteristics of the measuring cell and outputs the differential bridge voltage in mV.

The sensor designed for PCB mounting is available for the pressure range 0 – 12 bar. The sensor measures the applied pressure against the vacuum inside the measuring cell = absolute pressure.

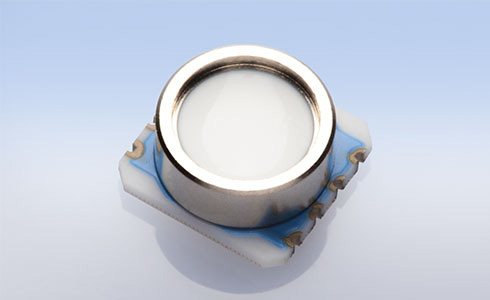

The absolute pressure sensor of the MS5212 series is suitable for reflow mounting and consists of a solderable ceramic substrate on which a piezoresistive pressure measuring cell is mounted. The measuring cell is protected by a metal ring or by a cap. The dimensions of the ceramic carrier with metal protective cap or ring are: 7.6 x 7.6 mm2.

It is suitable for applications in which the user wants to use his own amplifier electronics and if necessary can perform the compensation itself or does not make high demands on the accuracy.

Features

- Pressure range: 0-12 bar, absolute

- Temperature range: -40°C – 125 °C

- Supply voltage: max. 20 V

- uncompensated output signal (mV)

- High overpressure range

- High reliability, low drift

- Low Cost SMD ceramic Package

- Reflow capability

- RoHS and REACH compliant

Applications

- High resolution Altimeters, Variometers

- Engine controls

- Tire pressure

- Diver´s computers

MS5401-MS5412 – absolute pressure sensor 1-12 bar not compensated

-

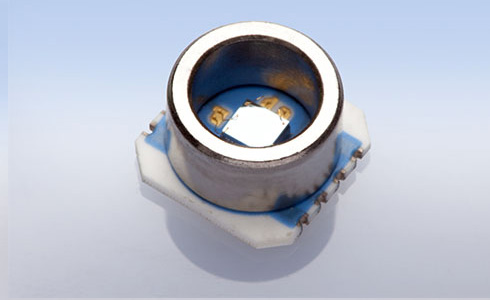

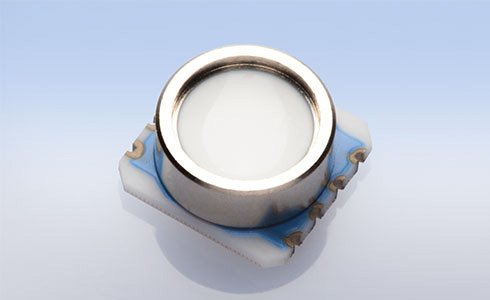

The MS54XX SMD pressure sensor series is designed for pressure sensor systems with highest demands on resolution and accuracy. The device consists of a silicon micro machined pressure sensor die mounted on a 6.2 x 6.4 mm ceramic carrier protected by a metal cap. The uncompensated sensor puts out the differential voltage of the measurement cell. This voltage has to be amplified by an adequate instrument amplifier.

The MS54XX-AX impresses with high sensitivity (240mV FS) and the MS54XX-BX impresses with high linearity (±0.05%FS). The measuring cell of the MS54XX-XM is surrounded by a metal ring, which can be filled with silicon gel.

MS54XX-AM, high sensitivity, absolute

Pressure range 1, 7 and 12bar, metal cap and gel protectionMS54XX-BM, high linearity, absolute

Pressure range 1, 7 and 12bar, metal cap and gel protectionFeatures

- Pressure ranges: 1, 7 and 70 bar, absolut

- Temperature range: -40°C – 125 °C

- Supply voltage: max. 20 V

- uncompensated output signal (mV)

- Sensitivity: 240 – 392 mV FS (A-Version)

- Linearity: ±0.05 %FS (B-Version)

- High overpressure range

- High reliability, low drift

- Low cost SMD package

- Reflow capability

- RoHS and REACH compliant

Applications

- High resolution Altimeters, Variometers

- Pneumatic systems

- Hydraulics

- Tire pressure

- Diver’s computers

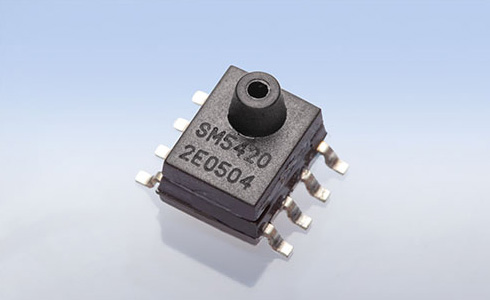

SM5420E – mV-absolute pressure sensor 30-100 psi

-

The SM5420E is a non-amplified OEM sensor* for absolute pressure measurement in the SOIC-8 package for SMD mounting. It has the properties of a measuring cell and outputs the differential bridge voltage in mV.

The series of SM5420E sensors cover a pressure range of 2 to 7 bar and is available with nozzle or with hole. The absolute pressure sensors consist of a piezoresistive pressure measuring cell, which in the standard version is provided with a protective gel for better media compatibility.

The operating temperature range is -40 to 125 ° C. The sensors are suitable for OEM applications for which another amplifier or microcontroller is provided, which further processes the 95 mV signal. The resolution of the sensors is not limited by any A/D conversion. Specifically, the pressure sensors can be used in rapid pressure measurements e.g. in pneumatics or as a pressure switch. They are suitable for high-volume projects.

Features

- Pressure ranges: 0-30, 0-60, 0-100 psi

- Supply voltage 0-6.5 V

- Unamplified output max. 135 mV

- Uncompensated

- Not temperature compensated

- Linearity ± 0,02 % FS

- Offset ± 35 mV

- SOIC-8 housing

Applications

- Tire pressure monitoring

- Leakage check

- HVAC-Applications

- Manometers

- Barometers

- Altimeters

- Pneumatics

- Sports equipment

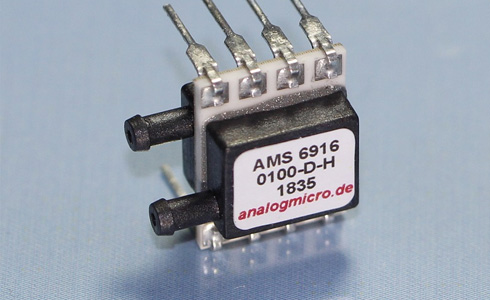

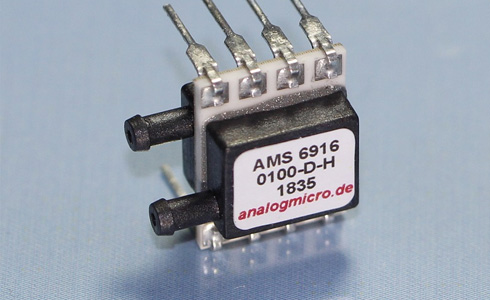

AMS 6916 – analog pressure sensor with ratiometric output

-

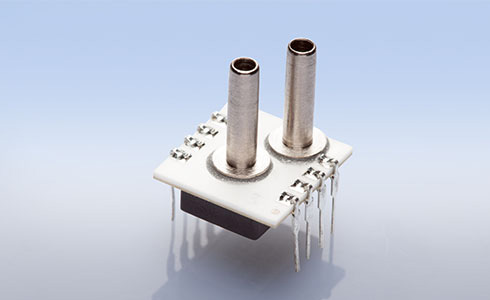

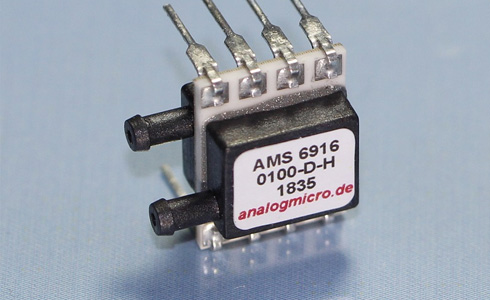

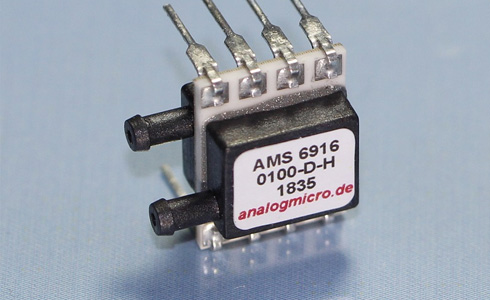

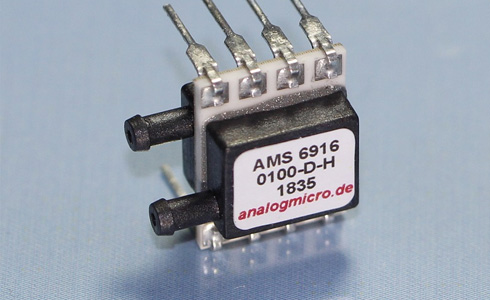

AMS 6916 pressure sensors are a series of high-precision OEM sensors* with a digital I²C-interface with multiple pressure ranges from 0-5 mbar to 0-1200 mbar and customizable pressure ports.

AMS 6916 are calibrated and compensated for across a wide temperature range of -25 to +85°C. These pressure sensors come as a dual in-line package (DIP) for assembly on printed circuit boards (PCBs) 13 x 10 mm² and are fully operational without the need for any additional components. The electrical connection is made via the DIP solder pins; pressure is connected via two vertical metal tubes.

The pressure sensors of this series are one-sided media resistant by underside pressurization* and have a ratiometric voltage output of 0.5 … 4.5 V.

Features

- Relative, absolute and differential pressure ranges 5 mbar to 1.2 bar

- Calibrated and temperature compensated

- Temperature range: -25 – 85 ° C

- Voltage output 0.5 … 4.5 V

- 3.3 or 5.0 V voltage supply

- High accuracy

- RoHS and REACH compliant

Applications

- Breathing control

- Gas flows, back pressure measurements

- Vacuum monitoring

- Industrial process monitoring

- Heating / Vacuum / Ventilation / Air Conditioning (HVAC)

- Barometric measurements

- Medical technology

- Fill level

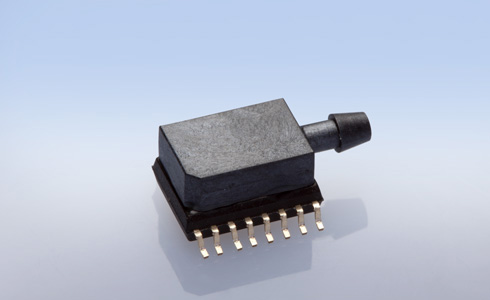

SM6844 – analog absolute pressure sensor 0-15 psi in SOIC16

-

The SM6844 is a analog OEM sensor* with a novel silicon measuring cell and modern electronic signal processing.

The integrated signal processor enables calibration and temperature compensation during manufacturing. The fully balanced SM6844 is offered in a standard SOIC16 package with a horizontal pressure port for SMD mounting. As output signal, the pressure-proportional information is available as a ratiometric signal 0.5 – 4.5 V. The 6844 is a self-contained sensor that does not require additional circuitry.

