- Offer Profile

- For more than 55 years, the ProMinent Group has been a manufacturer of components and systems in the field of fluid metering as well as a reliable solution partner for water treatment. The Group is headquartered in Heidelberg, Germany. More than 2,600 employees in about 50 own sales, production and service companies as well as representations guarantee service and availability in more than 100 countries all over the world.

Chemical Transfer Pumps Chemical Transfer Pumps

-

On the move

ProMinent chemical transfer pumps are used to pump liquids from container A to container B. The media may have a wide range of different chemical properties, so the pumps need different functional principles. ProMinent engineers work hard to make sure that liquid and pump are fully compatible. They approach every application with the same ProMinent standards of maximum diligence and quality.

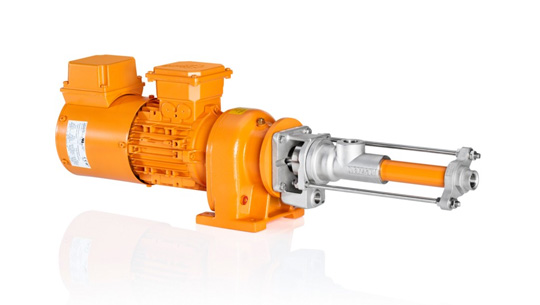

Spectra Progressive Cavity Pumps

-

Capacity range 2.4 – 12,000 l/h, 12 – 3 bar

The eccentric screw pump Spectra meters liquid polyelectrolytes in concentrated and dilute form. It can be used, for example, in waste water treatment or sludge dewatering.Your benefits

- Low-pulsation pumping

- Feed rate is proportional to the speed

- Reversible pumping direction

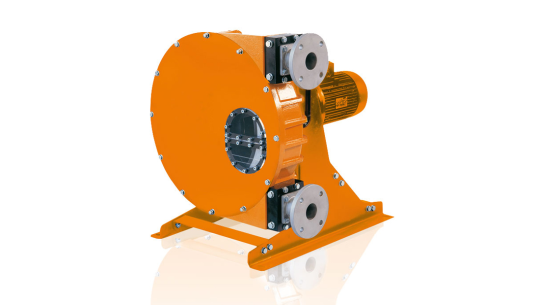

von Taine® Centrifugal Pumps

-

Capacity range up to 22,500 l/h, discharge lift up to 23.5 mWC

The solenoid-coupled centrifugal pump vonTaine® for the pumping of liquid media works safely and reliably: liquid media are pumped leak-free.Your benefits

- Safe and reliable: Leak-free pumping of liquid chemicals

- Coupling between motor and impeller via magnetic coupling

DULCO®Trans Barrel Pumps

-

Pump capacity according to size 900, 2,800 or 3,750 l/h

The application range of the DULCO®Trans depends on the chemical resistance of the materials used.Your benefits

- Reliable pumping of liquid chemicals

- Pump sets available for different delivery containers

- Pump nozzle for convenient filling of liquids

- Undervoltage trigger prevents unintentional start-up after an interruption to the operating voltage.

- The overcurrent safety switch prevents overloading of the motor.

Duodos Air Operated Diaphragm Pump

-

Capacity range up to 6,700 l/h, discharge lift up to 70 mWC

Air-operated Diaphragm Pump Duodos for pumping liquid media.Your benefits

- No electrical components are required because the pumps are air-operated

- Duodos pumps are run-dry safe and self-priming

Metering Pumps

-

How do metering pumps work?

Most metering pumps are oscillating displacement pumps. An exactly defined volume of liquid is drawn into the displacement body on the reciprocal stroke and forced into the metering line on the compression stroke. The pump settings can be changed to achieve consistently accurate metering.

Microprocessor technology since 1988

The accurate control of the pumps is made possible by microprocessor technology. Sophisticated monitoring functions ensure reliability in operation and minimum chemical consumption and optimum disinfection. Interfaces integrate the pumps into a fully automated process.

Over one million of our pumps are in use all over the globe, delivering reliable, accurate performance under the toughest conditions. Our proven design principles guarantee a high standard of quality and precision.

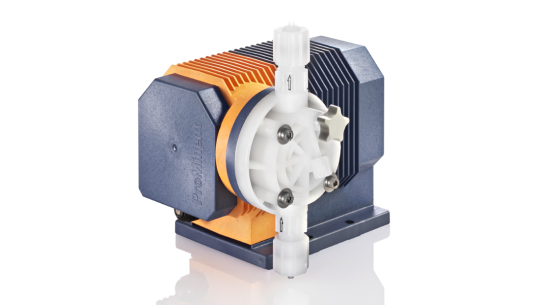

Solenoid Driven Metering Pumps

-

Solenoid diaphragm metering pumps are available in capacities ranging from 0.74 to 75 l/h at a back pressure of 16 to 2 bar. To be able to meter almost any liquid chemicals, ProMinent uses a very extensive range of materials.

Where they are used

- General: Chemical metering up to 75 l/h

- Potable water treatment: Metering of disinfectants

- Cooling circuits: Metering of corrosion inhibitors and biocides

- Waste water treatment: Metering of flocculants

- Paper industry: Metering of additives

- Plastics production: Metering of additives

What are the advantages?

Because there is only one moving part, the drive is virtually wear-free. The pump requires no lubricated bearings or shafts; the maintenance and repair costs are therefore very low. The continuous running characteristics are excellent.

Solenoid-Driven Metering Pump gamma/ XL

-

Capacity range 8 – 80 l/h, 25 – 2 bar

The gamma/ XL is a smart, connectible solenoid-driven metering pump that is setting new standards in terms of productivity, reliability and cost-effectiveness.Your benefits

- Simple adjustment of the capacity directly in l/h or in gph

- Integrated pressure measurement and display for greater safety during commissioning and in the process

- Bluetooth and Wi-Fi connection for the simple configuration and call-up of process data (optional)

- Capacity adjustment range 1:40,000

- Direct input of the required final concentration with volume-proportional metering tasks in concentration mode

- Virtually wear-free solenoid drive, overload-proof and economical

Solenoid Driven Metering Pump Beta®

-

Capacity range 0.74 – 32 l/h, 25 – 2 bar

All-purpose solenoid metering pump for metering liquid media in water treatment and chemical processes: Solenoid driven metering pump Beta®. Cost-effective, overload-proof, adaptable to existing signal transducers.Your benefits

- Simple adjustment of metering capacity via stroke rate and stroke length

- Adaptation to existing signal transducers by external control via potential-free contacts with pulse step-up and step-down

- Suitable for use with almost all liquid chemicals thanks to the available material combinations: PP, PVDF, clear acrylic, PTFE and stainless steel

- Self-bleeding dosing head design in clear acrylic/PVC and PP

- Virtually wear-free solenoid drive: economical and overload-proof

- Economical operation with up to 50% energy-savings, thanks to higher pump efficiency

Solenoid Driven Metering Pump gamma/ X

-

Capacity range 1 ml/h – 45 l/h, 25 – 2 barnew

The solenoid diaphragm metering pump gamma incorporates a wealth of eXcellent ingenuity! With integrated pressure measurement, it ensures the smooth running of your metering process. The gamma/X is ideal for all metering work involving liquid media.Your benefits

- Virtually wear-free solenoid drive, overload-proof and economical

- Suitable for continuous micro-metering from 1 ml/h thanks to the regulated solenoid drive

- Simple adjustment of the capacity directly in l/h

- Direct input of required final concentration in volume-proportional metering tasks

- Detection of hydraulic malfunctions or blocked discharge lines ensures smooth process

- Integrated pressure measurement and display for greater safety during commissioning and in the process

Solenoid Driven Metering Pump delta®

-

Capacity range 7.5 – 75 l/h, 25 – 2 bar

A high-end diaphragm metering pump: The solenoid driven metering pump delta ® is the first of its kind to have a regulated solenoid drive. Virtually wear-free, extremely economical and with a self-bleeding dosing head design.Your benefits

- Adjustment of the capacity directly in l/h

- Adaptation to existing signal transducers by external control via potential-free contacts with pulse step-up and step-down

- External control via 0/4 – 20 mA standard signal with adjustable assignment of signal value to stroke rate

- Organise work processes conveniently with the optional process timer. The alternative to timers or PLCs.

- Optional PROFIBUS® interface for connection to process control systems

- Suitable for use with almost all liquid chemicals, thanks to the available material combinations PVDF, clear acrylic and stainless steel

Motor Driven Metering Pumps

-

It's all thanks to the electric motor

Motor driven metering pumps need to be robust, reliable and able to run on their own without supervision. Metering pumps with mechanically actuated diaphragms can be used almost universally in low pressure ranges. And what about servicing? Minimal. Accuracy? Uncompromising. Value for money? The best.

Well adjusted

The stroke length and stroke rate – in this case the motor speed – can be adjusted to alter the capacity of this pump. The rotation of the electric motor is stepped down by a worm gear and converted into a linear stroke movement by a cam. The slide rod transfers this stroke movement to the diaphragm in the dosing head. Two non-return valves prevent the feed chemical from flowing back during pumping.

