- Offer Profile

-

SMW-AUTOBLOK – innovative and flexible

SMW-AUTOBLOK offers a comprehensive portfolio of work holding solutions for Automotive, OCTG, Industrial equipment and Aerosopace. A modular system of standard products allows the flexible use for different applications.

All our high quality standard products are in stock, and thus offer a quick availability.

We develop, produce and distribute our sytems with passion worldwide.SMW-AUTOBLOK – always a step ahead.

Turning

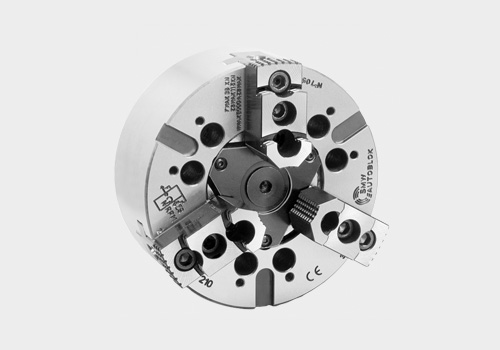

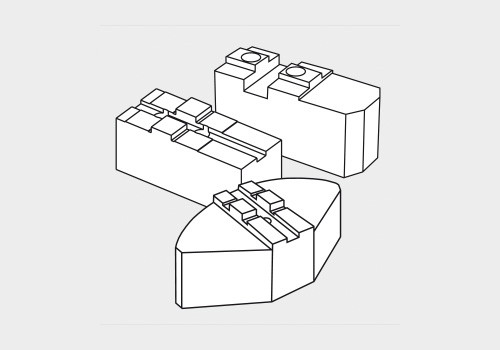

Manual chucks

- ■ Manual chucks (straight serration)

■ Manual chucks (inclined serration)

■ With quick jaw change system

■ 4 jaws independet manual chucks

■ Manual jaw box

Closed center power chucks

- ■ 2, 3, 4 or 6-jaw version

■ Inch, metric serration or tongue & groove

Open center power chucks

- ■ With large through hole

■ 2, 3, or 4-jaw version

■ Inch or Metric serration

Quick jaw change power chucks

- ■ With quick jaw change

■ Straight serrated jaws

■ Tongue & groove, or pallet system

Application chucks

- ■ Pull-down chucks

■ Compensating chucks

■ Indexing chucks

■ Shaft chucks

■ Column chucks

■ 6 jaw 2+2+2 chucks

Diaphragm chucks

- ■ With quick jaw change

■ With axial fingers

■ Open center chucks

■ With fine adjustment

■ Recommended types of cylinder

Collet chucks

- ■ Collet chucks

■ Bar pulling chucks

Mandrels

- ■ Manual operated expanding mandrels

■ Power operated expanding mandrels

■ Adapter flanges

Cylinders

- ■ Closed center cylinders

■ Open center cylinders

■ Double piston cylinders

Front-end chucks

- ■ Pneumatic/hydraulic front-end chucks

■ Control units

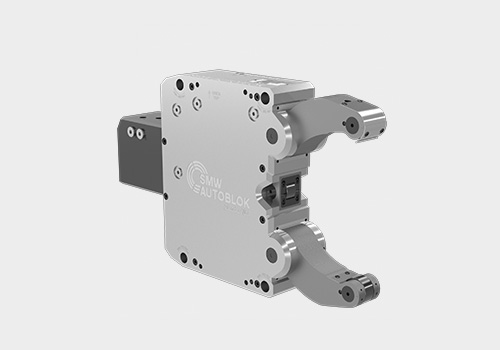

Steady Rests

- ■ Self-centering Steady Rests

■ Standard, Basic and Premium Line

■ Grinding Steady Rests

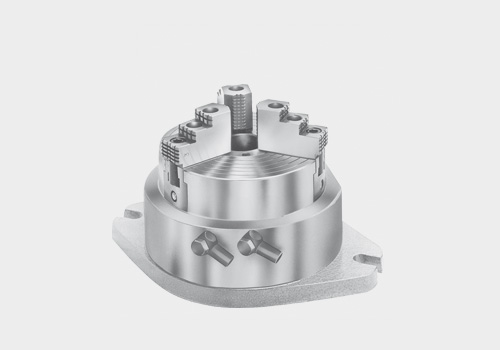

Stationary chucks

- ■ With 2 or 3 jaws

■ Built-in hydraulic or pneumatic cylinder

Accessories

- ■ Chuck switching system

■ Chuck adapters

■ Clamping jaws

■ T-nuts

■ Grippers

■ Gripping force meter

■ Grease

■ Accessories

General catalog Turning 19E

Grinding

Grinding Steady Rests

-

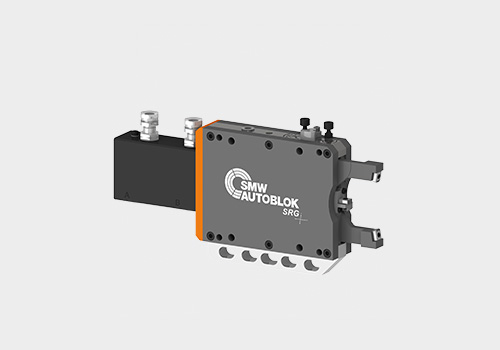

SRG | SRG-B:

High precision grinding Steady Rests

Grinding diameter Ø 3 - 126 mm■ Fine adjustment of the grinding center

■ Retractable arms

■ Suitable for follow-down grinding

■ High rigidity

Precision air chucks

-

AcuGrind:

High precision air chucks

Chuck sizes Ø 80 - 250 mm■ For OD and ID clamping

■ Built-in pneumatic actuation

■ For universal grinding applications

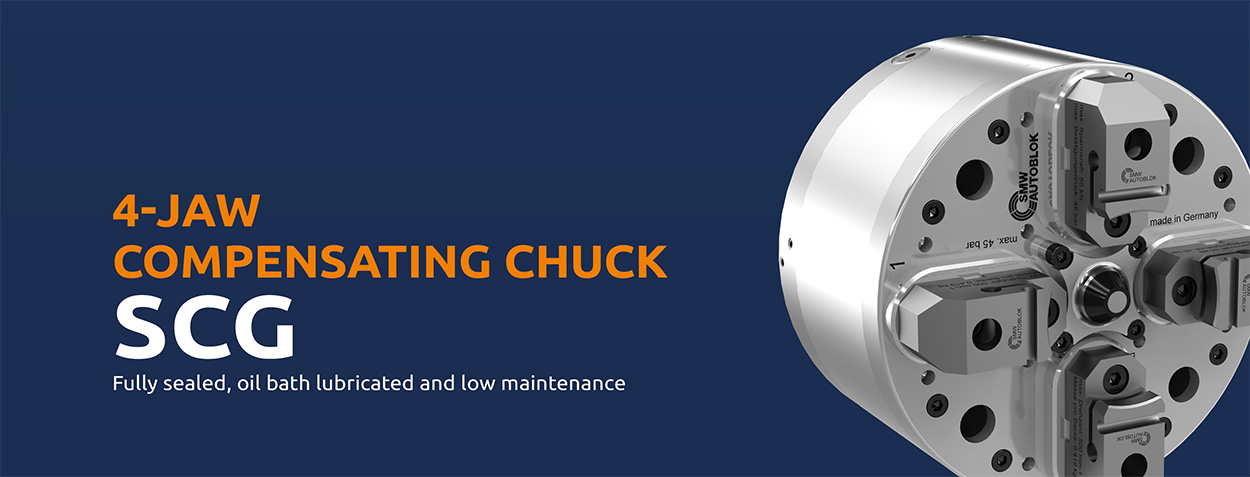

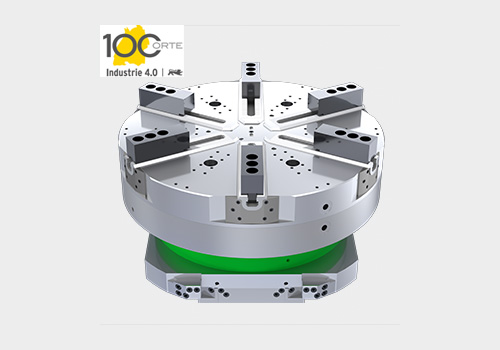

2+2 compensating chucks

-

SCG:

