- Offer Profile

-

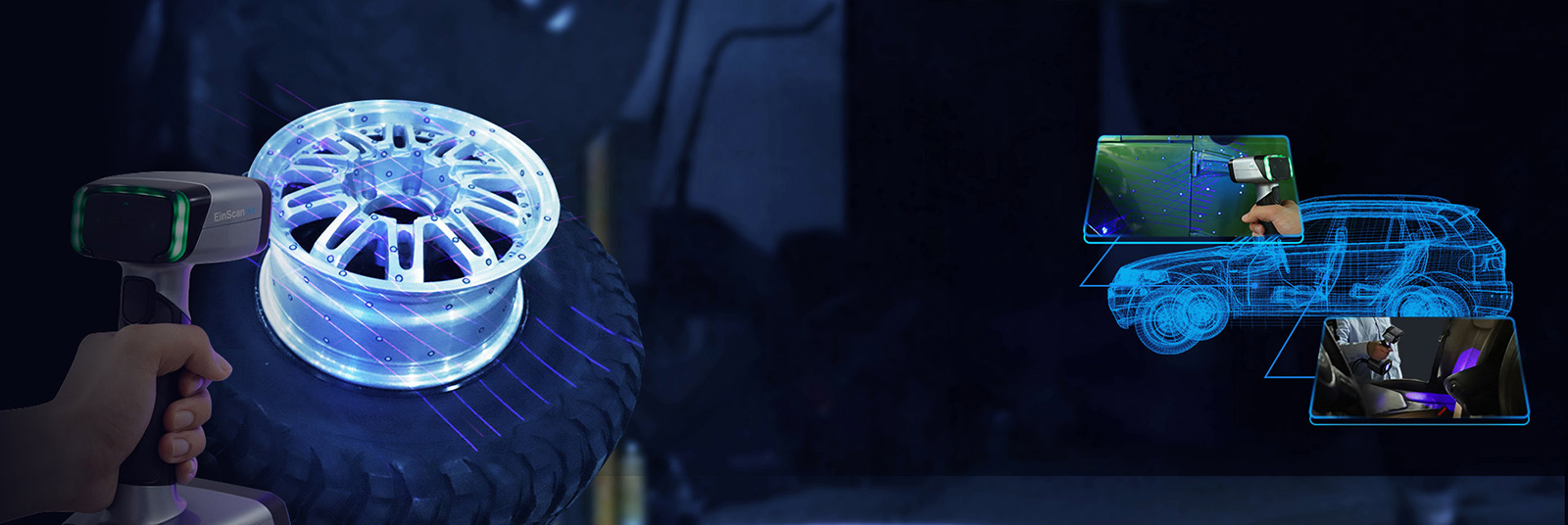

3D Digital Technologies

SHINING 3D develops, manufactures and commercializes a wide range of 3D technologies, including 3D scanners for multiple industries and applications, different types of 3D printers, and professional software from CAD design to 3D inspection.

SHINING 3D has focused on the research & development, manufacturing, and application of high-precision 3D digital products for over 18 years. Offering accessible, efficient and high-tech solutions, SHINING3D is committed to becoming a key contributor of the 3D digital technology field with global influence, promoting the popularization and application of 3D digital technology.

3D Metrology Solution

-

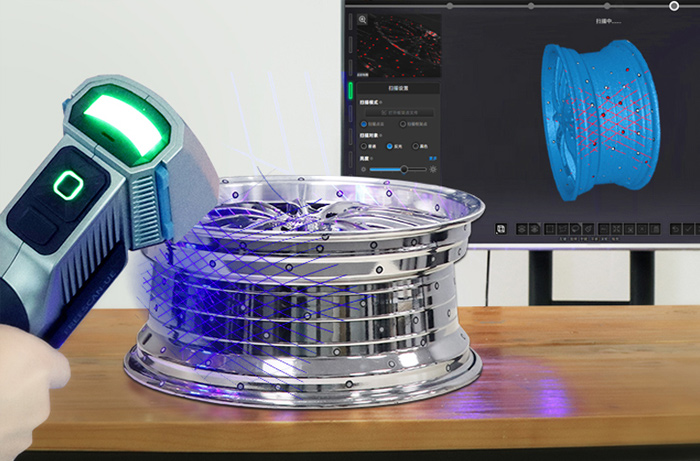

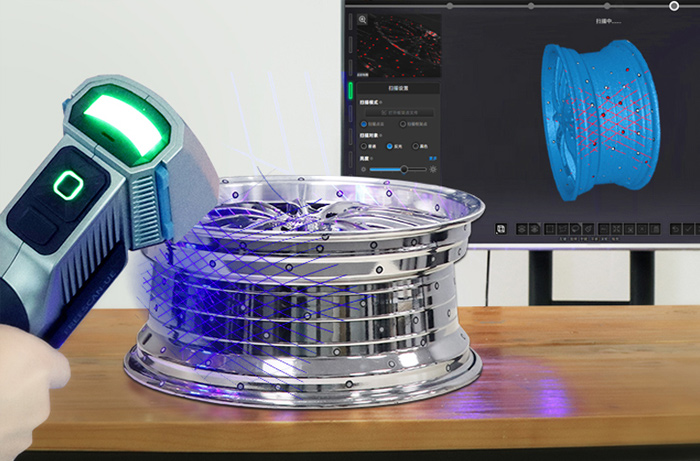

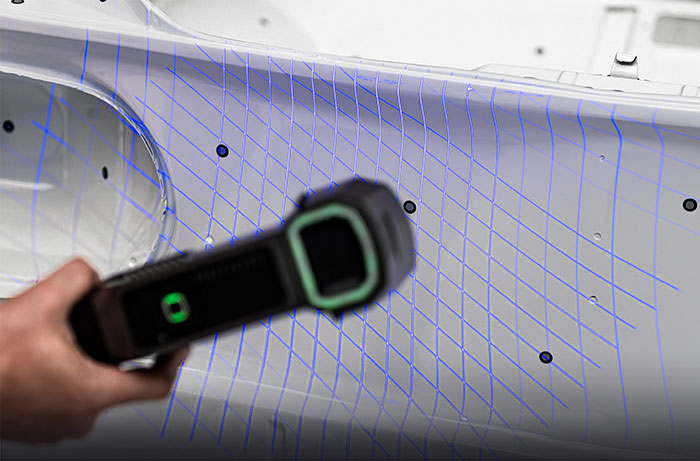

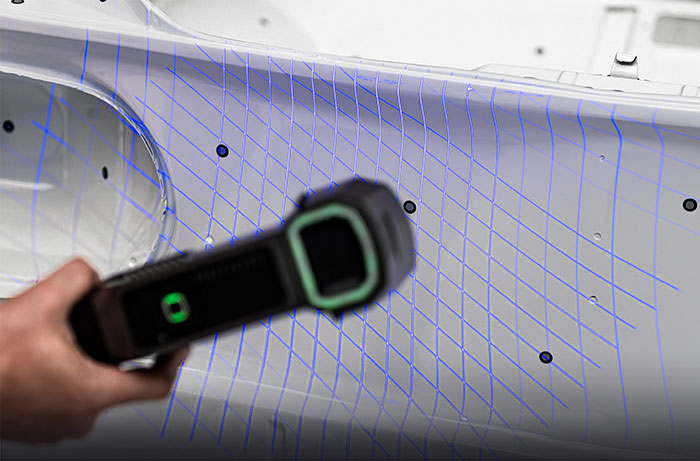

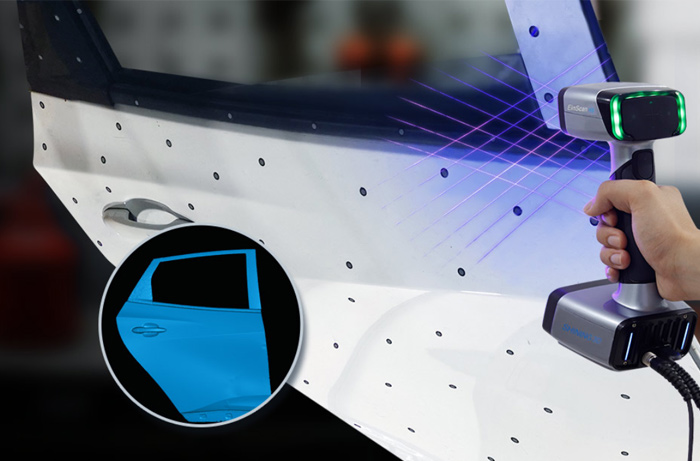

SHINING 3D owns multiple core technologies in the field of 3D machine vision based 3D inspection, bringing a variety of independent research and development equipment including laser handheld 3D scanner, blue-light high-precision 3D scanner for inspection system, intelligent robot automatic 3D inspection system, wireless optical portable CMM system and etc.

Industries: Aerospace, Automotive & Transportation, Power Generation, Industrial Manufacturing and Other Industries.

Applications: 3D Inspection, Simulation, Reverse Engineering, Product Development, and etc.

