- Offer Profile

-

Sherborne Sensors’ core operations focus on the design and manufacture of precision Accelerometers, Inclinometers, and Load Cells. Our products enjoy unsurpassed industry standing for ultra-reliability and long-life precision in critical military and industrial applications.

While we offer a large range of standard off-the-shelf units to meet the requirements of many applications; a large percentage of our business is the manufacture of custom sensors to meet customer’s specific requirements in both civilian and military markets.

Accelerometers

- herborne Sensors’ manufactures a range of high precision accelerometer sensors to measure linear acceleration and deceleration with accuracy and reliability. Our sensors are used in demanding space, aviation, military and industrial applications around the world.

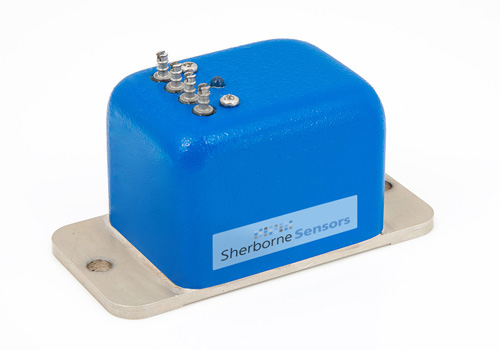

Servo: A215 accelerometer, voltage o/p miniature size, pin termination

-

The Sherborne Sensors’ A200 range of Servo Accelerometers measure vector acceleration with high accuracy using a closed loop force balance torquer mechanism. A pendulous mass develops a torque proportional to the product of its mass unbalance and the applied acceleration. The movement of the mass is detected by a position sensor whose output signal is connected to a servo amplifier.

The resulting current is fed into the torque motor which then develops a torque exactly equal to, but directly opposed to the initial torque from the pendulous mass. The mass then stops moving, assuming a position minutely differing from it’s initial zero ‘g’ position. Simultaneously, the current to the torque motor is fed through a stable resistor to provide an output voltage proportional to the applied acceleration.

The system is electronically damped by means of a phase advancing network within the integrated servo amplifier. By adjusting the parameters of the servo amplifier and related electronic networks, the operating characteristics of a servo accelerometer can be optimised to suit a particular application.

Features- Available in ranges from ±1g to ± 20g

- High resolution down to 0.05 mg

- Closed loop force balance system

- Flight qualified versions available

- Self-Test facility

- DC Input – DC Output

- Manufactured to ISO 9001:2000 and AS9100B standards

Applications

- Flight test monitoring

- Accident data collection

- Structural health monitoring

- Flight simulators

- Braking control on mass transit systems

- Road bed analysis

- Data acquisition systems

- Low frequency analysis

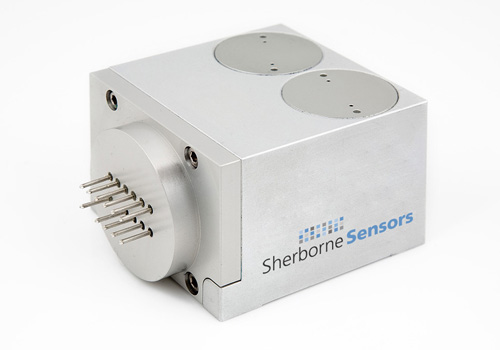

Servo: A220 accelerometer, voltage o/p miniature size, pin termination

-

The Sherborne Sensors’ A200 range of Servo Accelerometers measure vector acceleration with high accuracy using a closed loop force balance torquer mechanism. A pendulous mass develops a torque proportional to the product of its mass unbalance and the applied acceleration. The movement of the mass is detected by a position sensor whose output signal is connected to a servo amplifier.

The resulting current is fed into the torque motor which then develops a torque exactly equal to, but directly opposed to the initial torque from the pendulous mass. The mass then stops moving, assuming a position minutely differing from it’s initial zero ‘g’ position. Simultaneously, the current to the torque motor is fed through a stable resistor to provide an output voltage proportional to the applied acceleration.

The system is electronically damped by means of a phase advancing network within the integrated servo amplifier. By adjusting the parameters of the servo amplifier and related electronic networks, the operating characteristics of a servo accelerometer can be optimised to suit a particular application.

Features- Available in ranges from ±1g to ± 20g

- High resolution down to 0.05 mg

- Closed loop force balance system

- Flight qualified versions available

- Self-Test facility

- DC Input – DC Output

- Manufactured to ISO 9001:2000 and AS9100B standards

- 1g bias option to compensate for earth’s gravity (A220 only)

Applications

- Flight test monitoring

- Accident data collection

- Structural health monitoring

- Flight simulators

- Braking control on mass transit systems

- Road bed analysis

- Data acquisition systems

- Low frequency analysis

Servo: A220 accelerometer, voltage o/p miniature size, pin termination

-

Using the same torquer mechanism and servo electronics as the A220 series, the A260 features a switching regulator to enable direct operation from a single ended dc power supply. Galvanic isolation between primary and secondary circuits provides total electrical isolation between the input supply and signal output. To meet certain measuring requirements, especially in certain aerospace applications, this series has provision for an optional active filter with low output impedance and 1g bias circuitry for vertical mounting.