High precision 4 jaw chuck

2+2 compensating■ 2+2 jaws independently operated

■ Hydraulic actuation

■ Quick change center or adjustable

■ For grinding

■ Fully sealed and low maintenance

Diaphragm Technology

-

D | D-Kombi | D-Plus | D-Vario:

Diaphragm chucks

Chuck sizes Ø 210 - 400 mm■ Diaphragm technology for highest precision

■ External or pitchline clamping

■ With or without open center

High precision face drivers

-

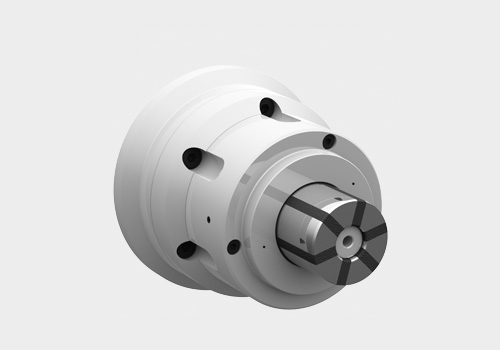

FDG:

High precision face drivers

for machining between center pins■ Machining of the entire surface of the workpiece with one single operation

■ Power operated on the side of the spindle

■ Highest run-out accuracy

Pneumatic pancake cylinder

-

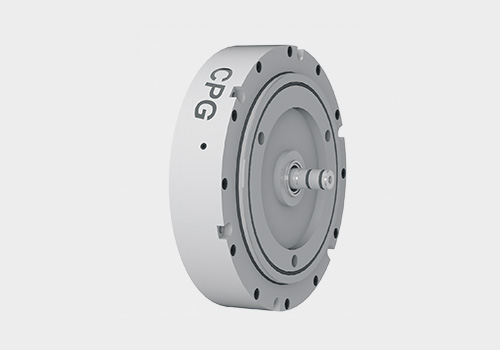

CPG:

Pneumatic pancake cylinder for diaphragm

chuck D-VARIO and face driver FDG■ Easy installation for grinding and turning machines without hydraulic unit

■ Operating pressure 2-8 bar

■ Medium feed for air / coolant

Segment sleeve mandrel

-

EM-S:

