- Offer Profile

-

COORDINATE MEASURING MACHINES

Top quality industrial measurement technology

The WENZEL range is based on this principle. Tactile, optical and scanning sensors are fundamental to 3D coordinate measuring technology. In sectors such as automotive, aircraft and mechanical engineering as well as in plastics and medical technology, WENZEL products not only offer precise and highly accurate standard coordinate measuring machines, but also customer-specific solutions.

The more complex the structures of the parts, components or products are, the more sophisticated and adaptable the appropriate measurement technology must be. The metrological verification of geometries and free-form surfaces requires suitable metrology solutions for the task. In addition to the external characteristics, at WENZEL we can make internal structures in detail measurable, visible and traceable using computer tomography-based 3D X-ray measurement technology.

Coordinate Measuring Machines and Gear Metrology

Large Measuring Machines

3D coordinate measuring machine LH Gantry

-

LH Gantry for measurements of large workpieces

The LH Gantry is a CNC coordinate measuring machine in gantry design with touch-trigger or scanning probe system. The LH Gantry enjoys all of the attributes of the smaller LH Bridge machine family but has been configured to provide for the inspection of large and heavy parts.

The WENZEL LH Gantry CMM showcases a monolithic design with an integral granite table negating the need for a special foundation. Due to their active pneumatic vibration damping and automatic temperature compensation, the LH Gantry is protected against vibration and thermal effects. The ‘high drives’ of the LH Gantry also ensure maximum stability even during dynamic movements.

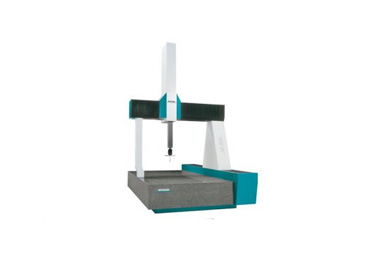

3D coordinate measuring machine LH 1210

-

Bridge-type CMM with a large measuring range and excellent accessibility

Precise, dynamic and reliable. The LH is a universal and flexible instrument for different applications. The revolutionary design of the new LH offers high mechanical accuracy, perfect ergonomics and dynamics. The new generation of LH is equipped with an incremental measuring system, which has a fine grating period, and excellent dirt immunity. As a result best position resolution and stability at high speed for all linear axes are possible.

Intelligent software and accessory options and a comprehensive service package complete the top LH CMM concept.

3D coordinate measuring machine LH 1512

-

Bridge-type CMM with a large measuring range and excellent accessibility

The CNC-bridge design measuring machine LH is the perfect solution for all common measurement tasks. The machines of the LH Series are being used for quality control, process control, production control, the development of prototypes and reverse engineering. From miniature gears to rocket building, in small agile shops, at innovative mid-size enterprises or world-famous conglomerates – or simply wherever high measuring requirements define the demands.

The LH machines are capable for a variety of probe head and scanner combinations. From fixed to motorized and adjustable probe heads. From simple measuring probes to high-precision and optical probe systems. The LH is suitable for demanding measuring tasks, fast form checks, extreme accuracy and scanning of any 2D and 3D curves and outlines.

The LH Series stands out due to an excellent price-performance ratio and flexible applications. LH CMMs are a safe investment because they are very durable and versatile.

3D coordinate measuring machine LHF

-

Bridge-type CMM for precise measurements of large workpieces

When it is all about the accurate measurement of large gears or other high precision parts offers the LHF Gear high flexibility concerning ergonomics of the measuring volume. The at-grade design realizes excellent free moving space and easy loading of the measuring volume.

Bridge type measuring machine for gear metrology

Just as the 3D coordinate measuring machines of the LH Gear series is the LHF Gear equipped with a rotary table for the precise 4-axes-measurements of gearings. So gears and other rotationally symmetrical parts with a diameter greater than 4000 mm can be measured.

Medium Measuring Machines

3D coordinate measuring machine LH

-

Medium bridge-type CMMs for highest dynamics and precision

Precise, dynamic and reliable. The LH is a universal and flexible instrument for different applications. The revolutionary design of the new LH offers high mechanical accuracy, perfect ergonomics and dynamics. The new generation of LH is equipped with an incremental measuring system, which has a fine grating period, and excellent dirt immunity. As a result best position resolution and stability at high speed for all linear axes are possible.

Intelligent software and accessory options and a comprehensive service package complete the top LH CMM concept.