The A260 series accelerometers have been used successful in aerospace, military and industrial applications for many decades. The acquisition of this technology by Sherborne Sensors allows customers to benefit from the same exceptional product qualities as its predecessors, with the added benefits of extensive applications engineering support, global technical sales presence, repair, refurbishment and calibration services, stocking programs, and continuous product improvements.

Features- Available in ranges from ±1g to ± 20g

- High resolution down to 0.05 mg

- Closed loop force balance system

- Flight qualified versions available

- Self-Test facility

- DC Input – DC Output

- Manufactured to ISO 9001:2000 and AS9100B standards

- Connector and solder pin options

- Wide operational temperature range

- –55° to + 95°C

- 1g bias option to compensate for earth’s gravity

- Low pass electronic filter options

Applications

- Flight test monitoring

- Accident data collection

- Structural health monitoring

- Flight simulators

- Braking control on mass transit systems

- Road bed analysis

- Data acquisition systems

- Low frequency analysis

Servo: A323-A325 Ultra low range accelerometer, voltage or current o/p, connector termination.

-

The A320 Series are high precision, closed loop, servo balance, ultra-low range accelerometers that can be used for a wide variety of industrial and aerospace applications.

Features- Fully self-contained – simply connect to a DC power source and a readout or control device for a complete operating system

- High-level output signal

- ±1/10 g to ± 2g ranges available

- Extremely rugged, withstands 1500g shock

Applications

- Flight test monitoring

- Accident data collection

- Structural health monitoring

- Flight simulators

- Braking control on mass transit systems

- Road bed analysis

- Data acquisition systems

- Low frequency analysis

A545 accelerometer, single axis, dual axis, triple axis, voltage output, pin termination

-

The A545 range of Solid State Accelerometers measure vector acceleration with high accuracy and incorporate a MEMS micromachined piezo-resistive strain gauge bridge silicon sensor, incorporating a gas damping and positive over-range stops. Available ranges are from ± 2 to ± 200g.

Unlike fluid damped devices, the gas damping employed in the MEMS micromachined piezo-resistive strain gauge bridge sensor is essentially independent of temperature. The accelerometer also incorporates positive mechanical stops conferring excellent shock resistance and is compensated for the effects of temperature on both sensitivity and zero offset. The accelerometer is packaged in a robust aluminium alloy case with solder pins for ease of electrical connections.

Applications

- Data acquisition systems

- Crash recorders

- Fatigue life monitoring and prediction

- Monitoring and controlling deceleration in mass transit systems

- Road bed analysis and fault detection equipment for high speed railways

- Military and civil flight simulators

- Autopilots

- Low frequency vibration monitoring.

A640 Single Axis Accelerometer

-

The A600 range of Solid State MEMS Accelerometers measure vector acceleration with high accuracy using a micromachined (MEMS) silicon sensor incorporating an air damping feature. Unlike fluid damped devices the air damping employed is essentially independent of temperature. The transducer also incorporates positive mechanical stops conferring excellent shock resistance. The accelerometer is compensated for the effects of temperature on both sensitivity and zero. Typical applications include data acquisition systems, crash recorders, fatigue life monitoring and prediction; monitoring and controlling deceleration in mass transit systems; road bed analysis and fault detection equipment for high speed railways; military and civil flight simulators; autopilots and low frequency vibration monitoring.

The A640 series will in many cases replace the now discontinued Series A400 accelerometers and is mechanically inter-changeable.

Features- Ranges ±1g to ±20g

- Essentially zero temperature coefficent of damping ratio

- Filtered and unfiltered outputs simultaneously available

- Integral temperature compensation

- DC input / DC output

- Signal ground isolated from power ground

- High reliability

Applications

- Data acquisition systems

- Crash recorders

- Fatigue life monitoring and prediction

- Monitoring and controlling deceleration in mass transit systems

- Road bed analysis and fault detection equipment for high speed railways

- Military and civil flight simulators

- Low frequency vibration monitoring

Inclinometers

- Sherborne Sensors’ high precision inclinometers measure horizontal and vertical angular inclination with virtually infinite resolution; providing highly accurate tilt and inclination measurements for demanding military and industrial applications.

Servo: LSI Series ±14° to ±90°

-

Single Axis Inclinometer, ±15Vdc input, voltage o/p, pin

The LSI Series is a range of gravity referenced servo inclinometers are used in a variety of industrial and military applications where high precision angular measurements are required.

Models are available in a variety of ranges from +/-14.5 degrees to +/-90 degrees with low impedance output voltage signals. Electrical terminations are via solder pins.

Features

- Available ranges from ±14.5° to ±90°

- Resolution to 2 arc second (0.0006°)

- High level ±5 VDC output proportional to sine of the angle of tilt

- Electrical terminations via solder pins

- Fully self-contained and able to connect to a DC power source and readout or control device, to form a complete tilt measurement system

- Environmentally sealed to IP65

- Continuous operation in temperatures of -18°C to +70°C

- Rugged construction with high reliability

- Optional power supplies and display indicators

- Custom design and manufacturing capabilities are available to meet customers specific application requirements

Applications

- Level control of machines and structures

- Safety control of cranes and lifting equipment

- Civil engineering studies

- Marine ballast transfer systems

Servo: LSOC Series ±1° to ±90°

-

LSOC_P L Inclinometer Voltage output, connector termination ±1° to ±90°

The LSO is a high precision gravity referenced servo inclinometer are used in a variety of industrial and military applications. Models are available in a variety of angular ranges each with low impedance output signals. Electrical terminations are via 6-way bayonet lock connector (LSOC) or solder pins (LSOP).