Segment sleeve mandrel

Clamping diameter Ø 18 - 105 mm■ For ID clamping

■ Very rigid design

Catalog Grinding

Stationary Workholding

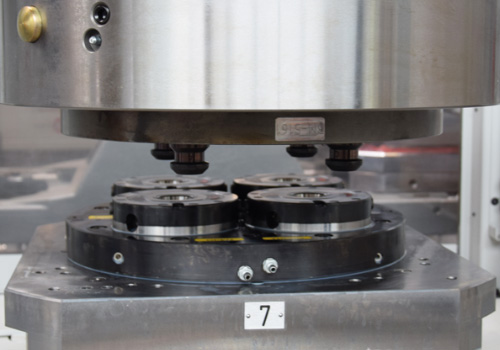

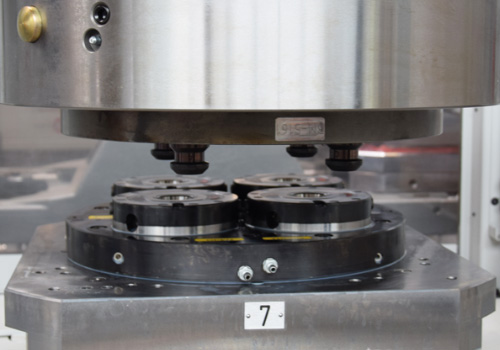

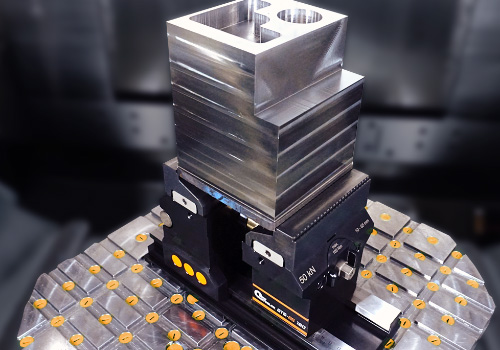

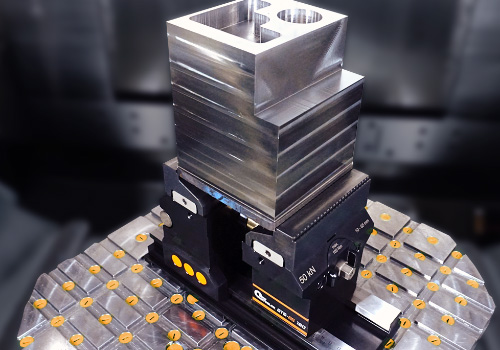

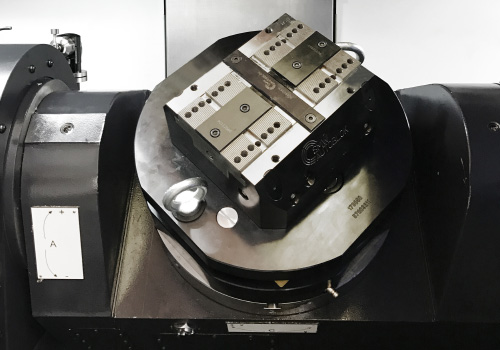

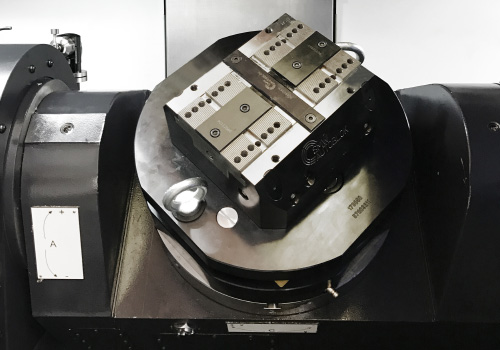

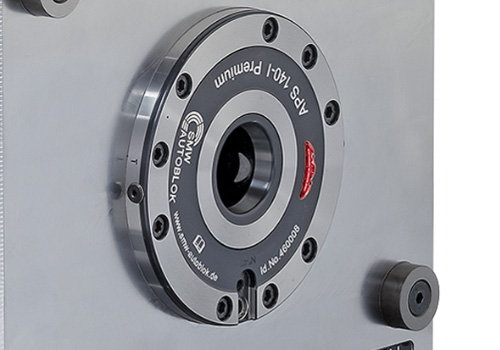

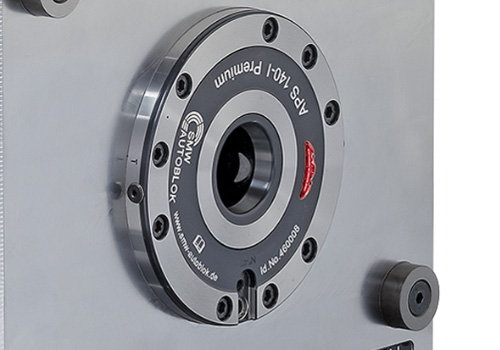

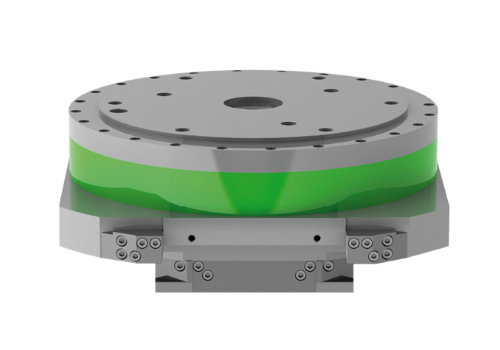

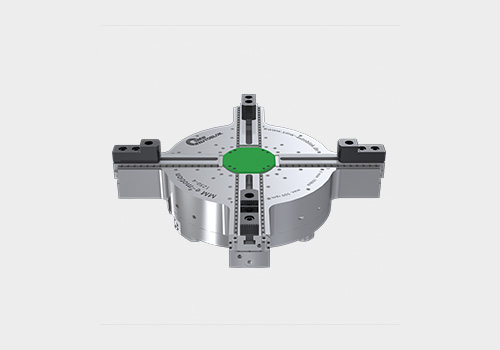

APS Zero Point Clamping System

-

With the new APS zero point clamping system, users can reduce set-up times by up to 90%.

The APS zero point clamping system can be used in all operations such as turning, milling,

measuring, eroding or grinding. This means users benefit from significantly reduced costs due

to reduced set-up times while increasing the availability of machines throughout the production line.

3 different ranges – Basic, Premium and Top – offer optimum solutions for all application requirements.

- Significantly reduced costs due to reduced set-up times

- Modular construction kit system: existing clamping systems can be modified very easy

- Low installation height due to the compact design

- Highest process reliability and repeat accuracy < 0.005 mm

- Wear-resistant and protected against rust (or stainless) due to heat treated elements and an extra hard protective coating

- Maximum pull-in forces until 45 kN (APS 190) thanks to turbo function

- Highest stiffness by means of 3 clamping slides (Premium / Top-Version)

- Fully sealed (proofline)

- Interchangable to the Workpiece Positioning System WPS

ZeroAct

-

Cennectable fl exible zero point clamping module, Fully sealed

- Up to 3 ZeroAct modules could be connected in a row with central actuation

- Single quick-actuation for the rapid opening and closing of the modules with only 270° rotation

- Extremly flat design

- Huge reduction of set-up times for highest efficiency

- Safe workpiece clamping with maximum holding forces and highest repeatability

- Flexible configurations for customized use

- 4 indexing slots

- Interchangeable to the proven zero point system APS / WPS

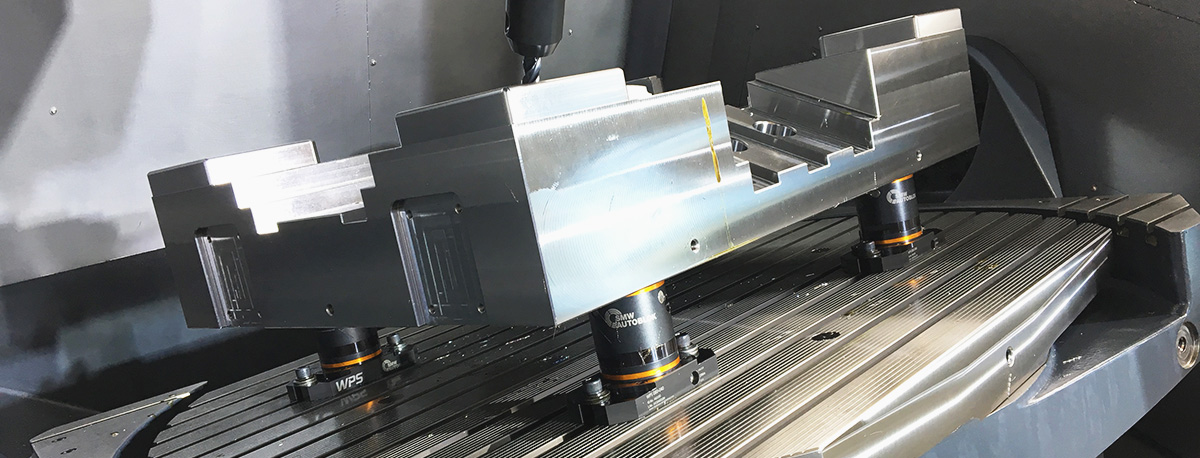

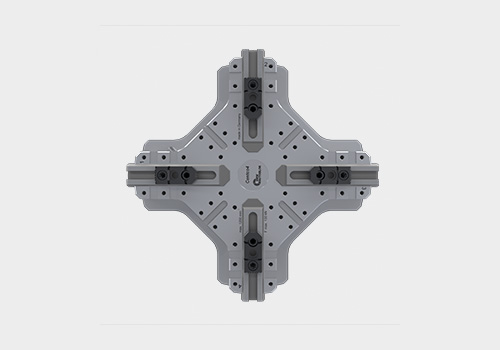

WPS WORKPIECE POSITIONING SYSTEM

-

Manual Zero Point Clamping System for the Workpiece Direct Clamping

- Huge reduced set-up times for highest efficiency

- Safe workpiece clamping with maximum holding forces and highest repeatability

- Ideal for 5-axis machining

- Single quick-actuation for the rapid opening and closing of the modules with only 3.5 rotations

- Flexible configurations for customized use

- Interchangeable to the proven zero point system APS

technical data

- Diameter 80 mm

- Pull-in force 15 kN

- Repeatability < 0.005 mm

- Holding force 50 kN

- Proofline® = fully sealed - low maintenance

WPS Mini Workpiece

-

Single quick-actuation for the rapid opening and closing, Fully sealed

- Huge reduction of set-up times for highest effi ciency

- Safe workpiece clamping with maximum holding forces and highest repeatability

- Ideal for 5-axis machining

- Central quick actuation (270° rotation)