Features

- Pressure range: 15 psi absolut

- Compensated temperature range: -40 – 125°C

- Supply voltage: 6 V

- Compensated, analog, ratiometric output signal 0.5 – 4.5 V

- Resolution 11 bit

- Accuracy: 1% FS

- SOIC16 housing for SMD mounting

- RoHS and REACH compliant

Applications

- Altimeter and barometric instruments

- Negative pressure monitors

- Household appliances

SM11X1 – BAP-barometric absolute pressure sensor 150-1’800 mbar

-

The SM11X1 series barometric absolute pressure sensors are compact OEM sensors* for measuring the barometric air pressure in the range of 150 – 1800 mbar (SM1111A: 150 – 1’150 mbar, SM1111B: 600 – 1’650 mbar, SM1131: 400 – 1’800 mbar, SM1171: 400 – 1’150 mbar). They offer a 16-bit signal processing and an accuracy of 1 mbar in the temperature range of 0 – 80 ° C.

The operating temperature range of -40 – 125 ° C is very broad and suitable for versatile use with a very good accuracy of 2 mbar.

The integrated ASIC enables calibration and temperature compensation during production. Alternatively, a ratiometric analog output or digital I²C or SPI outputs are available. The digital ones output not only the pressure but also the temperature information as a digital value.

The fully balanced SM11X1 are offered in a standardized SOIC8 package for automated SMD mounting. The SOIC pressure sensors are self-sufficient and do not require additional circuitry.

The barometric air pressure (BAP) sensors are available in three different types with different electrical outputs. The supply voltage is either 3.3 V or 5 V. The power consumption of the digital versions can be lowered by command from 5 mA to 10 μA in sleep mode.

Features

- Barometric absolute pressure between 150 mbar and 1’800 mbar

- Wide temperature range: -40 – 125 ° C

- Supply voltage: 3.3V / 5.0 V

- Compensated, calibrated output signal

- Output format: I²C / SPI / ratiometric

- Resolution 16 bit

- Accuracy 1 mbar

- Digital signal processor ASIC

- SOIC 8 housing for SMD mounting

- RoHS and REACH compliant

Applications

- Weather monitoring

- Medical technology

- Blood pressure measurement

- Negative pressure wound therapy

ME770 / ME771 / ME772 – ceramic, analog, relative and absolute OEM pressure sensor

-

The ME77X series pressure sensors are piezoceramic OEM sensors* with integrated signal processing. The sensors deliver a ratiometric* (ME770) or a non-ratiometric (ME772) voltage and a 4-20 mA (ME771) current signal for two-wire operation.

The ME77X series is available in relative pressure, absolute pressure and sealed gage * versions. The sensors are individually and fully calibrated and temperature compensated.

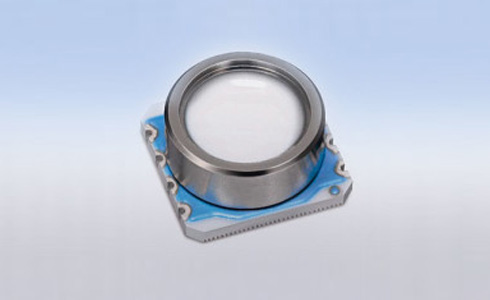

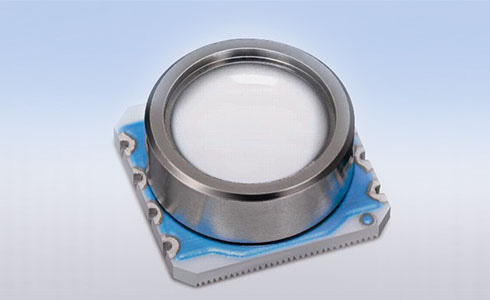

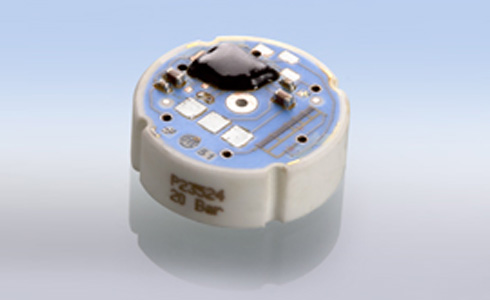

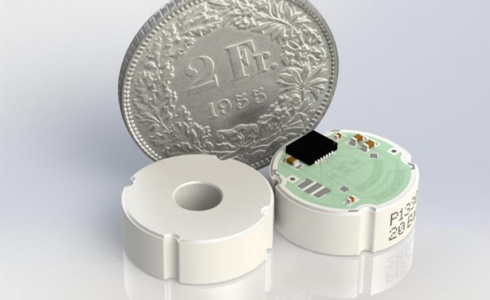

These OEM sensors consist of a ceramic body with an 18 mm diameter and an octagonal membrane flush on the front. The electronics are located on a circuit board that is mounted on the back of the ceramic body.

Thanks to the excellent chemical properties of the ceramic material, the pressure sensors of the ME77X series are resistant to almost all, including aggressive, media.

Features

- Pressure range: 0.5 – 600 bar

- Relativ-, absolut- and sealed gage-variants

- Temperature range: -25 °C – 125 °C

- 0.5 – 4.5 V (ratiometric), 0 – 10 V (non-ratiometric) or 4-20 mA output

- Accuracy: 1 % FS

- Calibrated, compensated and amplified

- Long-term stability: 0.3 % FS/Year

- Very high media resistance

- Ceramic sensor with flush diaphragm

- EMC protected

- RoHS and REACH compliant

Applications

- Automotive applications

- Industrial technology

- Medical technology

- Process monitoring

- Pneumatic applications

- Hydraulic applications

ME780 / ME782 – ceramic pressure sensor for relative and absolute pressure up to 600 bar

-

The ME78X series pressure sensors are piezoceramic OEM sensors* with integrated signal processing. The sensors provide a ratiometric* 0.5 – 4.5V voltage signal (ME780) or a digital I2C signal (ME782).

The ME78X Series is available in relative pressure, absolute pressure and sealed gage* versions. The sensors are individually calibrated, temperature compensated and linearized.

The ME78X series consists of a 18 mm diameter ceramic body with an octagonal membrane mounted on it. The electronics are located directly on the back of the ceramic body. The sensors are available with different electrical connections.

Thanks to the excellent chemical properties of the ceramic, the pressure sensors of the ME78X series are resistant to almost all, including aggressive media.

Features

- Pressure range: 0.5 – 600 bar

- Relative, absolute and sealed gage pressure

- Temperature range: -25°C – 125°C

- Supply voltage: 3.3 or 5 V

- 0.5 – 4.5 V or I2C output

- Accuracy: ±1% FS

- Calibrated, compensated and amplified

- Long-term stability: 0.3 % FS/year

- Very high media resistance

- Ceramic sensor with flush membrane

- EMC protected

- RoHS and REACH compliant

Applications

- Automotive applications

- Industrial automation

- Medical technology

- Process monitoring

- Pneumatics

- Hydraulics

AMS 5105 – pressure sensor with switching output

-

The AMS 5105 series of OEM sensors are fully signal conditioned, amplified, temperature compensated sensors in a dual in-line package (DIP) configuration with a 0,5 -4,5 V /2,5±2V analog output und and two independent, logical switching outputs. They are qualified for absolute, relative and differential measurement.

The AMS 5105 are calibrated and compensated in the temperature range of -25 – 85°C. High precision, high stability and low drift are the result of a combination between the MEMS technology and a microelectronics signal conditioning ASIC.

The AMS 5105 series pressure sensors are based on a highly stable, piezoresistive pressure sensor chips mounted on a ceramic substrate. The electronically programmable ASIC is contained in the same package to provide calibration and temperature compensation.

USB-Starter Kit as accessory available for installation of the two binary outputs via I²C bus and USB-interface of a PC, also for programming an individual I²C bus address and adjusting the switching barriers, the hysteresis and switching type.

Features

- Relative, differential and absolute pressure: 5 mbar – 2 bar

- Temperature range: -25 – 85 °C

- Supply voltage: 5 V

- Analog output (ratiometric)

- Two programmable switching outputs

- Adjustable switching parameters

- Calibrated and temperature compensated

- High precision

- High overpressure range

- RoHS and REACH compliant

- Product Made in Germany

Applications

- Pressure controller and switch

- Vacuum monitoring

- Level sensing

- Heating / ventilation / air conditioning monitoring

- Filter monitoring with alarm function

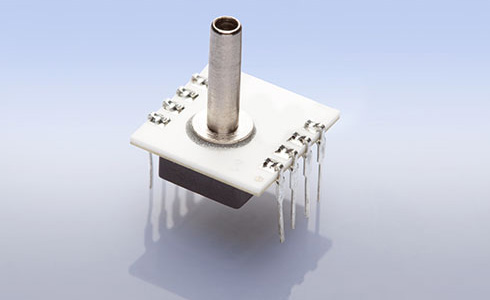

86A – analog pressure sensor with stainless steel membrane 150 psi

-

The 86A is a small profile, media compatible, piezoresistive silicon pressure sensor packaged in a 316L stainless steel housing and is designed for o-ring mounting. The sensing package utilizes silicone oil to transfer pressure from the 316L stainless steel diaphragm to the sensing element. The 86A is designed for high performance, low pressure applications. A custom ASIC is used for temperature compensation, offset correction, and provides an amplified output of 0.5 to 4.5V.

The 86A is designed for applications such as: level controls, tank level measurement, OEM equipment, corrosive fluids and gas measurement systems, sealed systems, manifold pressure measurement, barometric pressure measurement and submersible depth monitoring. Its gage type reference has a pressure range of 0-1 to 0-150psi while its absolute type reference ranges from 0-15 to 0-150psi.

Features

- Pressure range: 0 – 1 psi to 0 – 150 psi

- Temperature range: -20 °C – +85 °C

- Supply voltage: 5.0 Vdc

- 0.5 – 4.5 V ratiometric output

- ±3 % overall accuracy

- Relative and absolute pressure versions

- Calibrated and compensated

- Small diameter

- Assembly with o-ring

- RoHS and REACH compliant

Applications

- Level sensing and monitoring

- Measuring systems for corrosive liquids and gases

- Chemical plants

- Pharmaceutical plants

- Immersion probe

- Medical control systems

ME780 / ME782 – ceramic pressure sensor for relative and absolute pressure up to 600 bar

-

The ME78X series pressure sensors are piezoceramic OEM sensors* with integrated signal processing. The sensors provide a ratiometric* 0.5 – 4.5V voltage signal (ME780) or a digital I2C signal (ME782).

The ME78X Series is available in relative pressure, absolute pressure and sealed gage* versions. The sensors are individually calibrated, temperature compensated and linearized.

The ME78X series consists of a 18 mm diameter ceramic body with an octagonal membrane mounted on it. The electronics are located directly on the back of the ceramic body. The sensors are available with different electrical connections.

Thanks to the excellent chemical properties of the ceramic, the pressure sensors of the ME78X series are resistant to almost all, including aggressive media.

