- Offer Profile

- Our mission is to be your no. 1 go-to partner for sensors and sensor solutions with outstanding design and reliability. Using technological intelligence, we aspire to raise the bar when it comes to sensor technology. Doing so helps people and companies achieve sustainability, efficiency, good health, safety and quality of life. Every day, together with our partners and customers, we pursue the collective goal of shaping the future of the automotive industry, industrial sector, building and HVAC technology, medical technology and consumer electronics long term through innovation.

Your expert for pioneering sensor technology

- Our mission is to be your no. 1 go-to partner for sensors and sensor solutions with outstanding design and reliability. Using technological intelligence, we aspire to raise the bar when it comes to sensor technology. Doing so helps people and companies achieve sustainability, efficiency, good health, safety and quality of life. Every day, together with our partners and customers, we pursue the collective goal of shaping the future of the automotive industry, industrial sector, building and HVAC technology, medical technology and consumer electronics long term through innovation.

Applications

Medical/care

-

Smart inhalers Supporting asthma and COPD patients during inhalation

- Immediate feedback on inhalation technique

- Improved drug dosing and intake

- Monitoring of adherence and disease progression

Measuring inhalation flow profiles and monitoring medication delivery with smart inhalers helps prevent application errors and improve disease management. With sensor solutions for smart inhalers, Sensirion helps improve drug efficacy, makes it easier for patients to use inhalers correctly, and provides physicians with valuable insights into disease progression.

Industrial/logistics

-

Gas meters - Sensirion gas meter modules are based on the thermal-mass measurement principle. More than 6 million gas meters in the field and third-party studies after 10 years of field installation underpin this proven measurement technology.

- Proven technology, certified for the future

- Low power consumption and competitive on costs

- Competitive on costs

- Easy, fast and cost-efficient MID approval

- Tamper-proof and smart

HVAC/appliance

-

Refrigerators - Condensation control for refrigerators - Humidity sensors help control the heaters by adjusting the on-time of the heater depending on the dew point. This saves energy by heating door frames only when needed.

- Efficiently preventing condensation and dripping

- Intelligent control for maximum energy efficiency

- Better energy classification of refrigeration equipment

Consumer

-

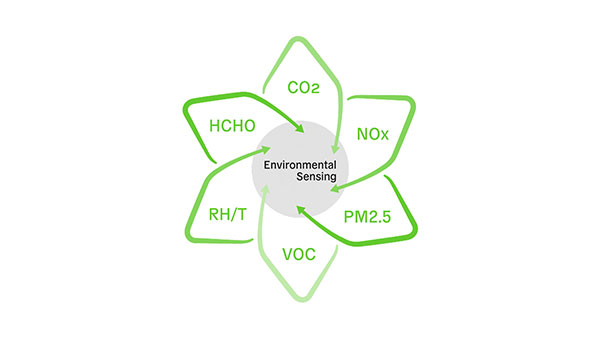

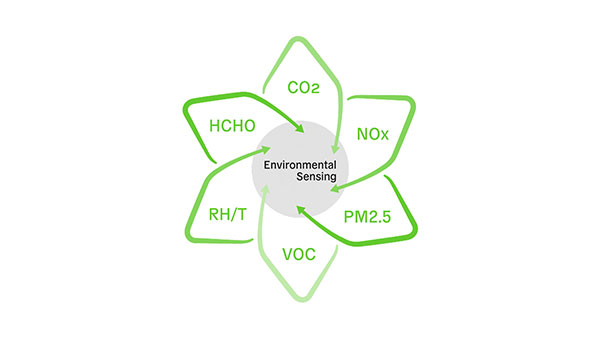

Air purifiers - Smart air purifiers thanks to environmental sensors - Environmental sensors provide accurate measurement of environmental parameters such as particulate matter, VOC, formaldehyde, humidity and temperature to monitor air quality and the condition of filters in use.