Multifunctional Metrology 3D Scanner

FreeScan Combo

-

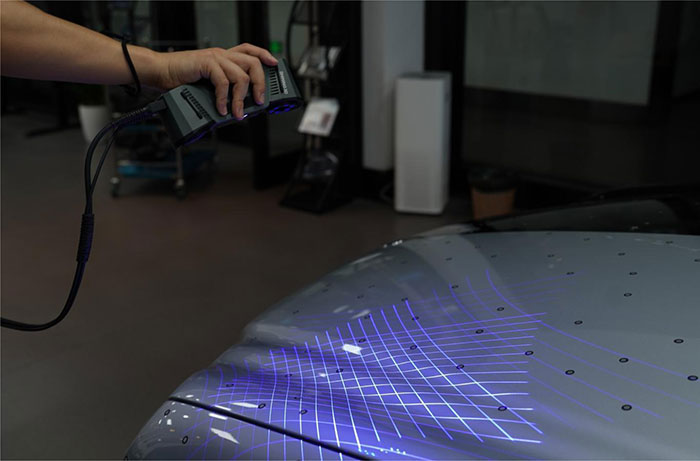

Hybrid Light Source and Multifunctional Handheld 3D Scanner

- Light Source: Blue Laser + Infrared VCSEL

- Accuracy: Up to 0.02 mm

- Weight: 620g

- Compact Size: 193mm x 63mm x53mm

The FreeScan Combo, with a small size of 193x63x53mm and weighed only 620g, has dual light sources: blue laser and infrared VCSEL. Being a lightweight and portable metrology scanner, it is equipped with four working modes: multiple lines scanning, single line scanning, fine scanning, infrared scanning.

Features:

- The FreeScan Combo, with a small size of 193x63x53mm and weighed only 620g, has dual light sources: blue laser and infrared VCSEL.

- 4 scanning modes, multiple scan choices

- Metrology-grade accuracy*, the accuracy under the multiple lines scanning mode can achieve up to 0.02mm.

FreeScan Combo can be used to achieve metrology-level precision inspection, reverse design, additive manufacturing, and other applications in many manufacturing sectors, including the automotive industries, aerospace, rail transportation, heavy industries, mold manufacturing, casting and foundry and medical industries.

Portable Wireless CMM Scanning System

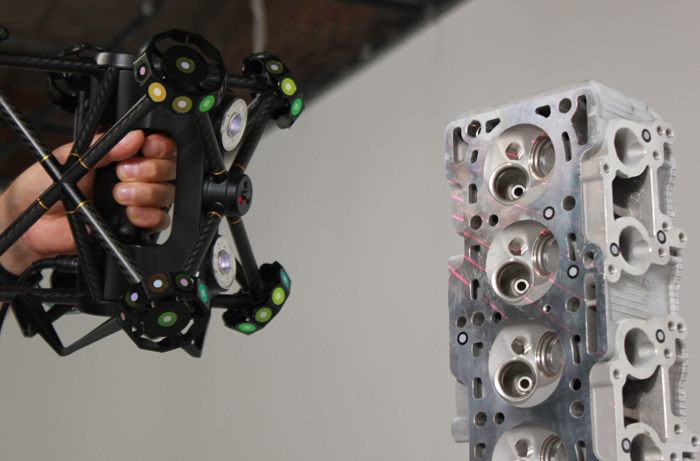

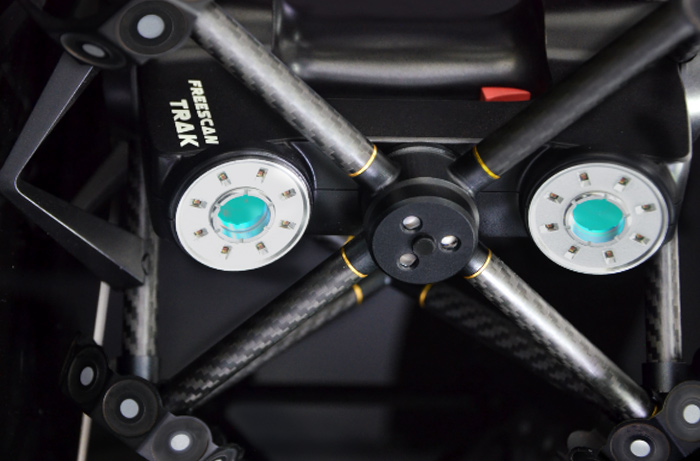

Portable Wireless CMM Scanning System: FreeScan Trak

-

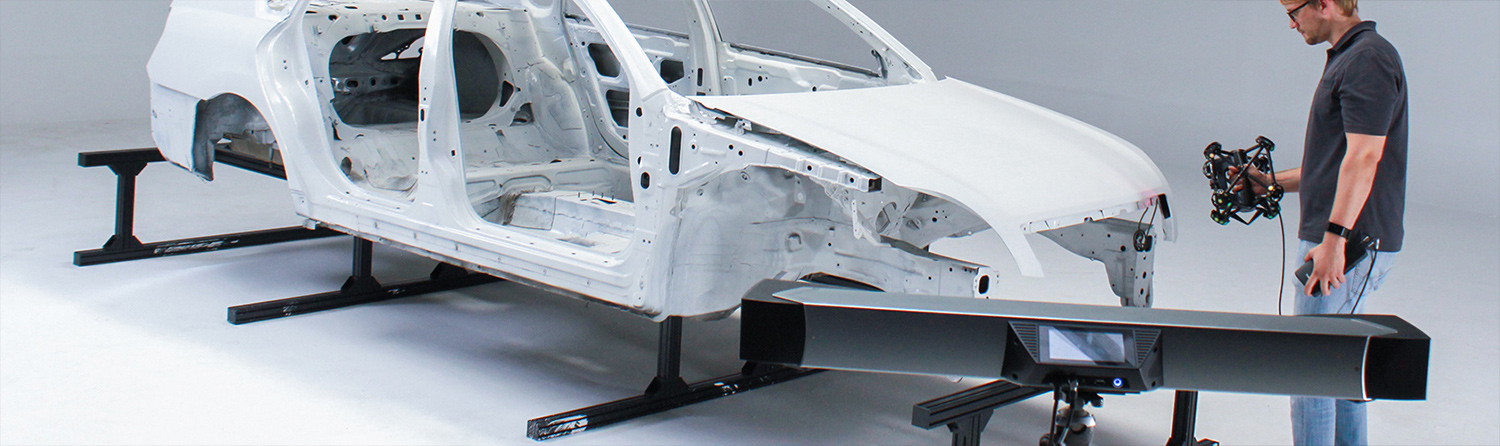

Based on SHINING 3D’s latest technology, the optical tracker is capable of capturing the spatial position of the scanner structure in real time, offering a portable, efficient, and reliable 3D measurement solution. The system helps the operator to get rid of the time-consuming process of sticking markers. This makes it simple to obtain the 3D data of medium to large size objects with metrology-grade accuracy. It is suitable for various static and dynamic applications, including large scale 3D inspection in aerospace, automotive, shipping and energy industries etc.

Dynamic referencingThe markers are used to create a reference structure system. The tracker or the part can be moved freely during measurement, allowing users to scan in unstable environment.

Metrology-grade measurementsThe accuracy is up to 0.03mm and the resolution can be up to 0.05mm. The system has high repeatability.

Wireless technologyNo physical cables between the tracker and the scanner. Use a precise wireless technology between the two terminals to setup 3D scan measurement system.

The Scanner- Independent working mode

The scanner retains the light source and can be used as a standalone scanner to do some scanning jobs. - AIRMASTER wireless solution

The scanner can be adapted to AIRMASTER™ and does not need any cable connections to the computer or to the optical tracker. - Lightweight

The weight is 1.2kg and it is easy to be held.

- Volumetric Accuracy: 15m³ ,0.1mm

- Resolution: 0.050mm

- Measurement Rate: 480,000 measurements/s

- Part Size Range (recommended): 0.2–6m

- Connection Type: Support wireless and wired connection

- FreeTrak-Weight: 7.2kg

- FreeTrak-Dimensions: 1079mm x 237mm x 110mm

- FreeTrak-Light Source: Infrared LED

- FreeTrak-Laser Class: N/A

- FreeTrak-Stand-off Distance: 3000mm

- FreeTrak-Depth-of-field: 2000mm

- FreeTrak-Scanning Area: 3000mm x 2500mm

- Connection Standard: IEEE802.11n/ac, IEEE802.3ab

- Output Formats: .stl、.asc

- FreeScan Trak-Weight: 1.2kg(scanner)+900g(airmaster)