Features

- Pressure range: 0.5 – 600 bar

- Relative, absolute and sealed gage pressure

- Temperature range: -25°C – 125°C

- Supply voltage: 3.3 or 5 V

- 0.5 – 4.5 V or I2C output

- Accuracy: ±1% FS

- Calibrated, compensated and amplified

- Long-term stability: 0.3 % FS/year

- Very high media resistance

- Ceramic sensor with flush membrane

- EMC protected

- RoHS and REACH compliant

Applications

- Automotive applications

- Industrial automation

- Medical technology

- Process monitoring

- Pneumatics

- Hydraulics

MS5534 – digital absolute pressure sensor 10-1100 mbar

-

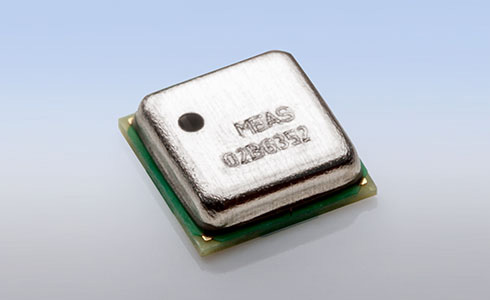

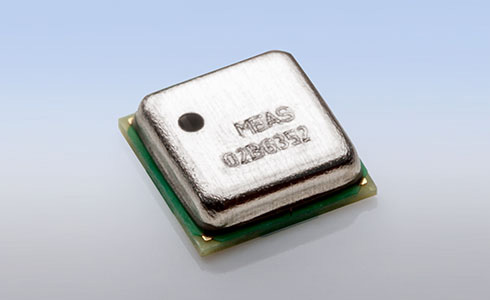

The MS5534 pressure measurement module consists of a SMD-hybrid device including a piezoresistive pressure cell and an ADC-Interface IC. It provides 16 Bit data words from a pressure- and temperature-dependent voltage. Additionally the module contains 6 readable coefficients for a highly accurate software calibration for the pressure and temperature measurement. The MS5534 is a low-power, low-voltage device with automatic power down (ON/OFF) switching. A 3-wire interface is used to communicate with a microcontroller.

The devices have a very low standby-current. The optimal compromise about refresh rate and average current consumption can individually be defined by the application software.

Features

- Pressure range: 10 – 1.100 mbar, absolut

- Temperature range: -40 °C – 125 °C

- Supply voltage: typ. 3 V

- Resolution pressure: 0.1 mbar

- Resolution temperature: 0.01 °C

- current consumption: 4 μA (Standby: max. 0.1 μA)

- digital 3 wire interface (16 bit)

- Automatic power-down operation

- Media resistant

- Reflow capability

- RoHS and REACH compliant

Applications

- Mobile altimeters and barometric measuring systems

- Weather stations

- Sports watches

- GPS receiver

- Air traffic control

- Performance measurement in sports equipment

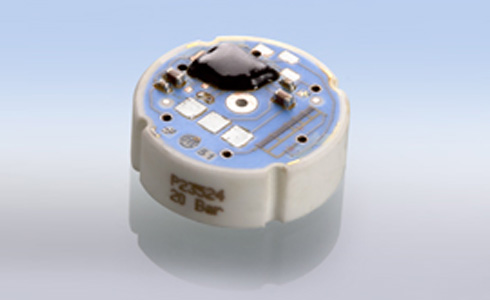

MS5535 – digital absolute pressure sensor 14-30 bar

-

The MS5535 pressure measurement module consists of a SMD-hybrid device including a piezoresistive pressure cell and an ADC-Interface IC. It provides 16 Bit data words from a pressure- and temperature-dependent voltage. Additionally the module contains 6 readable coefficients for a highly accurate software calibration for the pressure and temperature measurement. The MS5535 is a low-power, low-voltage device with automatic power down (ON/OFF) switching. A 3-wire interface is used to communicate with a microcontroller.

The devices have a very low standby-current. The optimal compromise about refresh rate and average current consumption can individually be defined by the application software. The MS5535 is protected by a metal ring filled with silicon gel on a ceramic hybrid 9x9mm for a pressure range: 0 … 200 PSI abs. and working within an operating temperature: -40 … +125°C.

Features

- Pressure range MS5535C: 0 – 14 bar, absolut

- Pressure range MS5535-30C: 0 – 30 bar, absolut

- Temperature range: -40 °C – 125 °C

- Resolution pressure: 1.2 mbar MS5535C

- Resolution pressure: 3 mbar MS5535-30C

- Resolution temperature: 0.01 °C

- Voltage supply: typ. 3 V

- Current consumption: 4 μA

- Standby: max. 0.1 μA

- Dimensions: 9.0 x 9.0 x 4.28 mm³

- digitale 3 wire interface (16 bit)

- Automatic power-down operation

- Reflow capability

- RoHS and REACH compliant

Applications

- Pneumatic applications

- Mobile water depth gauges

- Dive computers and diver watches

MS5840-02BA – miniature pressure sensor 10-2’000 mbar

-

The MS5840-02BA is a digital OEM sensor* that measures high-resolution absolute pressure. The sensor is matched and outputs the measured values as digital output signals via an I2C interface.

The reflow-capable sensor is designed for the pressure range of 10 – 2,000 mbar and is media-protected with a gel coating. In addition to the pressure, the pressure sensor measures the temperature from -20 to 85 °C.

The pressure sensor MS5840-02BA consists of a piezoresistive pressure measuring cell and an amplifier A/D interface IC, which are built on a ceramic substrate (3.3 x 3.3 x 1.7 mm³). The metal attachment protects the electronic components, facilitates O-ring assembly and makes the sensor water-resistant. The sensor converts the measured pressure- and temperature-dependent signal of the measuring cell into a 16bit data code. In addition, 6 individual coefficients are stored in the sensor, which allow the highly accurate software correction for pressure and temperature measurement by an external microprocessor. The I²C interface is used for serial communication with the microprocessor.

The sensor is designed for applications with a digital system environment. Since a processor already exists here at the system level, it can be used for the simple calculation of the current pressure and temperature values.

Features

- Pressure range: 10 – 2’000 mbar absolute

- Temperature range: -20 .. + 85 °C

- Resolution pressure: 0.016 mbar

- Resolution Temperature: 0.002 °C

- Supply voltage 1.5 – 3.6 V

- Low power consumption: 0.6 μA (standby <0.1 μA)

- I2C interface

- Ceramic substrate with metal cap: 3.3 x 3.3 x 1.7 mm

- RoHS and REACH compatible

Applications

- Mobile water depth measurement

- Diving computer

- Sports watches

- Pneumatics

- Compressor control

MS5540 – digital absolute pressure sensor 0-1100 mbar for SMD

-

The MS5540C pressure measurement miniature module consists of a SMD-hybrid device including a piezoresistive pressure cell and an ADC-Interface IC. It provides 16 Bit data words from a pressure- and temperature-dependent voltage. Additionally the module contains 6 readable coefficients for a highly accurate software calibration for the pressure and temperature measurement. The MS5540C is a low-power, low-voltage device with automatic power down (ON/OFF) switching. A 3-wire interface is used to communicate with a microcontroller.

The devices have a very low standby-current. The optimal compromise about refresh rate and average current consumption can individually be defined by the application software.

MS5540-CM: protected by a metal ring filled with silicon gel on a ceramic hybrid 6.2×6.4qmm

Pressure range: 10…1100mbar (0.15 … 16 PSI) abs.; operating temperature: -40 … +85°C

The MS5540-C is fully software compatible to previous version MS5540-B.Features

- Pressure range: 10 – 1100 mbar, absolut

- Temperature range: -40 ° bis +85 °C

- Resolution pressure: 0.1 mbar

- Resolution temperature: 0.01 °C

- Supply voltage: typ. 3 V

- Current consumption: 5 μA (Standby: max. 0.1 μA)

- Digital 3 wire interface (16 bit)

- Automatic power-down operation

- Media resistant

- Reflow capability

- RoHS and REACH compliant

Applications

- Mobile altimeters and barometric measuring systems

- Sports watches

- Weather monitoring stations

- GPS receivers

- Air traffic control

- Performance measurement in sports equipment

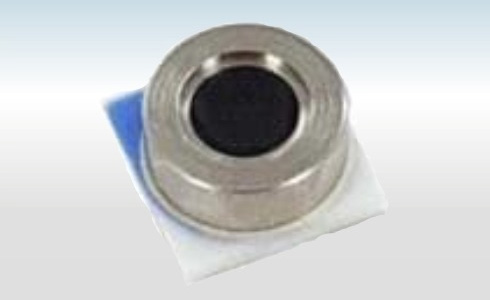

MS5541 – digital absolute pressure sensor for pneumatic applications

-

The MS5541 pressure measurement miniature module consists of a SMD-hybrid device including a piezoresistive pressure cell and an ADC-Interface IC. It provides 16 Bit data words from a pressure- and temperature-dependent voltage. Additionally the module contains 6 readable coefficients for a highly accurate software calibration for the pressure and temperature measurement. The MS5541 is a low-power, low-voltage device with automatic power down (ON/OFF) switching. A 3-wire interface is used to communicate with a microcontroller.

The devices have a very low standby-current. The optimal compromise of refresh rate and average current consumption can individually be defined by the application software.

MS5541-CM: protected by a metal ring filled with silicon gel on a ceramic hybrid 6.2×6.4mm

Pressure range: 0 … 200 PSI abs.; operating temperature: -40 … +85°CFeatures

- Pressure ranges: 14 and 30 bar, absolut

- Temperature range: -40 °C – +85 °C

- Resolution pressure: 1.2 mbar (14 bar sensor)

- Resolution pressure: 3.0 mbar (30 bar sensor)

- Resolution temperature: 0.01 °C

- Supply voltage: typ. 3 V

- Current consumption: 4 μA (Standby: max. 0.1 μA)

- Digital 3 wire interface (16 bit)

- Automatic power-down operation

- Media resistant

- Reflow capability

- RoHS and REACH compliant

Applications

- Pneumatic applications

- Mobile water depth gauges

- Dive computers and diver watches

MS5803 – series digital absolute pressure sensors up to 1 / 2 / 5 / 7 / 14 / 30 bar

-

The MS5803-xxBA is a new generation of high resolution sensors with SPI & I²C interface. The sensor module includes a high linearity pressure sensor with an ultra low power 24 bit ADC with internal factory calibrated coefficients. It provides precise digital 24 bit pressure and temperature values and different operation modes that allow the user to optimize for conversion speed and current consumption. A high resolution temperature output allows the implementation of an altimeter/thermometer function without an additional sensor. Gel protection and an antimagnetic stainless steel cap allow the use in 100m waterproof altimeter/compass watches.

Features

- Pressure ranges from 1 to 30 bar

- Supply voltage 1.8 – 3.6 V

- Temperature range: -40°C – 85 °C

- Resolution pressure: 0.012 mbar (MS5803-01BA)

- Resolution temperature: <0.01 °C

- I²C and SPI interface up to 20 MHz

- Fast conversion under 1ms (adjustable)

- Low power consumption, 1 μA (standby <0.15 μA)

- Suitable for outdoor applications

- ESD protected

- Small size: 6.2 × 6.4 mm

- Excellent long-term stability

- RoHS and REACH compliant

Applications

- Mobile altimeters and mobile barometric measuring systems

- People search and navigation devices

- Weather stations

- Sports watches

- GPS receiver

- Air traffic control (Variometer)

- Pneumatic applications

- Mobile water depth gauges

- Dive computers and diver watches

MS5805 – digital miniaturized absolute pressure sensor for o-ring assembly

-

The MS5805-02BA is a new generation of high-resolution altimeter sensors from MEAS Switzerland with I²C bus interface. It is optimized for altimeters and variometers with an altitude resolution of 20 cm. The sensor module includes a high-linearity pressure sensor and an ultra low power 24 bit ΔΣ ADC with internal factory-calibrated coefficients. It provides a precise digital 24 Bit pressure and temperature value and different operation modes that allow the user to optimize for conversion speed and current consumption. A high-resolution temperature output allows the implementation of an altimeter/thermometer function without any additional sensor.