The motor driven metering pumps can handle the following substances:

- Chemicals up to over 1,000 l/h

- Disinfectants in potable water treatment

- Disinfectants in cooling circuits

- Flocculants in waste water treatment

- Additives in the paper industry

- Additives in plastic manufacturing

Impressive benefits

The pumps offer a very wide performance range. They also offer extremely accurate metering even under fluctuating pressure conditions (rigid characteristic curve). This results in reduced chemical consumption and precise process control.

Need a higher performance class? These pumps always deliver robust, low-cost power. They are also flexible: they can be controlled via the stroke length and motor speed, allowing them to be seamlessly integrated and/or retrofitted in automated processes. Energy consumption depends on the power required, not the other way round. And lastly, specially designed metering profiles allow optimum metering results.

Motor-Driven Metering Pump Sigma X Control Type – Sigma/ 1 - S1Cb

-

Capacity range S1Cb: 21 – 117 l/h, 12 – 4 bar

The Sigma control type is a smart motor-driven metering pump that is setting new standards in terms of productivity, reliability and safety.The new Sigma X range – reliable, smart and connectible

The Sigma X diaphragm metering pump covers a capacity range of 21 to 1,040 l/h in versions S1Cb, S2Cb and S3Cb. Its patented multi-layer safety diaphragm guarantees maximum process reliability. Efficient protection of the power end from overloading by means of an integral frequency converter with microprocessor control(ler).

One highlight is the standardised operating concept with click wheel and 4 additional operating keys on a removable operating unit. A large illuminated LCD and a 3-LED display for operating, warning and error messages, visible from all sides, offers additional operating convenience.

The Sigma, like all smart ProMinent metering pumps, can be flexibly connected to various bus systems.

It has a large adjustment range thanks to a combination of frequency and stroke length adjustment. The pump works with high precision across the entire frequency range. Accurate and complication-free metering of viscous and gaseous media by adjustment of the movement profile.

Operating statuses are simply remotely transmitted via an additional output or relay module. A built-in timer, included as standard, controls time-dependent metering cycles.

Relevant spare parts can be shown in the display. The integral log book significantly improves process management, optimisation and troubleshooting.Your benefits

- Safe: In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling.

- Integrated relief valve protects the pump against overloading and reliable operation by means of a bleed option during the metering process.

- External control is scalable via potential-free contacts with pulse step-up and step-down, batch mode or via a 0/4-20 mA standard signal.

- Flexibly connectible: Connection to process management systems via integral PROFIBUS®, CANopen interface.

- Integral log book saves up to 300 events and simplifies troubleshooting and analysis of the cause.

Motor-Driven Metering Pump Sigma X Control Type – Sigma/ 2 - S2Cb

-

Capacity range S2Cb: 61 – 353 l/h, 16 – 4 bar

The Sigma control type is a smart motor-driven metering pump that is setting new standards in terms of productivity, reliability and safety.The new Sigma X range – reliable, smart and connectible

The Sigma X diaphragm metering pump covers a capacity range of 21 to 1,040 l/h in versions S1Cb, S2Cb and S3Cb. Its patented multi-layer safety diaphragm guarantees maximum process reliability. Efficient protection of the power end from overloading by means of an integral frequency converter with microprocessor control(ler).

One highlight is the standardised operating concept with click wheel and 4 additional operating keys on a removable operating unit. A large illuminated LCD and a 3-LED display for operating, warning and error messages, visible from all sides, offers additional operating convenience.

The Sigma, like all smart ProMinent metering pumps, can be flexibly connected to various bus systems.

It has a large adjustment range thanks to a combination of frequency and stroke length adjustment. The pump works with high precision across the entire frequency range. Accurate and complication-free metering of viscous and gaseous media by adjustment of the movement profile.

Operating statuses are simply remotely transmitted via an additional output or relay module. A built-in timer, included as standard, controls time-dependent metering cycles.

Relevant spare parts can be shown in the display. The integral log book significantly improves process management, optimisation and troubleshooting.Your benefits

- Safe: In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling.

- Integrated overload shut-down in the pump control to protect the pump from overloading and thus significantly reduce pressure surges caused by blockages.

- External control is scalable via potential-free contacts with pulse step-up and step-down, batch mode or via a 0/4-20 mA standard signal.

- Flexibly connectible: Connection to process management systems via integral PROFIBUS®, CANopen interface.

- Integral log book saves up to 300 events and simplifies troubleshooting and analysis of the cause.

Motor-Driven Metering Pump Sigma X Control Type – Sigma/ 3 - S3Cb

-

Capacity range S3Cb: 182 – 1,040 l/h, 12 – 4 bar

The Sigma control type is a smart motor-driven metering pump that is setting new standards in terms of productivity, reliability and safety.The new Sigma X range – reliable, smart and connectible

The Sigma X diaphragm metering pump covers a capacity range of 21 to 1,040 l/h in versions S1Cb, S2Cb and S3Cb. Its patented multi-layer safety diaphragm guarantees maximum process reliability. Efficient protection of the power end from overloading by means of an integral frequency converter with microprocessor control(ler).

One highlight is the standardised operating concept with click wheel and 4 additional operating keys on a removable operating unit. A large illuminated LCD and a 3-LED display for operating, warning and error messages, visible from all sides, offers additional operating convenience.

The Sigma, like all smart ProMinent metering pumps, can be flexibly connected to various bus systems.

It has a large adjustment range thanks to a combination of frequency and stroke length adjustment. The pump works with high precision across the entire frequency range. Accurate and complication-free metering of viscous and gaseous media by adjustment of the movement profile.

Operating statuses are simply remotely transmitted via an additional output or relay module. A built-in timer, included as standard, controls time-dependent metering cycles.

Relevant spare parts can be shown in the display. The integral log book significantly improves process management, optimisation and troubleshooting.Your benefits

Safe: In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling.

Integrated relief valve protects the pump against overloading and reliable operation by means of a bleed option during the metering process.

External control is scalable via potential-free contacts with pulse step-up and step-down, batch mode or via a 0/4-20 mA standard signal.

Flexibly connectible: Connection to process management systems via integral PROFIBUS®, CANopen interface.

Integral log book saves up to 300 events and simplifies troubleshooting and analysis of the cause.

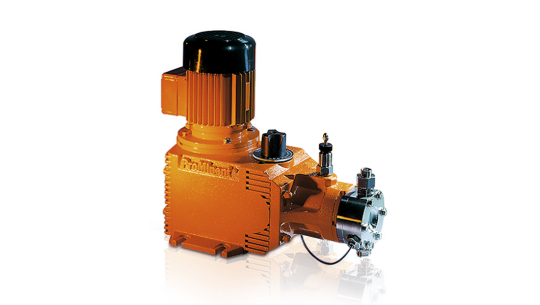

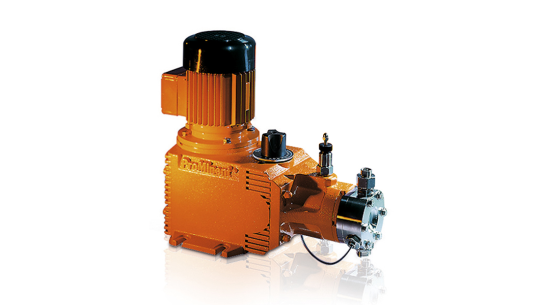

Motor Driven Metering Pump alpha

-

Capacity range 1.0 – 30.6 l/h, 10 – 2 bar

The motor-driven metering pump alpha is the metering pump for liquid media and the optimum solution for simple applications. Robust, low-noise, chemical-resistant, with precise metering and good suction capacity.Your benefits

- Precise metering and good suction capacity by soft controlled suction and compression strokes

- Tough plastic housing – shock-proof and chemical-resistant

- Suitable for higher viscosity media, thanks to spring-loaded valves

- Low-noise operation

Motor Driven Metering Pump Sigma/ 1 (Control Type)

-

Capacity range 17 – 117 l/h, 12 – 4 bar

The Sigma / 1 Control can be used flexibly as an extremely robust motor-driven diaphragm metering pump. Excellent process safety and reliability is guaranteed with the patented multi-layer safety diaphragm. Highlights include removable control unit, adjustable metering profiles, as well as a variety of power end and control configurations.Your benefits

Excellent process safety and reliability

- In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling

- Integrated relief valve protects the pump against overloading and bleed option during the suction process ensures reliable operation

- Metering reproducibility is better than ± 2% with a 30-100% stroke length adjustment range under certain defined conditions and with proper installation.