- Flexible confi gurations for customized use

- To adapt WPS Mini on WPS 080

Lowest clamping depth without pre-marking

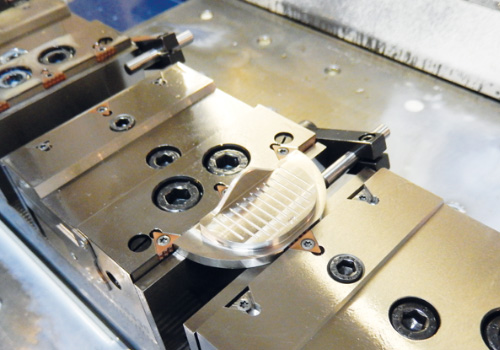

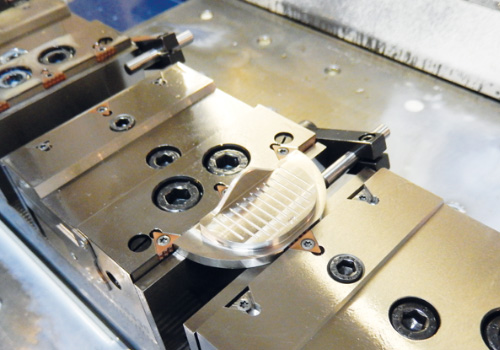

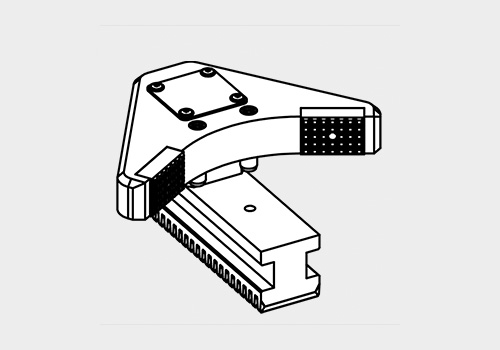

-

Thanks to the SinterGrip clamping inserts, it is possible to clamp workpieces safe with a clamping

depth of just 3.5 mm, so the workpiece can be completely machined in a single operation.

This reduces the cost of materials, particularly where raw material costs considerably influence

the piece price. SinterGrip also optimizes the performance of the machine and tools: faster cutting

and feeding speeds mean larger cutting volumes and shorter machining times for each workpiece.

In addition, production steps required until now, such as workpiece pre-marking, are no longer

necessary. Eliminating the pre-marking process reduces investment costs and saves on upstream

processing costs. Considerable time is also saved as the workpiece, it can be clamped immediately

by eliminating upstream processes.

The triangular insert with pyramidal teeth penetrates into the material, creating a positive fit

between the clamp and the workpiece. The forces and vibrations generated during machining

are evenly distributed and absorbed.

SinterGrip comes in 3 different versions for different materials: steel, hardened steel

(up to 54 HRC)/titanium and aluminium/plastic. SinterGrip is compatible with all commonly

available types of vices and clamping devices.- Lowest clamping depth only 3.5 mm

- No pre-marking necessary

- Highest forces and active vibration absorption

- Increasing of the cutting forces compared to other systems

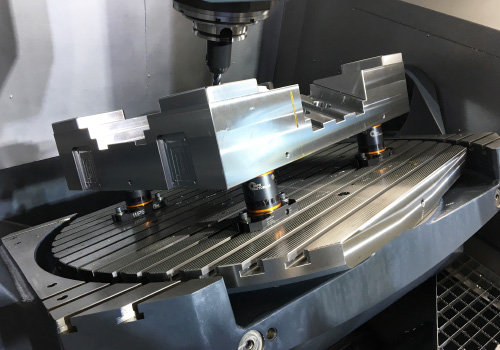

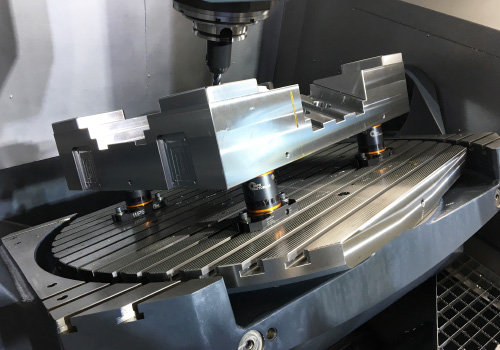

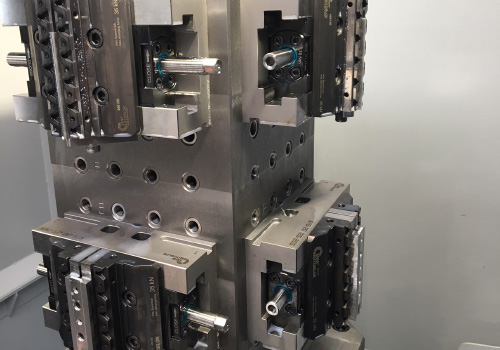

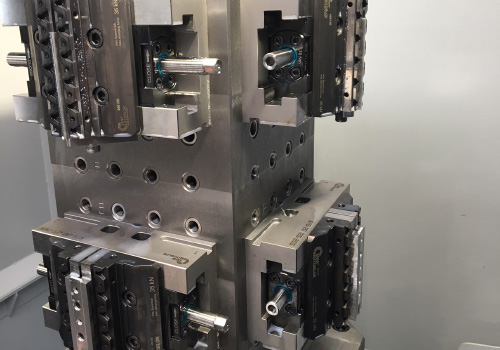

GT5 5-Axis Machine Tools

-

5-Axis Machine Tools ensures the following advantages:

- Ideal suitable for OP 10 use

- Compact design with best accessibility of the machine spindle

- High adjustable clamping forces

- Jaws with SinterGrip clamping inserts for clamping of workpieces with lowest depth and without pre-marking

- Interfaces for all well known zero point clamping systems

- Clamping range 100 mm or 200 mm

GT5-2G

-

Fully sealed – protected spindle, Centrical clamping

- Toolless jaw quick change

- Clamping range extension within seconds due spindle extension

- High clamping forces - no pre punching necessary

- Protected spindle

- Plane surface for parallels used for finish machining

- Mechanical power amplifier

- Displaceable fixed jaw

- Highest reliability and repeatility

- Optical check for the end position

GTO – Precise, universal stationary chuck for collets

-

The GTO stationary chuck for standard collets is particularly impressive, above all due to its high

gripping force, accuracy and rigidity.

Lateral bearing surfaces also allow the chuck to be mounted vertically or horizontally. Profitability

is increased due to considerably reduced set-up times since collets can be changed very quickly.

Thanks to its extremely compact design, the GTO is ideal for 5-axis machining.- Rapid and easy mounting

- Quick change of the standard collets

- Sensitive adjustment of the clamping force possible

- Highest repeatability ≤ 0.01 mm

- Vertical or horizontal mounting possible

- Compact design, ideal for 5-axis machining

- Pull-down effect

- 3 versions for clamping diameters 4 until 100 mm

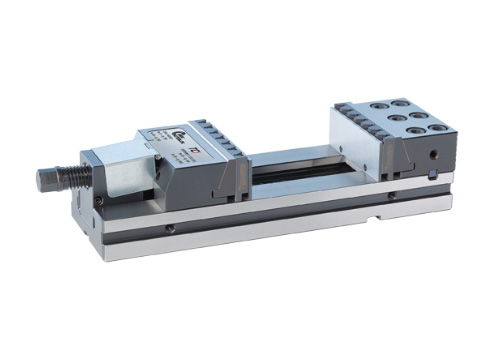

Power Vices

-

Power vices can be pneumatic, hydraulic or spring actuated, self-centering or with a fixed jaw.

