- Offer Profile

-

Sensors, Safety and Control Technology for plant and machinery

Klaschka has been developing and manufacturing electronic components and systems for the automation of plant and machinery for more than 50 years. These products (Sensors, Measuring Relays, Controllers, Double Blank Detectors and Sheet Thickness Sensors) are employed for detecting, positioning and checking, for controlling and regulating, for pulse rate detection, for monitoring and detecting errors, and for operating and observing. Certified Safety Switches and Controllers are available for safety-critical applications.

Detection - Identification - Safeguarding - Controlling Monitoring

-

Non-contact sensors (proximity switches, inductive, capacitive and ultrasonic sensors) are used for precision sensing of dynamic motions. Klaschka "All Metal" Sensors and Pulse Sensors are specially designed for very high speeds and challenging applications with switching frequencies higher than 10 kHz.

In combination with measurement relays and controllers, non-contact identification (RFID) and tamper-proof safety switches with extremely large switching distances (safety and security) ensure reliable process steps in plant and machinery.

Klaschka offers a wide range of Double Blank Detectors for sheet detection and thickness measurement in the metal-forming industries. The universal BDK-Doublesheet-Detector-system is firmly established in the automotive industry. For applications that do not need this functionality, there are lower-cost systems of Double Sheet Detectors, Doublesheet Controllers and Sheet Thickness Sensors. These are used in many fields when handling and processing metal and metal-coated materials to avoid damage and downtime.

Typical applications are: Production lines for automotive industries, presses and forming technology, textile machines, printing machines, packaging machines, conveying technology, machine tools, robotics and assembly technology, water and sewage systems, railed and commercial vehicles.

