- Offer Profile

- Epilog Laser was founded with a clear vision: to make advanced laser technology accessible to businesses of all sizes. Since 1988, we’ve been at the forefront of both CO₂ and fiber laser innovation, helping our customers create, cut, and mark with unmatched precision.

Laser Machines - Fusion Maker Lasers

- Starter Series – 12, 24, & 36 The Fusion Maker by Epilog Laser is our newest entry-level CO2 laser engraving, cutting, and marking system, combining hobbyist-level pricing with industrial-level engineering. It can produce engraving and cutting projects from a variety of materials including wood, acrylic, textiles, paper, plastic, and much more. Comprised of the Fusion Maker 12, 24, and 36, all the laser machines in the Maker Series feature Epilog’s revolutionary IRIS™ Camera System that gives laser operators a real-time image of the engraving table so they can quickly and accurately position their artwork on even the most uniquely shaped items. The Fusion Maker Lasers may be a starter series, but right out of the box, you’ll be experiencing professional-level results.

Fusion Maker 12

- Work Area: 24" x 12" (610 x 305 mm)

- Material Thickness: 7" (178 mm)

- Laser Tube Types: Air-cooled, metal/ceramic Waveguide tube, replaceable.

- Laser Tube Wattages: CO2: 30 or 40 watts

- Engraving Speed: Up to 60 IPS (1.5m/s)

- IRIS™ Cameras: 1 overhead

Fusion Maker 24

- Work Area: 24" x 24" (610 x 610 mm)

- Material Thickness: 10" (254 mm)

- Laser Tube Types: Air-cooled, metal/ceramic Waveguide tube, 10.6 micrometers. Epilog Laser Manufactured.

- Laser Tube Wattages: CO2: 40 watts

- Engraving Speed: 2 overhead

Fusion Maker 36

- Work Area: 36" x 24" (914 x 610 mm)

- Material Thickness: 10" (254 mm)

- Laser Tube Types: Air-cooled, metal/ceramic Waveguide tube, 10.6 micrometers. Epilog Laser Manufactured. User replaceable.

- Laser Tube Wattages: CO2: 40 or 50 watts

- Engraving Speed: 2 overhead

Fusion Edge - Business Series

-

Epilog’s newest laser machines combine our top-of-the-line technology and our latest features into smaller-format systems, with 120 IPS (3.05 m/s) engraving speed and 5G acceleration.

Featuring up to 120 IPS (3.05 m/s) engraving speeds, 5g acceleration, and a variety of wattage configurations, the Fusion Edge Laser Series from Epilog can help you boost your productivity and expand your product offerings. Comprised of the Fusion Edge 12, 24, and 36, all the machines in the Edge Series feature Epilog’s revolutionary IRIS™ Camera System that gives laser operators a real-time image of the engraving table so they can quickly and accurately position their artwork on even the most uniquely shaped items. Systems in the Fusion Edge Series can engrave and cut a variety of materials including wood, acrylic, fabric, cork, rubber, slate, glass, and so much more. Additionally, these easy-to-use laser machines include a 7-inch LED-lit touch display, trace capabilities at the laser, as well as SAFEGUARD™ features that keep the mechanics of your laser cleaner than ever.

Fusion Edge 12

-

- Work Area: 24" x 12" x 7" (610 x 305 x 178 mm)

- Laser Options: CO2 or Fiber

- CO2: 50 or 60 watts

- Fiber: 30 watts

- IRIS™ Cameras: 1 overhead

Fusion Edge 24

-

- Work Area: 24" x 24" x 10" (610 x 610 x 254 mm)

- Laser Options: CO2

- CO2: 50 or 60 watts

- Fiber: n/a

- IRIS™ Cameras: 2 overhead

Fusion Edge 36

-

- Work Area: 36" x 24" x 10" (914 x 610 x 254 mm)

- Laser Options: CO2

- CO2: 60, 80, or 100 watts

- Fiber: n/a

- IRIS™ Cameras: 2 overhead

Fusion Pro Lasers - Industrial Series

-

Engineered for speed, precision, and ease of use, the Fusion Pro Series from Epilog Laser is designed to elevate your production workflow. With engraving speeds of up to 165 IPS (4.2 m/s), 5g acceleration and power up to 200 Watt these systems deliver exceptional output.

Available in three sizes—Fusion Pro 24, 36, and 48—this series offers a range of CO₂, fiber and dual source laser configurations, making it the perfect solution for a variety of materials and applications, from signage and personalization to industrial marking.