- Ensuring optimal indoor air quality

- Autonomous device control

- Reduction of dust and pollen pollution

- Increased energy efficiency

Mobility

-

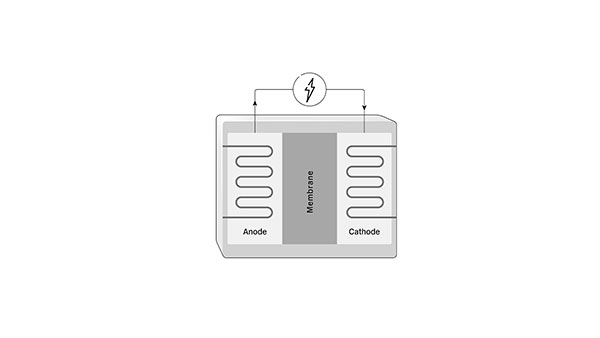

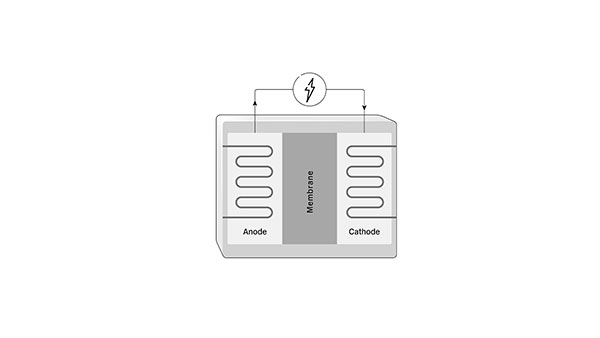

Hydrogen for fuel cells - Leakage detection and optimized fuel cell parameters - Hydrogen is one of the most important sources of cheap and clean energy. Fuel cell electric vehicles are expected to play an important role in the mobility industry in the future and will require sensor solutions for increased safety, energy efficiency and durability.

- Leakage monitoring

- Optimization of process parameters

- Reliability of the technology

Humidity and temperature sensors (RH/T)