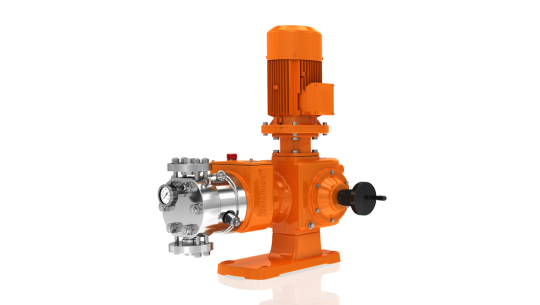

Motor Driven Metering Pump Sigma/ 1 (Basic Type)

-

Capacity range 17 – 144 l/h, 12 – 4 bar

The Sigma/ 1 Basic is an extremely robust motor-driven metering pump with patented multi-layer safety diaphragm for excellent process safety. It offers a wide range of power end designs, such as three-phase or 1-phase AC motors, even for Exe and Exde areas with ATEX certification.Your benefits

Excellent process safety and reliability:

- In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling

- Integrated relief valve protects the pump against overloading

- Reliable operation by bleed option during the suction process

Motor Driven Metering Pump Sigma/ 2 (Control Type)

-

Capacity range 61 – 353 l/h, 16 – 4 bar

The Sigma/ 2 Control is a robust motor-driven diaphragm metering pump with a patented multi-layer safety diaphragm for outstanding process safety and reliability. The integrated automatic overload shut-down offers further protection for the pump. Removable operating unit and adjustable metering profiles enable the versatile use of this pump.Your benefits

Excellent process safety and reliability:

- In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling

- Automatic, integrated overload shutdown to protect the pump and bleed option during the suction process to ensure reliable operation

Motor Driven Metering Pump Sigma/ 2 (BasicType)

-

Capacity range 50 – 420 l/h, 16 – 4 bar

Robust motor-driven diaphragm metering pumps, like the Sigma/ 2 Basic guarantee excellent process reliability with their patented multi-layer safety diaphragm. The diaphragm metering pump offers a wide range of power end versions, even for Exe and Exde areas with ATEX certification.The robust pump for safe and reliable use.

The Sigma/ 2 diaphragm metering pump together with pumps of type Sigma/ 1 and Sigma/ 3 represent an integrated product range. They cover the capacity range from 17 to 1,030 l/h, with a consistent operating concept, control concept and spare parts management. A wide range of drive versions is available, including some for use in Exe and Exde areas with ATEX certification.

Your benefits

Excellent process safety and reliability:

- In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling

- Integrated relief valve protects the pump against overloading

- Reliable operation by bleed option during the suction process

Flexible adaptation to the process:

- The entire Sigma product range is available as standard in a "Physiologically safe in respect of wetted materials" design.

- Metering pumps with electro-polished stainless steel metering head and EHEDG certification enable them to be used in hygienically challenging applications

- Wide range of power end versions, also for use in Exe and Exde areas and different flange designs for the use of customised motors

Motor Driven Metering Pump Sigma/ 3 (Control Type)

-

Capacity range 182 – 1,040 l/h, 12 – 4 bar

The motor-driven diaphragm metering pump Sigma/ 3 Control guarantees excellent process reliability, thanks to its patented multi-layer safety diaphragm. Intelligent features, such as removable operating unit and adjustable metering profiles, as well as a variety of power end and control configurations, enable the versatile use of this pump.Your benefits

Excellent process safety and reliability:

- In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling

- Integrated relief valve protects the pump against overloading and bleed option during the suction process ensures reliable operation

Motor Driven Metering Pump Sigma/ 3 (Basic Type)

-

Capacity range 146 – 1,030 l/h, 12 – 4 bar

The patented multi-layer safety diaphragm for excellent process safety and reliability is just one feature of the extremely robust motor-driven diaphragm metering pump Sigma/3 Basic. It also offers a wide range of power end versions, such as three-phase or 1-phase AC motors, even for Exe and Exde areas with ATEX certification.Your benefits

Excellent process safety and reliability:

- In the event of an accident, the feed chemical does not escape to the outside nor into the pump's power end, thanks to the patented multi-layer safety diaphragm with optical (optionally electric) signalling

- Integrated relief valve protects the pump against overloading

- Reliable operation by bleed option during the suction process

Motor Driven Metering Pump Vario C

-

apacity range 8 – 76 l/h, 10 – 4 bar

The motor-driven metering pump Vario C delivers a high level of process quality for continuous metering within simple metering tasks. It can be used, for example, in the metering of additives or flocculants in chemical metering.Your benefits

- Excellent suction capacity, gentle metering stroke and consistently precise metering

- Excellent process quality: Metering reproducibility is better than ± 2% within the stroke length adjustment range of 30 to 100%

- Flexible adjustment of the pump capacity by means of the stroke length in 1% increments

- Fibreglass-reinforced plastic housing

- Good adaptation to the specific application, thanks to 4 different gear reduction ratios and 2 sizes of liquid ends in 4 material designs

- Power end optionally available with three-phase or single-phase AC motor

Pneumatic Metering Pumps

-

Goodbye to electrical components

The pneumatic diaphragm metering pump is used wherever there is no available electrical power. The compression stroke is provided by compressed air applied to a diaphragm, which drives the PTFE-coated metering diaphragm. The suction stroke is provided by a spring-loaded force. The pump capacity is determined by the stroke length and stroke rate. Typical applications include animal feed treatment, paint spraying and car wash systems and fertiliser metering in horticulture.

Why we love it

When there is no available electrical supply voltage, our air-driven pump provides an excellent alternative. It achieves stroke rates of up to 180 strokes/min. Its spring-loaded valves are also suitable for higher-viscosity media, making it a very versatile solution. It is available in PVDF and stainless steel.

Pneumatic Metering Pump Pneumados

-

Capacity range 0.76 – 16.7 l/h, 16 – 2 bar

The metering pump Pneumados has a pneumatic power end and can be used in places without electrical supply voltage, with suction stroke performed by spring force.Your benefits

- No electrical supply voltage needed

- Material version PVDF and stainless steel

- Stroke rate of up to 180 strokes/min

- Spring-loaded valves for higher-viscosity media

Precision Plunger Metering Pumps

-

The metering pump with finesse

Continuous, highly precise and safe metering in the microlitre range: with the latest generation, the ProMinent precision plunger metering pump. It has an output range of 150 - 1500 ml/h at 60 - 20 bar. Even single stroke metering up to 1 μl/stroke can be delivered. The stroke rate can be infinitely adjusted from 1 stroke/h to 100 strokes/min.

In its element

This pump is ideal in situations where very small volumes of liquid (from around 0.02 ml/h) need to be continuously metered, for example in laboratories or the processing industry. Work processes can also be organised with the ProMinent process timer, the convenient alternative to timers or PLCs. It is also possible to set up a PROFIBUS® interface for connection to process control systems. The only thing our engineers expect to be overwhelmed with is curious questions.

Pneumatic Metering Pump Pneumados

-

Capacity range 150 – 1,500 ml/h, 60 – 20 bar

The precision plunger metering pump mikro delta® meters reliably, ultra-accurately and constantly in the microlitre range – one of the latest generation of solenoid metering pumps. Higher pressures can be achieved thanks to half the stroke length and double the stroke rate compared to the previous model.Your benefits

- Ideally suited for continuous micro-metering from approx. 0.2 l/h

- Adaptation to existing signal transducers by external control via potential-free contacts with pulse step-up and step-down

- External control via 0/4 – 20 mA standard signal with adjustable assignment of signal value to stroke rate

- Organise work processes conveniently with the optional process timer - the alternative to timers or PLC

- Optional PROFIBUS® interface for connection to process control systems

- Virtually wear-free solenoid drive: Overload-proof and cost-effective

Process Metering Pumps

-

Zero compromise

There is no room for compromise in high-end applications in the petrochemical and oil and gas industries. Risks must be eliminated when metering toxic, corrosive and flammable liquids. Reliable metering pumps need to be able to withstand very high pressure levels and extreme temperatures. What could be a more obvious solution for very challenging applications than ProMinent cutting-edge technology?

Diaphragm Metering Pumps

-

Not just sealed, hermetically sealed!

Hermetically sealed metering units and resistant materials allow ProMinent diaphragm process metering pumps to convey aggressive media with ease. But that's not all. Maintenance-free and fault-free operation also depends on the quality of the diaphragm, which is why ProMinent always ensures that its products are equipped with extremely durable diaphragms.

Tried-and-tested combination

A strong diaphragm, sealed metering units and resistant materials make a very useful combination in oil/gas production (onshore/offshore), refineries, and the chemical and petrochemical, pharmaceutical, cosmetic and food production industries. In the process industry, ProMinent special metering pumps are used.

Practical benefits

The micrometre adjustment dial for the stroke length allows the operator to make precise adjustments and achieve high reproducibility. Operation remains reliable even during fluctuations in mains voltage thanks to compensation. Different control types make easy process integration possible. The dosing head is self-bleeding, which also makes it suitable for gaseous media.

Keep moving

ProMinent always holds a wide range of pump accessories in stock. Our principle is that ProMinent pumps are extendable, flexibly adaptable and modular in design. The pump should fit your requirements, not the other way round.

Diaphragm Metering Pump Makro/ 5

-

Capacity range of single pump: 1,540 – 4,000 l/h, 4 bar

The diaphragm metering pump Makro/ 5 is used to meter reactants and catalysts in the chemical industry. Thanks to its modular construction, it can adapt outstandingly to the actual requirements of each application.Your benefits

Process reliability:

- Metering reproducibility is better than ± 2% within the 30-100% stroke length range under defined conditions and with correct installation.