Fusion Pro 24

-

- Work Area: 24" x 24" x 9" (610 x 610 x 228 mm)

- Laser Options: CO2, Fiber, or Dual Source

- CO2: 60 or 100 watts

- Fiber: 30 watts

- Dual Source: 60 watt CO2 and 30 watt Fiber lasers or 100 watt CO2 and 50 watt Fiber lasers

- IRIS™ Cameras: 2 overhead + registration

Fusion Pro 36

-

- Work Area: 36" x 24" x 9" (914 x 610 x 228 mm)

- Laser Options: CO2 or Dual Source

- CO2: 60, 80, 100, or 120 watts

- Fiber: n/a

- Dual Source: 80 watt CO2 and 30 watt Fiber lasers or 100 watt CO2 and 50 watt Fiber lasers

- IRIS™ Cameras: 2 overhead + registration

Fusion Pro 48

-

- Work Area: 48" x 36" x 12.25" (1219 x 914 x 311 mm)

- Laser Options: CO2 or Dual Source

- CO2: 80, 100, 120, 200 watt watts

- Fiber: n/a

- Dual Source: 100 watt CO2 and 50 watt Fiber lasers or 120 watt CO2 and 50 watt Fiber lasers

- IRIS™ Cameras: 2 overhead + registration

Fusion Galvo G100

- Metal Marking Machine

The Fusion Galvo by Epilog Laser combines fast engraving of metals with quick and efficient project setup. This innovative laser machine produces a variety of marks on metal, including deep engraving, polished white marks, and deep black annealed etching. Project setup is fast and easy using Epilog’s Laser Dashboard and artwork placement is exceptionally precise thanks to the IRIS™ camera system. The Fusion Galvo features an exceptionally user-friendly interface and uses high-quality parts and components, giving you unbeatable metal etching results.

Fusion Galvo G100

-

The Fusion Galvo engraving machine from Epilog Laser combines leading-edge galvo technology and our latest features that allow manufacturers to quickly and easily engrave metal parts and components.

- Work Area: F163: 4" x 4" (101 x 101 mm), F254: 6" x 6" (152 x 152 mm)

- Material Thickness: F163: 10" (254 mm), F254: 6" (152 mm)

- Laser Source: Fiber, air-cooled, 1064nm

- Laser Source Wattages: 30-watt pulsed, 30-watt MOPA, or 60-watt MOPA fiber configurations

- IRIS™ Camera System: 2 overhead

- Software Compatibility: Works with most Windows-based CAD and design software

- Wireless Connectivity: Included

- Included Lenses: F163 and F254 lens

- Resolution: Fully-flexible & user-controlled from 75 – 1200 dpi

- Print Driver & Software: Laser Dashboard™, Epilog Job Manager™

- Internal Memory: Store multiple files up to 1 GB. Engrave any file size.

Laser Applications and Uses

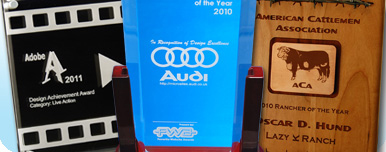

Award Engraving

- Though our lasers are capable of tackling many applications, Epilog actually got its start in the awards industry back in 1988. Since then, our customers in this space have gone from engraving simple name plates on trophies to creating unique, customized awards for all types of occasions. One of our customers even makes the coveted Grammy Award – the highest achievement in music! From corporate awards to employee recognition pieces to student trophies and far beyond, Epilog Laser machines are so versatile and user-friendly, you can create nearly any kind of award you need – quickly and easily.

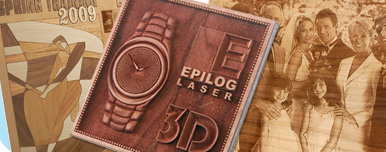

Wood Engraving and Cutting

-

Why are woodworkers increasingly adding a laser engraving machine from Epilog to their workspace? It’s because the versatility of the laser can’t be matched for woodworking projects.

Wood cutting and engraving are two of the most popular applications for the laser because they can encompass so many different projects. From cabinetry to photo frames to knife handles, Epilog Laser systems are used in almost every woodworking category you will run across. Whether you are working with hardwoods, veneers, inlays, mdf, plywood, walnut, alder, or cherry, you can engrave amazingly intricate images with a laser system.

Laser Etching & Engraving Glass

-

Glass engraving and etching with a CO2 laser produces a beautiful frosted effect, allowing you to etch custom logos and designs on nearly any glass product.

Epilog's Rotary Attachment option makes setting up glassware for engraving a breeze! The rotary allows you to easily set up different sizes of glasses, mugs, vases and wine bottles for engraving. The rotary turns the piece as the laser etches your pattern. No special measurements are required to create these custom etchings!