- FreeScan Trak-Dimension: 210mm*210mm*215mm

- FreeScan Trak-Light Souce: RED LED & 7 Laser Crosses + 1 extra line

- FreeScan Trak-Laser Class: Class 2

- FreeScan Trak-Stand-off Distance: 300mm

- FreeScan Trak-Depth-of-field: 250mm

- FreeScan Trak-Scanning Area: 275mm x 250mm

- Independent working mode

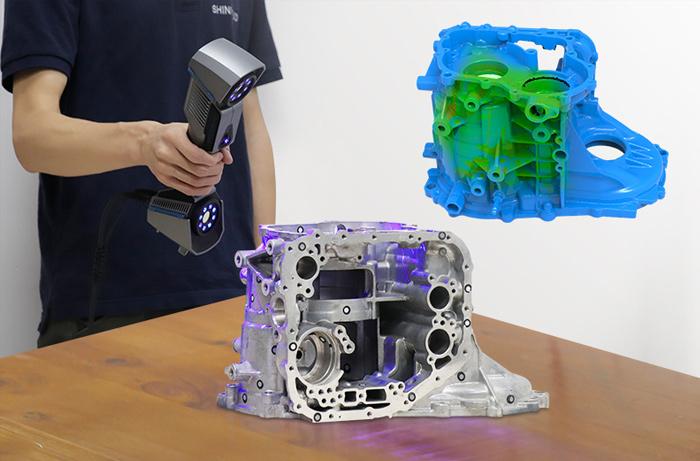

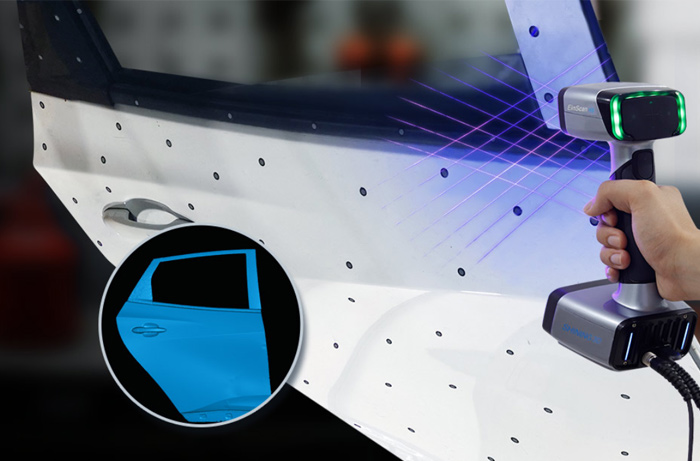

Laser Handheld 3D Scanner

FreeScan UE Pro

- For High Precision Metrology-grade Inspection

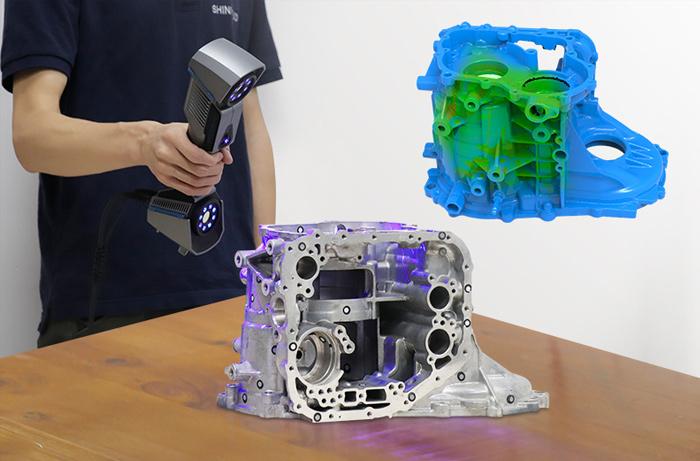

FreeScan UE Pro Laser Handheld 3D Scanner inherits the high-precision, metrology-grade accuracy, and lightweight design of FreeScan UE, while improving the ability of fine scanning and global precision control of large-scale workpiece scanning. It adopts 26+5+1 blue laser lines and integrates a photogrammetric module. Taking into account speed, accuracy and details, this professional 3D metrology solution can be applied to different sized scanning scenarios and perform metrology-grade accuracy inspection, reverse design, additive manufacturing and other applications.

Features:

- Metrology-Grade High Accuracy: Accuracy up to 0.02mm, delivers consistent scanning results with high precision

- Global Precision Control

- Multiple Scanning Modes

- Easy Operation: Inheriting the lightweight and ergonomic design of the UE series, the user-friendly scanning software enables an easy operation and shortens the learning curve.

- Wide Range of Material Adaptations: Supports scanning of black and high-reflective surfaces, more efficient scanning process.

- Fine and Rich Details

- Seamless docking to inspection and design software

FreeScan UE Laser Handheld 3D Scanner

-

As the blue laser handheld 3D scanner of the FreeScan series, FreeScan UE inherits the iconic features of "high accuracy" and "high precision". At the same time ergonomic and lightweight equipment design, make it easier to hold and operate, providing metrology-grade, high-accuracy inspection solutions for the automotive, transportation, aerospace industry, moulding inspection, energy generation, machinery manufacturing and etc.

Metrology-class high accuracyAccuracy up to 0.02mm, Volumetric accuracy 0.02mm+0.04mm/m.

Stability of repetitive measurementWhen measuring the same workpiece repeatedly, FreeScan UE delivers consistent results, proving stability and reliability.

Portable and lightweightedThe device weights only 670g, facilitating handheld scanning more easily and avoiding fatigue due to long working time.

Wide range of material adaptationsSupporting the scan of black and reflective surfaces to accommodate a wider range of scanning applications.

High efficiencyThe scan area can reach 510*520mm, providing larger field of view for a smoother and more efficient scanning experience.

- Scan Mode: Multiple Lines Scan, Single Line Scan

- Scan Accuracy: Maximun 0.02mm

- Volumetric Accuracy: 0.02+0.04mm/m

- Scan Speed: 650,000 points/s (UE7); 1,020,000 points/s (UE11)

- Working Distance: 500mm

- Max. Scan Depth: 300mm-700mm

- Max. Scan Range: 510mm*520mm

- Spacial Distance between Points: 0.05mm-3mm

- Light Source: 14 lines+1 line blue laser ray (UE7); 22 lines +1 line blue laser ray (UE11)

- Light Category: Class 2M (eye safe)

- Transmission Mode: USB 3.0

- Volume: 298mmx90mmx74.5mm

- Weight: 670g

- Powering: 12V,5.0A

- Working Temperature: 0-40℃

- Working Moisture: 10-90%

- Wireless Function: optional

- Certification: CE,FCC,ROHS,WEEE,KC

FreeScan Trio

-

98 Laser Lines, Zero Markers

The FreeScan Trio's thorough 98-laser-line mode eliminates the need for markers, efficiently capturing all your workpieces. Paired with an ultra-fast scan speed of up to 3,010,000 points/s, you'll truly feel the acceleration in your workflow.

Features

With its fast and innovative 98-laser-line mode, the FreeScan Trio is SHINING 3D's first marker-free laser 3D scanner. Less preparation, more efficiency.

The FreeScan Trio's three additional laser scanning modes deliver unrelenting accuracy, each reaching up to 0.02mm with markers. This metrology device also features built-in photogrammetry to offer an impressive volumetric accuracy of up to 0.02mm + 0.15mm/m.

Whether you need speed or accuracy on small or large assemblies, the versatile FreeScan Trio is geared for all your projects.- 98 laser lines for marker-free scanning

- Speed up to 3,010,000 points/s

- Three 5 megapixel cameras

- Accuracy up to 0.02 mm with markers

- 4 scanning modes and built-in photogrammetry

High-Precision 3D Inspection Scanner

AutoScan Inspec

-

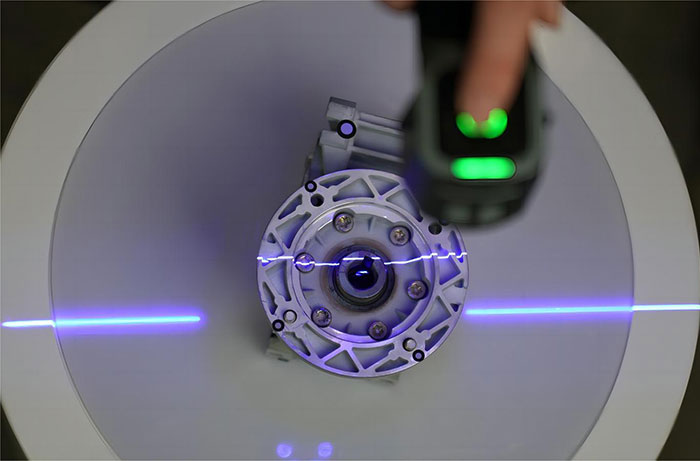

Automatic Desktop 3D Inspection Scanner

AutoScan Inspec is a fully automatic desktop 3D inspection scanner that innovative integrates high-accuracy 3D scanning and 3D inspection. Featuring intuitive user interface, easy operation and AI intelligent scanning algorithm, AutoScan Inspec offers fully automatic scanning experience with metrology-grade accuracy and fine detail. Designed for scanning small and complex parts, AutoScan Inspec can be applied in inspection and quality control, reverse engineering, product design and etc.

Metrology-grade AccuracyAdvanced blue-light 3D scanning technology brings users the scan accuracy within 10μm to ensure high level of accuracy required by quality inspection.

Automatic ScanningAs a fully automated desktop 3D scanner for 1-click scan, AutoScan Inspec features 3-axis for multi-angle scanning, enabling users to obtain 3D scans easily and rapidly.

Fine DetailProvides precisely detailed 3D scan for small and complex objects using dual-camera of 5 mega pixels.

Applications- Non-Contact Measurement

- Inspection and Quality Control

- Reverse Engineering

- Product Design

- Scanning Area: 100*100*75mm

- 3D Scanning Priciple: Structured light 3D scanning

- Accuracy: ≤10μm

- Rotation Axis: 3 Axis

- Camera Resolution: 2*5.0MP

- Weight: 7.5kg

- Working Temperature: 10°C~30°C

- Power: DC24V

- Output Format: STL

- O/S: Windows 10, 64 bits

- Light Source: Blue Light

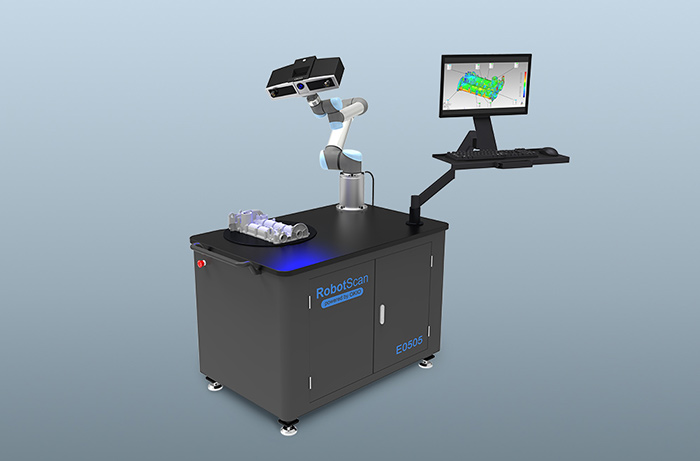

RobotScan E0505 Robot Automatic 3D Scanning System

-

SHINING3D’s intelligent robot automatic 3D inspection system, RobotScan, integrates the blue light high-accuracy industrial 3D scanning technology with the unique intelligent inspection technology to complete the whole scanning process through "one click”, thus greatly improving the inspection efficiency.