Diaphragm Metering Pump Makro TZ

-

Capacity range of single pump: 260 – 2,100 l/h, 12 – 4 bar

The modular construction of the diaphragm metering pump Makro TZ with adjustable eccentric drive mechanism and mechanically deflected multi-layer safety diaphragm makes it wonderfully adaptable to the capacity requirements of the respective application.Your benefits

Excellent process safety and reliability:

- Patented multi-layer safety diaphragm with integral diaphragm rupture warning system

- Metering reproducibility is better than ± 2% within the 30 – 100% stroke length range under defined conditions and with correct installation

Diaphragm Metering Pump ProMinent EXtronic®

-

Capacity range of single pump: 0.19 – 60 l/h, 10 – 1.5 bar

The diaphragm metering pump Extronic® is perfectly suited for the sensitive use of liquid media in facilities with an explosive gas atmosphere as well as for mines at risk of firedamp, as it is approved in compliance with the EC EX Regulation 94/9/EC (ATEX).Your benefits

Optimum adaptation for use in areas at risk from explosion

- ATEX-compliant in line with EExd IIC T6 and EExd I/IIC T6

- Excellent operating and functional reliability by a microprocessor controller, which compensates for fluctuations of mains voltage and automatically switches from 50 to 60 Hz operation

- Broad range of applications with an operating voltage of 500 V, 230 V and 115 V

- Ease of integration into processes thanks to the range of control types (internal, external contact, analogue)

- Also suitable for gaseous media, thanks to self-bleeding head

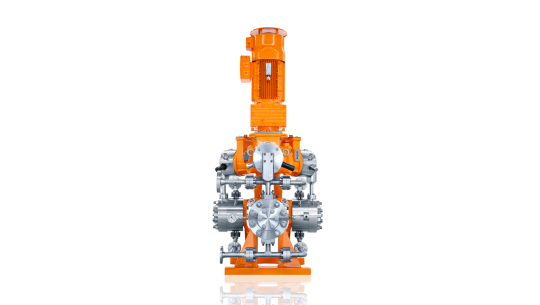

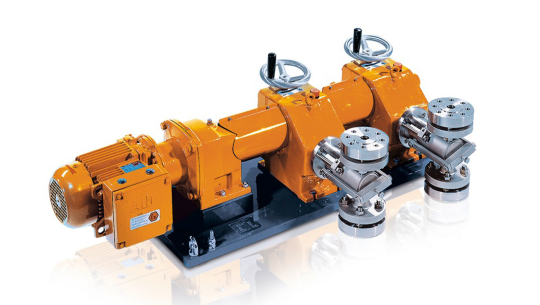

Diaphragm Process Pump TriPower®

-

Capacity range 4 – 38 m3/h, 415 – 50 bar

The process diaphragm pump TriPower® is perfect for use in the oil/gas industry or in the chemical industry. It is compact yet high-performance and has a multi-layer safety diaphragm. Its compact design enables it to be installed in the smallest space.Your benefits

Excellent process safety and reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve protects against overloading

- Safe, leak-free metering, even with aggressive, corrosive and flammable media.

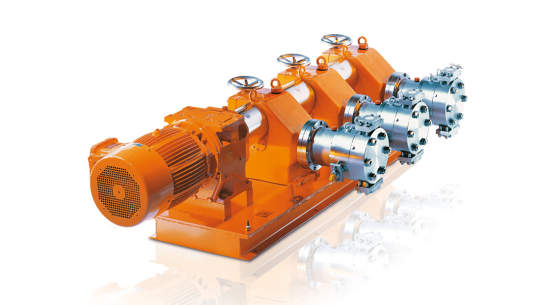

Diaphragm Process Pump Zentriplex

-

Capacity range 424 – 8,000 l/h, 367 – 36 bar

The Zentriplex guarantees excellent performance and provides outstanding efficiency as an oscillating triplex process diaphragm pump, with an extremely small footprint thanks to the space-saving arrangement of the pump and drive unit. It also stands out on account of its efficiency, as minimal material and labour are required.Your benefits

Excellent conservation of resources:

- Excellent energy efficiency.

- Diaphragm replacement without dismantling the suction and discharge lines ensures cost-effective maintenance of the pump

- Low noise emissions

- Very quiet thanks to complete balancing of masses

- Only one connection required by the customer. Collective discharge and suction lines are integrated in the pump

- Low flow rate pulsation

Hydraulic Diaphragm Metering Pumps

-

Pressure and back pressure

High pressures are no problem in metering systems as long as there is something to counter them. ProMinent hydraulic diaphragm metering pumps therefore use a hydraulic fluid to create back pressure. You will soon notice the benefits for the diaphragm.

Where ProMinent hydraulic technology is found:

- Oil and gas production (onshore/offshore)

- Refineries

- Chemical and petrochemical industry

- Pharmaceuticals & cosmetics

- Food production

- Packaging industry (bottling pumps)

Your benefits

It works, it works well, and it lasts for a long time. The hydraulic control is very precise and requires only minimal maintenance. The diaphragms are durable and provide consistently accurate metering. The technology also offers a high standard of safety. There is a pressure relief valve in the hydraulic end as protection against overload. The multi-layer diaphragms are equipped with a diaphragm rupture warning system as standard. So there is no risk of the feed chemicals mixing with the hydraulic oil.

Hydraulic Diaphragm Metering Pump Hydro/ 2

-

Capacity range of single pump: 3 – 72 l/h, 100 – 25 bar

As an extremely robust hydraulic diaphragm metering pump, the Hydro/ 2 meets the most exacting safety requirements. Its modular construction, with either one or two dosing heads, 4 gear ratios, 2 dosing head sizes and 3 dosing head materials, offers a very high degree of flexibility in terms of areas of application.Your benefits

Excellent process safety and reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- Metering reproducibility is better than ± 1% within the 20-100% stroke volume range under defined conditions and with proper installation

Hydraulic Diaphragm Metering Pump Hydro/ 3

-

Capacity range of single pump: 10 – 180 l/h, 100 – 25 bar

The Hydro/ 3 is an extremely robust hydraulic diaphragm metering pump. It meets the most exacting safety requirements. Its modular construction offers extremely good flexibility in terms of application, for example in the oil and gas industry.Your benefits

Excellent process safety and reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- Metering reproducibility is better than ± 1% within the 20-100% stroke volume range under defined conditions and with proper installation

Hydraulic Diaphragm Metering Pump Hydro/ 4

-

Capacity range of single pump: 130 – 1,450 l/h, 25 – 7 bar

The Hydro/ 4 is an extremely robust hydraulic diaphragm metering pump, which meets the most exacting safety requirements – it is equipped as standard with a pressure relief valve and PTFE multi-layer diaphragm with diaphragm rupture warning system. Its modular construction offers extremely good flexibility in terms of applications.Your benefits

Excellent process safety and reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- Metering reproducibility is better than ± 1% in the 20-100% stroke volume range under defined conditions and with proper installation.

Hydraulic Diaphragm Metering Pump Makro/ 5

-

Capacity range of single pump: 450 – 6,108 l/h, 25 – 6 bar

The robust hydraulic diaphragm metering pump Makro/ 5 guarantees outstanding process reliability. Its modular construction offers extremely good flexibility and a large range of power end versions are available.Your benefits

Excellent process safety and reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- Metering reproducibility is better than ± 1% within the 10-100% stroke length range under defined conditions and with correct installation.

Hydraulic Diaphragm Metering Pump Orlita® Evolution 1

-

Capacity range of single pump: 3 – 355 l/h, 400 – 12 barnew

The Orlita® Evolution 1 meets the highest safety requirements as an extremely robust hydraulic diaphragm metering pump. It stands out, thanks to its PTFE multi-layer diaphragm with integral diaphragm rupture warning system and unique diaphragm position control. Its modular construction offers extremely good flexibility in terms of applications.Your benefits

Maximum process reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- The new diaphragm position control protects against operating faults (e. g. no damage in the event of a blockage on the suction or discharge side)

- Metering reproducibility is better than ± 1% within the 10 – 100% stroke length range under defined conditions and with correct installation

- Continuous bleeding of the hydraulic oil chamber ensures reliable operation

Hydraulic Diaphragm Metering Pump Orlita® Evolution 2

-

Capacity range of single pump: 6 – 900 l/h, 400 – 10 barnew

The Orlita® Evolution 2 meets the highest safety requirements as an extremely robust hydraulic diaphragm metering pump. It stands out, thanks to its PTFE multi-layer diaphragm with integral diaphragm rupture warning system and unique diaphragm position control.Your benefits

Maximum process reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- The new diaphragm position control protects against operating faults (e. g. no damage in the event of a blockage on the suction or discharge side)

- Metering reproducibility is better than ± 1% within the 10 – 100% stroke length range under defined conditions and with correct installation