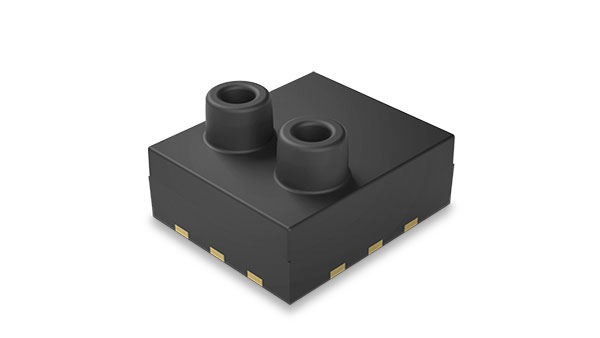

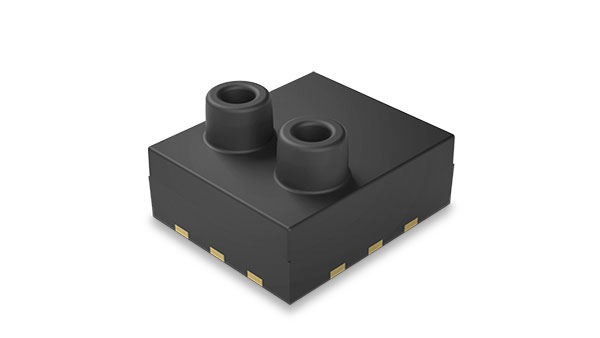

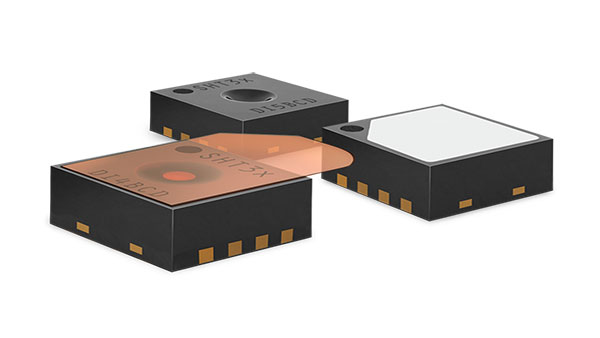

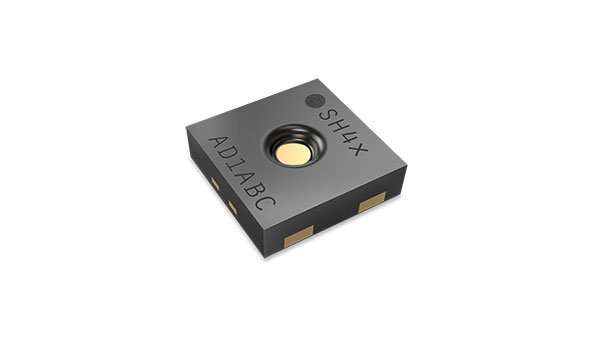

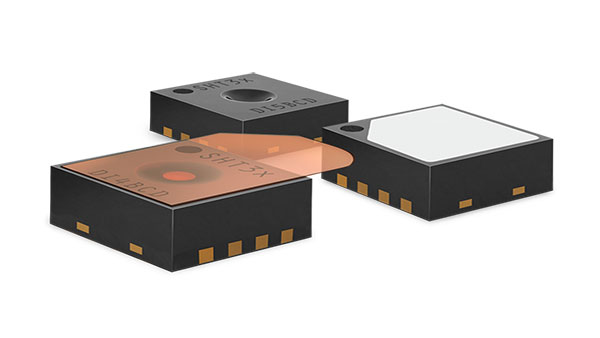

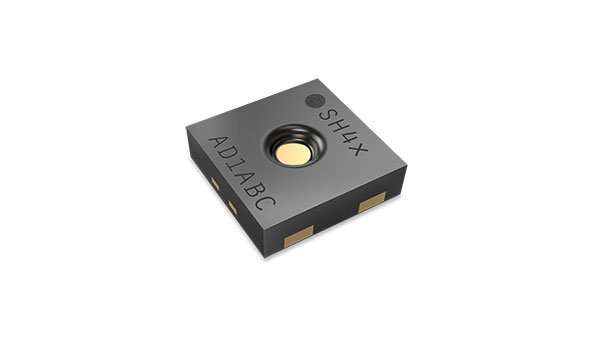

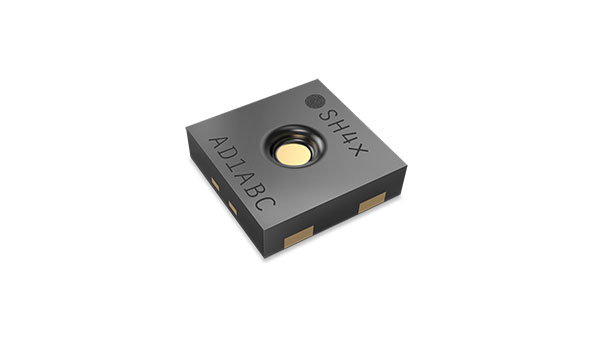

Humidity and temperature sensor SHT4x (RH/T)

- In line with Sensirion’s industry-proven humidity and temperature sensors, the SHT4x offers the best price-performance ratio on the market. Tape and reel packaging combined with its suitability for standard SMD assembly processes make the SHT4x ideal for high-volume applications.

The SHT4x builds on a completely new and optimized CMOSens® chip that offers reduced power consumption and improved accuracy specifications. With the extended supply voltage range from 1.08 V to 3.6 V, it’s the perfect fit for mobile and battery-driven applications. The exceptionally small size in a robust DFN housing enables integration into challenging designs while meeting the highest reliability demands, as demonstrated by the JEDEC JESD47 qualification.

The high-accuracy versions SHT41 and SHT45 feature typical and maximal accuracies that have been honed even further, down to ∆RH = ± 1.5% RH and ∆T = ± 0.1°C, making them suitable for the most demanding applications in all industries. The year 2022 will also bring additional protection options to complete the portfolio, meeting even the most rigorous technological challenges. The on-package filter membrane ensures IP67 compliance for exposed designs, while the protection option ensures reliable conformal coating.

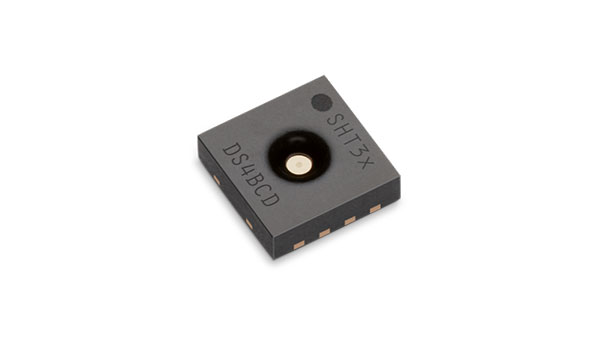

Humidity and temperature sensor SHT3x (RH/T)

- The digital SHT3x humidity sensor series takes sensor technology to a new level. As the successor of the SHT2x series it sets the industry standard in humidity sensing. The SHT3x humidity sensor series consists of a low-cost version with the SHT30 humidity sensor, a standard version with the SHT31 humidity sensor, and a high-end version with the SHT35 humidity sensor.

Automotive grade versions are also available. The SHT3x humidity sensor series combines multiple functions and various interfaces (I²C, analog voltage output) with a applications-friendly, very wide operating voltage range (2.15 to 5.5 V). The SHT3x humidity sensor is available in both large and small volumes.

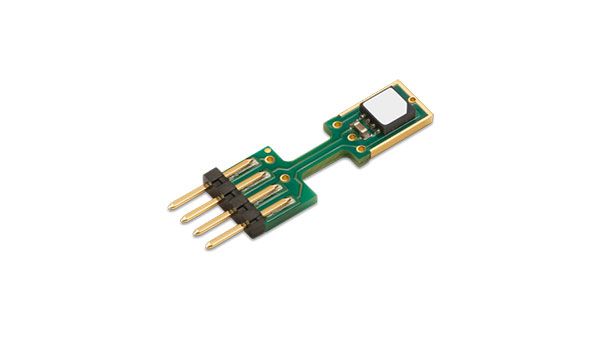

Humidity and temperature sensor SHT85 (RH/T)

- A highly accurate, digital pin-type relative humidity sensor for easy replaceability in a wide range of applications.