The LSO is extremely robust and will withstand shocks in excess of 1500g. The design is well proven with many thousands in use throughout the world in the most demanding of applications.

Features

- Fully self-contained – connect to a DC power source and a readout or control device for a complete operating system

- High-level DC output signal proportional to sine of the angle of tilt

- ±1° to ±90° ranges available

- Extremely rugged, withstands 1500g shock

Applications

- Bore-hole mapping, dam and rock shifts and other geophysical, seismic and civil engineering studies

- Ballast transfer systems for offshore barges, ships and other marine applications

- Level control and calibration systems

- Pipeline levelling, setting tilt of grading machines, crane overturning-moment alarms, and other heavy duty construction control requirements

- Large machinery installation and other electronic level applications

Servo: LSOC_P ‘L’ Series ±1° to ±90°

-

LSOC_P L Inclinometer Voltage output, connector termination ±1° to ±90°

The LSOC/P-L Series is a range of gravity referenced servo inclinometer used in a variety of industrial and military applications where high precision angular measurements are required, and in rugged and robust applications where high levels of vibration and mechanical shock up to 1500g are encountered.

Models are available in a variety of ranges from +/-1° to +/-90° with 4 to 20mA output. Electrical terminations are via a 6-way connector on the LSOC or solder pins on the LSOP variant.

Features

- Available ranges from ±1° to ±90°

- Resolution to 0.1arc second (0.00003°)

- High level 4 to 20mA output proportional to sine of the angle of tilt

- Electrical terminations via six-way connector (LSOC) or solder pins (LSOP)

- Fully self-contained and able to connect to a DC power source and readout or control device, to form a complete tilt measurement system

- Environmentally sealed to IP65

- Continuous operation in temperatures of -18°C to +70°C

- Rugged, 1500g shock survivability

- Optional mating connectors, power supplies and display indicators

- Custom design and manufacturing capabilities are available to meet customers specific application requirements

Applications

- Bore-hole mapping, dam and rock shifts and other geophysical, seismic and civil engineering studies

- Ballast transfer systems for offshore barges, ships and other marine applications

- Level control and calibration systems

- Pipeline levelling, setting tilt

Servo: LSOP Series ±1° to ±90°

-

LSOC Inclinometer ±1° to ±90°, voltage output, pin termination

The LSO is a high precision gravity referenced servo inclinometer that’s used in a variety of industrial and military applications. Models are available in a variety of angular ranges each with low impedance output signals. Electrical terminations are via 6-way bayonet lock connector (LSOC) or solder pins (LSOP).

This product is extremely robust and will withstand shocks in excess of 1500g. The design is well proven with many thousands in use throughout the world in the most demanding of applications.

Features

- Available ranges from ±1° to ±90°

- Resolution to 0.1arc second (0.00003°)

- High level 4 to 20mA output proportional to sine of the angle of tilt

- Electrical terminations via six-way connector (LSOC) or solder pins (LSOP)

- Fully self-contained and able to connect to a DC power source and readout or control device, to form a complete tilt measurement system

- Environmentally sealed to IP65

- Continuous operation in temperatures of -18°C to +70°C

- Rugged, 1500g shock survivability

- Optional mating connectors, power supplies and display indicators

- Custom design and manufacturing capabilities are available to meet customers specific application requirements

Applications

- Bore-hole mapping, dam and rock shifts and other geophysical, seismic and civil engineering studies

- Ballast transfer systems for offshore barges, ships and other marine applications

- Level control and calibration systems

- Pipeline levelling, setting tilt

Servo: T233 Series ±1° to ±90°

-

Single Axis Inclinometer, ±15Vdc input, voltage o/p, pin, ±3° to ±90°

The T233/5 Series is a range of dual axis gravity referenced servo inclinometers is used in a variety of industrial and military applications where high precision angular measurements are required, and in rugged and robust applications where high levels of vibration and mechanical shock up to 1500g are encountered.

Models are available in a variety of ranges from +/-1 degree to +/-90 degrees with low impedance output voltage signals and are precisely set up for dual axis operation. Electrical terminations are via a connector on the T233 or solder pins on the T235 variant.

Features

- Available ranges from ±1° to ±90°

- Resolution to 0.1arc second (0.00003°)

- High level ±5 VDC output proportional to sine of the angle of tilt

- Electrical terminations via six-way connector (T233) or solder pins (T235)

- Fully self-contained and able to connect to a DC power source and readout or control device, to form a complete tilt measurement system

- Environmentally sealed to IP65

- Continuous operation in temperatures of -18°C to +70°C

- Rugged, 1250g shock survivability

- Optional mating connectors, power supplies and display indicators

- Custom design and manufacturing capabilities are available to meet customers specific application requirements

Applications

- Level control of machines and structures

- Safety control of cranes and lifting equipment

- Civil engineering studies

- Geophysical and seismic studies

- Machinery and structural alignment

- Pipeline leveling

- Marine ballast transfer systems

- Satellite antenna

Servo: T435 ‘L’ Series ±3° to ±90°

-

T435 Single Axis Inclinometer, 4-20 mA output, pin termination

The T435 ‘L’ series is a family of single axis, high-precision, closed loop, gravity referenced servo inclinometers. Ideal for use within a variety of application environments and where space is at a premium.