In addition, two different jaw strokes are available: a standard stroke for maximum clamping forces

and a long stroke for extended jaw strokes. The highly compact power vices make it possible to

determine the jaw position and control the workpiece support (SL type). This makes them ideal

for automation or for Industry 4.0 applications.- Minimum interference due to the compact design

- Protected against contamination (SL Proofline fully sealed)

- Linear pressure adjustment

- Highest repeatability and rigidity

- Suitable for automation

- Integrated channels for air purge

- 2 jaw interfaces (Tongue & groove and fine serration 1.5 x 60°)

- Wide range of standard products

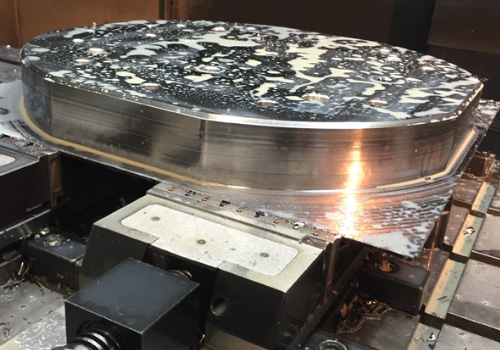

Multiple Clamping System

-

SMW-AUTOBLOK offers two different multiple clamping systems: CV with serration 2.5 x 60° and TB with

serration 2.0 x 60°. Both of these multiple clamping systems come with different jaw widths and lengths.

For the CV system, the "CLAK-SYSTEM" quick change system for jaws and parallels is available as an option.

The user can also clamp safe raw parts using jaws fitted with SinterGrip clamping inserts (see photo).- Best use of the machine table

- Wide range of standard accessories

- Highest efficiency due to rapid set-up times

- Maximum flexibility: can be used for single or multi clamping on the machine table and also on tombstones

Customized Tombstones - shortest delivery times RT

-

The intelligently designed modular system of the RT tombstones offers an extended product range

with the shortest possible delivery times. The tombstones can also be individually equipped with a

wide variety of stationary clamping systems and delivered ready for operation. Suitable geometries

offer optimum accessibility to the machine spindle with the highest accuracy and precision.

The RT tombstones are available in steel (hardened steel if required), cast iron or aluminium

version and offer maximum rigidity and excellent vibration damping. The clamping areas are pre-milled,

fine milled or provided with a grid bore holes, depending on the customer's requirements. In addition

to the extensive catalogue, special sizes with short delivery times are also available upon request.

The RT tombstones are suitable for standard machines according to DIN 55201 or JIS 6337-1980.- Modular system: wide range of standard products and shortest delivery times

- Highest stiffness and anti-vibration design

- Best accessibility of the machine spindle to the workpiece

- Highest accuracy and precision

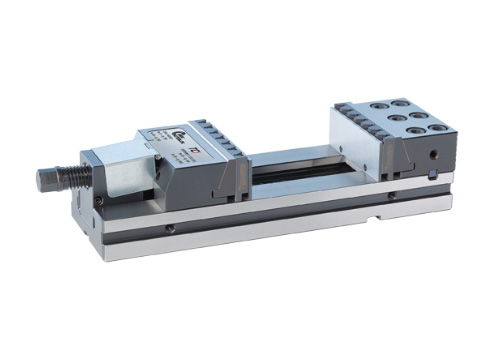

Precise machine vices from SMW-AUTOBLOK

-

The wide range of accessories guarantee the flexible use of the vices.

Also the clamping by using SinterGrip clamping inserts is possible as a standard.- High constant clamping forces

- Maximum rigidity of the body

- Highest precision and accuracy

- Economic efficiency and flexibility

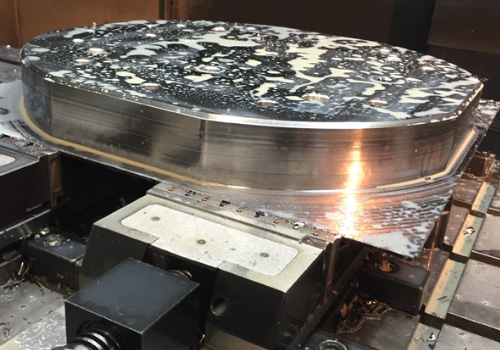

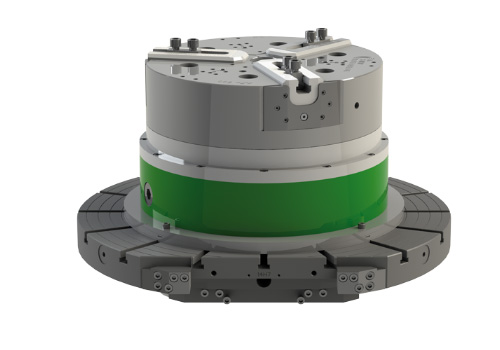

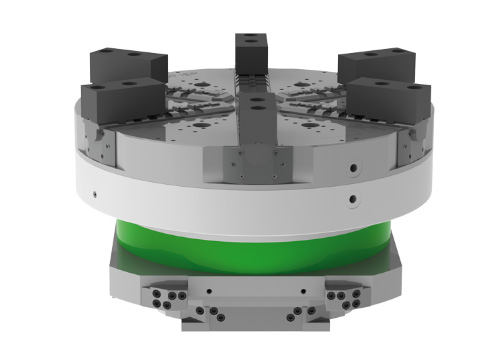

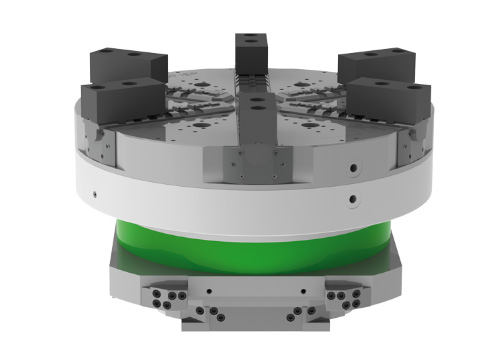

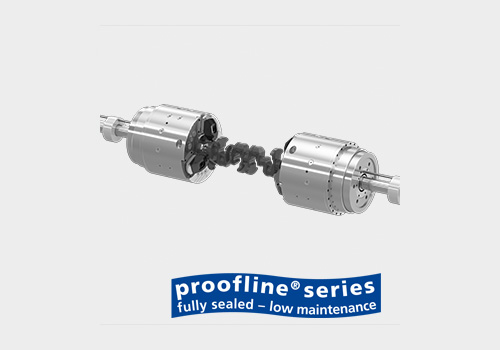

Multi Drive Power Flange F500

-

For the actuation of standard power chucks on mill-turn centers

Modular construction kit : customizable to customer requirements- For the operation of standard chucks

- Standard interface for chucks

- Monitoring of clamping force and position

- Top mounted or integrated in machine pallet

- Fully sealed (proofline)

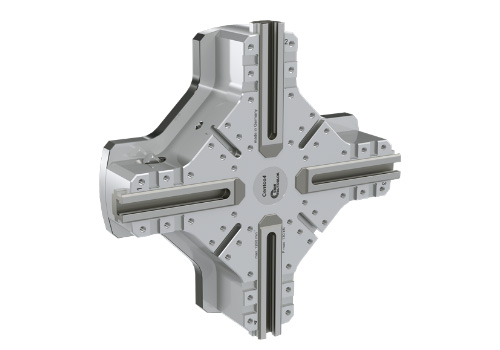

Centco4-MLW

-

2+2 self centering, Independent self centering clamping in 2 axis, Weight-optimized chuck body