LASER APPLICATIONS CO2 Metal Marking Spray with a Laser

- CO2 laser machines can directly mark a variety of coated metals such as anodized aluminum or powder coated stainless steel. However, bare metals reflect the wavelength of a CO2 laser, meaning direct marking typically requires a fiber laser source. Fortunately for CO2 laser owners, there’s another great option. Bare metals like titanium or nickel plating can be pre-treated with a metal marking compound prior to engraving with a CO2 laser. The pre-treatment process is very simple and while it will not actually remove any of the metal material, you will be left with a durable and permanent raised mark on your bare metal products. Operators simply apply the marking solution – some common products include CerMark, Enduramark, and LaserBond – allow it to dry, and then perform the engraving as normal. The heat from the laser bonds the solution to the metal, resulting in a permanent black, silver, or sparkle-type mark from a CO2 laser machine.

Barcode Engraving with a Laser Engraver

- Laser engrave your barcodes, serial numbers, and logos with an Epilog Laser system. Our fiber laser systems directly engrave or mark any bare or coated metal including stainless steel, tool steel, brass, titanium, aluminum and much more, allowing you to create a variety of mark types in no time! Whether you’re engraving one piece at a time or a table full of components, with its easy setup process and precise marking capabilities, a fiber laser is an ideal choice for custom barcode engraving.

UID Laser Marking

-

Unique Identification (UID) is a Department of Defense (DoD) designed program for identification, traceability and accountability of government property purchases. Incorporating bar codes, data matrix codes and human readable text, the unique identification mark allows for lifecycle tracking of UID required items.

Whether applied directly to an individual part or to a non-removable tag affixed to the item, Epilog laser systems provide an inexpensive solution for UID marking requirements.

Laser Engraving & Cutting Leather

- Leather is an exceptionally popular material to laser engrave and cut for a variety of reasons. Raw leather sheets and premade leather products are relatively affordable, extremely durable, and have a high perceived value, especially when they are personalized for a customer with a laser. Combining an Epilog Laser and this versatile substrate can open the door to many profitable applications and opportunities, from fashion accessories to promotional products and everything in between.

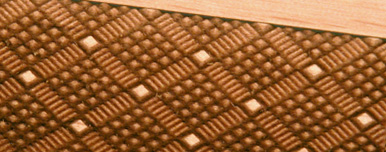

Gunstock Engraving and Checkering

-

While engraving and etching checkered patterns and other designs used to be done manually, Epilog’s innovative cutting and engraving solutions produce the hand-made results you want in just a fraction of the time.

From text to photos, logos and other graphics, our systems easily create intricate checker patterns and other engravings on any wooden gun stock. Adding additional texture, such as a checkered pattern, not only creates a sense of personal style, but can also improve your grip while shooting.

Laptop Engraving

-

With a laser system from Epilog, you can engrave laptops, creating customized, one-of-a-kind images that really stand out. Simply set the laptop into the laser system, scan in your image, logo or photo and print it to the laser.

You’ll be able to achieve amazing images on customer laptops. Concerned about security? A customized laptop is more likely to deter thieves from taking your computer, and will increase the chances of getting your laptop back should it be stolen.

Laser Engraving Machines for Schools, Universities, and Fablabs

- Laser engraving machines are a must-have in schools nowadays. Laser machines are not only used as a tool in the design of boxes and the making of prototypes; we’re also increasingly seeing complete teaching packages written around them. Experience with the lasers gives students enough experience to get started and sets them up for success in the future.

Laser Engraving Fabric &Textiles

-

Why are woodworkers increasingly adding a laser engraving machine from Epilog to their workspace? It’s because the versatility of the laser can’t be matched for woodworking projects.

Wood cutting and engraving are two of the most popular applications for the laser because they can encompass so many different projects. From cabinetry to photo frames to knife handles, Epilog Laser systems are used in almost every woodworking category you will run across. Whether you are working with hardwoods, veneers, inlays, mdf, plywood, walnut, alder, or cherry, you can engrave amazingly intricate images with a laser system.

Plastic Marking with a Laser

-

A fiber laser from Epilog is the perfect choice for marking engineered plastic parts with barcodes, serial numbers and logos. Our plastic marking systems come in a variety of sizes so you can laser mark large parts one at a time, or load the table with a jig of parts to engrave hundreds at once.

By using Ytterbium Fiber Laser (1062 nm) technology, the laser quickly creates a permanent mark on your plastic part by reacting with the chemicals in the plastic to create a colored mark on the plastic, whether it is black, white, orange, or many other colors of plastic.