Main ApplicationsPerform mass inspection of the measured parts:

- Output report for testing the quality of the parts.

- Output the error of the whole area or designated area, the error can be imported into the third party software, robot provides the real-time guidance for the finishing processing of the online parts .

Full Size Inspection

Obtain complete point cloud data through 3D scanning, thus making the full-size inspect.on possible.Mass Automatic Inspection

Conduct mass automatic inspection after the same workpiece has been programmed once.Fast Measurement Speed and Wide Range of Applications

The single measurement speed can reach up to 0.3 seconds, and can scan dark and general reflective objects without spray powder.Blue Light Technology

Adopts the blue light 3D scanning technology,which can effectively prevent metal reflection so as to improve the scanning quality.High Safety

The system is equipped with the optimal robot with extremely high safety protection.High Environment Adaptability

The system is compact, occupies a small area.- 3D Scanner-Sensor: 2 x 5 Million Pixels

- 3D Scanner-Single Scan Range: 320 x 240m㎡

- 3D Scanner-Point Distance: 0.16mm

- 3D Scanner-Grating Generator: Blue light technology

- 3D Scanner-Output Data Format: .asc、.stl、.obj

- 3D Scanner-Scanner Weight: 3.2kg

- 3D Scanner-Scan Speed: ≤ 1.5 s

- 3D Scanner-Single Shot Accuracy: ≤ 0.015mm

- 3D Scanner-Scan Mode: Non-contact Scan

- 3D Scanner-Dimensions ((L*W*H): 440*240*120mm

- Robot-Degrees Of Freedom: 6 rotating joints

- Robot-Working Radius: 850mm

- Robot-Movement: +/-360°

- Robot-Power Supply: 100-240 VAC 50-60 Hz

- Robot-Weight With Cable: 18.4kg

- Robot-TCP Speed: 1 m/s

- Robot-Repeatability: +/-0.01mm

- Robot-Load: 5kg

- Robot-Max Speed: 180°/s

- Robot-IP Classification: IP54

- Robot-Control Box Weight: 15kg

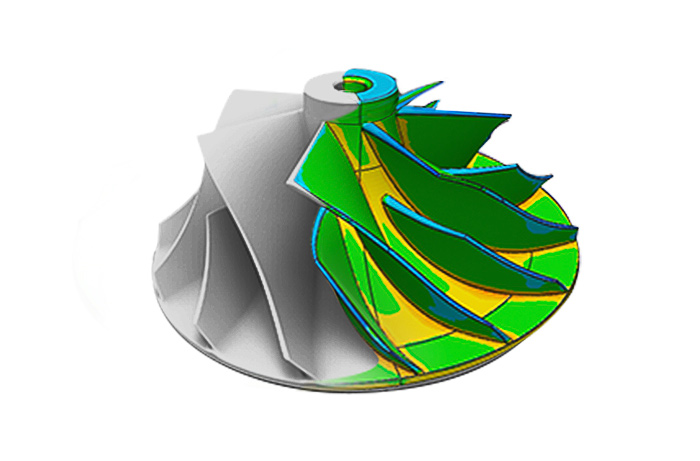

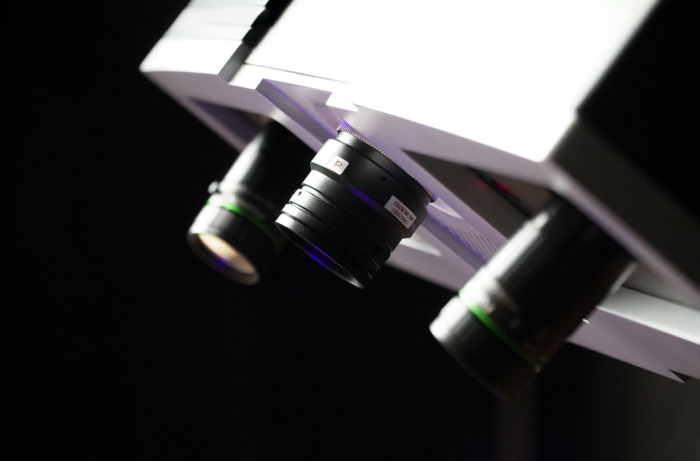

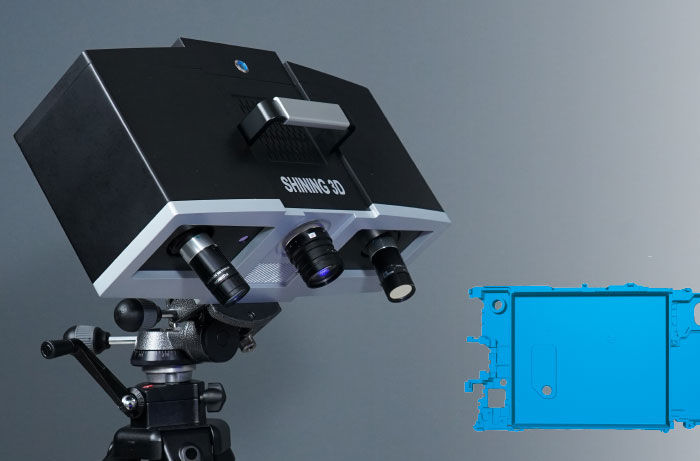

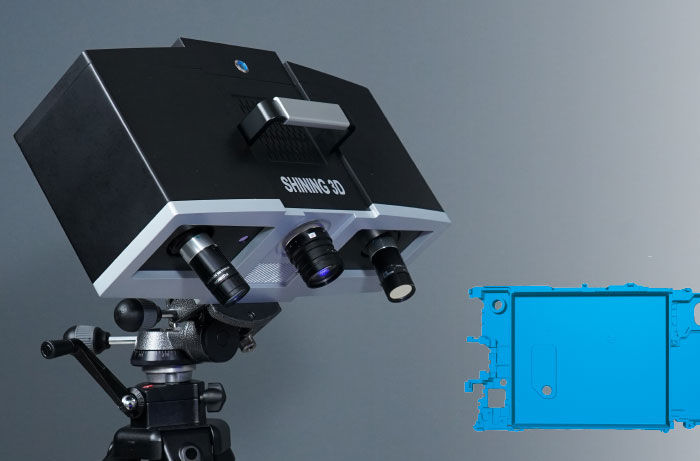

OptimScan-5M Metrology 3D Scanner

-

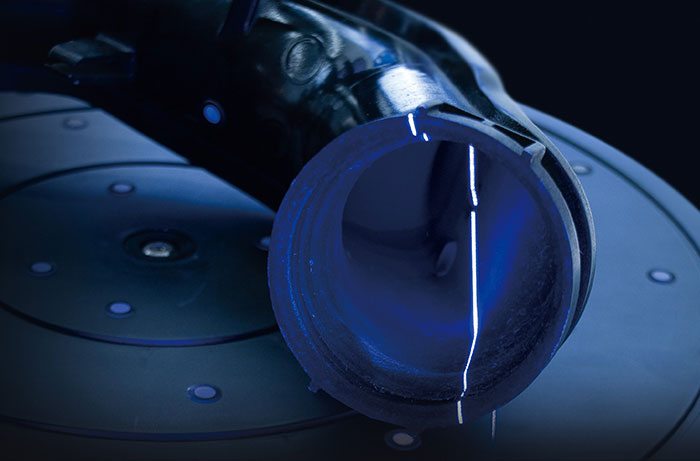

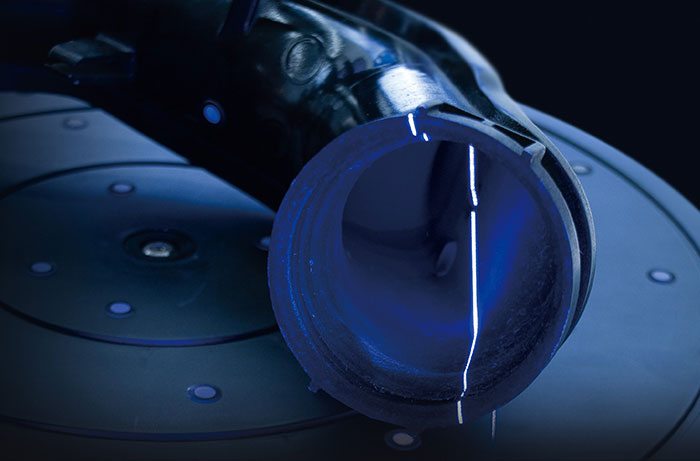

SHINING 3D OptimScan-5M 3D scanner is the latest blue light 3D scanner in the market, featuring high-end outlook, structure, component and configuration. Its 5.0 mega pixel cameras and blue light scanning technology bring users amazing scanning speed and accuracy, suitable for high-end application like defense, aerospace, mould industry, etc.

Blue Light Scanning TechnologyOptimScan-5M Metrology 3D Scanner equipped with Blue Light Technology enables you to scan more kinds of objects with dark color feature or metallic materials.