- Independent self centering clamping in 2 axis via 1 central actuating mechanism

- Mechanical centering of the workpiece

- Clamping of every workpiece geometry possible

- Weight-optimized chuck body

- Long lifetime due to case hardened parts

- Large range of standard top jaws

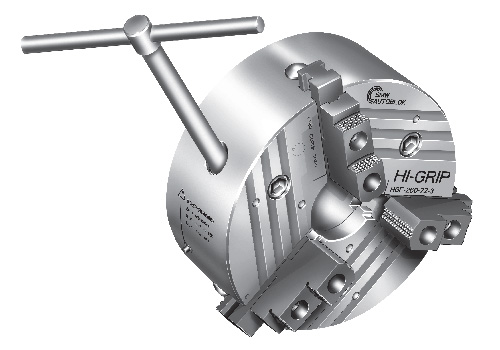

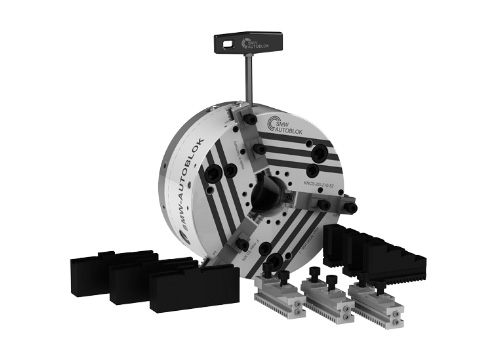

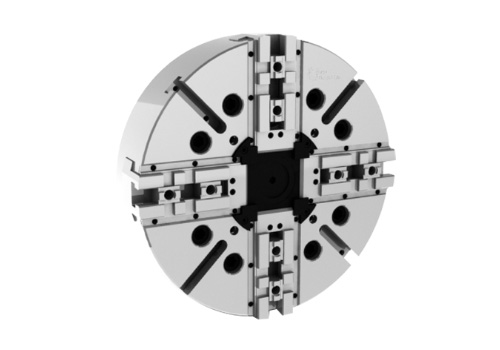

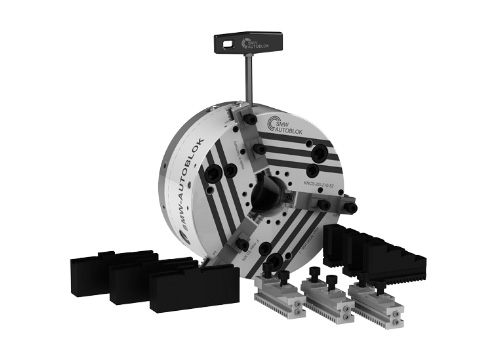

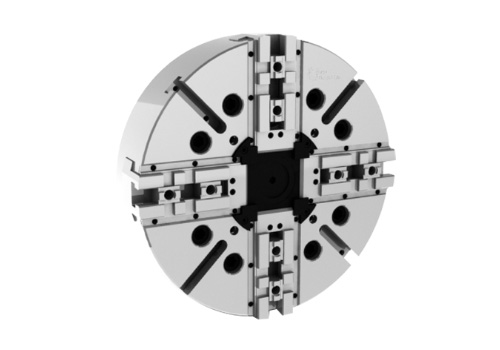

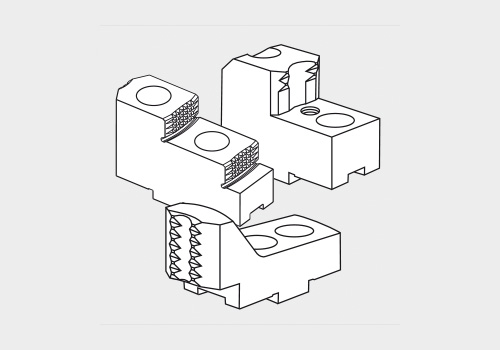

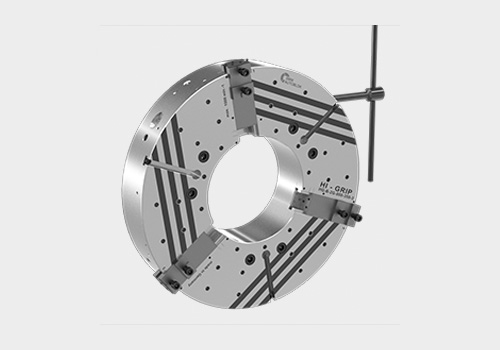

Manual chucks from SMW-AUTOBLOK

- 3-jaw manual chucks are particularly suitable for clamping workpieces in machining centres.

The HG-N, HG-NB and HG-2G manual chucks feature a built-in quick jaw change system as

standard and are available with diameters ranging from 160 to 1000 mm. The quick jaw

change system significantly reduces set-up times. The wedge bar design guarantees the

highest precision and accuracy.

The new generation HG-2G is mechanically sealed and low-maintenance. The sealing protects

the guideways and inside of the chuck against dirt. The HG-2G's optimized innovative

lubrication system guarantees a constant clamping force and reduces maintenance intervals.

The HG-2G manual chucks are available in sizes ranging from 400 to 630 mm

(additional sizes available on request).

PTF 4-jaw faceplates are suitable for clamping round, square or irregular workpieces.

Each individual jaw can be set radially by hand. Clamping forces can be increased many

times over through the use of a torque multiplier. The PTF faceplates are also sealed and

therefore resistant to dirt. PTF faceplates are available with diameters ranging from

1000 to 2000 mm.

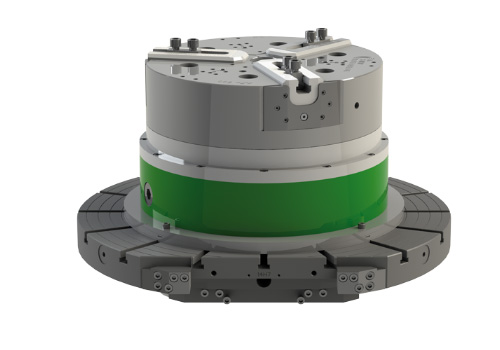

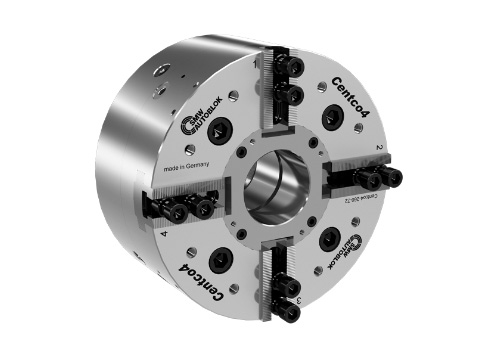

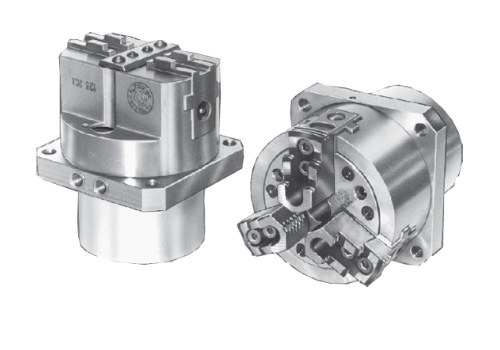

Centco4

-

2+2 self centering, Independent self centering clamping in 2 axis, Centrifugal force compensation