- Continuous bleeding of the hydraulic oil chamber ensures reliable operation

Hydraulic Diaphragm Metering Pump Orlita® Evolution 3

-

Capacity range of single pump: 21 – 1,330 l/h, 400 – 18 barnew

The Orlita® Evolution 3 meets the highest safety requirements as an extremely robust hydraulic diaphragm metering pump. It stands out, thanks to its PTFE multi-layer diaphragm with integral diaphragm rupture warning system and unique diaphragm position control.Your benefits

Maximum process reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- The new diaphragm layer control protects against impermissible operating statuses (e.g. no damage in the event of a blockage on the suction or discharge side)

- Continuous bleeding of the oil chamber ensures reliable operation

Hydraulic Diaphragm Metering Pump Orlita® Evolution 4

- Capacity range of single pump: 55 – 7,400 l/h, 400 – 10 barnew

The Orlita® Evolution 4 meets the highest safety requirements as an extremely robust hydraulic diaphragm metering pump. It stands out, thanks to its PTFE multi-layer diaphragm with integral diaphragm rupture warning system and unique diaphragm position control.Your benefits

Maximum process reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning system

- Integral hydraulic relief valve

- The new diaphragm position control protects against operating faults (e. g. no damage in the event of a blockage on the suction or discharge side)

- Metering reproducibility is better than ± 1% within the 10 – 100% stroke length range under defined conditions and with correct installation

- Continuous bleeding of the hydraulic oil chamber ensures reliable operation

Hydraulic Diaphragm Metering Pump Orlita® MF

-

Capacity range of single pump: 0 – 13,000 l/h, 700 – 6 bar

The hydraulic diaphragm metering pump ORLITA® MF offers reliable capacities even under high pressure and has a modular construction, therefore has versatile uses. Thanks to its modular design, this pump is tailored to meet your requirements even at very high pump capacities.Your benefits

Excellent process safety and reliability:

- PTFE double diaphragm with integrated diaphragm rupture warning system ensures precise and low-wear operation despite high pressures

- The product chamber is hermetically separated from the hydraulic part

- Integrated hydraulic relief valve and automatic bleed valve for the hydraulic chamber

- Wear-free, valveless enforced anti-cavitation of the hydraulic leakage guarantees optimum dosing precision

- Cone valves for use as suction and/or discharge valves with minimal wear, good self-cleaning and low pressure loss (NPSHR)

Plunger Metering Pumps

-

Plungers stand for accurate metering

The heart of the liquid end in a plunger metering pump is a highly resistant piston made from coated stainless steel. As soon as the plunger is moved into the dosing head, the suction valve closes and the feed chemical flows out of the dosing head through a discharge valve. When the plunger moves in the opposite direction, the discharge valve closes due to the negative pressure in the dosing head. Fresh feed chemical flows through the suction valve into the dosing head.

The versatile solution for all industries

ProMinent plunger metering pumps can be found in oil and gas production (onshore/offshore), refineries, the chemical and petrochemical industry, the pharmaceutical, cosmetic and food production industries, and as bottling pumps in the packaging industry. Can't find your industry? Contact us and we'll find the right pump for your application.

Plunger Metering Pump Makro TZ

-

Capacity range of single pump: 8 – 1,141 l/h, 320 – 11 bar

The plunger metering pump Makro TZ impresses with its excellent process reliability, outstanding flexibility and its modular construction enables it to be outstandingly adapted to the performance requirements of the respective application.Your benefits

Process reliability:

- Metering reproducibility is better than ± 0.5 % within the 10 – 100% stroke length range under defined conditions and with correct installation

Plunger Metering Pump Makro/ 5

-

Capacity range of single pump: 38 – 6,014 l/h, 320 – 6 bar

The plunger metering pump Makro/ 5 can virtually be used throughout the low-pressure range and its modular construction enables it to be outstandingly adapted to the performance requirements of the respective application.Your benefits

Process reliability:

- Metering reproducibility is better than ± 0.5 % within the 10 – 100% stroke length range under defined conditions and with correct installation

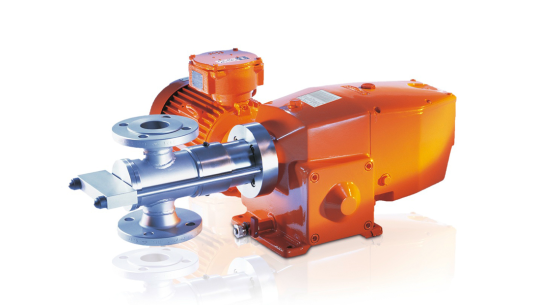

Plunger Metering Pump Meta

-

Capacity range 6 – 59 l/h, 216 – 52 bar

The extremely high-performance Meta is a plunger metering pump with the option of adjusting the pump capacity in 0.2% increments. It offers a wide range of power end versions, such as three-phase or 1-phase AC motors, even for Exe and Exde areas with ATEX certification.Your benefits

Excellent process safety and reliability:

- Metering reproducibility is better than ± 0.5 % within the 10 – 100% stroke length range under defined conditions and with correct installation

Plunger Metering Pump Orlita® DR

-

Capacity range of single pump: 0 – 4,000 l/h, 400 – 4 bar

The plunger metering pump Orlita® DR does not need valves and can be operated within a broad stroke rate range. It is therefore suitable for use with high-viscosity and extremely high-viscosity media of up to 106 mPas within a wide temperature range from -40 °C to 400 °C, for example in the food industry.Your benefits

Optimum adaptation to processes with high-viscosity and extremely high-viscosity media, even containing solid fractions:

- Low-wear and precise operation even at high pressures, thanks to the rotary plunger with abrasion-resistant / wear-resistant surface coating

- Valve-free operation guarantees a broad stroke rate range

- Wide range of uses: Operating pressure of up to 400 bar, temperature range of - 40 °C to + 400 °C

- Pump direction can be selected depending on the fitting position of the plunger

- A reverse suction effect is continuously adjustable by rotating the pump head around its longitudinal axis

- Power end configuration ideal for installation in any position (vertical or horizontal)

Plunger Metering Pump Orlita® PS

-

Capacity range of single pump: 0 – 37,000 l/h, 400 – 4 bar

The high-performance plunger metering pump ORLITA® PS enables precise pump capacities even at maximum pressure and temperatures of up to +400 °C. The ORLITA® PS pump has a modular construction and thus versatile uses.Your benefits

Flexible adaptation to the process:

- Precise capacity even at maximum pressure

- Metering reproducibility is better than ± 0.5 % within the 10-100% stroke length range under defined conditions and with correct installation.

- Cone valves for use as suction and/or discharge valves with minimal wear, good self-cleaning and low pressure loss (NPSHR)

- Excellent hydraulic efficiency

Plunger Metering Pump Sigma/ 2 (Basic Type)

-

Capacity range 2 – 76 l/h, 320 – 12 bar

The plunger metering pump Sigma/ 2 (Basic Type) is an extremely robust plunger metering pump with high-performance plunger and the option to adjust the pump capacity in 0.2% increments. It offers a wide range of power end versions, such as three-phase or 1-phase AC motors, even for Exe and Exde areas with ATEX certification.Your benefits

Excellent process safety and reliability:

- Metering reproducibility is better than ± 1% within the 10 – 100% stroke length range under defined conditions and with correct installation

Peristaltic Pumps

-

Our most adaptable pumps

Peristaltic pumps DULCO®flex are amongst the most adaptable pumps from ProMinent. They are suitable for an enormously wide pump capacity range. The smaller DF2 to DF4 types of pumps have been specially designed for metering work in swimming pools, hot tubs or spa and wellness zones. The large peristaltic pumps DFA to DFD are ideal for specific tasks, as well as for extremely high pump capacities and pressures in laboratories and in industry. All models follow a simple operating principle and are extremely safe and easy to use.

Peristaltic Pumps for higher capacity range

Hose pumps of the DULCO®flex DFAa series

-

Feed rates of up to 105 l/h at 2 bar

The peristaltic pump DULCO®flex DFAa (designed as a low-pressure pump) is suitable for metering the smallest volumes in laboratories.Your benefits

- Simple to operate

- Reversible pumping direction

- Hose materials suitable for various chemicals

- Simple and quick hose change

- Ideal for pumping pasty, high-viscosity, abrasive and gaseous media

- Self-priming

Hose pumps of the DULCO®flex DFBa series

-

Feed rates of up to 649 l/h at 8 bar

The peristaltic pump DULCO®flex DFBa is designed for low and medium pump capacities of up to 649 l/h at 8 bar.Your benefits

- Simple to operate

- Reversible pumping direction

- Hose materials suitable for various chemicals

- Simple and quick hose change

- Ideal for pumping pasty, high-viscosity, abrasive and gaseous media

- Self-priming

Hose pumps of the DULCO®flex DFCa series

-

Feed rates of up to 8,900 l/h at 8 bar

High pump capacities are not a problem with the peristaltic pump DULCO®flex DFCa. It is equipped with extra rollers and fabric-reinforced hoses for industrial use.Your benefits

- Simple to operate

- Reversible pumping direction

- Hose materials suitable for various chemicals

- Simple and quick hose change

- Ideal for pumping pasty, high-viscosity, abrasive and gaseous media

- Self-priming

Hose pumps of the DULCO®flex DFDa series

-

Feed rates of up to 15,000 l/h at 15 bar

The peristaltic pump DFDa is designed for maximum pump capacities and high pressures and is winning customers over with its noiselessness and long service life. It is fitted with shoes and fabric-reinforced hoses – perfect for industrial use.Your benefits

- Simple to operate

- Reversible pumping direction

- Hose materials suitable for various chemicals

- Simple and quick hose change

- Ideal for pumping pasty, high-viscosity, abrasive and gaseous media

- Self-priming

Peristalic Pumps for lower capacity range

Peristaltic Pump DULCO®flex DF2a

-

Capacity range 0.4 – 2.4 l/h at max. 1.5 bar back pressure

The peristaltic pump DULCO®flex DF2a meters chemicals functionally, cost-effectively and quietly – ideal for use in swimming pools, hot tubs, and in spa and wellness facilities.Your benefits

- Smooth inner wall reduces deposits.