Higher Performance- Adjustable Scan Ranges

- 5.0 mega pixels cameras bring you higher resolution, better quality

- Overall accuracy could be contained within 0.08mm/m

- Single scan time is under 1.5 seconds

- Data registration is free to switch between automatic alignment and manual alignment.

Suitale for applications of military industry, aerospace industry, molding industry, etc.

Reliable and Portable

Non-contact 3D scanning can be applied in complex component like turbine blade measurement and inspection, consuming around 10% of the total time needed with traditional CMM system. Not only faster, but also full dimension inspection and measurement can be carried out.- Projection light is safe for eyes

- Small and portable, possible for large size parts scanning

- User-friendly cross-bar makes it easier to be carried

- Compatible with OptimScan-3M/5M

- Easily measuring the positions that non-contacted scanning is inaccessible, such as very deep holes

- Optical CMM measurement technology

- Wireless bluetooth transmission

- Light and portable design

- Single Scan Range: 400x300mm²/200x150mm²/100x75mm²/Customize

- Single Shot Accuracy: 0.015mm/0.01mm/0.005mm/Customize

- Point Distance: 0.16mm/0.08mm/0.04mm/Customize

- Camera Resolution: 5.0 MPx2

- Light Source: Blue light ( LED )

- Single Scan Speed: < 1.5 s

- Output Data Format: .asc、.stl、.obj、 etc., and compatible with the mainstream 3D software

OptimScan 5M Plus

-

High-Precision 3D Inspection System

- Light Source: Blue light (LED)

- Accuracy: Up to 0.005 mm

- Camera Resolution: 5.0 MP x 3

- Scan Speed: ≤1.5 s

OptimScan-5M Plus is High-Precision 3D Inspection scanner with narrow-band blue light source and upgraded high-resolution industrial lens, it provides better detail performance in scanning and smoother data quality.

Three sets of high-resolution industrial lenses are used according to different size object, making it more flexible and adaptable. It is widely applied in reverse engineering, quality inspection and quality control.Features:

- High Resolution: Three 5 mega pixel high resolution cameras and 1080P projection were used to obtain high precision features.

- Multiple Scan Range: Different scanning range is realized by switching off different lenses and recalibration to ensure a finer scanning performance. Different lenses have the same working distance without manual adjustment

- High Accuracy: Single shot accuracy can reach up to 0.005mm, scanner provides the function of environmental vibration detection and effectively ensure high quality data and precision.

- HDR Function: The HDR function helps to scan high contrasted objects like black and white objects to get complete data.

- One-click Integration Module Function: The system integrates the "one-click" automatic markers alignment module and the GREC global deviation control module, which effectively reduces alignment errors and get high-quality data with high precision.

- Workflow: Support Multiple data formats. Support mainstream reverse design or 3D inspection software. It has a high-precision discrete data fitting algorithm, and has obtained the accuracy certification of Physikalisch-Technische Bundesanstalt (PTB).

Photogrammetry

DigiMetric

- The DigiMetric photogrammetric system is a new type of 3D measurement equipment and known as a new generation of optical digital coordinate measuring machine, which is widely used in large and heavy equipment manufacturing industries such as automotive, aerospace, power generation equipment and engineering machinery, and has marked a new era in the field of large-size workpiece rapid 3D measurement technology.

3D Digitizing Solutions

-

SHINING 3D has been developing 3D digitizing technologies for more than 10 years and is committed to promoting 3D scanning technologies at a large scale, as well as improving the efficiency of high-quality 3D modeling. From high-end 3D scanners for professional industries to entry-level 3D scanners for general purpose 3D modeling, SHINING 3D makes“3D Scan – Intelligent Design – 3D Print” solutions accessible to all.

Industries: Aerospace, Automotive, Industrial Manufacturing, Art & Architecture, Healthcare, Education, and other Emerging Industries.

Applications: Reverse Engineering, Product Development, Computer Graphics, Virtual Display, VR/AR, 3D Data Archiving, Digital Diagnosis, and more.

Multi-Functional Handheld 3D Scanner

EinScan HX

-

Hybrid Blue Laser & LED Light Source Handheld 3D Scanner

Based on years of 3D measurement experience and market demand, SHINING 3D innovatively integrates blue LED light and blue laser into EinScan HX handheld 3D scanner. The hybrid laser and LED light sources make EinScan HX compatible with a wider range of object sizes, meeting multiple needs of users. High efficiency and reliable result give EinScan HX more application possibilities.

Hybrid Blue Laser & LED LightInnovatively integrated with dual blue LED light and blue laser, improves scanning materials adaptability with less limitation for a wider range of applications. LED light scanning allows rapid 3D scanning. Laser scanning, which is less sensitive to ambient light, gives better performance to reflective and dark color surface.

Reliable ResultsThe high resolution and accuracy meet the needs of most industrial applications for reverse engineering and measuring.

- Minimum point distance 0.05 mm

- Accuracy up to 0.04 mm under Laser Scan

Processing speed of EinScan HX under Rapid Scan Mode is up to 1,200,000 points/s, and multiple blue laser lines under Laser Scan Mode makes scanning of most objects in minutes for reverse engineering, CAD/CAM, 3D printing and etc.

Portable & Easy OperationEinScan HX is plug and play with user friendly software, which is easy to operate, no matter you are newbie or with professional experience in 3D scanning. The portability and flexibility use of EinScan HX has been considered to its ergonomic design for a more efficient and comfortable scanning experience.

- Ergonomic Design

- Weight:710g

With built-in color camera, it supports full color texture capturing and tracking by texture.

EinScan H2

-

High Texture Resolution Handheld 3D Scanner

The EinScan H2 improves on its predecessor with a 5MP resolution texture camera, enhanced accuracy, and 3 infrared VCSEL projectors for more photorealistic textures and better quality data. Its wide scanning area and adjustable working distance make it suitable for various scenes and objects, both small and large, in narrow or wide spaces. The EinScan H2 is an efficient 3D scanning tool that can revolutionize your workflow.

Major Updates:

- 5MP texture camera

- 3 VCSEL projectors

- Accuracy up to 0.05mm

- Ultra-wide FOV and adjustable working distance

Update your equipment to higher texture effects and accuracy, the EinScan H2 trade-in program will provide you an unprecedented discount to get the latest hybrid light source 3D scanner with high texture resolution.

- Photorealistic Texture: Captures rich, bright colors and clean textures for photorealistic 3D models.

- Superior Environmental Adaptability: Provide superior material and lighting adaptability, effortlessly handling various surface types and scanning environments.

- Hybrid Light Source: Dual Light source improves scanning efficiency.

- Ultra-wide FOV and Adjustable Working Distance

- Optimized for Face and Body 3D Scanning

- Multiple Applications: With its 2-in-1 technology, ergonomic design, and excellent software algorithms, the EinScan H2 is a versatile solution fit for many use cases. Use it anywhere, any time, for prosthetics, virtual display, cultural preservation, digital art, custom-fit clothing, education, furniture design, and much more.