3D coordinate measuring machine XOrbit

-

Bridge-type CMM for mediumsized workpieces at an affordable price

The WENZEL XOrbit is the ideal coordinate measuring machine, wherever the core aspects of measuring are required and where rapidity and ease of use are in demand. It can be used for checking incoming goods and throughout the production cycle until final inspection since it fulfils all major demands. Whether for individual or serial measurements, XOrbit is suitable for universal applications.

The WENZEL XOrbit is a cost effective derivative of the world´s renowned WENZEL LH series. XOrbit utilizes the industry standard Renishaw heads, touch probe and scanning probes.

XOrbit is the perfect CMM for companies purchasing their initial coordinate measuring machine, considering a 2nd user unit, or for the larger production operations needing to distribute multiple CMM’s. XOrbit has the optimum price/performance values.

Small Measuring Machines

3D coordinate measuring machine LH 54

-

Bridge-type CMM LH for measurements of small workpieces

The CNC-bridge design measuring machine LH 54 is the perfect solution for all common measurement tasks. It is used for quality control, process control, production control, the development of prototypes and reverse engineering.

The LH 54 is capable for a variety of probe head and scanner combinations. From fixed to motorized and adjustable probe heads. From simple measuring probes to high-precision and optical probe systems. The LH is suitable for demanding measuring tasks, fast form checks, extreme accuracy and scanning of any 2D and 3D curves and outlines.

The LH 54 stands out due to an excellent price-performance ratio and flexible applications.

3D coordinate measuring machines from WENZEL are a safe investment because they are very durable and versatile.

3D coordinate measuring machine XOrbit 55

-

Bridge-type CMM for small workpieces at an affordable price

The WENZEL XOrbit is the ideal coordinate measuring machine, wherever the core aspects of measuring are required and where rapidity and ease of use are in demand. It can be used for checking incoming goods and throughout the production cycle until final inspection since it fulfils all major demands. Whether for individual or serial measurements, XOrbit is suitable for universal applications.

The XOrbit 55 is WENZEL’s global CMM and is our most price efficient CNC model. It is a cost effective derivative of the world´s renowned WENZEL LH series. XOrbit utilizes the industry standard Renishaw heads, touch probe and scanning probes.

XOrbit is the perfect CMM for companies purchasing their initial coordinate measuring machine, considering a 2nd user unit, or for the larger production operations needing to distribute multiple CMM’s. XOrbit has the optimum price/performance values.

Horizontal Arm Measuring Machines

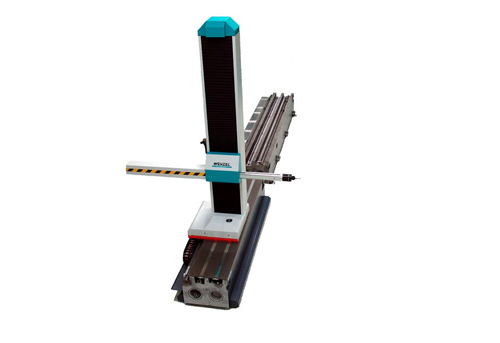

3D coordinate measuring machine RS

-

IN USE EVERYWHERE

The RS is a good-value, mechanical bearing, horizontal arm CMM, side mounted onto an inherently stable base plate. RS generally does not need a foundation so can be easily installed into an existing room.

The RS is used for production related measurement of typical components such as individual vehicle components, assemblies, plastic parts and other large components.

RS machines are often installed as duplex or double arm, called RSD (where the arms oppose each other) to increase the measurement volume.

The RS can be equipped with the latest Renishaw probe systems including Renishaw PHS infinite positioning head, 3-axis scanning or touch trigger probe systems and the WENZEL optical sensors, SHAPETRACER and WM | LS 70.

RS is available in 2 accuracy levels – Standard and Premium depending on accuracy requirements.

3D coordinate measuring machine RA

-

CLEARING THE WAY FOR PRECISE RESULTS

RA is a good-value, mechanical bearing, horizontal arm CMM, top mounted onto an inherently stable base plate or runway. RA does need a foundation so the base plate or runway can be installed flush with the floor so as to make part loading easy.

RA machines are often installed as duplex or double arm (where the arms oppose each other) to increase the measurement volume. The system is then called RAD when installed on a base plate or RAFD when installed on a runway.

The RA is used for production related measurement of typical components such as car bodies, individual vehicle components, assemblies, plastic parts and other large components.