The digital humidity sensor SHT85 is Sensirion’s best-in-class humidity sensor with a pin-type connector for easy integration and replacement. It builds on a highly accurate SHT3x sensor with long-term stability that is at the heart of Sensirion’s new humidity and temperature platform. The unique package design allows for the best possible thermal coupling to the environment and decoupling from potential heat sources on the main board. The SHT85 features a PTFE membrane dedicated to protecting the sensor opening from liquids and dust according to IP67 without affecting the response time of the RH signal.

It thus allows for sensor use under harsh environmental conditions such as high exposure to dust. Final accuracy testing on the product level ensures best performance, making the SHT85 the ultimate choice for even the most demanding applications.

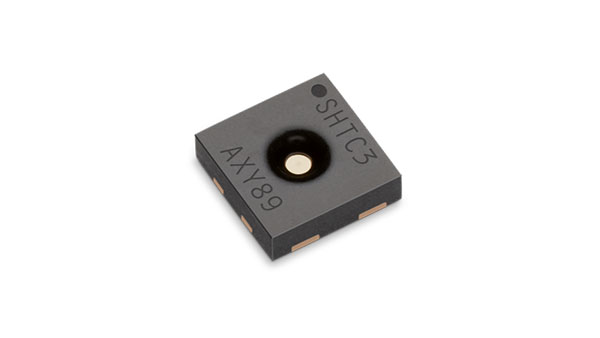

Humidity and temperature sensor SHTC3 (RH/T)

- The SHTC3 is a digital humidity and temperature sensor optimized for battery-driven applications and high-volume consumer electronics. The sensor has been designed to overcome conventional limits in size and power consumption in order to fulfill current and future requirements, and offers an unmatched performance-price ratio. The SHTC3 improves the performance and flexibility of the SHTC1, while maintaining its proven reliability.

Sensirion’s CMOSens® Technology offers a complete sensor system on a single chip, consisting of a capacitive humidity sensor, a bandgap temperature sensor, analog and digital signal processing, A/D converter, calibration data memory, and a digital communication interface supporting I2C fast mode. The small 2 x 2 x 0.75 mm3 DFN package enables applications in even the most limited space. The sensor covers a humidity measurement range of 0 to 100% RH and a temperature measurement range of -40°C to 125°C with a typical accuracy of ±2% RH and ±0.2°C. The broad supply voltage of 1.62 V to 3.6 V and an energy budget below 1 μJ per measurement make the SHTC3 perfectly suited to mobile or wireless applications powered by battery.

With the industry-proven quality and reliability of Sensirion’s humidity and temperature sensors providing constant accuracy over a large measurement range, the SHTC3 offers the best performance-price ratio. Tape and reel packaging combined with suitability for standard SMD assembly processes make the SHTC3 ideal for high-volume applications.

Humidity and temperature sensor SHT2x (RH/T)

- The digital SHT2x humidity sensor series is used in high volumes in a wide variety of applications and has today become the de facto industry standard. The SHT2x series consists of a low-cost version with the SHT20 humidity sensor, a standard version with the SHT21 humidity sensor, and a high-end version with the SHT25 humidity sensor. The open cavity mold package - which encapsulates the complete chip except for the humidity sensor area - protects the capacitive humidity sensor against external impact and facilitates excellent long-term stability. The SHT2x sensors are available both in large and small volumes.

Embedded in a reflow solderable dual-flat no-leads (DFN) package of 3 × 3 × 1.1 mm³, the SHT2x provides calibrated, linearized sensor signals in digital, I²C format. The SHT2x humidity sensor series contains a capacitive-type humidity sensor, a band-gap temperature sensor, and specialized analog and digital integrated circuits – all on a single CMOSens® chip. This yields superior sensor performance in terms of accuracy and stability as well as minimal power consumption.

Every sensor is individually calibrated and tested. Lot identification is printed on the sensor and an electronic identification code is stored on the chip – which can be read out on command. Furthermore, the resolution of the SHT2x humidity sensor can be changed on command (8/12 bit up to 12/14 bit for RH/T) and a checksum helps to improve communication reliability. With this set of features and its proven reliability and long-term stability, the SHT2x humidity sensor series offers an outstanding price-performance ratio. To test a humidity sensor from the SHT2x series, two evaluation kits, EK-H4 and EK-H5, are available.

Evaluation kits for Sensirion's humidity and temperature sensors

-

Start testing Sensirion’s sensors fast and easy with our evaluation kits.