Available in ranges from ±3° to ±90° with a form factor measuring only 61mm (2.41 inches) high and a diameter measuring less than 37mm (1.46 inches). The T435 ‘L’ has a high-level 4-20mA signal, proportional to the size of the angle of tilt. Units are fully self-contained, and able to connect to a DC power source and readout or control device, to form a complete operating system. Units are extremely rugged, and can withstand a 1500g-shock event. Solder pin terminations are standard.

The 4-20mA output of the T435 ‘L’ series is specifically designed for electrically noisy environments, or where inclinometer output signals must travel over a long distance. T435 ‘L’ series inclinometers operate on a single 24Vdc supply and the output series load resistance can be as high as 400Ω. Sherborne Sensors’ T435 ‘L’ series inclinometers have a long and successful market history in precision tilt applications around the world.

Features

- Available ranges from ±3° to ±90°

- Resolution to 0.2arc second (0.00006°)

- High level 4 to 20mA output proportional to sine of the angle of tilt

- Electrical terminations via solder pins

- Fully self-contained and able to connect to a DC power source and readout or control device, to form a complete tilt measurement system

- Environmentally sealed to IP65

- Continuous operation in temperatures of -18°C to +70°C

- Rugged, 1500g shock survivability

- Optional power supplies and display indicators

- Custom design and manufacturing capabilities are available to meet customers specific application requirements

Applications

- Bore hole mapping, dam and rock shifts and other geophysical, seismic & civil engineering studies

- Downhole logging

- Any precision measurement application where space is at a premium

Servo: T935 Series ±1° to ±90°

-

T935 Single Axis Inclinometer, voltage output, pin termination

The T935 Series is a range of gravity referenced servo inclinometers used in a variety of industrial and military applications where high precision angular measurements are required, and in rugged and space restrained applications where high levels of vibration and mechanical shock up to 1500g are encountered.

Models are available in a variety of ranges from +/-1 degree to +/-90 degrees with low impedance output voltage signals and can be stacked for dual axis operation. Electrical terminations are via solder pins.

Features

- ± 1° to ± 90° ranges

- Extremely rugged, fluid filled, withstands 1500g shock

- Extended pins with chamfered housing edge for ease of soldering

- Laser marked part and serial number

- Stackable for dual axis X and Y measurements

Applications

- Bore Hole Mapping

- Structural Health Monitoring

- Continuous Casting Mould Alignment

- Railway Maintenance Equipment

- Mobile and Stationary Antenna Aiming

Digital: DSIC-1 & DSIC-2 Series Inclinometers

-

Single axis or Dual axis DSIC with 5, 15 or 60 degree angular range

The DSIC Series is a range of single and dual axis gravity referenced digital output servo inclinometers with total error band of less than 0.08 degrees over -20°C to +70°C. Suitable for use in a variety of industrial and military applications where high precision angular measurements are required, and in rugged and robust applications where high levels of vibration and mechanical shock up to 1250g may be encountered.

Models are available in a variety of angular ranges from +/-5° to +/-60° with RS485 ASCII outputs and electrical terminations are via a connector.

Features

- Resolution 0.001°

- Total accuracy < 0.08° over -20°C to +70°C

- Mechanical shock 1,000g 0.5ms half sine

- Industry-standard RS485 output

- 19-bit analog to digital conversion

- 9 to 18 or 18 to 36 VDC unregulated supply options

- Closed loop servo inclinometer sensing element

- Dynamic filtering, allowing fast response with high vibration rejection

- Built-in temperature sensing and active compensation

- User-configurable output bandwidth

- Wide range of bus speeds supported

- Non-volatile configuration memory

Applications

- Ordnance Aiming Systems

- Rail track monitoring

- Optical sighting equipment

- Seismic and civil engineering analysis

- Precision platform level control

Wireless: WTS-BSU Wireless Telemetry Base Station

-

The WTS-BSU is a simple, single-channel USB device allowing the interfacing of a WTS Wireless Inclinometer with a PC.

The WTS-BSU is a simple, single channel USB device allowing the interfacing of a WTS Wireless Inclinometer with a PC.

Features

The WTS-BSU is housed in a stand-alone plastic housing supplied with an integral lead and USB connector allowing simple connection to a PC. It draws power from the USB bus and therefore no further components are required to control remote devices. Software is supplied that allows the user to:

- Select a required device.

- View the value on a simulated LCD display

- Log the data to a .csv file.

Applications

The WTS Wireless Tilt System is a flexible, all-weather radio telemetry system designed to provide high accuracy remote angle measurement data. The WTS enables surveyors, geotechnical specialists and structural engineers to record and log data remotely without the cost and impracticality of traditional wired methods.

The heart of the system is the WTS Wireless Inclinometer; a high-accuracy robust instrument utilising advanced MEMS sensor technology to ensure maximum reliability. A variety of complementary base stations and either PC or handheld data acquisition modules is offered to allow a complete measurement system to be configured to suit any particular application.