- Independent self centering clamping in 2 axis via 1 central actuating mechanism

- Mechanical centering of the workpiece

- Clamping of every workpiece geometry possible

- Centrifugal force compensation for maximum speed

- Long lifetime due to case hardened parts

- Large range of standard top jaws

High Precision Power Chucks

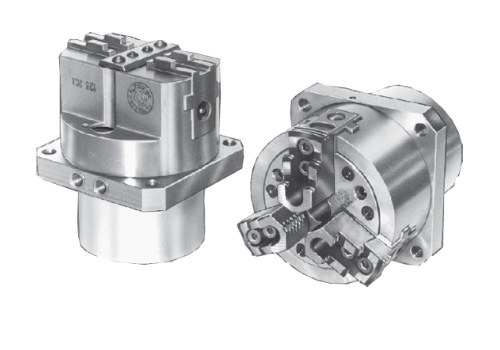

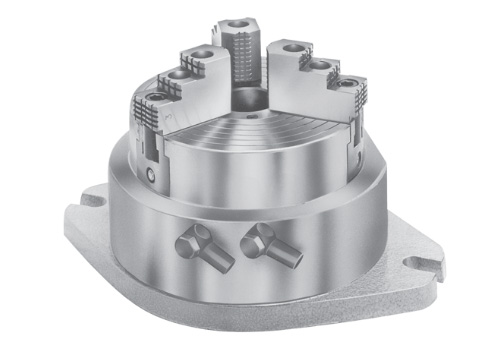

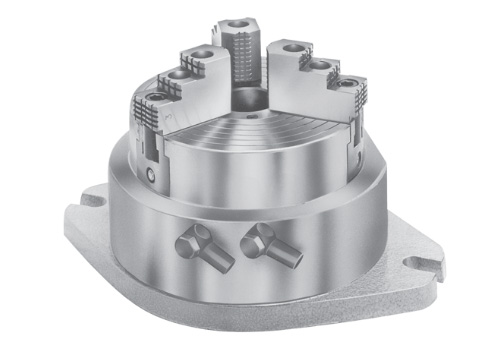

Stationary Chucks

- Stationary clamping systems have an integrated acutating cylinder.

The actuation is either pneumatic or hydraulic.

Stationary chucks working high efficient and ensures high cost-effectiveness.

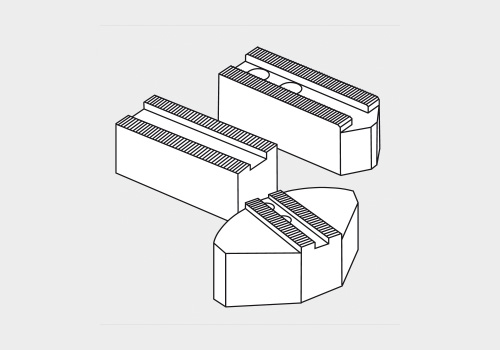

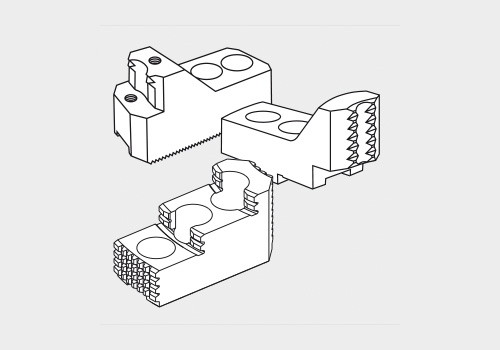

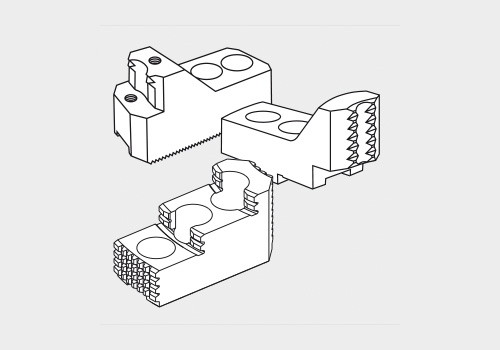

Jaws

Soft top jaws - INCH

- ■ INCH serration

■ 1/16” x 90° or 3/32” x 90°

Hard top jaws - INCH

- ■ INCH serration

■ 1/16” x 90° or 3/32” x 90°

Soft top jaws - METRIC

- ■ METRIC serration

■ 1,5 x 60° or 3 x 60°

Hard top jaws - METRIC

- ■ METRIC serration

■ 1,5 x 60° or 3 x 60°

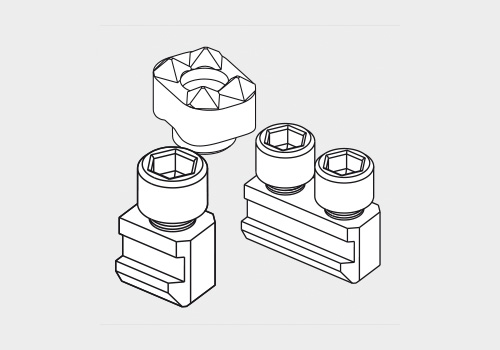

T-nuts | Grippers

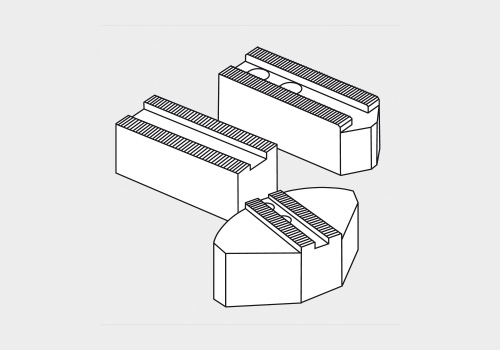

Soft top jaws - tongue&groove

- ■ Tongue & groove

Hard top jaws - tongue&groove

- ■ Tongue & groove

Quick jaw change - straight

- ■ for manual and power chucks

■ straight modular serration

■ System SMW/Reishauer

Quick jaw change - helix

- ■ for manual and power chucks

■ helix modular serration

■ System Forkardt

Accessories

- ■ special jaws

■ boring rings

■ dress and cleaning plate

■ calculations

Pendulum Jaws

- ■ for thin walled or deformation sensitive components

■ cost-efficient solution

■ short set up times: from 3-point to 6-point clamping

■ modular design: all parts interchangea

Jaws

Product News

RT e-motion

-

Electro-mechanical tombstone with integrated drives

- Each clamping device can be controlled individually

- Wireless transmission of energy and data via induvtive coupler system

- Clamping station can be equipped individually

- Permanent monitoring of the clamping force and clamping positions

- Various strokes and forces individually programmable

- Plug & Play

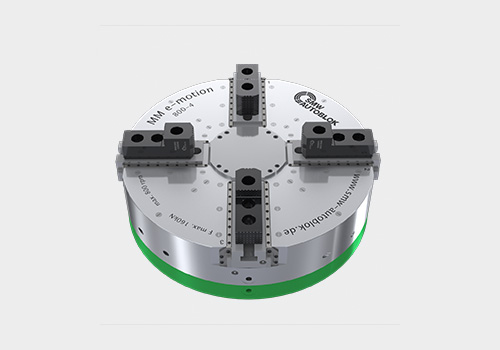

MM e-motion

-

Electro-mechanical universal 4-jaw chuck

- Each jaw driven and controlled via e-motor

- Wireless transfer of power and sensoric via inductive coupler

- Clamping of any shape workpieces

- Automatic adjustment of the center line

- Constant monitoring of the clamping force and the clamping position while rotation