- Hose materials: PharMed® or Viton®

- Virtually silent operation

- Simple handling

- Enhanced service life of the hose due to spring-loaded rollers, which keep the rolling pressure constant

- Robust and protected against spray water from all sides: Housing made of impact-resistant and chemical-resistant PPE

Perestaltic Pump DULCO®flex DF3a

- Capacity range 0.4 – 2.4 l/h at max. 1.5 bar back pressure

Fragrance metering in spa and wellness facilities: efficient and high-performance with the peristaltic pump DULCO®flex DF3a. They are used wherever small volumes of fragrances need to be metered.Your benefits

- Employees can therefore operate it quickly: It can be operated simply and reliably with language-neutral user guidance and programming via four buttons on the front

- Quietly operating, does not disturb the spa and wellness experience: Low-noise synchronous motor

- Ideal for retrofitting: Simple to integrate into existing systems

- Efficient operation by economical operation: "Meters only when needed"

DULCO®flex DF4a Peristaltic Pump for Flocculant Metering

-

Capacity range 1.5 – 12 l/h, 4 – 2 bar

The peristaltic pump DULCO®flex DF4a for metering flocculants and activated charcoal treats water precisely and accurately. It is ideal for use in swimming pools, hot tubs or spa and wellness facilities. An operating pressure up to 4 bar is possible.Your benefits

- Language-neutral user navigation

- Continuous adjustment of capacity

- Hose materials in PharMed® and Tygon®

- Full control, as the capacity is shown in l/h in the display

- Safe and reliable operation: Flow volume and concentration can be entered reproducibly

- Long service life: Spring-loaded rollers stabilise rolling pressure and reduce wear and tear on the hose

Disinfection Systems and Oxidation Systems

-

All the resources invested in technology research and development were well worth it, because when it comes to hygienically pure water, ProMaqua®products and systems are state-of-the-art.

Developing solutions, providing support

Starting from the huge range of available products, ProMinent experts assemble exactly the system that best supports the application. Our product offering extends from metering pumps for all capacity ranges through to measuring and control technology, membrane filtration systems and established disinfection processes. We deliver efficient, safe and high-performance complete solutions. And of course we also offer worldwide technical support.

Chlorine Dioxide Systems

-

Chlorine dioxide

This agent disinfects regardless of the pH. It has a very good sustained-release effect and remains active in the pipes for many hours to days. Chlorine dioxide can be used to treat entire water systems to combat legionella. Chlorine dioxide reliably breaks down biofilms in pipes and tanks.

Stable, safe, clean

Chlorine dioxide always has its full disinfectant effect because it does not react with ammonia or ammonium. By contrast, the chlorination of water can produce chlorophenols and other strongly smelling compounds. This is not the case with chlorine dioxide. There is also no formation of trihalomethanes (THM) or other chlorinated hydrocarbons.

Chlorine Dioxide System Bello Zon® CDEa

-

5-140 g/h chlorine dioxide. Max. flow at 0.2 ppm ClO2 metering is 700 m3/h

Chlorine dioxide system, which continuously produces ClO2 according to the acid/chlorite method with diluted chemicals. Extremely simple operation, clear construction, analogue control, manual control or via contacts.Your benefits

- Minimal training required thanks to extremely simple operation

- Minimal investment costs

- Short lead times

- Excellent operating safety

- Simple process integration

Chlorine Dioxide System Bello Zon® CDKc

-

8 – 12,000 g/h chlorine dioxide. Max. flow rate at 0.2 ppm ClO2 metering is 60,000 m3/h

Chlorine dioxide system for continuous production, metering and monitoring of chlorine dioxide with concentrated chemicals. Bello Zon® CDKc is a ready-to-use convenient system with integrated intrinsically safe pre-dilution station.Your benefits

- Cost saving through minimal acid consumption

- Cost-effective operation by the use of inexpensive concentrated output chemicals

- Efficient operation, thanks to production, metering and monitoring of ClO2 with just one system

- Maximum operating safety and purity of the CIO2 produced through the use of PVDF reactors

- Integrated measuring and control technology

- Perfect quality management, thanks to integrated storage of all operating parameters and measured values

Chlorine Dioxide System Bello Zon® CDLb with Multiple Points of Injection

-

0 – 120 g/h capacity with storage of up to 60 g of chlorine dioxide for peak metering. Max. flow rate at 0.2 ppm ClO2 metering capacity of 600 m3/h, up to 6 points of injection possible as standardnew

Flexible solutions for the production and metering of ClO2 adapted to our customer's tasks, requirements and anticipated pricing. Made-to-measure systems constructed from modules designed to work together. electrical components.Your benefits

- Very easy way to provide several points of injection according to requirements

- Cost-effective way to provide several points of injection

- Outstanding operating safety and reliability, thanks to intrinsically safe process control

- Ultra-simple process integration

Chlorine Dioxide System Bello Zon® CDLb

-

0 – 120 g/h capacity with storage of up to 60 g of chlorine dioxide for peak metering. Max. flow rate at 0.2 ppm ClO2 metering capacity of 600 m3/h

Chlorine dioxide system for production of a chlorine-free chlorine dioxide solution, especially suitable for multiple points of injection. Bello Zon® CDLb produces ClO2 discontinuously using the acid/chlorite process with diluted chemicals.Your benefits

- Reduced costs thanks to minimal use of chemicals

- Cost-effective way to provide several points of injection

- Quick ramp-up time after downtime thanks to long-term stability of chlorine dioxide solution

- Maximum output due to closed gas transport system

- Outstanding operating safety and reliability, thanks to intrinsically safe process control

- Ultra-simple process integration

Chlorine Dioxide System Bello Zon® CDVc

-

1 – 2,000 g/h chlorine dioxide. Max. flow at 0.2 ppm ClO2 metering is 10,000 m3/h

Chlorine dioxide system for monitoring and metering chlorine dioxide and diluted chemicals. Maximum output and safety due to special reactor concept. Bello Zon® CDVc can be easily and safely integrated into any water treatment process.Your benefits

- Efficient operation, thanks to production, metering and monitoring of ClO2 with just one system

- Maximum operating safety and purity of the CIO2 produced through the use of PVDF reactors and stroke length-monitored pumps

- No need for external control due to integrated measuring and control technology

- Perfect quality management, thanks to integrated storage of all operating parameters and measured values

- Automatic monitoring of operating parameters and maintenance intervals

- Simple and safe operation, thanks to clear navigation in plain text

Electrolysis Systems

-

No chemicals required

There is no need to transport chemicals. No need to store or handle hazardous substances. Instead, sophisticated systems use harmless sodium chloride – ordinary salt – to produce chlorine, hydrogen and sodium hydroxide. Which means good news for the environment.

It's really very simple

Electrolysis is an economically sensible and technically perfected alternative to the metering of sodium hypochlorite or other disinfectants. The chlorine can either be metered into the water directly as hypochlorous acid (HOCl) or temporarily stored with the sodium hydroxide in the form of sodium hypochlorite (NaOCl).

Reassuring to know

Disinfection with sodium chloride is completely safe. With ProMinent electrolysis systems you can confidently say goodbye to the storage, transport and handling of hazardous chemicals. You can generate chlorine and perform pH correction with a single system (CHLORINSITU® IV Plus/compact). ProMinent electrolysis systems are negative pressure systems, so they offer maximum operating reliability.

Electrolysis System CHLORINSITU® IIa

-

Output 60 – 300 g/h of chlorine

CHLORINSITU® IIa is a compact on-site electrolysis system for the production of a low-chlorate hypochlorite solution from sodium chloride and electrical energy. A key advantage is its simple process management and excellent system safety through integral ventilation.Electrolysis system CHLORINSITU® IIa with open cell electrolysis: improved efficiency through innovative design.

The new CHLORINSITU® IIa combines the proven and durable design of the open electrolysis

cell with an innovative design. An exceptional quality of hypochlorite solution is achieved when the salt and power output is increased. The special cell design thus reaches a chlorine concentration of 9 g/l in the product.

The chlorate content of the product is significantly below the limit value specified in EN 901.