The RA can be equipped with the latest Renishaw probe systems including Renishaw PHS infinite positioning head, 3-axis scanning or touch trigger probe systems and the WENZEL optical sensors, SHAPETRACER and Die RA kann mit RENISHAW-Sensorsystemen wie z. B. PH10M, PHS (stufenlos), schaltenden Tastern sowie den optischen WENZEL-Sensoren SHAPETRACER und WM | LS 70 ausgerüstet werden.

RA is available in 2 accuracy levels – Standard and Premium depending on accuracy requirements.

3D coordinate measuring machine RAplus

-

HIGHEST DYNAMICS AND PRECISION

RAplus is a high-performance, mechanical bearing, horizontal arm CMM, top mounted onto an inherently stable base plate or runway. RAplus does need a foundation so the base plate or runway can be installed flush with the floor so as to make part loading easy.

RAplus machines are often installed as duplex or double arm (where the arms oppose each other) to increase the measurement volume. The system is then called RADplus when installed on a base plate or RAFDplus when installed on a runway.

The RAplus is used for production related measurement of typical components such as car bodies, individual vehicle components, assemblies, plastic parts and other large components.

The RAplus can be equipped with the latest Renishaw probe systems including Renishaw PHS infinite positioning head, 3-axis scanning or touch trigger probe systems and the WENZEL optical sensors, SHAPETRACER and WM | LS 70.

RAplus is available in 2 accuracy levels – Standard and Premium depending on accuracy requirements.

3D coordinate measuring machine RAX

-

PRECISION IN LARGE FORMAT

RAX is the latest CNC horizontal arm CMM from WENZEL and is specifically designed for the needs of the automotive industry. The RAX was designed especially for very precise measurement of large volume components, such as car and truck bodies. High rigidity and a superior drive system guarantee high precision measurement results. RAX does need a foundation so the base plate or runway can be installed flush with the floor so as to make part loading easy.

RAX machines are often installed as duplex or double arm (where the arms oppose each other) to increase the measurement volume.

The RAX can be equipped with the latest Renishaw probe systems including Renishaw PHS infinite positioning head, 3-axis scanning or touch trigger probe systems and the WENZEL optical sensors, SHAPETRACER and WM | LS 70.

3D coordinate measuring machine RUF

-

THE PERFECT COMPLEMENT

The RUF under-floor measuring arm is the ideal complement to an RAD, RADplus or RAX duplex installation when difficult to access features need to be measured from below. The arm is available in manual or CNC versions. The measuring range depends on the RAD, RADplus or RAX machine that the RUF is combined with. The measuring arm points vertically upwards and can work individually or in a shared coordinate system with the arms above the floor, acting in a collision protected and synchronised manner.

The RUF is normally equipped with the Renishaw PH10M or MIH.

Industrial Computed Tomography

Desktop-CT exaCT S

- The compact desktop CT exaCT® S is the ideal solution for volume measurement of small components. exaCT® S is small enough to fit on every desk and offers a maximum of performance in a minimum of space. The high resolution allows a detailed analysis, even of the smallest components. Possible analysis range from micro-measurements to micro-material-testing. Based on the modular concept differing system variants can be configured. The systems vary in power of the x-ray tube, size of the detector and measurement volume. Every variant of the exaCT® S line is characterized by its compact design, ergonomics and the idea of combining high efficiency and flexibility with a small footprint.

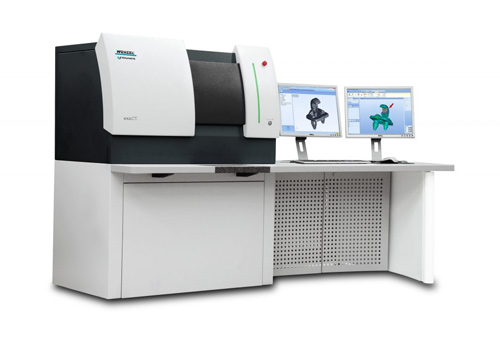

CT-Workstation exaCT M

- The new exaCT® M CT-Workstation is based on an innovative concept. During the design process WENZEL Volumetrik always focused on the needs of the user. The result is a computed tomography system which is not similar in selected points to other industrial CTs, but is superior point by point to these systems. The CT-Workstations exaCT® M is set up as a modular system. Because of its modular design it is optimal adjustable to requirements of differing measurement tasks. The workflow of measuring and analyzing is combined in an optimal way, as a desk is integrated in the CT-Workstation exaCT® M. Also integrated: Software, service, consulting and training.

exaCT L - THE COMPACT POWERSYSTEM

- The exaCT L offers a simplified, cost-effective and completely automated workfl ow for the entire CT analysis process. Due to its high X-ray performance in combination with a fast detector, the exaCT L enables the measurement and inspection of components in a short time. Due to the intuitive user guidance, exact measurement results can allready be generated after a short training period. The exaCT L thinks ahead: Measuring parameters are automatically optimized by the system. In its performance class, the exaCT L is one of the most compact computed tomographs on the market. It has three independent axes and offers an impressive X-ray performance. Hardware and software offer the possibility of automated integration into the production line and are the appropriate answer to questions regarding Industry 4.0 solutions.