The kit combines plug-and-play hardware with an easy-to-use viewer software (ControlCenter) for in-depth evaluation. Each evaluation kit includes a Sensirion SensorBridge, all required connector cables, as well as various sensor samples. The SensorBridge features two independent I2C channels that allow simultaneous evaluation of two environmental sensor samples. The ControlCenter viewer software makes it possible to display and log the sensor signals for multiple sensors connected to several SensorBridges on the same PC.

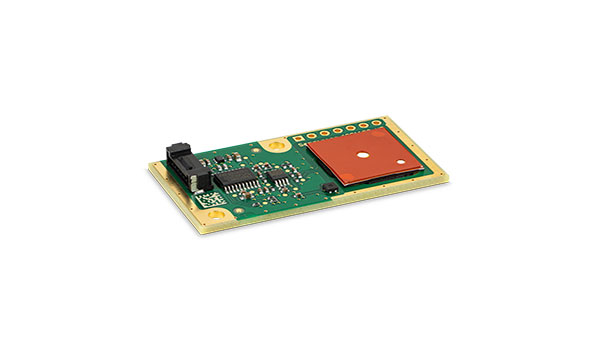

Humidity and temperature module SCC30-DB (RH/T)

- There are applications that require a humidity and temperature sensor to be located in a specific part of the device – often at a different location than the main control board, i.e. the sensor can not be assembled on the main board.

With the SCC30, customers can place a humidity and temperature sensor anywhere in a device and connect it to the main board with a cable without having to spend design resources for creating an own sensor module. Based on Sensirion’s experience and expertise in environmental sensing the SCC30 is optimized for easy design-in and sensing performance. The SCC30 offers superior sensor performance of capacitive type sensor elements and a very attractive price/performance ratio due to Sensirion’s latest generation of highly integrated humidity and temperature sensors SHT3x.

The module provides high reliability and excellent long-term stability, a broad supply voltage range of 2.4 to 5.5V and delivers fully calibrated and processed measurement values through an I²C interface. The compact design with connector and easy-to-use digital interface make the SCC30 a cost-effective and versatile plug & play solution for a wide range of applications.

SF2 filter cap for SHT2x to SHT4x humidity and temperature sensors

- Easily mountable solution to protect SHT2x/3x/4x, SHTC1 and SHTC3 humidity sensors. The SF2 filter cap protects against water, dust, soot, particles and other contaminants. It consists of a single piece of PBT and an integrated water vapor-permeable filter membrane.

The cavity inside the cap is designed so that the dead volume between membrane and sensor is negligible; hence the impact on response time for humidity measurements is reduced to a minimum. The cap is available in black with a black filter membrane.

The cap is made of a single piece of polybutylene terephthalate (PBT) with a filter membrane welded on. The cap is designed to be mounted after soldering by clipping the four pins on to the PCB. Together with the sensor, it provides a compact entity that can serve as an adaptor to the device housing. With the addition of adhesive for sealing to the PCB and use of an o-ring, it provides a waterproof mounting solution.

High-accuracy temperature sensors

STS3x

- The STS3x is Sensirion’s high-accuracy digital temperature sensor series. The STS3x temperature sensor utilizes the industry-proven CMOSens® Technology and wins over users with its increased intelligence, reliability, NIST traceability and improved accuracy specifications. There are also automotive grade versions available.

Every single STS3x is calibrated and 100% end tested. The calibration is performed with a reference sensor which is NIST traceable through an ISO/IEC 17025 accredited laboratory.

The functionality of Sensirion’s STS3x temperature sensor includes enhanced signal processing, two distinctive and user-selectable I²C addresses, and communication speeds of up to 1 MHz. The dual-flat no-leads (DFN) package has a footprint of 2.5 × 2.5 mm² while retaining a height of 0.9 mm. This allows for easy integration of the STS3x series into various applications. Additionally, the wide supply voltage range of 2.15 to 5.5 V and low current consumption (1.7µA typical average current at 1 measurement per second) guarantees compatibility with a wide range of applications.

Ultra-low-power temperature sensor STS4x

- The STS4x is Sensirion’s state-of-the-art, highly accurate digital temperature sensor series, boasting industry-leading lead times. It is a fully digital, highly cost-efficient temperature sensor platform that is available in different accuracy classes, currently represented by the STS40. The STS4x temperature sensor range features enhanced signal processing, three distinctive I²C addresses and communication speeds of up to 1 MHz. Moreover, the dual-flat no-leads (DFN) package has a footprint of only 1.5 × 1.5 mm² while retaining a height of 0.5 mm, which allows for an easy integration of the STS4x series into various applications. Additionally, the wide supply voltage range of 1.08 to 3.6 V and low current consumption of 0.4 µA for a typical average current at 1 measurement per second enables battery-driven designs. Taken together, the STS4x series achieves the greatest cost efficiency among comparable sensors on the market. Thanks to Sensirion’s CMOSens® Technology, the STS4x temperature sensor benefits from the high-tech engineering of a wide range of sensor components. It is designed for mass production, comes with a high signal-to-noise ratio and high process capability and is proven to be highly reliable and stable over the long term.