All relevant system components are accommodated in a compact and space-saving housing. Integral hydrogen drainage enables the system to be installed without any need for specific ventilation requirements for the installation place (no ATEX).

The system is immediately ready for use, thanks to its plug-and-play concept. Operation of the electrolysis

system has been consciously kept simple.

Available scope of delivery:- Corrosion-proof housing with ventilation fan

- Control with multicoloured touch panel

- Remote maintenance module (optional)

- Salt dissolving tanks outside of the housing

- Integrated product tank (50 l)

- Diaphragm metering pump for the metering of the chlorine solution (optional)

- Integrated softener

- Diaphragm metering pump for the metering of a hypochlorite solution (optional)

Electrolysis System CHLORINSITU® III Compact

-

Output of 25 – 50 g sodium hypochlorite per hour

Generation of sodium hypochlorite in smaller amounts for smaller swimming pools: Electrolysis system CHLORINSITU® III Compact.Your benefits

- Sodium hypochlorite solution low in chloride and chlorate with a high chlorine concentration (25 g/l FAC)

- Minimal acid consumption for pH correction, making savings of up to 70 % possible

- Cost-effective operation thanks to the use of sodium chloride as an inexpensive raw material and minimal chemical consumption for pH adjustment

- Robust, simple technology

- Compact space-saving design, ready mounted on a wall panel

Electrolysis System CHLORINSITU® IV Compact

-

Output of 25 – 50 g ultra-pure active chlorine per hour

Generate ultra-pure chlorine gas using the vacuum method with electrolysis system CHLORINSITU® IV Compact. Cost-effective, robust and compact.Your benefits

- Chlorination and pH value adjustment in a single system

- Production and metering of ultra-pure hypochlorous acid

- Cost-effective operation thanks to the use of sodium chloride as an inexpensive raw material and no consumption of chemicals for pH correction

- Safe vacuum system technology

- Robust, simple technology

- Compact space-saving design, ready mounted on a wall panel

Electrolysis System CHLORINSITU® II

-

Output of 50 – 2,400 g sodium hypochlorite per hour

Electrolysis system CHLORINSITU® II: Robust, safe and economical system for areas where carry-over of sodium chloride into the water being treated is not a problem.Your benefits

- Robust, simple technology

- Safe system control with remote diagnosis by Remote Control Engineer

- Cost-effective operation thanks to the use of sodium chloride as an inexpensive raw material and lower chemical consumption for pH adjustment

- Compact, space-saving design

- Improved working conditions for operating personnel

- No risk of confusing dangerous chemical tanks

Electrolysis System CHLORINSITU® III

-

Output of 100 – 10,000 g sodium hypochlorite per hour

Need sodium hypochlorite that is high-purity or low-chloride and low-chlorate? The electrolysis system CHLORINSITU® III is the solution. Can be used for potable water, waste water, process water, swimming pool water and in cooling towers.Your benefits

- Sodium hypochlorite solution low in chloride and chlorate with a high chlorine concentration (25 g/l FAC)

- Minimal acid consumption for pH correction, making savings of up to 70 % possible

- Safe system control with remote diagnosis by Remote Control Engineer

- Excellent service life of the diaphragm cells, thanks to constant vacuum

- A frequency-controlled circulation pump maintains the vacuum constant in the enclosed anode area

- Maximum operating safety due to their design as negative pressure systems

Electrolysis System CHLORINSITU® V Plus

-

Output of 100 – 3,500 g ultra-pure active chlorine per hournew

Generation of active chlorine in combination with a sodium hypochlorite solution using the vacuum process with the electrolysis system CHLORINSITU® V Plus. Chlorination and pH value adjustment from a single system.Your benefits

- Chlorination and pH adjustment with a single system

- Exceedingly low chloride and chlorate content

- Reservoir of sodium hypochlorite solution to cover peak demand

- Production and metering of ultra-pure hypochlorous acid combined with sodium hypochlorite production

- Excellent service life of the diaphragm cells, thanks to constant vacuum

- Maximum operating safety due to their design as negative pressure systems

Electrolysis System CHLORINSITU® V

-

Output of 100 – 3,500 g ultra-pure active chlorine per hournew

Generate ultra-pure active chlorine using the vacuum method with electrolysis system CHLORINSITU® V. Suited to applications for metering hypochlorous acid and simultaneously correcting the pH value.Your benefits

- Chlorination and pH adjustment with a single system

- Exceedingly low chloride and chlorate content

- Production and metering of ultra-pure hypochlorous acid without temporary storage

- Safe system control with remote diagnosis by Remote Control Engineer

- Excellent service life of the diaphragm cells, thanks to constant vacuum

- A frequency-controlled circulation pump maintains the vacuum constant in the enclosed anode area

Ozone Systems

-

Powerful and effective

ProMinent ozone systems are normally used for the treatment of potable water, swimming pool water, water in the food and beverage industry, aquarium and pool water in zoos, and cooling and process water.

Disinfection and oxidation

The greatest advantage of ozonisation is that it produces no by-products. In water, ozone breaks down into oxygen again with a half-life of a few minutes. In potable water disinfection it is mainly used when oxidation is desired in addition to disinfection, allowing inorganic substances such as iron and manganese to be easily removed. In Germany, ozone is only permitted to be used for oxidation.

Ozone system OZONFILT® OZVb

-

Ozone capacity 10 – 70 g ozone/h

OZONFILT® OZVb is powerful and compact and is ideal for efficient ozone generation from compressed air in the output range of up to 70 g/h. The turnkey ozone system including mixing equipment offers everything you need for safe and seamless operation.Powerful and environmentally-friendly disinfection and oxidation

Ozone systems OZONFILT® OZVb are pressurised systems in which compressed air is fed into the ozone generator.

Ozone is generated from the oxygen content of the surrounding air, via a compressor and is inducted into the process based on demand. Ozone

can now be generated in values of up to 20 g/Nm3, safely and reliably in the many demanding environments and plant room locations globally. Ozone

concentrations within the water to be treated with values of between 3 and 12 ppm can be achieved using our coordinated mixing equipment with an efficiency of up to 95%.Your benefits

- Safe and seamless operation through continuous monitoring of all relevant operating data

- Simple, safe and reliable operation with process visualisation, thanks to large, colour and clear 4.3" touch panel

- Compact system with integral air treatment

- Turnkey complete system with perfectly coordinated mixing device including back pressure valve, vacuum breaker and static mixer

- Direct injection without injector system for up to 4 bar back pressure

- Low maintenance and operating costs, thanks to maintenance-free generator concept and virtually infinite service life

Ozone System OZONFILT® Compact OMVa

-

Ozone capacity 5 – 70 g ozone/h

The OZONFILT® Compact OMVa is a complete, ready-to-use ozone system. The components are perfectly coordinated to each other.Your benefits

- Excellent process reliability through the use of a pre-assembled, complete ozone treatment stage with perfectly matched components.

- Well-thought-out installation on a stainless steel frame for plug-and-play connection

- Modular construction which can still be customised

- Compression-proof ozone generator built in compliance with DIN 19627

- Destruction of residual ozone gas for the removal of traces of ozone gas

- Room air monitoring for traces of ozone gas via a gas detector with a sensor with long-term stability

Ozone System OZONFILT® OZMa

-

Ozone capacity 70 – 735 g ozone/h

OZONFILT® OZMa represents maximum operational safety with minimal operating costs. The ozone generator is maintenance-free and generates up to 735 g/h of ozone from compressed air or oxygen.Your benefits

- Economical: maintenance-free generator concept with virtually unlimited service life

- Up to 30% energy savings for air treatment, thanks to demand-led and self-optimising air drying compared with conventional air treatment.

- Automatic control of the operating gas depending on the ozone output, therefore reduced consumption of operating gas produced with intensive use of energy.

- High ozone concentration ensures optimum ozone solubility in water

- Direct injection without injector system at up to 2 bar back pressure

- Automatic ozone generation, virtually independent of fluctuations in main voltage and pressure

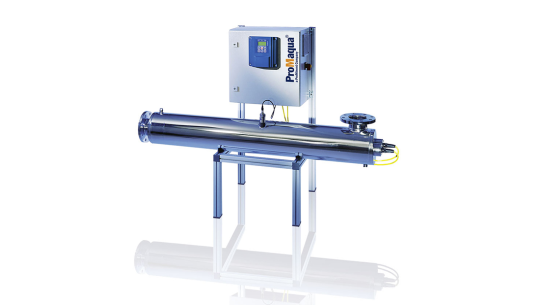

UV Systems

-

Gentle on people and the environment

UV radiation is a safe, chemical-free and reliable method of disinfection in modern water treatment. ProMinent Dulcodes® UV systems exploit the safety and reliability of UV disinfection in a wide range of applications. Scientific research and the many systems successfully in operation prove that UV is ideally suited to water disinfection.

Our hero: UV-C radiation

No one wants germs - and UV-C radiation in particular, with a wavelength ranging from 240 to 280 nm, attacks the vital DNA of the bacteria directly. The bacteria lose their reproduction capability and are destroyed. Even parasites, like Cryptosporidia or Giardia, which are extremely resistant to chemical disinfectants, are efficiently reduced.