The MS5805-02BA can be interfaced to virtually any microcontroller. The communication protocol is simple, without the need of programming internal registers in the device. This new sensor module generation is based on leading MEMS technology and latest benefits from MEAS Switzerland proven experience and know-how in high volume manufacturing of altimeter modules, which have been widely used for over a decade. The sensing principle employed leads to very low hysteresis and high stability of both pressure and temperature signal.

Features

- Pressure range: 10 to 2000 mbar

- Temperature range: -40°C – 85°C

- Resolution pressure: 0.02 mbar

- Resolution temperature: <0.01 °C

- Supply voltage: 1.8 – 3.6 V

- Very low current consumption: Standby max. 0.1 μA

- I²C / SPI interface

- Fast conversion under 0.5 ms (adjustable)

- Excellent long-term stability

- Media resistant

- ESD protected

- Small size: 4.5 × 4.5 mm2

- Reflow capability

- RoHS and REACH compliant

Applications

- Mobile altimeters and mobile barometric measuring systems

- People search and navigation devices

- Weather stations

- Sports watches

- GPS receiver

- Air traffic control (Variometer and datalogger)

MS5561 – digital miniaturized air pressure sensor 0-1100 mbar

-

The MS5561C pressure measurement miniature module consists of a SMD-hybrid device including a piezoresistive pressure cell and an ADC-Interface IC. It provides 16 Bit data words from a pressure- and temperature-dependent voltage. Additionally the module contains 6 readable coefficients for a highly accurate software calibration for the pressure and temperature measurement. The MS5561C is a low-power, low-voltage device with automatic power down (ON/OFF) switching. A 3-wire interface is used to communicate with a microcontroller.

The devices have a very low standby-current. The optimal compromise about refresh rate and average current consumption can individually be defined by the application software.

MS5561-C: protected by a metal cap filled with silicon gel on a ceramic hybrid 6.2×6.4mm2

Pressure range: 10…1100mbar (0.15 … 16 PSI) abs.; operating temperature: -40 … +85°C.Features

- Pressure range: 10 -1100 mbar, absolut

- Temperature range: -40 °C – 85 °C

- Resolution pressure: 0.1 mbar

- Resolution temperature: 0.01 °C

- High precision due to individual correction data

- Supply voltage: typ. 3 V

- Current consumption: 4 μA (Standby: max. 0.1 μA)

- digital 3 wire interface (16 bit)

- Dimensions: 4.75 x 4.25 x 1.6 mm³

- Reflow capability

- RoHS and REACH compliant

Applications

- Mobile altimeters and barometric measuring systems

- Weather stations

- Sports watches

- Smart clothing

- GPS receiver

- Air traffic control

- Performance measurement in sports equipment

MS5637 – digital miniaturized absolute pressure sensor 2 bar or 30 bar

-

The MS5637 is a digital OEM sensor* that measures absolute pressure and ambient temperature with high resolution. The sensor is compensated and outputs the measured values as digital output signals via an I²C interface.

The reflowable sensor MS5637-02BA03 is designed for the pressure range of 10 – 2000 mbar, but optimized for the pressure range 300 – 1200 mbar. The newer version of the MS5637-30BA is designed for the range 0-30 bar and optimized for the range 0.3 – 14 bar. In addition to the pressure, the sensors measure the temperature from -40 to 85 ° C.

The MS5637 pressure sensors consist of a piezoresistive pressure cell and an amplifier A/D-interface-IC, housed in a QFN package (3.0 x 3.0 x 0.9 mm³). The sensor converts the measured pressure- and temperature-dependent signal of the measuring cell into a 16-bit data word. In addition, 6 individual coefficients are stored in the sensor, which allow the highly accurate software correction for the pressure and temperature measurement by an external microprocessor. The I²C interface is used for serial communication with the microprocessor.

The sensors are intended for applications with a digital system environment. Since there is already a processor at system level, this can be used to easily calculate the current pressure and temperature values.

Features

- Pressure range 0.01 – 2 bar and 30 bar

- Temperature range: -40°C – 85 °C

- Supply voltage: 1.5 – 3.6 V

- I²C interface

- Resolution pressure: 0.016 mbar

- Resolution temperature: typ. <0.01 °C

- Very low current consumption: Standby max. 0.14 μA

- ESD protected

- QFN housing: (3.0 x 3.0 x 0.95 mm³)

- RoHS and REACH compliant

Applications

- Mobile altimeters and mobile barometric measuring systems

- People search and navigation devices

- Smartphones, tablet PCs

- Weather stations

- Sports watches

- GPS receiver

- Air traffic control (Variometer)

- Pneumatics

MS5607 – digital barometric pressure sensor 10 – 1200 mbar with high resolution

-

The MS5607 is a high precision pressure sensor module* and includes a linear pressure measurement element (pressure die) and an ultra low power 24 bit ΣΔ- A/D-converter with internal factory calibrated coefficients. The main function is to convert the uncompensated analogue voltage from the pressure die to a 24bit digital value, as well as providing a 24 bit value for the temperature. These values can be calculated with the aid of the internal coefficients in any external processor to the real calibrated values. The MS5607 provides different operations modes that allow optimizing for speed and current consumption. A consumption of 0.9μA at one conversion per second (8bit) to 12.5μA (24bit) and resolution selection per conversion enables an optimum application specific power performance trade-offs to be realized.

The modules communicate via a four-wire SPI or two-wire I²C interface. The MS5607 is mounted in a small QFN-package and allows the integration in miniaturized mobile devices without any additional components.The sensing principle employed leads to very low hysteresis and high stability of both pressure and temperature signal.

Features

- Pressure range: 10 to 1200 mbar

- Altitude resolution 20 cm

- Temperature range: -40 °C to 85 °C

- Supply voltage: 1.8 to 3.6 V

- Resolution pressure: 0.024 mbar

- Resolution temperature: typ. <0.002 °C

- Very low current consumption: Standby max. 0.14 μA

- I²C and SPI interface

- ESD protected

- DFN housing: 5.0 x 3.0 x 0.95 mm³

- RoHS and REACH compliant

Applications

- Mobile altimeters and mobile barometric measuring systems

- People search and navigation devices

- Weather stations

- Sports watches

- GPS receiver

- Air traffic control (Variometer and datalogger)

MS5611 – high resolution barometric sensor 10 – 1200 mbar

-

The MS5611 is a high precision pressure sensor module* and includes a linear pressure measurement element (pressure die) and an ultra low power 24 bit ΣΔ- A/D-converter with internal factory calibrated coefficients. The main function is to convert the uncompensated analogue voltage from the pressure die to a 24bit digital value, as well as providing a 24 bit value for the temperature. These values can be calculated with the aid of the internal coefficients in any external processor to the real calibrated values. The MS5611 provides different operations modes that allow optimizing for speed and current consumption. A consumption of 0.9μA at one conversion per second (8bit) to 12.5μA (24bit) and resolution selection per conversion enables an optimum application specific power performance trade-offs to be realized.

The modules communicate via a four-wire SPI or two-wire I²C interface. The MS5611 is mounted in a small QFN-package and allows the integration in miniaturized mobile devices without any additional components. The sensing principle employed leads to very low hysteresis and high stability of both pressure and temperature signal.

Features

- Pressure range: 10 to 1200 mbar

- Temperature range: -40 °C to 85 °C

- Altitude resolution: 10 cm

- Resolution pressure: 0.012 mbar

- Resolution temperature: 0.01 °C

- Supply voltage: 1.8 to 3.6 V

- Very low current consumption: Standby max. 0.14 μA

- I²C and SPI interface

- ESD protected

- QFN housing: 5.0 x 3.0 x 0.95 mm³

- RoHS and REACH compliant

Applications

- Mobile altimeters and mobile barometric measuring systems

- People search and navigation devices

- Weather stations

- Sports watches

- GPS receiver

- Air traffic control (Variometer and datalogger)

MS5837 – small absolute pressure sensor for 2 or 30 bar with high resolution

-

The MS5837 are digital OEM sensors* that measure the absolute pressure* with high resolution. They are compensated and output the measured values as digital output signals via an I²C interface.

The reflowable sensors are designed for the pressure range of 300 – 1200 mbar (MS5837-02BA03) and 0 – 30 bar (MS5837-30BA) and are media-protected with a gel coating. In addition to the pressure, they measure the temperature from -40 to 85 ° C.

The MS5837 pressure sensors consist of a piezoresistive pressure cell and an amplifier A/D-interface-IC, housed in a QFN package (3.3 x 3.3 x 2.75 mm³). The metal top protects the electronic components and facilitates O-ring mounting. The sensor converts the measured pressure- and temperature-dependent signal of the measuring cell into a 24-bit data word. In addition, 6 individual coefficients are stored in the sensor, which allow the highly accurate software correction for the pressure and temperature measurement by an external microprocessor. The I²C interface is used for serial communication with the microprocessor.

The sensors are intended for applications with a digital system environment. Since there is already a processor at system level, this can be used to easily calculate the current pressure and temperature values.

Features

- Pressure ranges absolut: 100 – 2’000 mbar or 0 – 30 bar

- Temperature range: -40..+85 °C

- Resolution pressure: 0.016 mbar (MS5837-02BA03) / 0.2 mbar (MS5837-30BA)

- Resolution temperature: 0.002 °C

- Supply voltage 1.5 – 3.6 V

- Low power consumption: 0.6 μA (standby <0.1 μA)

- I2C interface

- Ceramic substrate with metal cap: 3.3 x 3.3 x 2.75 mm³

- RoHS and REACH compliant

Applications

- Mobile altitude measurement

- Mobile water depth measurement

- Diving computer

- Bike computer

- Mobile altimeter/ barometer

- Sports watches

- Pneumatic devices

- Compressor control

MS5839 – chlorine resistant absolute pressure sensor up to 2 bar

-

The MS5839 is a digital OEM sensor* that measures the absolute pressure* with high resolution. It is compensated and outputs the measured values as digital output signals via an I²C interface.

The reflowable sensors are designed for the pressure range of 300 – 1200 mbar (MS5839-02BA36) and are media-protected with a chlorine resistant gel coating. They are also shielded. In addition to the pressure, they measure the temperature from -40 to 85 ° C.

The MS5839 pressure sensors consist of a piezoresistive pressure cell and an amplifier A/D-interface-IC, housed in a QFN package (3.3 x 3.3 x 2.75 mm³). The metal top protects the electronic components and facilitates O-ring mounting. The sensor converts the measured pressure- and temperature-dependent signal of the measuring cell into a 24-bit data word. The I²C interface is used for serial communication with the microprocessor.

The sensors are intended for applications with a digital system environment. Since there is already a processor at system level, this can be used to easily calculate the current pressure and temperature values.