- Remarkable Scanning Software

- Open for Everybody: Our SDK – Your Software

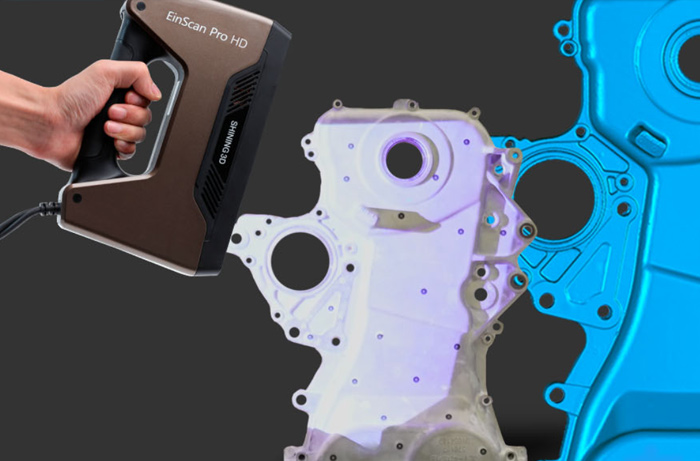

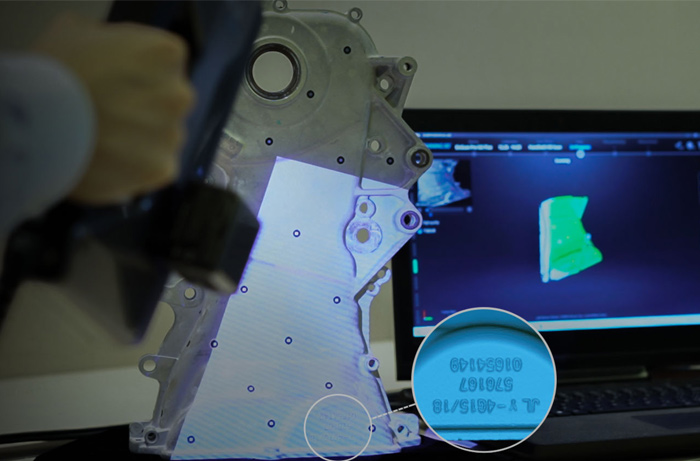

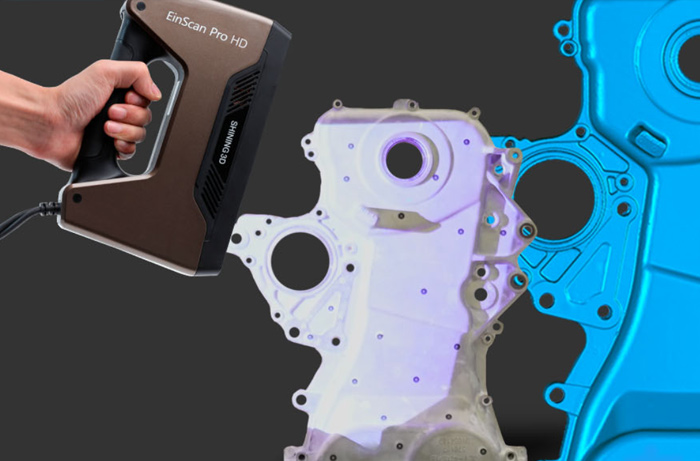

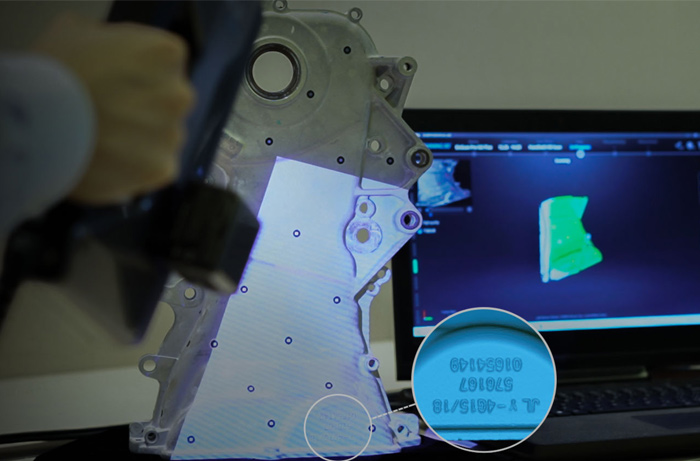

EinScan Pro HD

-

Improves the Efficiency of High-quality 3D Modeling

- Impressive high resolution for fine details

- Handle dark and casting metal surface with less limitations

- Fast scan speed for high efficiency

Inherited multi-functional and modular design of EinScan Pro series handheld 3D scanner, EinScan Pro HD delivers unparalleled performance in capturing high resolution and accuracy by handheld scanning. Exceptional versatility and powerful optimizations come together for the ultimate high-efficiency and professional-grade 3D scanning experience. It is reliable assistant for designers and engineers who care about high quality 3D modeling.

Impressive High Resolution for Fine DetailsBy adopting a new structure light projection modular, the stripe pattern scanning which was traditionally used in Fixed Scan Mode is now utilized to Handheld HD Scan Mode. By 0.2mm minimum point distance setting with optimized algorithm, it brings high resolution and accuracy in handheld scanning as good as under fixed scan.

Less Limitations of Scan ObjectsWith new lighting projection hardware and software algorithm, EinScan Pro HD is capable to scan a wider range of objects of dark or black color and casting metal surface, enriching the capability for 3D scanning of materials.

High Accuracy for High Quality 3D ModelingBy kinds of positioning methods, both scanner or objects can be moved during scanning.

It delivers accuracy up to 0.04 mm in Fixed Scan Mode. Under handheld scanning mode by marker alignment, the volumetric accuracy is up to 0.045mm+0.3mm/m.

EinScan Pro 2X Plus

-

Professional 3D Digitizing Solution for Versatile Applications in an Easy Way

- Offers an enhanced Handheld HD Scan Mode and enlarged scan range

- Captures 3D model of medium to large size objects with high efficiency

- Meets demands for wider range of applications

- Scan Speed (Handheld Rapid Scan) 30 fps 1,500, 000 points/s

- (Handheld HD Scan) 20 fps 1,100, 000 points/s

- 100 Data Capture Lines

- Enlarged Scan Range 312 X 204 mm

- Scan Accuracy (Fixed Scan) 0.04 mm

- Volumetric Accuracy (Handheld HD Scan) 0.05 mm + 0.3 mm/m

- Minimum Point Distance (Handheld HD Scan) 0.2 mm

- Scan Modes: Handheld Rapid Scan, Handheld HD Scan, Fixed Scan

- Align Modes: Feature alignment, markers alignment, turntable coded targets alignment,

and manual alignment.

Desktop 3D Scanner

-

Are you in the market for a desktop 3D scanner? Looking for something that offers good, reliable performance at a reasonable price?

Our stationary EinScan solutions may be just what you need. With the EinScan-SP V2 and the EinScan-SE V2, you'll experience smooth workflows and obtain precise 3D data.

All you have to do is place your object on the automatic turntable, and the software takes control. It can order the turntable to pivot at a given amount of degrees – say, 40 degrees – for an optimal amount of scans. Plus, you don't need to worry about losing track when flipping objects over. Our intelligent software will recognize the object's features and automatically merge the scans.

How do desktop 3D scanners work?Our desktop 3D scanners, the EinScan-SE V2 and SP V2, use structured light technology. This works by projecting a light pattern onto the object. The 3D scanner’s camera then takes a picture of the illuminated object, registering the pattern’s deformation.

By comparing the original pattern to the deformed one, the 3D scanner software is able to determine the object’s 3D shape. The process, which takes a few seconds, repeats several times for each of the object's sides. Once each face has been scanned, you obtain a 3D point cloud with hundreds of thousands of points. These XYZ coordinates form triangles which, together, form a 3D mesh.

EinScan-SP V2

-

The expert choice with enhanced experience

- Precise calibration in a simple way, achieving high accuracy of better than 0.05 mm

- Faster scanning speed

- Multiple alignment modes

- Enables high-resolution 3D modeling even for professional users

- Extensive scanning range from small to large

- Easy Operation, Faster Scanning Speed

- Fine details

- Compatible with 3D printers

- Extensive post-processing functions

- Capable of Reverse Engineering and Design in Office

- EXScan S for macOS

Applications:

- Education: Primary, middle and high school, K12 education, training on 3D design

- Design & Art: High-quality 3D design, 3D printing applications, reverse engineering

- Digital Industry Animation, CG, VR& AR

- Archiving and Sharing: 3D digital archiving, data sharing

EinScan-SE V2 3D Scanner

-

A powerful companion for educators and individuals

- Easiest 3D scanning experience for non-technical users

- Dual scan modes: Auto Scan and Fixed Scan

- Easy to operate and great price-to-performance ratio

Visible white light, no laser, eyes secure for children.

Easy Operation, User Friendliness, and Faster Scanning- One-click scanning

- Automatic calibration with no rigid set-up required

- 8 seconds for a single scan

- 2 minutes for a 360-degree scan under auto scan mode

- Auto meshing to watertight 3D data

- Seamlessly connect to 3D printers

- Provide API access service for any brand 3D printers.

- Software of EinScan-SE/SP has the functions of filling holes,

- smoothing and sharpening, and can also readjust the data

- coordinates in the post-processing process to provide more

- perfect 3D data for subsequent applications.

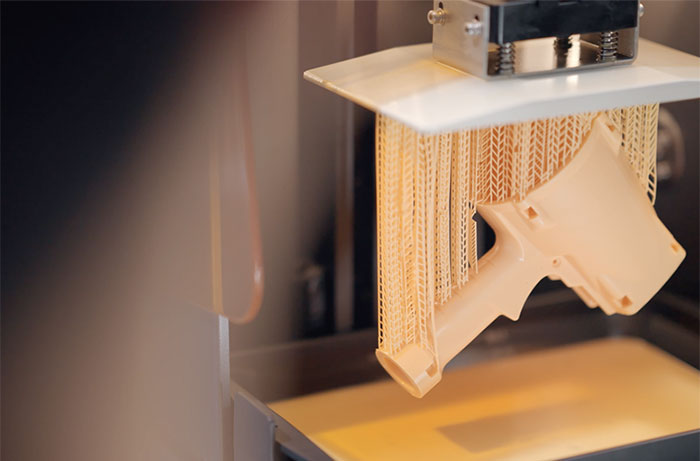

Additive Manufacturing Solutions

-

SHINING 3D provides advancing additive manufacturing technologies including DLP 3D printers for both rapid prototyping and direct digital manufacturing.

Applications: Parts Production, Rapid Prototyping, Jigs and Fixture, Product Customization, Injection Molding, Medical Devices, and etc.

AccuFab-L4K

-

A high-precision resin 3D printer that improves prototyping efficiency and shortens the new product development lifecycle.