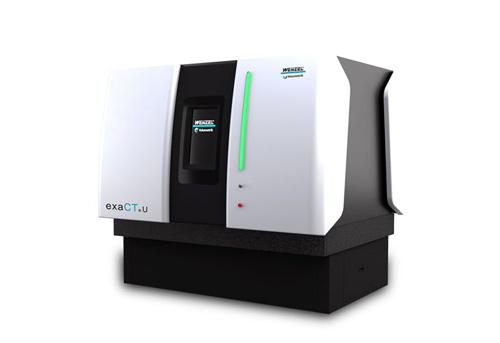

Desktop-CT exaCT® XS

-

The exaCT U offers a simplified, cost-effective and fully automated workflow for the entire CT analysis process. Due to its high performance combined with a large measuring volume, the exaCT U enables the measurement and testing of large components with higher densities.

Due to intuitive user guidance, exact measurement results can be generated after a short training period. The exaCT U thinks along with you: Measurement parameters are automatically optimized by the system.

In its performance class, the exaCT U is one of the most compact computer tomographs on the market. It has five independent traversing axes and offers impressive resolution. Hardware and software offer the possibility of automated integration into the production line and deliver market-driven answers to questions about industry 4.0.

WENZEL was awarded the Customer Value Leadership Award 2017 from Frost & Sullivan for the exaCT U.

s

Optical Highspeed Scanning

Optical CMMs

CORE D

-

CORE D is a 5-axis, optical CMM system which is ideal for measurement of small to medium turbine blades, medical implants or any other parts with similar characteristics of polished, reflective surfaces and sharp edges.

The characteristics above are measured with a unique, “Double-eye” sensor which ensures good point accessibility and even collects reliable data with the axis of the light beam up to 85ᵒ to the surface normal.

The new generation of CORE D has an automatic cover which closes during the measurement cycle ensuring perfect optical, thermal and clean conditions. The CORE D is shop-hardened, designed to be robot loaded and occupies a small footprint.

The CORE D can also be calibrated to ISO standards just like a CMM.

CORE M

-

CORE M is a 6-axis, optical CMM system which is ideal for measurement of medium to the largest turbine or fan blades or any other parts with similar characteristics of polished, reflective surfaces and sharp edges.

The characteristics above are measured with a unique, “Double-eye” sensor which ensures good point accessibility and even collects reliable data with the axis of the light beam up to 85ᵒ to the surface normal.

The new generation of CORE M has a cover which is closed during the measurement cycle ensuring perfect optical, thermal and clean conditions. The CORE M is shop-hardened and occupies a relatively small footprint.

The CORE M can also be calibrated to ISO standards just like a CMM.

Measuring Software

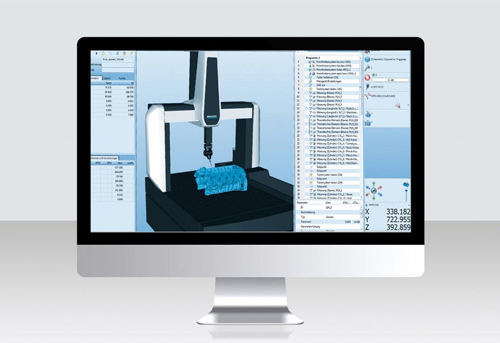

Metrosoft QUARTIS

- Metrosoft QUARTIS is the established measuring software from WENZEL Metromec. This softwarew allows the dimensional evaluation of the data captured with an exaCT®. Metrosoft QUARTIS provides the comprehensive functionality of the worldwide used measuring software, even for the evaluation of inner structures.

CT Analyzer

-

WM | CT Analyzer is WENZEL's software for handling voxel data from CT systems.

WM | CT Analyzer imports volume data automatically from WENZEL exaCT® machines and calculates surfaces automatically, even for multi-materials.