Highway agencies, bridge and civil structure owners spend large revenues assessing structural health by visual or other types of consuming inspection methods of bolted and welded joints, together with other vital structural elements. Obtaining multiple readings to monitoring the entire structure can be costly and labour intensive. Using the WTS Wireless Tilt System, a single structure can be fitted with low power WTS Inclinometers at strategic points, thus helping to determine where weak points may be and when maintenance is required.

Additionally, the WTS Wireless Tilt System may be used in the verification of design calculations when new structures are manufactured providing valuable data to refine computer models of structural behavior.

Wireless: WTS-H-NR Series ±5° to ±60°

-

Wireless Inclinometer, Horizontal mounting, non-rechargeable.

The WTS Wireless Tilt System is a flexible, all-weather radio telemetry system designed to provide high accuracy remote angle measurement data. The WTS gives surveyors, geotechnical specialists, and structural engineers the ability to record and log data remotely without the cost and inefficiency of traditional wired methods.

The heart of the system is the WTS Wireless Inclinometer; a high-accuracy robust instrument utilising advanced MEMS sensor technology to ensure maximum reliability. A variety of complementary base stations and either PC or hand-held data acquisition modules allow a complete measurement system to be configured to suit any particular application. A variety of fixed base stations and hand-held readers are available to enable the user to tailor the system to their optimal requirements.

Highway agencies, bridge and civil structure owners spend large revenues assessing structural health by visual or other types of consuming inspection methods of bolted and welded joints, together with other vital structural elements. Obtaining multiple readings to monitor the entire structure can be costly and labour intensive. Using the WTS Wireless Tilt System, a single structure is fitted with low power WTS Inclinometers at strategic points, thus helping to determine where weak points may be and when maintenance is required.

Additionally, the WTS Wireless Tilt System is used in the verification of design calculations when new structures are manufactured, providing valuable data to refine computer models of structural behaviour.

Features

- Advanced MEMS inclinometer design for ultra-reliability and performance.

- Distortion free digital 2-way radio system for data integrity.

- Very low power consumption for long battery life.

- Worldwide licence exempt 2.4 GHz radio.

- Option of hand held remote display or PC interface for data capture.

- Remote power on/off (sleep/wake).

- > 100 metre range.

- Multi-channel operation.

Applications

The WTS enables surveyors, geotechnical specialists and structural engineers to record and log angle data remotely without the cost and impracticality of traditional wired methods.

Wireless: WTS-H-R Series ±5° to ±60°

-

Wireless Inclinometer, Horizontal mounting, rechargeable.

The WTS Wireless Tilt System is a flexible, all-weather radio telemetry system designed to provide high accuracy remote angle measurement data. The WTS gives surveyors, geotechnical specialists and structural engineers the ability to record and log data remotely without the cost and inefficiency of traditional wired methods.

The heart of the system is the WTS Wireless Inclinometer; a high-accuracy robust instrument utilising advanced MEMS sensor technology to ensure maximum reliability. A variety of complementary base stations and either PC or hand-held data acquisition modules allow a complete measurement system to be configured to suit any particular application. A variety of fixed base stations and hand-held readers are available to enable the user to tailor the system to their optimal requirements.

Highway agencies, bridge and civil structure owners spend large revenues assessing structural health by visual or other types of consuming inspection methods of bolted and welded joints, together with other vital structural elements. Obtaining multiple readings to monitoring the entire structure can be costly and labour intensive. Using the WTS Wireless Tilt System, a single structure is fitted with low power WTS Inclinometers at strategic points, thus helping to determine where weak points may be and when maintenance is required.

Additionally, the WTS Wireless Tilt System may be used in the verification of design calculations when new structures are manufactured providing valuable data to refine computer models of structural behaviour.

Features

- Advanced MEMS inclinometer design for ultra-reliability and performance.

- Distortion free digital 2-way radio system for data integrity.

- Very low power consumption for long battery life.

- Worldwide licence exempt 2.4 GHz radio.

- Option of hand held remote display or PC interface for data capture.

- Remote power on/off (sleep/wake).

- > 100 metre range.

- Multi-channel operation.

Applications

The WTS enables surveyors, geotechnical specialists and structural engineers to record and log angle data remotely without the cost and impracticality of traditional wired methods.

Wireless: WTS-V-NR Series ±5° to ±60°

-

Wireless Inclinometer, Vertical mounting, non-rechargeable

The WTS Wireless Tilt System is a flexible, all-weather radio telemetry system designed to provide high accuracy remote angle measurement data. The WTS gives surveyors, geotechnical specialists and structural engineers the ability to record and log data remotely without the cost and inefficiency of traditional wired methods.

The heart of the system is the WTS Wireless Inclinometer; a high-accuracy robust instrument utilising advanced MEMS sensor technology to ensure maximum reliability. A variety of complementary base stations and either PC or hand-held data acquisition modules are offered to allow a complete measurement system to be configured to suit any particular application. A variety of fixed base stations and hand-held readers are available to enable the user to tailor the system to their optimal requirements.

Highway agencies, bridge and civil structure owners spend large revenues assessing structural health by visual or other types of consuming inspection methods of bolted and welded joints, together with other vital structural elements. Obtaining multiple readings to monitor the entire structure can be costly and labour intensive. Using the WTS Wireless Tilt System, a single structure is fitted with low power WTS Inclinometers at strategic points, thus helping to determine where weak points may be and when maintenance is required.