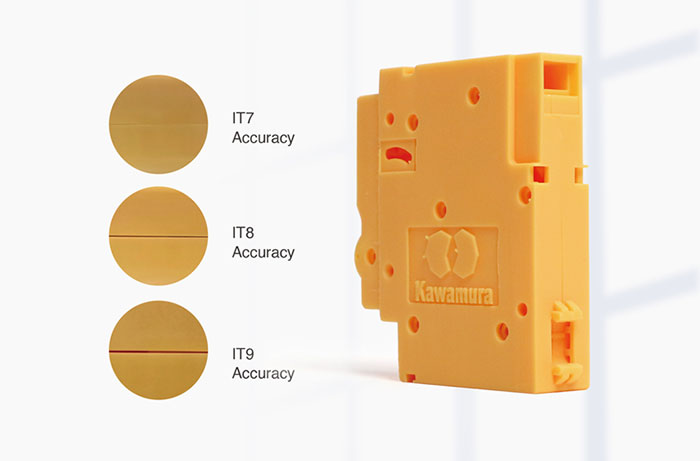

- Accurate Precise

IT7- level printing accuracy, to ensure the printing size is consistent with the design size. - Outstanding Uniformity

High luminance uniformity achieves up to 90%. - Beyond the Limits

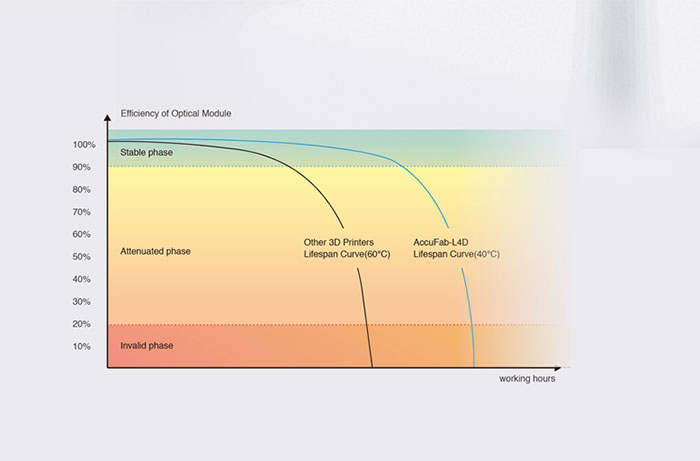

Provides not only the possibility to obtain features, smaller than a pixel, but also superior surface finish. - State-of-the-Art Robustness

AccuFab- L4K’s 5 million layers tested in real engineering condition provides state- of- the- art reliability.. - District Cooling System

DCS (District Cooling System) maintains the temperature of optical system under 40℃, while extending the 3D printer lifespan significantly. - Industrial Grade Components and Quality Inspections

Assembly production adopts industrial-grade components, passed 21 strict factory inspections, to ensure the high quality of the factory equipment.

- Resolution: 3840×2400

- Pixel Size: 0.05mm

- Wavelength: 405mm

- Light Intensity: 3mw/cm^2

- Light Source: UV LED + LCD

- Print Size: 192mm × 120mm × 180mm

- Print Speed: 10~50mm/h

- Tolerance: ±0.05mm

- Layer Thickness: 0.025 / 0.05 / 0.075 / 0.1 mm

- Working Temperature: 20~30℃

- Working Humidity: 30~70%

- Interface: 5” touch screen

- Connection: Wi-Fi/Ethernet/Thumb drive

- Weight: 19kg

- Printer Dimensions: 360mm × 360mm × 530mm

- SHINING 3D Engineering Material: White Material: TR01, S1; Yellow Material: DM12; Transparent Material: SG01; Black Material: S2; Washable Material: W1

- BASF Engineering Material: Durable Material: ST45, ST80; Rigid Material: RG35, RG50; Flexible Material: FL60, EL150

- Third Party Certified Resin: Third party resin materials approved by SHINING 3D, also can be used in AccuFab-L4K High-Precision Stereolithography 3D Printer

- Accurate Precise

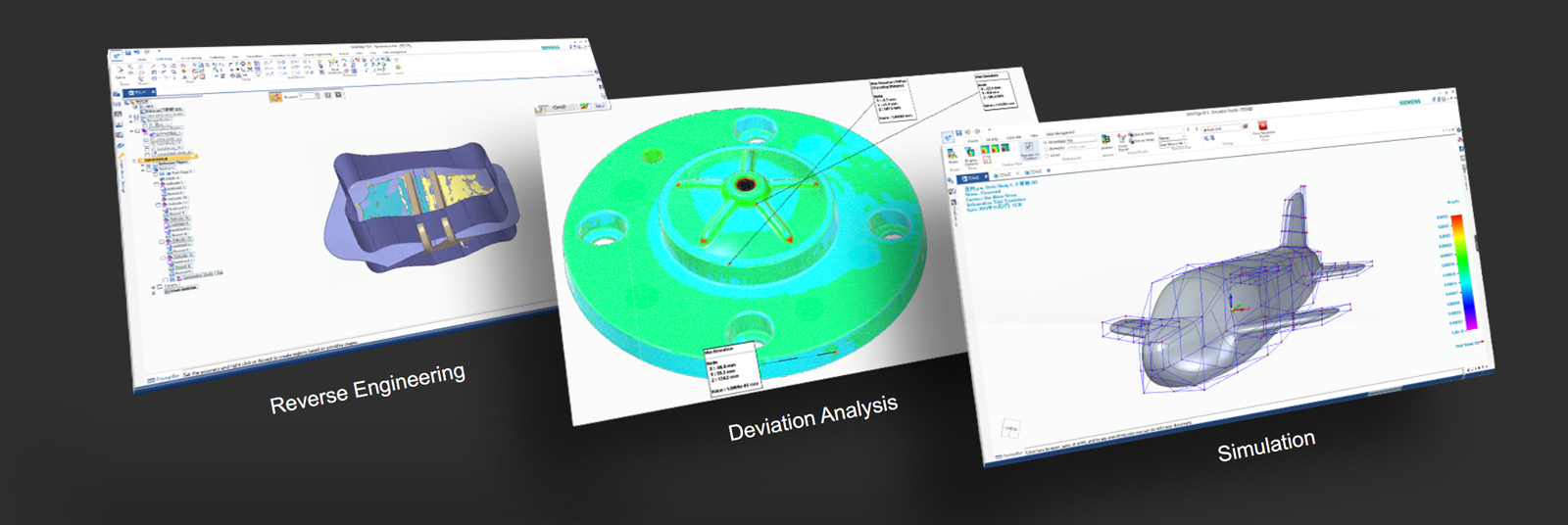

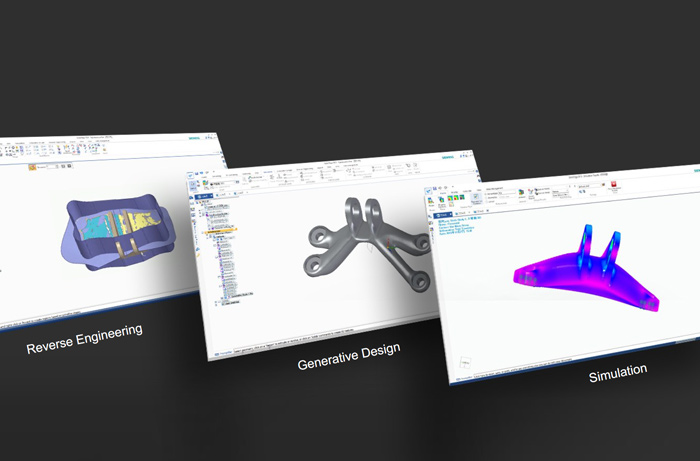

3D Software

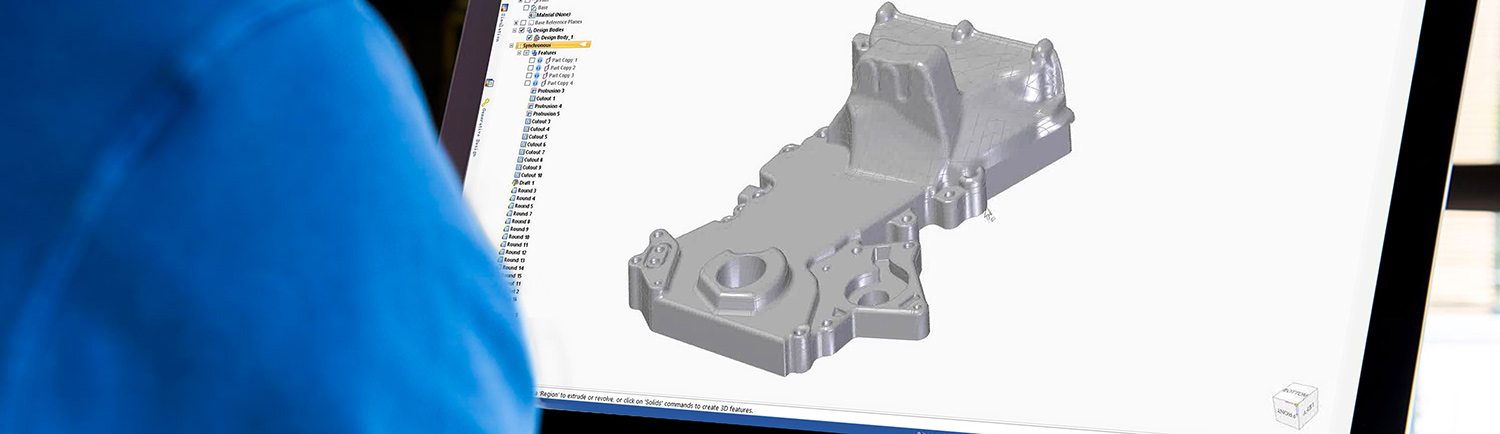

- Through independent R&D as well as cooperation with worldwide well-known partners, SHINING 3D provides professional software solutions covering 3D scanning, 3D design, inspection, simulation and additive manufacturing for customers in various industries.

Solid Edge SHINING 3D Edition

-

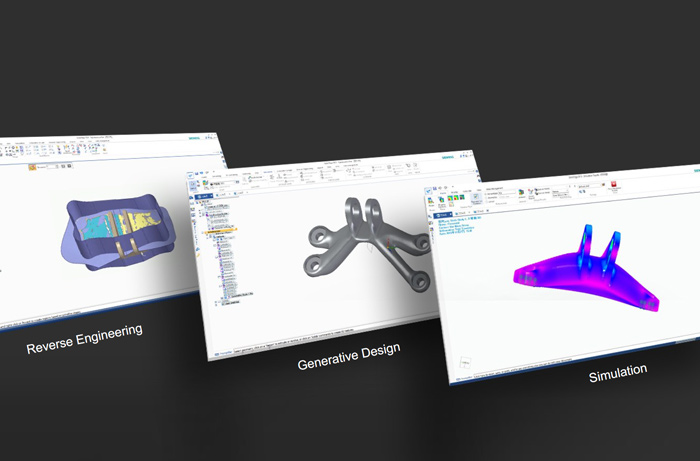

SHINING 3D partners with SIEMENS PLM software, a leading global industrial software solution provider,

to offer users Solid Edge SHINING 3D Edition.