Carbon Dioxide Sensors

STC31

-

CO₂ accuracy of ±(0.5 vol% + 3% MV) @0-100 vol%

The STC31 is a chip-sized gas concentration sensor for high range, accurate CO₂measurements designed for high-volume production.

The sensor is based on a revolutionized thermal conductivity measurement principle, which results in superior repeatability and long-term stability. This makes the STC31 the perfect choice for applications where reliability is key. Thermal conductivity technology has an ultra-low power consumption, even compared to low-power optical sensor. This makes it the ideal choice for battery operated applications, delivering top-performance at an absolute minimal power budget.

The STC31 features a digital I²C interface, which makes it easy to connect directly to a microprocessor. The outstanding performance of these sensors is based on Sensirion’s patented CMOSens® Technology, which combines the sensor element, signal processing and digital calibration on a small CMOS chip. The well-proven CMOS technology is perfectly suited for high-quality mass production and is the ideal choice for demanding and cost-sensitive OEM applications.

More Environmental Sensors

Environmental Sensor Node SEN5x

- The SEN50 environmental node is part of the SEN5x family and represents a straightforward sensor solution platform for the accurate measurement of particulate matter. Thanks to proprietary algorithms, the module enables straightforward integration into various applications. This allows device manufacturers to save valuable project time and personnel resources and focus on their core competencies. End customers receive reliable air quality measurement data based on the SEN50 and benefit from improved air quality to increase health and comfort.

Please note: Cables are not included. If cables are needed, please have a look at the SEK-SEN5x Evaluation kit.

Multi-Pixel Gas Sensors SGP - VOC Sensor SGP40

- The SGP40 is Sensirion’s new digital VOC (volatile organic compounds) sensor designed for easy integration into air purifiers or demand-controlled ventilation.

SGP40 is Sensirion’s new digital VOC (volatile organic compounds) sensor designed for easy integration into air treatment devices and air quality monitors. Based on Sensirion’s CMOSens® Technology, the SGP40 offers a complete sensor system on a single chip and features a digital I²C interface, a temperature-controlled micro-hotplate and a humidity-compensated indoor air quality signal. In combination with Sensirion’s powerful VOC Algorithm (part of the gas index algorithm software), the sensor signal can be directly used to evaluate indoor air quality, e.g., for triggering the gradual fan control of an air treatment device. Both the SGP40 chip and VOC algorithm feature unrivalled robustness in the final application over their lifetimes. Pushing the multipixel and multi-hotplate approach to the next level of individual control of each sensing element, the SGP40 enables a drastic reduction in power consumption, making it suitable for battery-driven applications as well. Sensirion’s state-of-the-art production process guarantees high reproducibility and reliability.

Particulate Matter Sensor SPS30

- The MCERTS-certified SPS30 particulate matter (PM) sensor marks a new technological breakthrough in optical PM sensors. Its measurement principle is based on laser scattering and makes use of Sensirion's innovative contamination-resistance technology. This technology, together with high-quality and long-lasting components, enables precise measurements from the device's first operation and throughout its lifetime of more than ten years.

PM2.5 refers to particulate matter with particle diameter up to 2.5 microns and is among the most dangerous air pollutants. Due to their small size, PM2.5 particles can travel deep into the human lung and cause a variety of health issues; for instance, by triggering asthma attacks or contributing to cardiovascular disease. The SPS30 will enable the implementation of innovative air quality monitoring devices that prevent air pollution damage.

Formaldehyde Sensor SFA30

- The SFA30 is Sensirion’s new digital formaldehyde sensor designed for easy integration into air purifiers, demand-controlled ventilation systems, or indoor air quality monitors.

Based on Sensirion’s electrochemical technology, the SFA30 offers excellent formaldehyde sensing performance with a uniquely low cross-sensitivity to other VOCs. The sensor module’s on-board SHT sensor provides accurate humidity and temperature readings and enables a fully temperature/humidity compensated and factory calibrated formaldehyde concentration output in ppb. Selectable digital UART and I²C interface options, a standard electrical connector, and versatile mounting options make the integration easy. Relying on Sensirion’s experience in environmental sensing and a patented electrochemical cell with anti-dry technology, the SFA30 offers excellent long-term stability and 6 years service lifetime.