Features

- Pressure ranges absolut: 100 – 2’000 mbar

- Temperature range: -40..+85 °C

- Resolution pressure: 0.016 mbar (MS5837-02BA03) / 0.2 mbar (MS5837-30BA)

- Resolution temperature: 0.002 °C

- Supply voltage 1.5 – 3.6 V

- Low power consumption: 0.6 μA (standby <0.1 μA)

- I2C interface

- Ceramic substrate with metal cap: 3.3 x 3.3 x 2.75 mm³

- RoHS and REACH compliant

Applications

- Mobile altitude measurement

- Mobile water depth measurement

- Diving computer

- Bike computer

- Mobile altimeter/ barometer

- Sports watches

- Pneumatic devices

- Compressor control

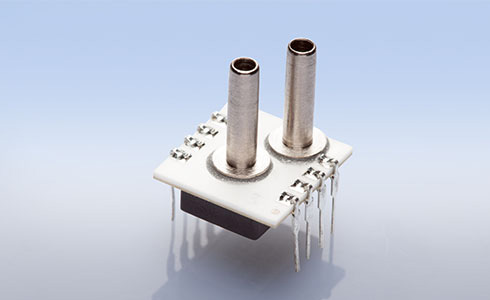

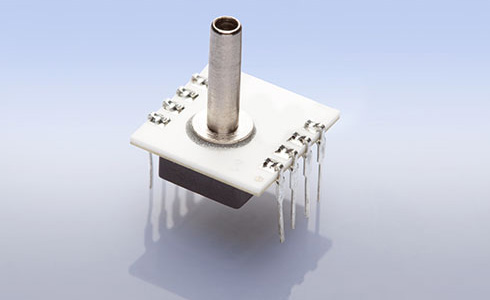

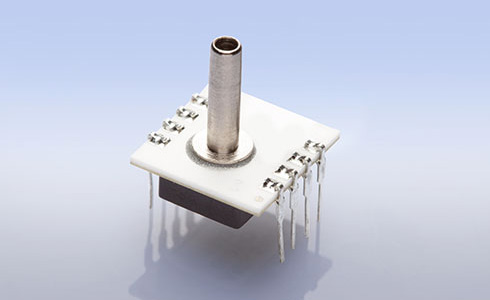

AMS 5915 – digital pressure sensor 2,5 mbar – 16 bar

-

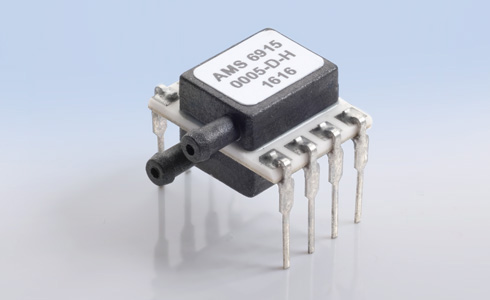

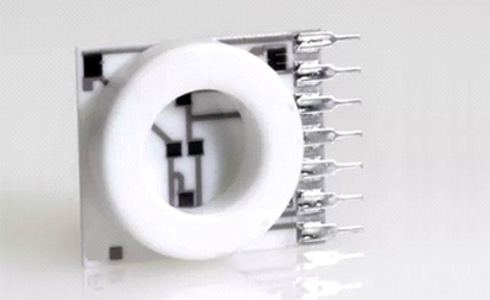

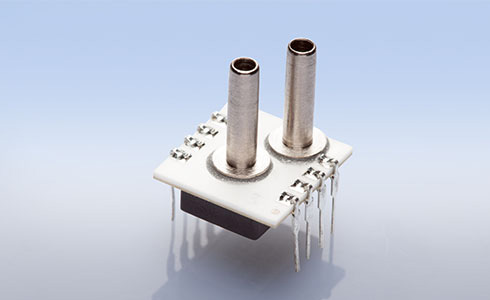

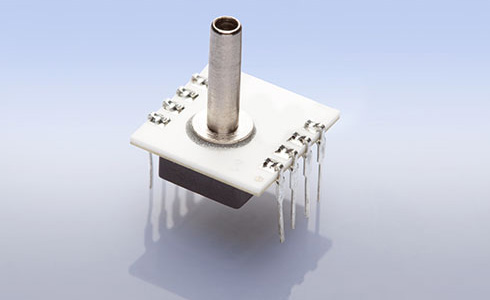

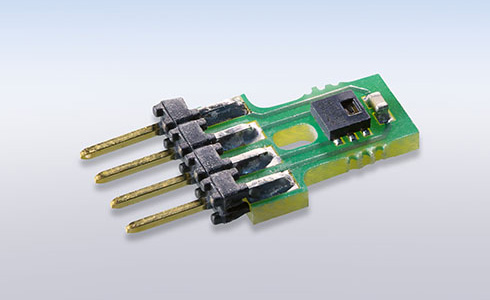

AMS 5915 pressure sensors are a series of high-precision OEM sensors* with a digital I²C-interface with multiple pressure ranges from 0-2,5 mbar to 0-16 bar and customizable pressure ports.

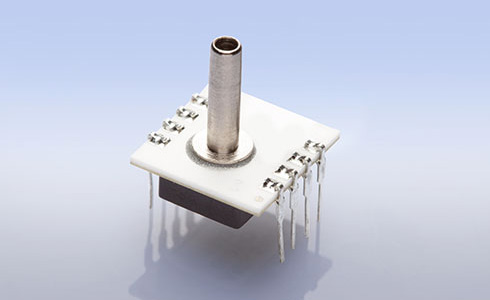

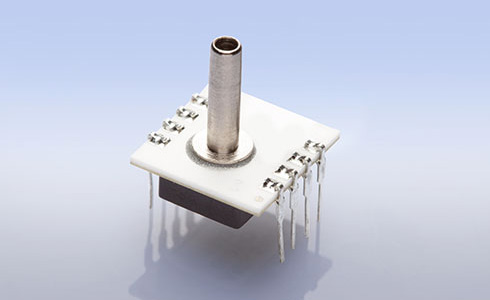

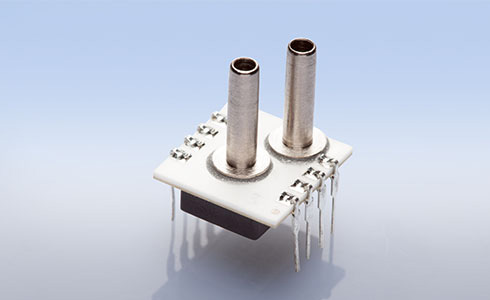

AMS 5915 are calibrated and compensated for across a wide temperature range of -25 to +85°C. These pressure sensors come as a dual in-line package (DIP) for assembly on printed circuit boards (PCBs) 15 x 15 mm² and are fully operational without the need for any additional components. The electrical connection is made via the DIP solder pins; pressure is connected via two vertical metal tubes.

The AMS 5915 combine a micromachined, high quality piezoresistive measuring cell with a modern, digital signal conditioning mixed-signal CMOS-ASIC on a ceramic substrate.Features

- Relative, absolute und differential, bidirectional differential pressure ranges 2,5 mbar to 16 bar

- Temperature range: -25°C – 85°C

- I²C-Bus-Interface

- For pneumatic use

- Pressure and temperature output via I²C bus

- 3.3V power supply

- large connection/tubes variants

- High accuracy

- RoHS and REACH compliant

- Product made in Germany

Applications

- Respiratory control

- Medical measurement technology

- Gas flows, back pressure measurements

- Heating / Vacuum / Ventilation / Air Conditioning (HVAC)

- Barometric measurements

- Pneumatics

- Vacuum monitoring

- Level sensing

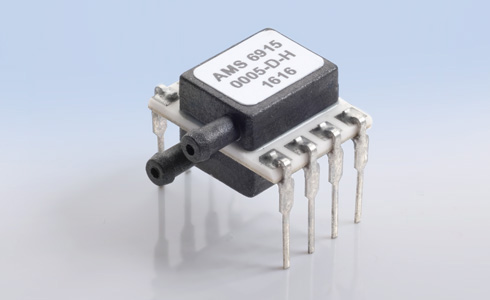

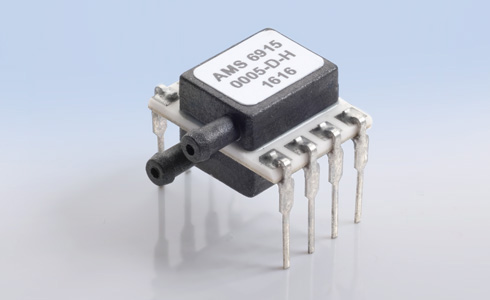

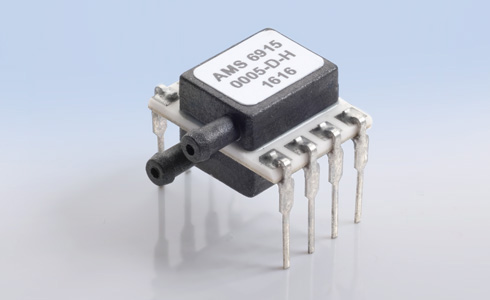

AMS 6915 – miniaturized pressure sensor with I2C

-

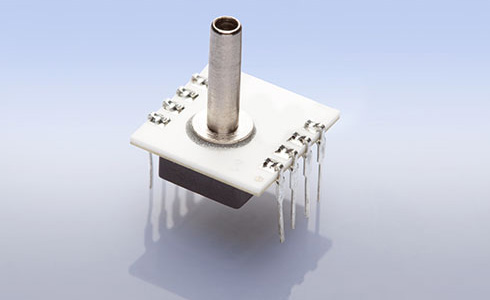

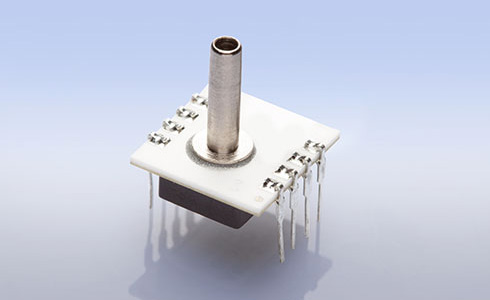

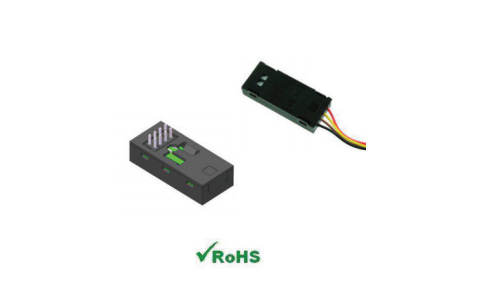

AMS 6915 pressure sensors are a series of high-precision OEM sensors* with a digital I²C-interface with multiple pressure ranges from 0-2.5 mbar to 0-1200 mbar and customizable pressure ports.

AMS 6915 are calibrated and compensated for across a wide temperature range of -25 to +85°C. These pressure sensors come as a dual in-line package (DIP) for assembly on printed circuit boards (PCBs) 13 x 10 mm² and are fully operational without the need for any additional components. The electrical connection is made via the DIP solder pins; pressure is connected via two vertical metal tubes.