- Sealed and low maintenance

MM e-motion LightWeight

-

Weight optimized electro mechanical patented universal 4-jaw chuck

- Same functionality as MM-e-motion

- Lower chuck weight allows higher workpiece loads

- Lower height allows more Z-Travel of the machine

- Monoblock chuck body for highest rigidity

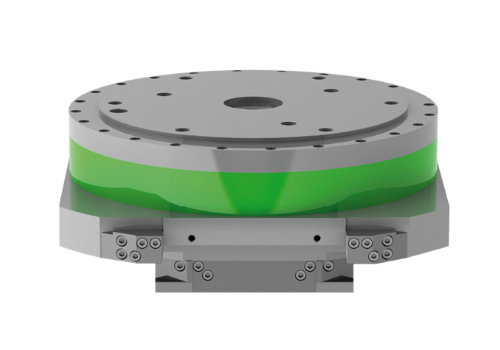

F500 e-motion

- Received an award for Industry 4.0: F500 e-motion:

Electro-mechanical actuation flange

- For actuation of standard power chucks on millturn centers

- Wireless transfer of power and sensoric via inductive coupler

- Electric driven

- Safety systems – electronical and mechanical

- Bidirectional linear regulation of clamping force

- Sealed and low maintenance

BB e-motion

- Electro-mechanical chuck with large

through hole for machining of pipe

- Each jaw driven and controlled via e-motor

- Wireless transfer of power and sensoric via inductive coupler

- Self-centering or compensating clamping

- Automatic centering function

- Constant monitoring of the clamping force and the clamping position under rotation

- Sealed and low maintenance

Inductive Couplers

- Inductive power- and data transmission

■ For mechatronic workholding, handling systems and robotic

■ Power transmission up to 1800 W

■ Signal- and BUS transmission

■ Protected according to IP 67

■ Different versions and sizes availabl

LPS-4.0 14 | 48 | 120 IO

- Lineares Position Sensorfor hydraulic clamping cylinders

■ Analog or digital output signal

■ Monitoring of the entire cylinder stroke

■ Range 14 mm, 48 mm, 120 mm

■ IO Link standard interface

■ Industry 4.0 ready

■ Protection class IP 67

GFT-X 4.0

- Gripping force tester Multifunctional device

- Tablet with large display

- Wireless data transfer from measuring head to table via Bluetooth for the measuring of dynamic and static clamping forces

- Integrated workholding assistance systems

- Smart user interface

- Built-in camera in tablet

- Operation time in use: 8h

EMX

- Manual or power operated expanding madrels / Adapter flanges

- For turning, milling and grinding

- High rigidity

- Highest accuracy

- Air sensing

- Vulcanized and wear-resistant collets

COMOT

-

Collet Chuck Hybrid-Collet Chuck

- Large selection of standard collets

- Air sensing

- Radial fine adjustment

- Low deformation clamping of thin walled workpieces

- Rigid axial stop

Centco4

- 2+2 self centering and compensating 4-jaw chuck

- Independent self centering clamping

in 2 axis via 1 central actuating mechanism - Clamping of every workpiece geometry possible

- Centrifugal force compensation

- Large through hole

- Independent self centering clamping

Centco4-MLW

- 4-jaw manual chuck 2+2 self centering and compensating

- Independent self centering clamping

in 2 axis via 1 central actuating mechanism - Clamping of every workpiece geometry possible

- Weight-optimized chuck body

- Synchronous high precision jaw drives

- Independent self centering clamping

HFKS-2G

- High precision chuck for universal application

- Centrifugal force compensation

- Precise wedge hook actuation for highest clamping forces

- Large through hole

- Weight-optimized chuck body with best accessibility

- For easy deformed workpieces

CSC

- Crank shaft chuck with retractable jaws

- Self centering or compensating clamping

- Quick and safe automatic loading of the crank shaft because of retractabale jaws and centers

- Highest chip removal because of integrated hydraulic locking system

- Maximum machine availability because oil bath lubricated

- Fully sealed and low maintenance

SCG

- High precision 4 jaw chuck

2+2 compensating

- 2+2 jaws independently operated

- Hydraulic actuation

- Quick change center or adjustable

- For grinding

- Fully sealed and low maintenance

CCS

- Chuck switching system

- Short set-up times | high machine availability

- Highest repeatability and change-over accuracy

- Central actuating to couple the chuck and the draw tube

- Large through hole

- Optical control for the locking status

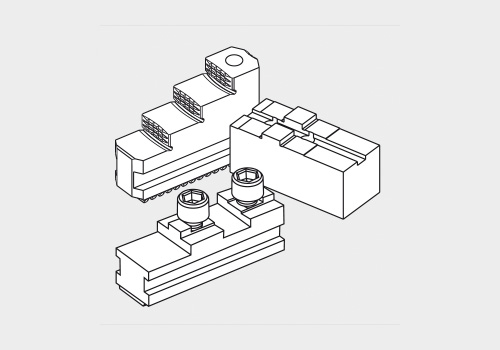

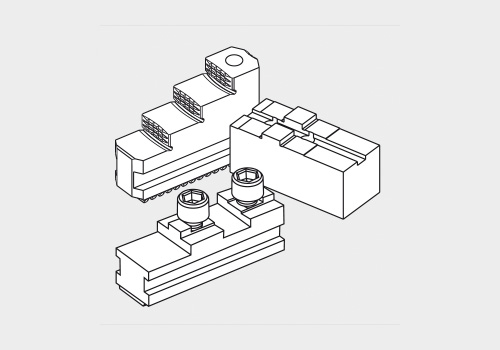

HG-2G

- HG-2G: Quick jaw change - sealed

Quick jaw change manual chuckØ 400 - 630 mm- With through hole

- Lubrication channels in the jaw guide ways

- Mechanic sealed – low maintenancee

- 3 jaws

HG-B-2G

- HG-B-2G: Quick jaw change

- sealed

Quick jaw change manual chuckØ 800 - 1000 mm- With extra large through hole

- All existing top jaws can be used

- Mechanic sealed – low maintenance

- 3 jaws

KNCS-2G

-

KNCS-2G: Quick jaw change

- sealedPower chuck sealed with quick jaw change

Ø 170 - 630 mm

Large through hole

Protection against dust and swarf

High flexibility: jaws radially adjustable/ reversible

3 Jaws

RX

-

RX:

Revolutionary steady rest

with innovative technology

Extra compact design with smallest outside dimensions

Large clamping range

Integrated coolant flush

Highest repeatability and centering accuracy

Linear stroke control

KNCS-matic

-

KNCS-matic: Quick jaw change

- automaticAutomatic quick jaw change

Ø 210 - 630 mm

Fully automatic set up with robot for

automatical machine

Standard KNCS-N jaws can be used

3 jaws