The advantages of UV treatment

Immediate and safe disinfection without the addition of chemicals. This results in highly effective disinfection regardless of the pH value. No undesirable substances are formed. The odour and taste of the water are not impaired. There is no need to store and handle chemicals. No reaction vessel or reaction tanks are required. A ProMinent UV system takes up very little space and keeps investment and operating costs low while delivering exceptional reliability and performance.

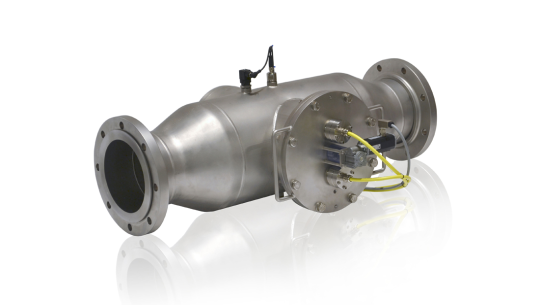

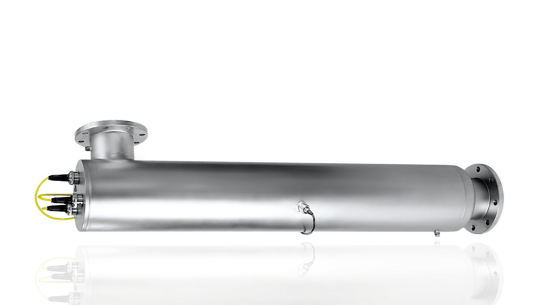

UV System Dulcodes LP

-

Flow up to 523 m³/h

The unique UV systems Dulcodes LP are synonymous with pioneering water treatment – efficient and free of chemicals.A world first: precise lamp dimming in seconds – even with varying flows and water temperatures.

Our patented Vario-Flux high-output lamps with dynamic lamp heating are used in the Dulcodes LP. Thanks to the unique combination of electronic ballast technology and the Vario-Flux lamps, they can be quickly and precisely dimmed over a broad power range of up to 50% of the nominal electrical power. This ensures automatic adjustment to varying flows and water temperatures at all times.

Efficiency even increases in dimmed mode, which has a particularly positive effect when the actual flow is below the maximum possible flow of the system.

The flow in the Dulcodes LP has been optimised in a reactor based on intensive computer simulation. At the same time the pressure loss is kept minimal. The resulting uniform radiation dose without over- or under-metering of a partial volumetric flow leads to minimal use of energy, a minimum number of lamps and significantly reduced life cycle costs.Your benefits

- UV system Dulcodes LP for a broad field of application for efficient, safe and chemical-free water disinfection

- Unique dynamic lamp heating adjusts the lamp output in seconds and provides for optimum disinfection even with rapidly varying flows and water temperatures

- Homogeneous UV dose, thanks to optimised flow characteristics in the reactor, guarantees maximum flow output with a minimum number of lamps and minimum pressure loss

- Reduced life cycle costs due to the long service life of Vario-Flux high-output lamps with low energy consumption and high UV output

- High flexibility thanks to vertical or horizontal installation and free choice of the flange position

- User-friendly and intuitive control for the display of operating statuses and adjustment of operating parameters

UV System Dulcodes A

-

Flow up to 739 m3/h new

The UV system Dulcodes A helps to ensure water quality. The UV system works energy-efficiently and cleanly based on continuously variable medium pressure lamps and can therefore automatically compensate for variations in the water quality or level of contamination.Your benefits

- Simple installation, thanks to the compact inline system, ensures minimal installation work and fast retrofitting

- Maximum flexibility when installing, thanks to the free choice of fitting position and direct installation in plastic pipes, as no UV radiation escapes from the reactor

- External power control via 0/4 - 20 mA standard signal for optimum adaptation of the system to changing operating conditions, such as flow fluctuations

- Automatic adjustment of the lamp output to a defined UV-C sensor signal with power increase to a raised, adjustable sensor signal via a digital input saves energy and extends the lamp service life.

- Unbeatable simple and quick maintenance: All maintenance work can be carried out quickly and conveniently from one side.

- Certified systems: NSF 50, CSA 22, UL508, comprehensively biodosimetrically validated to UVDGM 2006

UV System Dulcodes K

-

Flow up to 250 m3/h

Disinfection of saline sea water or thermal water without corrosion problems caused by the UV system Dulcodes K. The UV system consists of a reactor and a UV sensor made of highly UV-resistant plastic.Your benefits

- Reactor made of UV-stabilised high-density HD-PE, absolutely corrosion-free and temperature stable.

- Long-term salt water-resistant UVC sensor for monitoring the disinfection capacity, contamination of the lamp protection tubes, lamp ageing and water transmission.

- Highly efficient Opti Flux 290 W lamps provide maximum disinfection and flow rate with a minimum number of lamps.

- Ballasts with BUS interface for the gentle ignition and operation of the lamps

- The replacement of lamps is reduced to the absolute minimum.

- Low maintenance costs and low follow-on costs, as there are fewer, high-performance lamps featuring amalgam technology with an excellent service life of up to 14,000 hours.

UV System Dulcodes R

-

Flow up to 274 m3/h

UV system Dulcodes R for the disinfection of potable, process and swimming pool water. The system is used particularly when constituents, such as hardness, iron, manganese or organic substances, are present. Deposits are easily removed by the wiper mechanism even at maximum operating pressure without any need to interrupt operation.Your benefits

- Cleaning without interrupting operation: the manual wiper is easy to operate even when the system is pressurised. Thanks to their self-sharpening function, the wiper elements deliver maximum cleaning and have a long service life.

- Long-term stable UVC sensor for monitoring disinfection capacity, contamination of the lamp protection tubes, lamp ageing and water transmission

- Greater performance with fewer lamps: energy-efficient high-performance Opti-Flux 300 W lamps permit greater flow per lamp

- Longer maintenance cycles, reduced operating costs: 14,000 operating hours guaranteed (pro rata)

- Electronic ballasts for gentle ignition and lamp operation: replacement lamps are kept to a minimum.

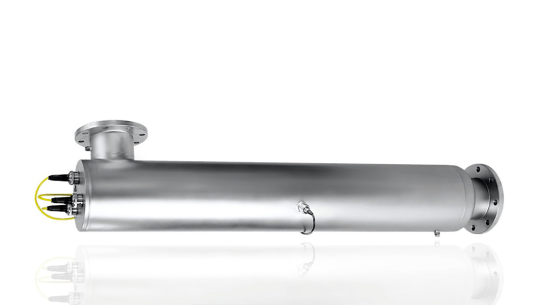

UV System Dulcodes S

-

Flow up to 569 m3/h

The UV system Dulcodes S for water treatment and disinfection in swimming pools. Combined chlorine is broken down and the typical swimming pool odour is eliminated: no more irritation for eyes, nose and skin. A manual stage switch permits adaptation to the required capacity requirement.Your benefits

- Simple installation, thanks to the compact inline system, ensures minimum installation costs and fast retrofitting.

- Maximum flexibility when installing, thanks to free choice of fitting position and direct installation in plastic pipes, as no UV radiation escapes from the reactor.

- Automatic switching on and off based on the chloramine value, for example used in conjunction with the DULCOMARIN® II.

- Unbeatable simple and quick maintenance: All maintenance work can be carried out quickly and conveniently from one side.

- Manual power control for optimum adaptation of the system to the respective capacity requirement (not for Dulcodes 1 x 0.65 and 1S).

- Manual or automatic wiper system for the efficient removal of deposits on the lamp protection tube. The wiper system can be easily retrofitted.

UV System Dulcodes W

-

Flow up to 600 m3/h

UV system Dulcodes W for the disinfection of pathogenic micro-organisms in potable, process or swimming pool water. Energy-efficient and excellent disinfection performance thanks to high-output lamps.Your benefits

- Compact system with excellent disinfection performance with minimum energy consumption. This is provided for by the hydraulically optimised reactor with low-pressure UV lamps arranged longitudinally to the flow.

- Long-term stable UVC sensor for monitoring disinfection capacity, contamination of the lamp protection tubes, lamp ageing and water transmission.

- Excellent output with fewer lamps. Energy-efficient high-performance High-Flux lamps up to 230 W permit greater flow per lamp.

- Operating costs reduced by longer maintenance cycles: guaranteed (pro rata) 10,000 operating hours.

- Electronic ballasts for the gentle ignition and operation of the lamps

UV System Dulcodes Z

-

Flow up to 230 m3/h

UV system Dulcodes Z for potable water treatment. Chemical-free disinfection, which conforms to all internationally established DVGW, ÖVGW and UVDGM standards. High-performance and energy-efficient high-output lamps.Your benefits

- DVGW and ÖVGW-certified, EPA and UVDGM-compliant

- Flexible use over a wide transmission and flow range by extended DVGW characteristic line certification.

- Minimum use of resources at maximum flow, thanks to uniform irradiation and homogeneous UV dosage with optimised flow guidance