The AMS 6915 combine a micromachined, high quality piezoresistive measuring cell with a modern, digital signal conditioning mixed-signal CMOS-ASIC on a ceramic substrate.Features

- Relative, absolute und differential, bidirectional differential pressure ranges 2.5 mbar to 1.2 bar

- Temperature range: -25°C – 85°C

- Pressure and temperature output via I²C bus

- 3.3 or 5.0V power supply

- High accuracy

- RoHS and REACH compliant

- Replacement product for the Honeywell HSC

- Product made in Germany

Applications

- Respiratory control

- Medical measurement technology

- Gas flows, back pressure measurements

- Heating / Vacuum / Ventilation / Air Conditioning (HVAC)

- Barometric measurements

- Level sensing

SM11X1 – BAP-barometric absolute pressure sensor 150-1’800 mbar

-

The SM11X1 series barometric absolute pressure sensors are compact OEM sensors* for measuring the barometric air pressure in the range of 150 – 1800 mbar (SM1111A: 150 – 1’150 mbar, SM1111B: 600 – 1’650 mbar, SM1131: 400 – 1’800 mbar, SM1171: 400 – 1’150 mbar). They offer a 16-bit signal processing and an accuracy of 1 mbar in the temperature range of 0 – 80 ° C.

The operating temperature range of -40 – 125 ° C is very broad and suitable for versatile use with a very good accuracy of 2 mbar.

The integrated ASIC enables calibration and temperature compensation during production. Alternatively, a ratiometric analog output or digital I²C or SPI outputs are available. The digital ones output not only the pressure but also the temperature information as a digital value.

The fully balanced SM11X1 are offered in a standardized SOIC8 package for automated SMD mounting. The SOIC pressure sensors are self-sufficient and do not require additional circuitry.

The barometric air pressure (BAP) sensors are available in three different types with different electrical outputs. The supply voltage is either 3.3 V or 5 V. The power consumption of the digital versions can be lowered by command from 5 mA to 10 μA in sleep mode.

Features

- Barometric absolute pressure between 150 mbar and 1’800 mbar

- Wide temperature range: -40 – 125 ° C

- Supply voltage: 3.3V / 5.0 V

- Compensated, calibrated output signal

- Output format: I²C / SPI / ratiometric

- Resolution 16 bit

- Accuracy 1 mbar

- Digital signal processor ASIC

- SOIC 8 housing for SMD mounting

- RoHS and REACH compliant

Applications

- Weather monitoring

- Medical technology

- Blood pressure measurement

- Negative pressure wound therapy

85BSD – digital pressure sensor with stainless steel membrane 5-300 psi

-

The 85BSD is a small profile, media compatible, piezoresistive silicon pressure sensor packaged in a 316L stainless steel housing. This 14-bit digital output pressure sensor supports I2C and SPI interface protocols in either a 3.3 or 5.0Vdc supply voltage.

With a diaphragm of just 13mm in diameter, this ASIC calibrated piezoresistive silicon pressure sensor is designed to be weldable or threaded with process fittings for high performance, low pressure applications. It utilizes silicone oil to transfer pressure from its 316L stainless steel diaphragm to its sensing element.

The 85BSD is configured in a backside, header-less design with a pressure range between 0-5 and 0-300psi in either absolute or gage reference type. Operating from -40°C to +125°C, it features both pressure and temperature read-out capabilities.

This backside digital output pressure sensor can be used for various applications such as: level controls, tank level measurement, corrosive liquid or gas measurement systems, OEM equipment, sealed systems, manifold pressure measurement, barometric pressure measurement and submersible depth monitoring.

Features

- Pressure ranges: relativ 05-300 psi, absolut 15-300 psi

- Temperature range: -40 °C to +125 °C

- Supply voltage: 3.3 or 5.0 Vdc

- Digital output: I²C or SPI

- Pressure resolution: 14 bit

- ± 1.0% total error

- Calibrated and compensated

- Screw or welding assembly

- Different electrical connections

- RoHS and REACH compliant

Applications

- Level sensing and monitoring

- Pneumatic applications

- Compressor monitoring

- Measurement of corrosive liquids

- Chemical process monitoring

- Monitoring of gases

- Immersion probe

86BSD – digital pressure sensor with stainless steel membrane 16 mm

-

The 86BSD is a small profile, media compatible, piezoresistive silicon pressure sensor packaged in a 316L stainless steel housing. This 14-bit digital output pressure sensor supports I²C and SPI interface protocols, may come in a 3.3 or 5.0Vdc supply voltage and is designed for o-ring mounting.

This small 16mm, ASIC calibrated pirezoresistive silicon pressure sensor is designed to be mountable with an o-ring seal for high performance, low pressure applications. It utilizes silicone oil to transfer pressure from its 316L stainless steel diaphragm to its sensing element.

The 86BSD is configured in a backside, header-less design with a pressure range of 1 – 300psi in either absolute or gage reference type. Operating from -40°C to +125°C, it features both pressure and temperature read-out capabilities.

This backside digital output pressure sensor can be used for various applications such as: level controls, tank level measurement, corrosive fluids and gas measurement systems, OEM equipment, sealed systems, manifold pressure measurement, barometric pressure measurement and submersible depth monitoring.

Features

- Relative and absolute pressure versions

- Pressure ranges: 0-1 psi to 0-300 psi

- Temperature range: -40 °C to +125 °C

- Supply voltage: 3.3 or 5.0 Vdc

- Digital output: I²C or SPI

- Pressure resolution: 14 bit

- ± 1.0% total error

- Calibrated and compensated

- O-ring assembly

- 16 mm diameter

- Wire connection

- RoHS and REACH compliant

Applications

- Level sensing and monitoring

- Tank monitoring

- Measuring systems for corrosive liquids and gases

- Pumps for corrosive media

- Pneumatic valves

- UAV altimeter and airspeed meter

- Air pressure measurement

- Retractable depth measurement

AMS 5812 – pressure sensor with analog & digital output

-

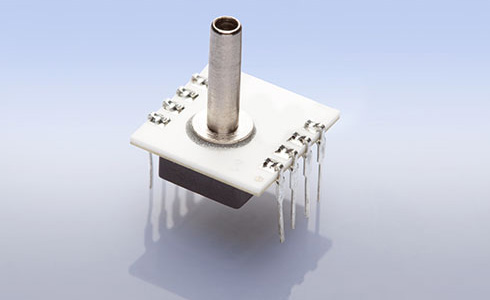

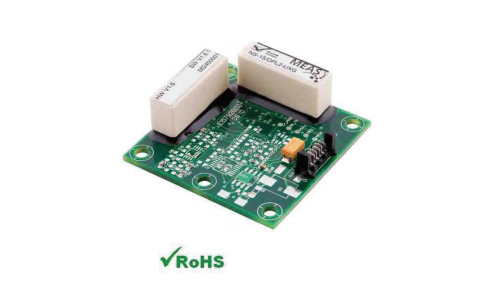

The AMS 5812 series of OEM sensors are fully signal conditioned, amplified, temperature compensated sensor in a dual in-line package (DIP) configuration with a 0,5 -4,5V/2,5 ±2V analog output und an I²C- interface.

The AMS 5812 are calibrated and compensated in the temperature range of -25 – 85°C. High precision, high stability and low drift are the result of a combination between the MEMS technology and a microelectronics signal conditioning ASIC.

The AMS 5812 series pressure sensors are based on a highly stable, piezoresistive pressure sensor chips mounted on a ceramic substrate. The electronically programmable ASIC is contained in the same package to provide calibration and temperature compensation.

Combining the sensor and the signal conditioning circuitry in a single package simplifies the use of advanced silicon micro machined pressure sensors. The pressure sensor 0.6×0.6 inch² can be directly mounted to a standard printed circuit board and no additional components are required for obtaining an amplified high level, calibrated pressure measurement.

Features

- Relative, absolute und differential pressure ranges 0.075 psi to 30 psi

- Temperature range: -25 °C to +85 °C

- 5 V power supply

- Analog output and I²C bus interface

- Temperature output via I²C bus

- Calibrated and temperature compensated

- High precision

- RoHS and REACH compliant

- Product made in Germany

Applications

- Respiratory control apparatus

- Medical measurement

- Gas flows, back pressure measurements

- Heating / Vacuum / Ventilation / Air Conditioning (HVAC)

- Barometric measurements

- Security applications

- Pneumatic applications

AMS 2710 – analog pressure sensor module with 10 V-voltage output

-

The AMS 2710 sensor is part of a series of miniaturized analog pressure transmitters* ready for use. AMS 2710 is a pressure sensor module* which fits for absolute, differential, gage and bidirectional differential pressure measurement.

One process of AMS 2710 production is the calibration as well as the compensation of temperature dependent drift of offset and span. No additional adjustment on the part of the customer is necessary. The sensor provides a 0…10 V output signal at 12 – 36 V voltage supply.

An integrated CMOS-DSP and EEPROM allow high accuracy in measurement capability. AMS 2710 comes as a pressure sensor module and is unilaterally mediaresistent due to underside pressurization*.

Features

- High accuracy in measurement

- Low total error between -25…+85ºC

- 0…10 V-Output signal

- Wide range of supply voltage

- Pressure sensor module

- Maintenance-free

- Product “Made in Germany”

- Simplest installation, quick start of operation

- RoHS compliant

Applications

- Barometric measurement

- Monitoring of industrial filters

- Pneumatic control

- Monitoring of vacuum, Heating, Ventilation and Air Conditioning (HVAC)

- Over- and under pressure measurement

AMS 4710 – pressure transmitter with 10 V-voltage output

-

The AMS 4710 sensor is part of a series of miniaturized analog pressure transmitters* ready for use. AMS 4710 is designed for fast screw assembly in a harsh industrial environment and fits for absolute, differential, gage and bidirectional differential pressure measurement.

One process of AMS 4710 production is the calibration as well as the compensation of temperature dependent drift of offset and span. No additional adjustment on the part of the customer is necessary. The sensor provides a 0…10 V output signal at 12 – 36 V voltage supply

An integrated CMOS-DSP and EEPROM allow high accuracy in measurement capability. AMS 4710 comes in a robust and compact plastic package (IP67) and is unilaterally mediaresistent due to underside pressurization*.

Features

- High accuracy in measurement

- Relative, absolute and differential pressure ranges 5 mbar to 2 bar

- Low total error between -25…+85ºC

- 0…10 V-Output signal

- Wide range of supply voltage

- High resolution

- Maintenance-free

- Product “Made in Germany”

- Simplest installation, quick start of operation

- RoHS and REACH compliant

Applications

- Barometric measurement

- Monitoring of industrial filters

- Pneumatic control

- Monitoring of vacuum, Heating, Ventilation and Air Conditioning (HVAC)

- Level sensing

- Over- and under pressure measurement

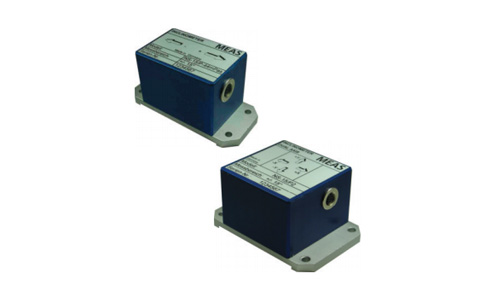

AMS 3010 – pressure transducer 10 V in metal housing

- The sensor AMS 3010 is part of a ready-to-use series of robust analog pressure transducers* in a matchbox-sized metal package (IP67). This series can stand system pressure up to 16 bar and is available for various pressure types and suitable for high precision measurements in industrial applications.