Liquid flow sensors

SLF3S-4000B - Liquid flow evaluation kit SLF3S-4000B

-

- Max. flow rate: 600 ml/min (H₂O and IPA)

- Connector: I²C

Includes:

- 1x SLF3S-4000B

- 1x SLF3x mounting clamp

- 1x SCC1 USB sensor cable

- 1x adapter cable with 6-pin connector to 4-pin M8

- 1x Ribbon cable from 6-pin connector to pigtail

- Quick start guide

Gas flow sensors

SGM6000

-

DThe SFM6000 is a valve-less sister variant of the SFC6000 mass flow controller, offering a great performance at an even lower price.

Applications: -Semiconductor: front opening unified pods (FOUP), glass coating and treatment

The SFC6000 mass flow controller is Sensirion’s next generation mass flow controller, impressing with an unbeatable priceperformance ratio and a very attractive delivery time of eight weeks. While the industry is currently struggling with delivery times of 30 to 53 weeks, SFC6000 samples are available within two to four weeks. In addition, selected SFC6000 configurations are available in distribution, meaning you can order them for initial testing and evaluation today and have the product in your mailbox tomorrow.

-Analytical instruments: gas chromatography, bioreactors

-Medical equipment: anesthesia, ventilation, heart-lung machines, N2O therapy

-Industrial automation

SFM4300

-

SFM4300 is the next generation flow meter for gas mixing applications. In a compact form factor, it offers outstanding accuracy and pressure robustness. Integrated CMOSens® Technology offers gas mixture outputs and highest performance down to smallest flows. Factory calibrations for standard gases and smart mixing options allow for easy integration and faster development time. Several options for fittings and the compact form factor support typical medical and industrial applications with compact designs

Key characteristics:

- Flow range 20 slm or 50 slm

- Calibrated for O2, Air, N2O, CO2 and mixtures

- Very low noise

- Excellent repeatability

- Pressure resistant

- I 2C interface

SFM3119

- The SFM3119 is a compact digital flow meter. It is the successor of the SFM3100 mass flow meter. Compared to its predecessor, the SFM3119 comes with a digital I²C output as well as improved specifications.

The SFM3119 mass flow meter is highly accurate and fast at flows of air, oxygen and mixtures thereof between -10 and 240 slm. It has a compact design and can be easily integrated into existing devices. The signal is internally linearized and temperature compensated. Furthermore, the SFM3119 flow meter has a low pressure drop.

Like all Sensirion flow sensors, the SFM3119 mass flow sensor is based on the patented CMOSens® Technology, which combines the sensor and analysis electronics on a single microchip. The result is a highly stable and precise system for demanding and cost-sensitive applications. The SFM3119 is particularly suitable for inspiratory flow sensing in applications like ventilation or anesthesia as well as for mixing oxygen and air to a very precise degree.

SFM3003

-

Sensirion’s SFM3003 is a versatile, low pressure drop, bidirectional flow meter. Based on the same form factor as the proven SFM3000 series, SFM3003 comes with a larger flow range of up to 300slm and offers additional features for measuring flows of air, oxygen and mixtures of air and oxygen. SFM3003 series is the ideal choice for medical and industrial applications.

Key charakteristics:

- Flow range up to 300slm

- Calibrated for O2, air and mixtures thereof

- I 2C interface

- Low pressure drop across the sensor

- No recalibration needed

- Bi-directional option up to -150slm

SFM3019

-

SFM3019 is Sensirion’s solution on providing high volumes of flow meters for medical ventilators in order to support the global pandemic situation due to the Corona virus outbreak. It relies on a modular approach of assembling approved parts with good availability to Sensirion and a high-volume through-put manufacturing. The housing geometry is based on the SFM3000 flow meter; hence it remains mechanically compatible to the SFM3000. A flow range from -10slm to +240slm and one directional flow supports high flow applications while still allowing to detect back flows. To minimize pressure-drop the SFM3019 is equipped with one mesh at the inlet.

- Flow range up to 240slm

- Calibrated for O2, air and mixtures thereof

- I 2C interface

- Low pressure drop across the sensor

- No recalibration needed

SFM3020

- The SFM3020 mass flow meter is the analog sibling of SFM3003 and particularly suitable for high-volume applications. The design of the flow channel results in a very low pressure drop, making it ideal for medical ventilation.

The flow of air and oxygen at rates from -10slm to 160slm is measured with excellent accuracy and extremely high speed. The signal is internally linearized and temperature compensated and provided as an analog output voltage for easy read out.

As part of the SFM3xxx platform, the SFM3020 is a versatile sensor solution for many different high-volume applications in which cost efficiency is the priority and analog the preferred interface. The outstanding performance of the SFM3020 sensor is based on Sensirion's patented CMOSens® Technology, which combines the sensor element, signal processing and digital calibration on a tiny microchip. The gas is measured by a thermal sensor element to provide an extended dynamic range and enhanced long-term stability compared to other flow measuring technologies. Thanks to this proven CMOSens® Technology, the flow meter is perfectly suited for high-quality mass production and is the ideal choice for demanding and cost-sensitive OEM applications.