Additionally, the WTS Wireless Tilt System is used in the verification of design calculations when new structures are manufactured providing valuable data to refine computer models of structural behaviour.

Features

- Advanced MEMS inclinometer design for ultra-reliability and performance.

- Distortion free digital 2-way radio system for data integrity.

- Very low power consumption for long battery life.

- Worldwide licence exempt 2.4 GHz radio.

- Option of hand held remote display or PC interface for data capture.

- Remote power on/off (sleep/wake).

- > 100 metre range.

- Multi-channel operation.

Applications

The WTS enables surveyors, geotechnical specialists and structural engineers to record and log angle data remotely without the cost and impracticality of traditional wired methods.

Wireless: WTS-V-R Series ±5° to ±60°

-

Wireless Inclinometer, Vertical mounting, rechargeable

The WTS Wireless Tilt System is a flexible, all-weather radio telemetry system designed to provide high accuracy remote angle measurement data. The WTS gives surveyors, geotechnical specialists and structural engineers the ability to record and log data remotely without the cost and inefficiency of traditional wired methods.

The heart of the system is the WTS Wireless Inclinometer; a high-accuracy robust instrument utilising advanced MEMS sensor technology to ensure maximum reliability. A variety of complementary base stations and either PC or hand-held data acquisition modules are offered to allow a complete measurement system to be configured to suit any particular application. A variety of fixed base stations and hand-held readers are available to enable the user to tailor the system to their optimal requirements.

Highway agencies, bridge and civil structure owners spend large revenues assessing structural health by visual or other types of consuming inspection methods of bolted and welded joints, together with other vital structural elements. Obtaining multiple readings to monitoring the entire structure can be costly and labour intensive. Using the WTS Wireless Tilt System, a single structure is fitted with low power WTS Inclinometers at strategic points, thus helping to determine where weak points may be and when maintenance is required.

Additionally, the WTS Wireless Tilt System may be used in the verification of design calculations when new structures are manufactured providing valuable data to refine computer models of structural behaviour.

Features

- Advanced MEMS inclinometer design for ultra-reliability and performance.

- Distortion free digital 2-way radio system for data integrity.

- Very low power consumption for long battery life.

- Worldwide licence exempt 2.4 GHz radio.

- Option of hand held remote display or PC interface for data capture.

- Remote power on/off (sleep/wake).

- > 100 metre range.

- Multi-channel operation.

Applications

The WTS enables surveyors, geotechnical specialists and structural engineers to record and log angle data remotely without the cost and impracticality of traditional wired methods.

MEMS: T640 Series +/-30° to +/-90°

-

T435 Single Axis Inclinometer, 4-20 mA output, pin termination

The T640 Series is a range of gravity referenced inclinometers used in a variety of industrial and military applications where precision angular measurements are required in rugged applications.

Models are available in a variety of ranges from +/-30° to +/-90° with low impedance filtered and unfiltered output voltage signals. Electrical terminations are via a 6-way connector on the T643 or solder pins on the T645 variant.

Features

- Ranges ±30º, ±60º and ±90º

- Essentially zero temperature coefficent of damping ratio

- Filtered and unfiltered outputs simultaneously available

- Integral temperature compensation

- DC input – DC output

- Signal ground isolated from power ground

Applications

- Data acquisition systems

- Roadbed analysis

- Platform levelling

- Structural monitoring

- Pipeline levelling

- Ship ballast transfer systems

Load Cells

- Sherborne Sensors is a global leader in the design and manufacture of load cells. Our clients benefit from our proven technical and solutions-based expertise in load cells, weigh cells and force transducer applications.

Compression: SS2 Series Load Cell

-

SS2 & SS3 Ultra Low Force Tension and Compression 30g and 60g

The S02 tension & compression S Type load cell offers a compact design for a variety of weighing and test and measurements applications. The S02 S-type Load Cell series (often known as S Beam load cells or Z Type load cells) provides accuracy, compact design features, overload protection and a wide capacity range from 0-250lb up to 0-20,000lb.

Features

The S02 S Type / Z-Type Strain Gage based Load Cell is suitable for tension or compression applications.

The load cells design incorporates side load and bending movement rejection making it idealy suited to general weighing and test & measurement applications. The S02 S Type Load Cell series provides accuracy, compact design features, English Threads, overload protection and a wide capacity range from 0-250lb up to 0-20,000lb.

Shear: U2000 Series Low Profile

-

U2000 Compression miniature load cell

The compactness of the U2000 micro load cell makes it ideal for use in applications where space is limited. The robust shear web design uses multiple strain gauges, strategically placed to counteract and minimise errors due to side loads and non-axial forces. The extremely low deflection and high frequency response are beneficial in high-speed measurements, especially where peak loads are being monitored.

Features

- 18mm (0.7 inch) ultra low miniature profile

- 2.5 to 25kN versions

- Stainless Steel construction

- Integral electrical connector

- High frequency response

- Sealed to IP54

Applications

- Transient force monitoring

- Press force measurement

- Materials testing

- Miniature size ideal for use in any applications where space is limited

Compression & Tension: SS4000M Series Load Cell

-

SS4000M ultra miniature tension / compression S-Beam

The SS4000M ultra miniature load cell is equally suitable for tension or compression applications and are especially useful where space is limited. The internal construction consists of a full bridge of transducer quality miniature strain gauges that are bonded to the transducer element. This element is manufactured from high strength aluminium alloy or stainless steel, depending on the force range.