One process of AMS 3010 production is the calibration as well as the compensation of temperature dependent drift of offset and span. An integrated CMOS-DSP and EEPROM allows high accuracy in pressure measurement. All sensors in this series provide an analog output signal of 0 .. 10 V and can be powered within a wide supply voltage range between 12 .. 36 V.

AMS 3010 comes in a rugged metal package with standard M5 female threads for pressure connection. Available with various pressure fittings and with or without connection cable, this pressure transducer can stand up to 16 bar system pressure*.Features

- High accuracy in measurement

- Low total error between -25…+85ºC

- 0…10 V-Output signal

- system pressure up to 16 bar

- Dust-and-water-tight (IP67)

- Maintenance-free

- Product „Made in Germany“

- Simplest installation, quick start of operation

- Low overall error

- REACH and RoHs compliant

Applications

- Barometric measurement

- Monitoring of industrial filters

- Pneumatic control

- Monitoring of vacuum

- Monitoring of Heating, Ventilation and Air Conditioning (HVAC)

- Over- and under pressure measurement

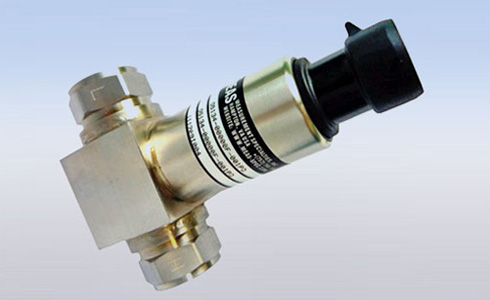

U5200 – mediaresistent pressure transmitter up to 689 bar

- The U5200 pressure transmitters* can measure absolute, relative, sealed gage* pressures and offer maximum flexibility for different configurations.

These pressure sensors have a high accuracy and a quick turnaround for demanding commercial and heavy industrial applications. The piezoresistive measuring cells are protected by a steel chamber (316L) with oil reservoir against media influence.

This series is suitable for measurement of liquid or gas pressure, even for difficult media such as contaminated water, steam, and mildly corrosive fluids.

The U5200 is mediaresistent and exceeds the latest heavy industrial CE requirements including overvoltage protection. The circuit is protected from reverse wiring at input and short circuit at output.

Features

- pressure ranges: 2 psi – 10 k psi

- absolute, gage, sealed and compound pressure

- 10 V/m EMI Protection

- Reverse Polarity Protection on Input

- Short Circuit Protection on Output

- Up to ±0.1% Accuracy

- Up to < ±0.75% Total Error Band

- excellent long time stability

- Compact Outline

- Stainless steel construction

- Temperature range: -40°C to +125°C

- Excellent stability

- Variety of mechanical and electrical Connections

- CE Compliant and Weatherproof

- RoHS an REACH conform

Applications

- Industrial Process Control and Monitoring

- Advanced HVAC Systems

- Refrigeration Systems

- Automotive Test Stands

- Off-Road Vehicles

- Pumps and Compressors

- Hydraulic/Pneumatic Systems

- Agriculture Equipment

DPH-100 – external pressure sensor for Panasonic pressure switch

-

The external pressure sensors Panasonic DPH-100 for air pressure measurement are used everywhere in the industrial gas control, where for reasons of space no pressure switch from Panasonic DP series can be installed or where its connection via pressure hoses causes disadvantages.

In large or difficult to access machines, the pressure hoses often have to be designed long, which reduces the possible clock rate, since the transmission medium air limits the speed of measurements. Short pressure hoses increase accuracy and the flexible cable is also used on moving machine parts. DPH-100 sensors can be equipped with up to 10 m long cables. The power supply of 12 .. 24 VDC is carried out via the pressure controller DPC-100.

Features

- Relative pressure sensor, calibrated and compensated

- Adjustable functions via display DPC-100

- Easy installation

- Three pressure ranges available:

- -1 .. 1 bar

- 0 .. 10 bar

- -1 .. 0 bar

- Operating temperature: 0 .. 50 ° C

- Humidity: 35 .. 85 %RH

- Supply voltage: 12 .. 24 VDC (via DPC-100)

- Current consumption below 15 mA

- Cable length up to 10 m

- RoHS and REACH compliant

Applications

- Electrical, electronic, semiconductor and automatic assembly industry

- Biomedical industry (laboratory automation)

- Pressure monitoring

- Vacuum control

- Leakage check

- Suction lift

- Processing industry

- Packaging machines

- Pneumatic Applications

- Bottling

MS8607 – triplesensor humidity, temperature, pressure

-

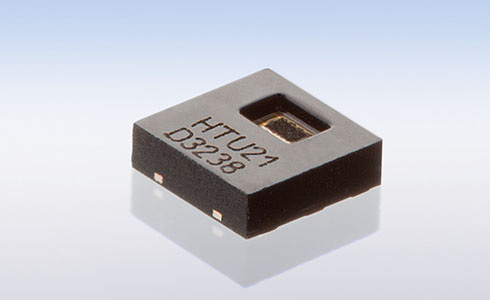

The MS8607 triple sensor combines a pressure sensing element for barometric pressure, a sensing element for humidity and a temperature detector with integrated, digital evaluation electronics (ASIC).

The sensor is suitable for reflow soldering and designed for a pressure range of 10 to 2,000 mbar yet optimized for a pressure range of 300 to 1,200 mbar. The MS8607 measures relative humidity within a range of 0 to 100% RH and temperatures of between -40 and +85°C with great accuracy.

The measured physical variables are amplified in the ASIC and converted into 24-bit data values for pressure and temperature and into a 16-bit value for relative humidity. The data values are available as independent output signals in I²C format. The internal I2C interface is used to communicate with an external microprocessor. In a simple algorithm this links the output signals with the individual, stored correction coefficients and thus calibrates the measurements.

Features

- Pressure measurement range: 10 to 2,000 mbar

- Humidity range of 0 to 100% RH

- Temperature range: -40 to +85°C

- Pressure resolution: 24 bits ≈ 0.016 mbar

- Humidity resolution: 0.04% RH

- Temperature resolution: 0.01°C

- Supply voltage: 1.5 to 3.6 V

- Low current consumption: max. 0.24 μA in standby

- I²C interface

- ESD protected

- QFN package: 5.0 x 3.0 x 1.0 mm3

- RoHS and REACH compliant

Applications

- Smartphones and tablet PCs

- Lifetrackers

- Sports watches

- HVAC applications

- Weather stations

- Driers/humidifiers

- Operational control of electrical systems

AMS 4516 – pressure transmitter with wireless bluetooth 4.2 signal

-

The miniaturized sensors in the AMS 4516 series are high-precision, ready-to-use transmitters* which are suitable for measuring absolute, relative and differential pressure. They transmit measurement data via Bluetooth Low Energy 4.2 (BLE; radio frequency of 2.4 GHz). The sensors are optimized for low power consumption and operated by a single cell battery (CR 2032). They have a free-field range of approximately 100 m. The sensors can be read out and configured using the AMS 4516 Android app (provided free of charge by AMSYS).

The offset and span are electronically calibrated and the temperature-related offset and span drift compensated for during manufacture, so that no subsequent calibration by the user is required. The wireless pressure transmitters are supplied in a compact, robust plastic package (IP67) for quick screw mounting and are suitable for external installation.

Thanks to Underside pressurization* the pressure transmitters are media resistant on one side and come in several different versions for a wide pressure range of 5 mbar to 2 bar.

Features

- Relative, absolute and differential pressure ranges of 5 mbar to 2 bar

- Operating range: 0–85°C

- Supply voltage: 2.7 to 3.6 V

- Bluetooth 4.2 signal transmission

- High resolution

- Battery operation (CF 2032)

- Maintenance free and suitable for industrial use

- Very easy mounting

- RoHS and REACH compliant

- Product made in Germany

Applications

Monitoring in places which are difficult to access for:

- Barometric measurements

- Industrial filter/ventilator monitors

- Pneumatic monitors

- Vacuum monitors

- Heating, ventilation and air conditioning system monitors

- Level sensing

AMS 4506 – barometric pressure transmitter with wireless bluetooth signal

-

The miniaturized sensors in the AMS 4506 series are high-precision, ready-to-use transmitters* which are suitable for measuring barometric absolute pressure. They transmit measurement data via Bluetooth Low Energy 4.2 (BLE; radio frequency of 2.4 GHz). The sensors are optimized for low power consumption and operated by a single cell battery (CR 2032). They have a free-field range of approximately 100 m. In addition, a gateway for data readout is available.

The offset and span are electronically calibrated and the temperature-related offset and span drift compensated for during manufacture, so that no subsequent calibration by the user is required. The wireless pressure transmitters are supplied in a compact, robust plastic package (IP67) for quick screw mounting and are suitable for external installation.

Features

- Barometric pressure 300 – 1’200 mbar (100 – 2’00 mbar)

- Operating range: 0–85°C

- Battery operation (CF 2032)

- Supply voltage: 1.7 to 3.6 V

- Bluetooth 4.2 signal transmission

- High resolution

- Maintenance free and suitable for industrial use

- Very easy mounting

- RoHS and REACH compliant

- Product made in Germany

Applications

Monitoring in places which are difficult to access for:

- Barometric measurements

- Vacuum monitors

- Weather stations

U5600 – wireless mediaresistent pressure transmitter

-

The U5600 are wireless pressure and temperature transmitters* with iOS, Android and Windows XP / 7+ compatibility.

These pressure transducers transmit the calibrated and temperature compensated signals via Bluetooth communication protocol (Bluetooth 4.0), enabling a wireless process control by that. The transmitters are powered by a simple button cell CR2032 / CR2050 and can be read via an app or PC software. They measure the absolute, the relative and the sealed gage* pressure independent of media and are available with many pressure connection variants.

The wireless U5600 transmitters* are recommended for their high accuracy, long-term stability and numerous protection features for demanding industrial applications. The piezoresistive measuring cells are protected by a steel chamber (316L) with oil reservoir against media influence. The U5600 are therefore particularly suitable for measuring pressure in liquids or gases. They can even be used in contaminated water, in hot steam and in weakly corrosive liquids.

Features

- Pressure ranges: 5 – 500 psi ( 350 mbar – 35 bar)

- Absolute, relative and sealed gage versions

- Temperature range: -10°C to +60°C

- Total error band < ± 0.75 % FS

- Long-term stability ± 0.1 % FS

- Battery life: 2 years for CR2050, 350 mAH battery and 5 seconds transmission interval

- Reverse polarity protection and short circuit protection

- Compact design, stainless steel construction

- Variety of mechanical pressure connections

- CE and FCC compliant

- IP67 water resistant

- RoHS and REACH compliant

Applications

- Industrial Process Control and Monitoring

- Advanced HVAC Systems

- Refrigeration Systems

- Automotive Test Stands

- Mobile work tools

- Off-Road Vehicles

- Hydraulic/Pneumatic Systems

- Agriculture Equipment

- Energy generation and energy management

AMS 8607BLE – wireless multisensor

-

The AMS 8607 BLE is a battery-powered Bluetooth Low Energy (BLE) multisensor for measuring relative humidity, barometric pressure and temperature. Data is transmitted via Bluetooth 4.1 and can be read out and configured by a smartphone app. The wireless sensor is ideal for use in devices that require all three metrics and are installed in hard-to-reach locations.