Mass flow controllers

SFC66000

-

The SFC6000 mass flow controller is Sensirion’s next generation mass flow controller, impressing with an unbeatable priceperformance ratio and a very attractive delivery time of eight weeks. While the industry is currently struggling with delivery times of 30 to 53 weeks, SFC6000 samples are available within two to four weeks. In addition, selected SFC6000 configurations are available in distribution, meaning you can order them for initial testing and evaluation today and have the product in your mailbox tomorrow.

The SFC6000 is very small and light and therefore allows the customer to optimize their devices in terms of size and weight. This is a decisive advantage, especially for portable devices. Furthermore, it offers great performance in terms of repeatability, accuracy, control range and speed. The SFC600 is highly integrated and has a very robust supply chain due to the very low number of electronic components used.

Differential Pressure

SDP800

-

The SDP800 sensor family is Sensirion’s series of differential pressure sensors designed for high-volume applications. The sensors measure the pressure of air and non-aggressive gases with superb accuracy and no offset drift. The sensors cover a pressure range of up to ±500 Pa (±2 inch H2O / ±5 mbar) and deliver outstanding accuracy, also at the lower end of the measuring range.

The SDP800 features an analog ratiometric voltage output, which is configurable to linear or square root by a separate pin. The outstanding performance of these sensors is based on Sensirion’s patented CMOSens® sensor technology, which combines the sensor element, signal processing, digital calibration and analog output on a small CMOS chip. The differential pressure is measured by a thermal sensor element using flow-through technology. The well-proven CMOS technology is perfectly suited for high-quality mass production and is the ideal choice for demanding and cost-sensitive OEM applications.

SDP3x

-

The SDP3x sensor family is Sensirion’s series of small differential pressure sensors designed for high-volume applications where size is a key requirement. It builds on the next generation CMOSens® sensor chip that is at the heart of Sensirion’s new differential pressure and flow sensing platform. The analog SDP3x sensors offer a calibrated and temperature compensated analog voltage output. The output signal is configurable: different measurement speeds, output curves and temperature compensations can be selected – even dynamically during operation mode.

- High reliability and long-term stability

- Best signal to noise ratio

- Industry-proven technology with a track record of more than 15 years

- Designed for mass production

- High process capability

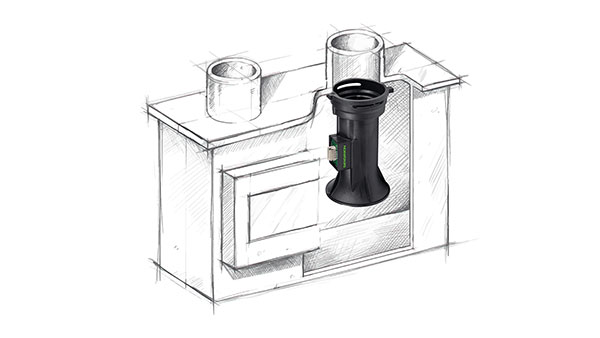

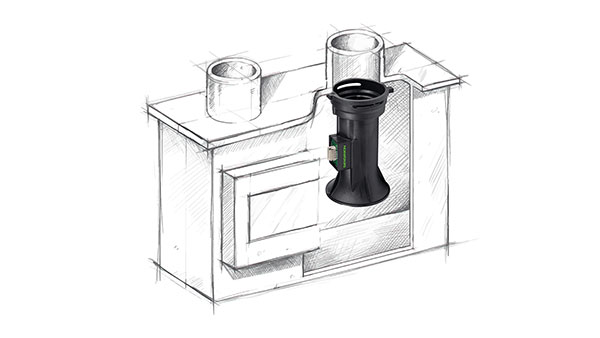

Gas metering solutions

SGM6400

-

The SGM64xx are the next generation gas meter modules, ready for the hydrogen future. Each module achieves MID accuracy with natural gas, LNG, biomethane, hydrogen blends and pure hydrogen. The maximum flow range for hydrogen is over 3x higher than that for natural gas. This means, no meter replacement is needed when natural gas in the network is gradually replaced with hydrogen.

SGM6300

-

The SGM63xx gas meter modules are Sensirion’s latest sensors for smart gas metering applications. Available in G1.6-G25 sizes, they achieve MID accuracy with natural gas, LNG, hydrogen blends and biomethane. Thanks to the latest generation CMOSens® flow chip, they are characterized by ultra-low power consumption. Sensirion’s thermal-mass module directly output volume flow at base conditions.