The load cell’s miniature design incorporates side load and bending movement rejection; despite its small size this transducer is highly accurate. Specially optimised OEM versions of the load cell are available for high volume applications.

The SS4000M ultra miniature load cell is equally suitable for tension or compression applications and is especially useful where space is limited. The internal construction consists of a full bridge of transducer quality strain gauges that are bonded to the transducer element. This element is manufactured from high strength aluminium alloy or stainless steel, depending on the force range. The load cell’s design incorporates side load and bending movement rejection; despite its small size the transducer is highly accurate. Specially optimised OEM versions of the load cell are available for high volume applications.

Features

- Available in ranges from ±10N to ± 500N

- Miniature, only 35mm high

- Incorporates bending moment and side load compensation

- Manufactured in ISO 9001:2008 and AS9100B Quality Control conditions

- 100% tested and supplied with an individual calibration certificate

- High stiffness and low deflection under load

Applications

The SS4000M series of miniature load cells consist of a bridge of transducer-quality strain gauges, bonded to the transducer element. This element is manufactured from high-strength alloy or stainless steel, depending upon range requirements.

The SS4000M is offered in ranges of +/-10N to +/-500N with 2mV/V output and units are temperature compensated over -10C to +60C for reliable operation in a variety of application environments.

With high-reliability performance characteristics in a small envelope size, the SS4000M series is suitable for use within high-volume OEM applications, as well as materials testing, laboratory analysis, research and development and general force measurements within space-constrained environments.

- Materials test

- Bi-directional force monitoring

- Miniature size provides general in-line force monitoring in limited space applications

Compression & Tension: SS5000M Series Load Cell

-

SS5000 Tension / Compression Load Cell

The SS5000 series are strain gauge based tension & compression, miniature universal load cells with integral amplification providing a high level output signal, operating from an unregulated supply voltage.

These universal load cells are fully compensated for the effects of temperature on the zero output and sensitivity and employ precision transducer quality bonded strain gauges inter-connected to minimise the effects of offset forces and bending moments as the primary transduction elements.

The SS5000 series are machined from stainless steel and have a high resistance to overload, shock and corrosion.

Features

The SS5000 series are manufactured from stainless steel and have unusually high resistance to overload, shock and corrosion. The transducer is fully compensated for the effects of temperature on the zero output and sensitivity and employs precision transducer quality bonded strain gauges inter-connected to minimise the effects of offset forces and bending moments as the primary transduction elements. The universal load cell is fitted with an integral multi-conductor cable properly bonded to ensure full EMC compatibility.

Applications

Sherborne Sensors SS5000, are a family of universal miniature strain gauge load cells, designed to measure both tension and compression loads. SS5000 is specially designed with integral amplification, offering users a high accuracy measurement output of +10 Vdc over their full range. Most load cells on the market of this type offer only mV output.

With units weighing just 250g, the size and performance characteristics of the SS5000 allows them to be used in a variety of applications, including:

- Materials testing

- Medical device design and testing

- QC and laboratory testing

- R&D projects

- Renewable energy systems

- Consumer products testing

- Robotics

- General force measurement

- Weighing and scale-related applications

The SS5000 offers four measurement ranges, from ±250 to ±2,000N (+3000N maximum), with units occupying a footprint of 44.5 cm in diameter, 31 cm in length, and reliably operating over a temperature range of -13 to +167 °F (-25 to +75 °C). Units feature an internal stainless steel load cell element, which offers unusually high resistance to overload, shock and corrosion.

The Wheatstone bridge design is fully compensated for temperature effects on zero output and sensitivity. Because of their highly durable construction, SS5000 universal load cells have superior long-term stability and minimal effects from small off-axis loads. All load cells come standard with an integral multi-conductor cable, and male thread studs for load attachment.

Compression & Tension: SS6000 Series Load Cell

-

SS6000 ±2,000kg bearing force load cell

The SS6000 series are strain gauge based tension & compression, miniature universal load cells with integral amplification providing a high level output signal, operating from an unregulated supply voltage.

These universal load cells are fully compensated for the effects of temperature on the zero output and sensitivity and employ precision transducer quality bonded strain gauges inter-connected to minimise the effects of offset forces and bending moments as the primary transduction elements.

The SS6000 series are machined from stainless steel and have a high resistance to overload, shock and corrosion.

Compression & Tension: U4000 Universal Series Load Cell

-

U4000 universal / compression miniature load cell

These load cells are suitable for use in a multitude of general purpose force measurement applications, and are equally suitable for tension, compression of universal load application.

Depending upon the load ranges, either double bending beam or shear force sensing transduction elements are employed. Both these techniques ensure considerable immunity to the effect of extraneous forces and moments.

The product may be readily customized by Sherborne Sensors ensuring a cost effective optimal force measurement solution.

Depending upon the load ranges, either double bending beam or shear force sensing transduction elements are employed. Both these techniques ensure considerable immunity to the effect of extraneous forces and moments. Transducer quality bonded foil strain gauges are utilised and configured in a fully active Wheatstone bridge configuration.