The sensor is suitable for reflow soldering and designed for a pressure range of 10 to 2,000 mbar yet optimized for a pressure range of 300 to 1,200 mbar. The MS8607 measures relative humidity within a range of 0 to 100% RH and temperatures of between -40 and +85°C with great accuracy.

This sensor is optimized for low power consumption and is powered by batteries. It has a range of about 100 m in the open field. The AMS 8607BLE is built into a plastic housing that allows for indoor and outdoor use.

Features

- Wireless multisensor

- Pressure, temperature and humidity measurement

- High resolution

- iOS and Android mobile app included

- Read, log, program the sensor via app

- Low overall error

- Long operating time (2 AA batteries)

- Maintenance-free

- Easy installation

- RoHS and REACH compliant

- Product “Made in Germany”

Applications

- Room monitoring

- Weather stations

- Cabinet monitoring

- Environmental monitoring

AMS 3516 – pressure transmitter with bluetooth 4.2 and analog output

-

The miniaturized sensors in the AMS 3516 series are high-precision, ready-to-use transmitters* which are suitable for measuring absolute, relative and differential pressure. They have a wired analog output signal and wireless signal transmission, thus providing a pressure signal which can be read out via Bluetooth without battery operation. The pressure transmitters come in several different versions for a wide pressure range of 25 mbar to 10 bar.

The offset and span are electronically calibrated and the temperature-related offset and span drift compensated for during manufacture, so that no subsequent calibration by the user is required. A 0–5-V signal is provided as an output and Bluetooth Low Energy 4.2 with a radio frequency of 2.4 GHz for monitoring communication with a mobile device. The sensors can be read out and configured using the AMS 3516 Android app (provided free of charge by AMSYS).

Features

- Relative, absolute and differential pressure ranges of 25 mbar to 10 bar

- System pressure of up to 16 bar

- Compensation range: -25–85°C

- Supply voltage: 8 to 36 V

- 0–5-V output signal

- Bluetooth 4.2 signal transmission

- Underside pressurization

- High resolution

- Low total error band

- Maintenance free and suitable for industrial use

- Very easy mounting

- RoHS and REACH compliant

- Product made in Germany

Applications

Wired and wireless signal transmission:

- Barometric measurements

- Industrial filter/ventilator monitors

- Pneumatic monitors

- Vacuum monitors

- Heating, ventilation and air conditioning system monitors

- Level sensing

relative pressure sensors

-

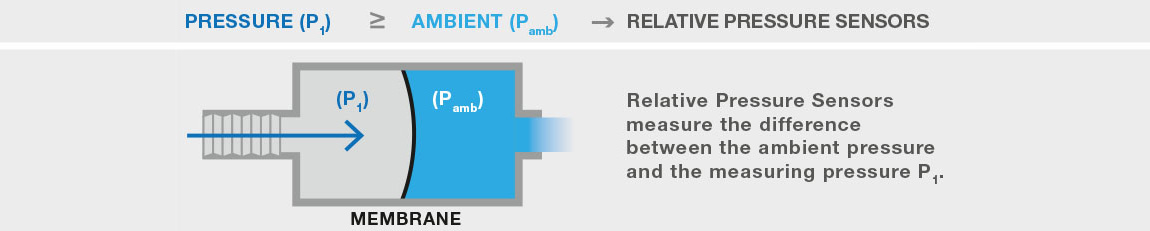

With the help of relative pressure sensors one compares a pressure in relation

to the ambient pressure and receives a signal, which is proportional to the

pressure difference.

The sensors offered here are suitable for applications in which there is a fixed ratio between the lower and the higher pressure. The measuring pressure P1 must be greater than the ambient pressure Pamb.

The AMSYS range of relative pressure sensors ranges from simple, uncompensated silicon cells over OEM sensors to high-precision amplified transmitters with standard output values.

-

With the help of relative pressure sensors one compares a pressure in relation

to the ambient pressure and receives a signal, which is proportional to the

pressure difference.

SM9G/D – uncompensated low pressure sensor in SOIC

- The SM9D and SM9G are differential and relative

pressure sensors that are neither compensated nor amplified. They have the

properties of the measuring cell and output the differential bridge voltage

in mV.

The uncompensated SM9X are offered in a standard SOIC-16 package with two vertical or horizontal pressure ports and one horizontal pressure port for SMD mounting. The output signal is a pressure-proportional mV signal. The SM9X are reflow-capable and suitable for automated mounting on PCB.Features

- Pressure ranges 0.15 / 0.6 /1.5 psi

- Relative and differential pressure

- Temperature range -40°C – 85°C

- Supply voltage 0 – 6.5 V

- Uncompensated mV output signal

- Sensitivity: 400 mV/psi; 200mV/psi; 80 mV/psi

- Various pressure connections

- SOIC 16 housing for SMD mounting

- RoHS and REACH compliant

Applications

- Gas flows

- Airflow control

- Fan control

SM5G – 90mV relative pressure sensor 5 or 15 psi in SOIC housing

- The SM5G is a differential and relative pressure

sensor that is neither compensated nor amplified. It has the properties of

the measuring cell and outputs the differential bridge voltage in mV.

The uncompensated SM5G is offered in a standard SOIC-8 package with a vertical pressure port for SMD mounting. The output signal is a pressure proportional mV signal. The SM5G is reflow-capable and suitable for automated mounting on PCB.Features

- Relative pressure ranges 0 – 5 psi and 0 – 15 psi

- Temperature range -40°C – 125°C

- Supply voltage: 0 – 10 V

- Uncompensated mV output signal

- Sensitivity: 24 mV/psi; 8 mV/psi

- SOIC-8 package for SMD mounting

- RoHS and REACH compliant

Applications

- Gas flows

- Airflow control

- Fan control

SM5651 / SM5652 – calibrated, not amplified pressure sensor

- The SM565X Series of OEM pressure transducers are

fully calibrated, temperature compensated pressure devices in Dual-In-Line

packages for printed circuit board mounting. These transducers offer

improved performance as well as the option for either constant current or

constant voltage excitation.

The SM565X Series pressure transducers are constructed by attaching a highly stable piezoresistive pressure sensor chip to a ceramic substrate. Thick film resistors on the ceramic are laser trimmed during manufacturing to provide zero offset calibration, temperature compensation for zero offset and temperature compensation for sensitivity.Features

- Pressure range 0-1.5 psi

- Choice between current (max. 3mA) or voltage supply (0-20V)

- Offset calibrated

- Low noise

- No ADC conversion

- Unamplified output signal (mV)

- Temperature compensated: 0 – 60°C

- Output span calibrated

- Offset adjusted

- Dual-In-Line Package (DIP)

- RoHS and REACH compliant

Applications

- Pressure monitoring in fast processes

- Variometer

- Internal pump pressure

- Process monitoring

- Respiratory control apparatus

- Flow monitoring

- Leakage check

- HVAC applications

AMS 6916 – analog pressure sensor with ratiometric output

-

AMS 6916 pressure sensors are a series of high-precision OEM sensors* with a digital I²C-interface with multiple pressure ranges from 0-5 mbar to 0-1200 mbar and customizable pressure ports.

AMS 6916 are calibrated and compensated for across a wide temperature range of -25 to +85°C. These pressure sensors come as a dual in-line package (DIP) for assembly on printed circuit boards (PCBs) 13 x 10 mm² and are fully operational without the need for any additional components. The electrical connection is made via the DIP solder pins; pressure is connected via two vertical metal tubes.

The pressure sensors of this series are one-sided media resistant by underside pressurization* and have a ratiometric voltage output of 0.5 … 4.5 V.

Features

- Relative, absolute and differential pressure ranges 5 mbar to 1.2 bar

- Calibrated and temperature compensated

- Temperature range: -25 – 85 ° C

- Voltage output 0.5 … 4.5 V

- 3.3 or 5.0 V voltage supply

- High accuracy

- RoHS and REACH compliant

Applications

- Breathing control

- Gas flows, back pressure measurements

- Vacuum monitoring

- Industrial process monitoring

- Heating / Vacuum / Ventilation / Air Conditioning (HVAC)

- Barometric measurements

- Medical technology

- Fill level

ME750/ ME751/ ME752 – ceramic, analog OEM pressure sensor for relativ pressure

- The ME75X series pressure sensors are piezoceramic OEM

sensors* with integrated signal processing. The sensors deliver a

ratiometric* (ME750), a non-ratiometric (ME752) voltage or a 4-0 mA (ME751)

current signal for two-wire operation.

All ME75X sensors are individually and fully calibrated and temperature-compensated relative pressure sensors.

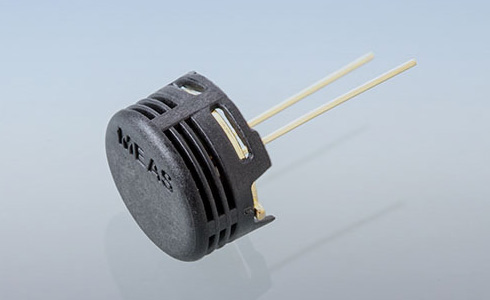

These OEM sensors consist of a monolithic ceramic body with an 18 mm diameter. The electronics are located on a circuit board that is mounted on the back of the ceramic body.

Thanks to the excellent chemical properties of the ceramic, the ME75X series pressure sensors are resistant to almost all, including aggressive, media.Features

- Pressure range from 1.6 to 400 bar relative pressure

- Temperature range: -25°C – 125°C

- 0.5-4.5 V (ratiometric), 0-10 V (non-ratiometric), 4-20 mA output

- Accuracy: 1% FS

- Calibrated, compensated and amplified

- Long-term stability: 0.3% FS / year

- Very high media resistance

- Ceramic sensor with flush membrane

- EMC protected

- RoHS and REACH compliant

Applications

- Automotive applications

- Industrial automation

- Medical technology

- Process monitoring

- Pneumatic applications

- Hydraulic applications

ME780 / ME782 – ceramic pressure sensor for relative and absolute pressure up to 600 bar

-

The ME78X series pressure sensors are piezoceramic OEM sensors* with integrated signal processing. The sensors provide a ratiometric* 0.5 – 4.5V voltage signal (ME780) or a digital I2C signal (ME782).

The ME78X Series is available in relative pressure, absolute pressure and sealed gage* versions. The sensors are individually calibrated, temperature compensated and linearized.

The ME78X series consists of a 18 mm diameter ceramic body with an octagonal membrane mounted on it. The electronics are located directly on the back of the ceramic body. The sensors are available with different electrical connections.

Thanks to the excellent chemical properties of the ceramic, the pressure sensors of the ME78X series are resistant to almost all, including aggressive media.

Features

- Pressure range: 0.5 – 600 bar

- Relative, absolute and sealed gage pressure

- Temperature range: -25°C – 125°C

- Supply voltage: 3.3 or 5 V

- 0.5 – 4.5 V or I2C output

- Accuracy: ±1% FS

- Calibrated, compensated and amplified

- Long-term stability: 0.3 % FS/year

- Very high media resistance

- Ceramic sensor with flush membrane

- EMC protected