As a new generation of digital innovation platform, Solid Edge SHINING 3D Edition includes reverse engineering, generative design, and simulation together with CAD tool in one platform.

SHINING 3D EinScan series 3D scanners, integrated with Solid Edge SHINING 3D Edition, provide users the solution covering “3D Digitize – Design & Simulate – Additive Manufacture” to generate much higher quality 3D data for production.Features:

- Better transition and reuse from 2D or 3D

- Core Modeling Capabilities

- From start to finish, simulation tools to meet your needs

- Direct output of models to your 3D printer

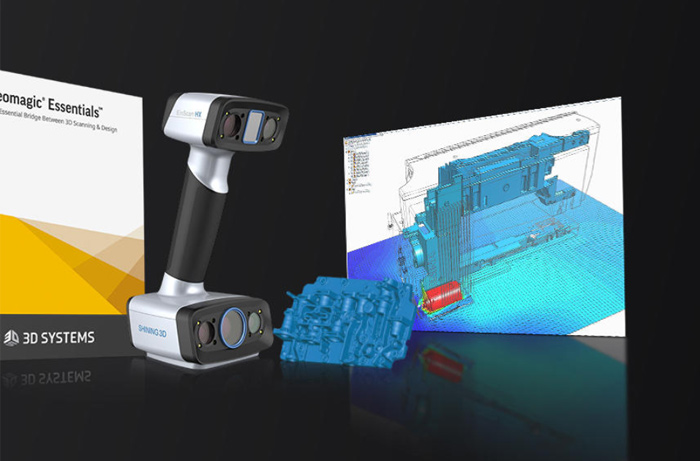

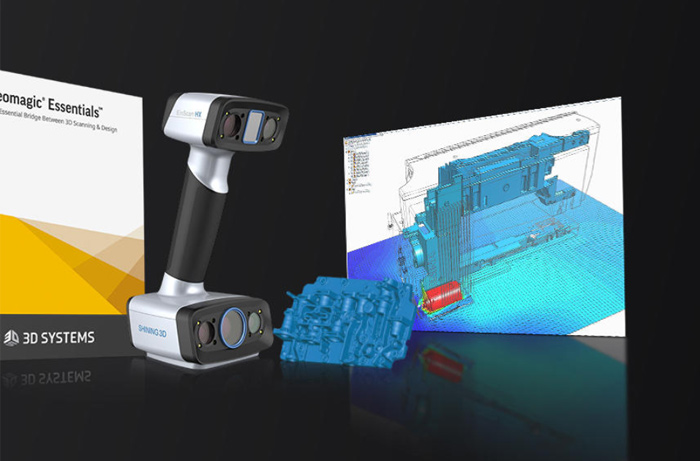

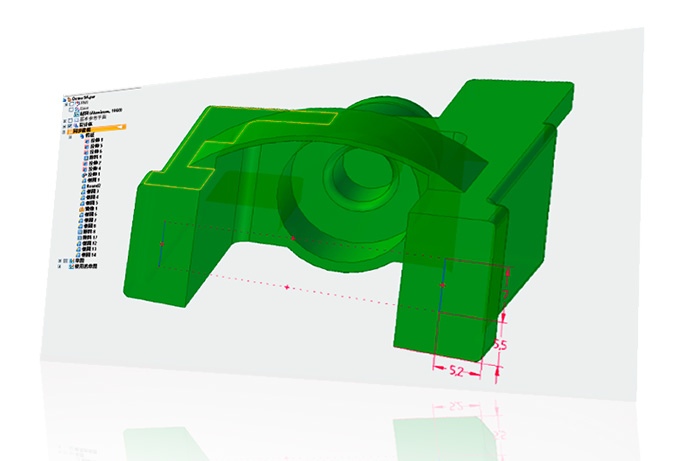

Geomagic® Essentials™

-

3D Systems and SHINING 3D have partnered together to bring you an all in one solution for your 3D scan to CAD needs.While modern CAD software is still quite limited in its ability to make use of 3D scan data, Geomagic Essentials brings you the tools needed to use the CAD system as part of your scan-based modeling workflow. Converting your 3D scans to CAD has never been easier. Geomagic Essentials is the bridge software that extracts all the necessary elements of a scanned part for immediate use in your CAD software.

• Bridging the Gap between 3D Scanning and CAD

• Low total cost of ownership

• Improving customer journey and experience

Geomagic Design X

- Geomagic Design X, the industry’s most comprehensive reverse engineering software, combines history-based CAD with 3D scan data processing so you can create feature-based, editable solid models compatible with your existing CAD software. Get to Market Faster

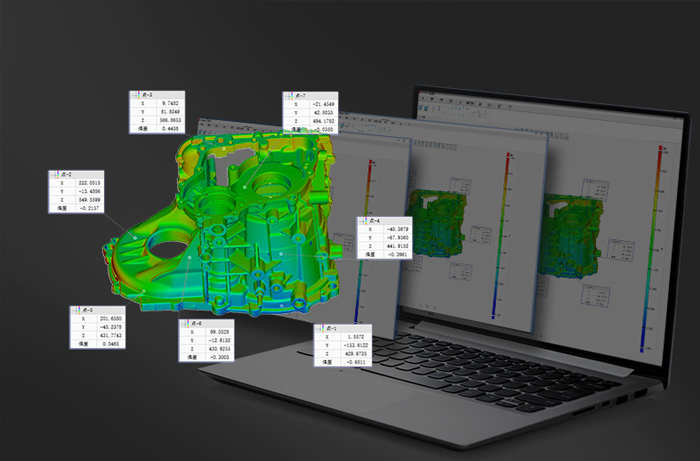

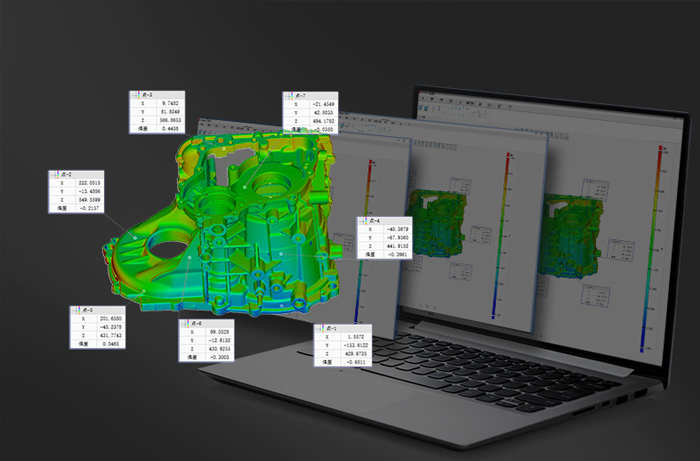

Geomagic ® Control X™

- Geomagic ® Control X™ is a comprehensive metrology software platform that delivers the industry’s most powerful tools within straightforward workflows. With Geomagic Control X quality managers are enabled with revolutionary ease-of-use, intuitive, comprehensive controls and traceable, repeatable workflows for the quality measurement process. Its fast, precise, information-rich reporting and analysis enable significant productivity and quality gains in any manufacturing workflow

Applications - Industrial Manufacturing

- Providing industrial-grade additive manufacturing equipment and high-precision 3D inspection systems, SHINING 3D helps enterprises from aerospace, automotive & transportation, power generation, tooling, industrial products and other fields to manufacture high-performance parts, enable flexible production, inspect complex structures and support scientific research.

Aerospace

-

Metal print for aerospace industriy enables the production of high performance metal print parts with lightweight structures, integrated design or complex topology.

3D digitizing and metrology solutions provide manufacturers with non-contact measurement of aircraft parts to ensure the efficiency of quality control.

Automotive & Transportation

-

Metal and plastic print technologies bring automotive and transportation industry a new method of lightweight components manufacturing and small batch parts production. Also, they are ideal for rapid prototyping, accelerating the efficiency of R&D process and save cost.

3D digitizing and metrology solutions can help engineers to perform reverse engineering and inspection of vehicles and parts, improving efficiency of product development and quality control.

Power Generation

-

In the field of power generation, the company uses additive manufacturing technologies to produce parts of high-performance complex structures.

3D digitizing and metrology solutions enable inspection of large machineries and industrial parts to ensure that they meet design requirements and to monitor the status of parts abrasion and deformation during long time operation.

Tooling

-

Plastic additive manufacturing technologies can also help to produce the tooling such as rapid mold, small batch jigs and fixtures, to help factories achieve maximum flexibility of manufacturing.

3D digitizing and metrology solutions guarantee the accuracy and efficiency of molds inspection.

Industrial Products

-

Additive manufacturing technologies directly manufacture small batch products to meet the increased customized demands. These technologies break the limitations of high volume, long delivery time and large inventory caused by traditional mass production process. They enable factories to produce high-quality metal and plastic parts of lightweight and integrated complex structures.

3D digitizing and metrology solutions help enterprises perform product development, 3D inspection and reverse engineering in high efficiency and high quality.