The transducer is fully compensated to eliminate second order errors due to temperature effects on zero and sensitivity. The load cell is manufactured from anodised high strength aluminium alloy or precipitation hardening stainless steel.

Features

- Stainless steel construction

- High Frequency Response

- Low Deflection

- 50N to 50kN ranges available

Applications

- General industrial, aerospace and military high accuracy force measurement.

- Materials testing

- Force references

Applications

- Sherborne Sensors manufactures and supplies a range of high quality and high precision sensors across a wide range of industries. Our products ranges include load cells, accelerometers, inclinometers and wireless sensors .

Aerospace

-

Load Cells

Our load cells are found in a variety of Aerospace testing and measurement applications. Aerospace companies such as Airbus, Lockheed Martin, Boeing, Northrop, Bombardier and Astrium depend on Sherborne Sensors’ load cells solutions.

The most popular aerospace load cell designs are often specified as low profile or miniature load cell designs and are mostly custom designed for specific purposes.

Typically, our load cells are used in a variety of load cell applications ranging from inclusion in active flight control systems to testing of aerospace assemblies such as braking and control systems.

Accelerometers and Inclinometers

Sherborne Sensors Accelerometer and Inclinometer products are in service across a number of Aerospace platforms including fixed wing, rotorcraft, space vehicles, UAV’s, UUAV’s, and cruise and ballistic missiles, on both mobile and fixed platforms.

Our Inertial products are used in a wide variety of applications including missile fire control radar systems, precise aiming of mobile, ground and naval antenna masts and dishes, towed arrays and dummy target missile platforms, general angle of attack measurements for aerial tankers and launch vehicle control.

Applications found in this space include missile fire control radar systems; precise aiming of mobile, ground and naval antenna masts and dishes; towed arrays and dummy target missile platforms; general angle of attack measurements for aerial tankers; and launch vehicle control.

Civil Engineering

-

Significant advances in computational capabilities, battery performance, sensor design, and structural analysis techniques are leading the abundance of sensor applications within the Civil Engineering and Construction communities. In many applications, sensors are deployed to enable proactive and predictive monitoring of the general health of a structure; buildings, bridges, levees, dams, or other structures whose integrity translates into the safety of those who use and depend on it.

Ideally, sensor systems are part of the initial construction process, but retrofit applications are also very common. Communicating the data from the sensor to the analysis node can occur both via wired and wireless networks.

Under the general category of structural health monitoring, Sherborne Sensor products monitor high-rise building dynamics by capturing subtle building movements based on changes in ambient temperature and traffic loads; subsidence in highly stressed and flexible structures such as suspension bridges and stadium roofs; the effects of seismic activity on large, land-based structures; and the effects of efforts to reinforce and preserve structural antiquities.

Sherborne Sensors’ range of sensors includes high-precision and high-quality load cells, accelerometers and inclinometers.

Industry

-

Sherborne Sensors manufactures and supplies a range of high-quality precision sensors for a range of industries. The range of applications is nearly endless and include such diverse installation as Nuclear Reaction Control, Robotics and Manufacturing lines and plants. One application where accuracy is paramount involves the monitoring and adjustment of the mould faces in continuous casting; this process ensures consistency in the product as process variables change. Our high precision and robust inclinometers enable these processes to run continuously for weeks/months on end without incurring any unscheduled downtime.

Sherborne Sensors offers a variety of products to support the inclination, acceleration and force measurements needed for production & industry applications. We work with production engineers to determine the most appropriate sensor for our clients; providing their customers with the data needed to confirm product or platform compliance to applicable regulations and standards.

Defense

-

Military organisations around the world are relying more and more on advanced sensor elements and integrated sensor systems to improve lethality, reduce cost, enable advanced capabilities, and protect the soldier, sailor, airman, or marine who is directly in harm’s way. Sherborne Sensors has a long and proud history in supporting British, American and other friendly forces around the world. Sherborne Sensors’ ‘custom team’ works to deliver created a range number of ‘bespoke’ sensors used in a mixture of Land, Naval and Air Applications.

These applications require the highest possible accuracy and reliability; in the most extreme of environments. These custom products have included; specialised enclosures, connectors, supporting electronics and other components that Sherborne Sensors is uniquely qualified to provide. With final applications ranging from turret control to antenna positioning, from structural health monitoring of ground and naval vehicles to munitions fire control Sherborne Sensors has the experience and expertise to deliver.

Transport

-

Modes and options for transportation of goods and people continue to evolve. Recently, both private industry and governments have recognized models based primarily on individual modes of transportation are not sustainable; both from an economic and environmental perspective. A mixture of individual and mass transportation solutions are needed. Accordingly, funds directed towards these solutions have increased dramatically, along with their technical requirements.

Two segments of transportation that represent keen interest are rail and barge. Both offer the opportunity to move large numbers of people and goods in significantly more efficient ways than individual cars, trucks or ships.

Sherborne Sensors is assisting leading manufacturers of these platforms and their customers by providing sensors for a variety of applications, such as inclinometers to monitor barge loading and unloading activities to ensure safe operations; vibration monitors for engine and drive line systems to proactively assist in identifying possible maintenance issues; angle analysis systems to verify rail track properties and conditions to ensure safe passage of both freight and passenger loads; and accelerometers to protect passengers and freight by modulating train acceleration and deceleration protocols.