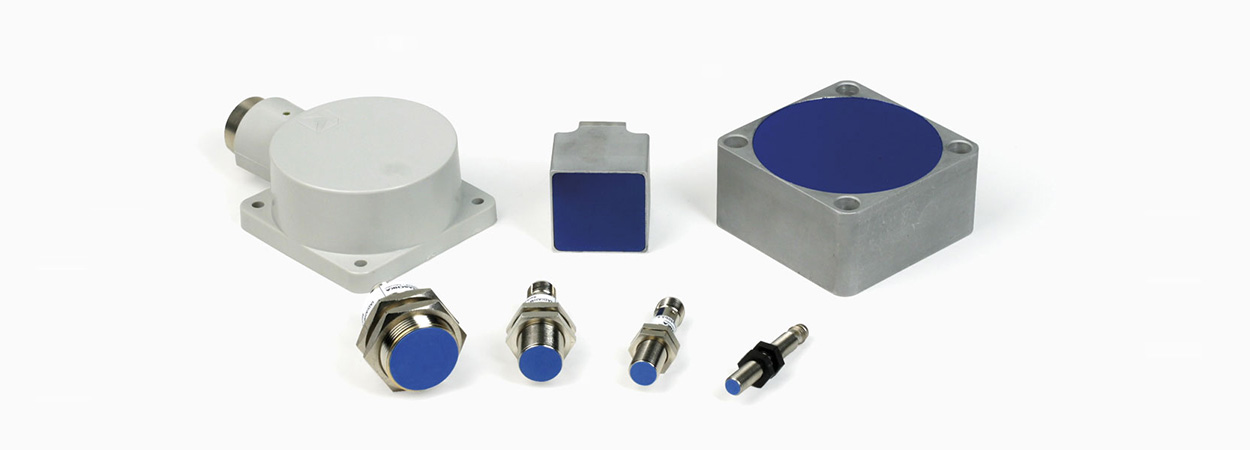

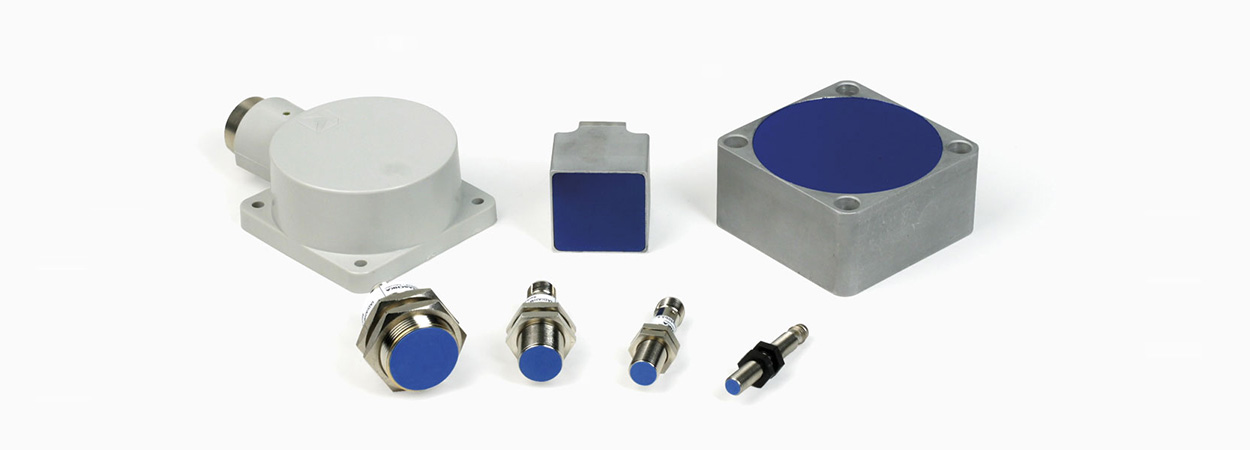

Sensors

-

Klaschka sensors in industrial plant and machinery are basic elements for automation. Since these non-contact, free-of-wear sensors work contactless and have no effect on the part they detect, their service life is almost unlimited. They are insensitive against pollution and can be used for a large ambient temperature range.

Proximity switches detect, with short response times, the final and intermediate positions for rotary and linear motions of machine parts.

Fast pulse sensors, equipped with evaluation devices, determine incrementally the rotational speed, stroke rate, and frequency as well as the position and the speed of moving machine parts.

Distance and position sensors supply either a current or a voltage (as option) which is analog to the measured variable. They are inexpensive absolute-value-devices with short operating times.

Inductive Proximity Switches

- For the contactless detection of metals. The sensor consists of a coil, which is part of an oscillating circuit in a measuring oscillator. The switch responds to all metal types. Concerning the " all metal" version, the switching distance is the same for all metals. >> go to Inductive Proximity Switches

Pulse Sensors

- For the contactless detection of motions with high frequency. Rotation speed sensors and speed pick-up encoders (mini-encoders) either have a hall element, a magnetically changeable resistsance or an inductance as sensing element. The maximum switching frequency is 25 kHz for switching distances > 2 mm. Also available as Double Pulse Sensor with integral detector for identifying the direction of rotation. >> go to Pulse Sensors

RFID Identification

- WIDENT/P position detector: Detection of several positions on, for example, shutter gates or rotary tables. WIDENT detection system: For robotics tool change couplings. >> go to RFID Identification

Ultrasonic Sensors

- Ultrasonic sensors are suitable for large distances. These acoustic sensors have a piezo-ceramic sound converter, which emits pulse packages and receives the reflected pulse packages in turn. The distance of the object is determined by measuring the running time. >> go to Ultrasonic Sensors

Capacitive Sensors

- Capacitve sensors are used for the detection of various materials (e. g. paper, plastic, wood). The configuration corresponds to that of the inductive proximity switch; the sensor element, however, consists of a capacitor. The sensor responds to conducting materials, i. e. apart from metals also to wood. >> go to Capacitive Sensors

Specific Sensors

- Sensors with special properties as well as customer-specific design. Examples are sensors for the thickness measurement, for film recognition, spark detection, pulse rate switches, inductive ring- and fork-shaped switches with the associating evaluation devices. Sensors for application in Nuclear Industry: In partnership with Centronic (UK) we produce for the international nuclear industry specific radiation tolerant proximity switches. When combined with a range of interface cards these detectors are the only certified radiation tolerant proximity system currently available. Radiation tolerant to 100 kGy or 1 MGy, depending on model. Requests desired. >> go to Specific Sensors

Safety Technology

- The reliable monitoring and shutting down of manufacturing processes when there are risks to people, material or machinery is essential for every plant operator. Klaschka safety switches and safety switching devices are certified to the Machinery Directive 2006/42/EG and comply with the requirements for control category 4 (EN ISO 13849-1) and are classified according to Performance Level (PL) for the highest safety requirements (SIL).

Safety Switch SIDENT

- The non-contact SIDENT safety switches are, compared to mechanic or magnetic safety switches, to a high degree tamper-proof. >> go to Safety Switch SIDENT.