In addition to the normal functions that are available in its sister product, WM | PointMaster, WM | CT Analyzer is also able to perform NDT functions such as testing for shrink holes and impurities, wall thickness analysis and segmentation and visualization of components in an assembly with different densities.

WM | GEAR & GEAR ANALYZER

-

WM | Gear is a completely new software package for data acquisition and measurement of involute cylindrical gears on WENZEL coordinate measuring machines. Together with the WM | Gear Analyzer for evaluation and presentation of the measurement results, a complete package for quality determination of involute gears is available. Without additional training, the operator can use the usual WM | Quartis capabilities to determine workpiece alignment, probe management and calibration. The WM | Gear software solution enables the determination of the usual gearing characteristics, determined according to the most common evaluation standards.

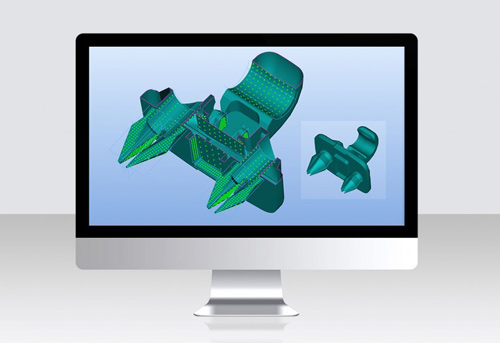

WM | PointMaster

-

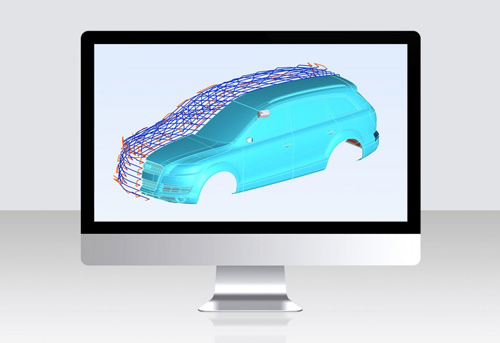

WM | PointMaster is WENZEL’s software for handling of point clouds from 3D scanning probes and voxel data from CT systems.

WM | PointMaster has three main modules;

Verification - Comparing and reporting point cloud data to nominal CAD data

Reverse Engineering – Taking point cloud data and constructing STL and finished surfaces.

Computed Tomography – Verification, Reverse Engineering and NDT functions using Voxel data from CT systems. (See also WM | CT Control for more information).

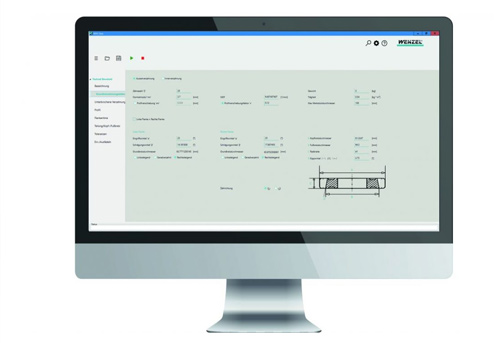

WM | SYS ANALYZER

- With the WM | SYS Analyzer software solution WENZEL offers extensive possibilities for controlling and analyzing measurement tasks and machines used. This allows the customer to have a “digital twin” of their part

and analyze their measurement data in an intelligent and flexible way. The WM | SYS Analyzer offers total data transparency for measuring machines and their measuring environment. Authorized users are provided with all necessary information in real time through an attractive interface. The WM | SYS Analyzer consists of three software modules. The basic module “Monitoring” is installed on the machine’s computer as standard on delivery. The advanced modules “Operations” and “Analytics” can be added at any time depending on the requirements of the machine.

WM | BLADE ANALYZER

-

PointMaster is the successful and reliable software from WENZEL with the modules Reverse Engineering, Verification, CAM Milling and Computed Tomography.

All modules are an integral part of the system solution based in the core software PointMaster. In addition the new release offers multicore acceleration with full 64 bit performance.

The success of PointMaster is based on the completely object-oriented handling. Most functions are supported with automatic functions. The easy of use is one of the strong points of PointMaster. It is possible to learn PointMaster in a few hours. Another of PointMaster’s major plus points is the visual assistance provided by the interactive feature ‘Shading’. This displays both artefacts and any areas of discontinuity, as well as feature lines, which are the key for surface segmentation. New functions such as surface trimming by use of B-spline curves, importing surfaces created in CAD systems for surface reconstruction and geometric feature recognition round off the wide range of new features in PointMaster Version 5.0.