Safety Switch (several positions)

- SIDENT safety switch for several positions. >> go to Safety Switch (several positions)

Safety Door Handle

- TGY safety door handles for safety systems applied with SIDENT safety switches. >> go to Safety Door Handle

Safety Relays

- ZSY safety controllers and installation of safety systems applied with SIDENT safety switches. >> go to Safety Relays

Accessories

- Leads and connectors for SIDENT safety switches. >> go to Accessories

SISTEMA Bibliotheca

- The BGIA, German Institute for Occupational Health and Safety, uses the SISTEMA software for assessing the safety in terms of the Machinery Directive. >> go to SISTEMA Bibliotheca

Double Sheet Metal Monitors

- Double sheet metal monitors and thickness measurement devices monitor the automated destacking and separation of ferrous (Fe) or non-ferrous (NE) metal sheets in metal processing equipment (e.g. presses) with automatic feeding systems such as destackers, robots, feeders, etc. By detecting double sheets or thickness measurement, the presence of two or more sheets stuck together can be reliably detected and the process stopped before the tool or the machine itself are damaged. In the universal BDK system, especially the user-friendly BDK Compact or the very cost-effective Doublesheet-Sensors BDK Uno and Duo sensors (which do not need an evaluation device), you are certain to find an optimum Sheet Thickness Detector. Do not hesitate to contact us: We would be pleased to help you.

Universal Double Sheet Metal Monitor BDK

- System BDKuniversal for safe double sheet detection of ferrous or non-ferrous sheets (single-surface contact and non-contact measurement, and double-surface non-contact measurement). >> go to Universal Double Sheet Metal Monitor BDK

Double Sheet Metal Monitor BDK-ET

- Double Sheet Metal Monitor for detecting double sheets in destackers and feeders of metal processing equipment (single-surface contact measurement of ferrous and non-ferrous sheets). >> go to Double Sheet Metal Monitor BDK-ET

Double Sheet Metal Monitor BDK Compact

- Cost-effective evaluation device with sensor for ferrous sheets (single-surface contact measurement). >> go to Double Sheet Metal Monitor BDK Compact

Double Sheet Metal Sensor BDK Uno

- BDK Uno Fe – Double Sheet Metal Sensor (without evaluation device, single-surface contact measurement) for thin ferrous sheets.

BDK Uno NE – Double Sheet Metal Sensor (without evaluation device, single-surface contact measurement) for non-ferrous sheets. >> go to Double Sheet Metal Sensor BDK Uno

Double Sheet Metal Sensor BDK Duo

- Double Sheet Metal Sensor (without evaluation device, double-surface non-contact measurement) for non-ferrous and ferrous sheets. Sensor suitable for conveyors and measurements in motion and at a standstill. >> go to Double Sheet Metal Sensor BDK Duo

Double Sheet Metal Sensor BDK Duo Flex

- Double Sheet Metal Sensor (without evaluation device, double-surface non-contact measurement) for non-ferrous and ferrous sheets. Variable mounting of the transmitting and the receiving module. Sensor especially suitable for conveyors and measurements in motion and at a standstill. >> go to Double Sheet Metal Sensor BDK Duo Flex

Measuring Relays & Controllers

-

Klaschka measuring relays and controllers comprise a wide range of controlling and monitoring devices for installation in plant and machinery and for control cabinets. The shock-resistant fibreglass-reinforced plastic housing is fire-resistant and weather-proof. The devices can be snapped on to a standard mounting rail or secured with screws to a mounting plate.

Measuring relays can be used e.g. for current, tension, isolation, phase and frequency:

- As converter and indicator for rotation and frequency.

- As auxiliary equipment for sensors.

- As controller and monitor for plant and machinery (lubrication systems, Conveyors).

- As PLC and controller for plants.

Rotational Speed and Frequency

- Evaluation of pulse sensor signals for generating switching commands and analog signals. >> go to Rotational Speed and Frequency

Current, Voltage and Frequency Monitor

- For supervision of currents and voltages. >> go to Current, Voltage and Frequency Converter

Monitoring Devices and Controllers

- Units for multiple monitoring and controlling functions for plant and machinery. >> go to Monitoring Devices and Controllers

Auxiliary Devices

- Auxiliary Devices for inductive switches, sensors and safety sensors. >> go to Auxiliary Devices

PLC Controllers

- Components for controlling, operating and monitoring automated plant and machinery in industry, or for environmental and distribution technologies. >> go to PLC Controllers