- Offer Profile

PRECISION BEARINGS &

High precision bearings and linear technology that offers a performance beyond standard specifications – this is our demand for the mechanical engineering industry. From single machine components through ready-to-install complete systems, Rodriguez believes in technically sophisticated, integrated and customized solutions that successfully satisfy the customer demands.s

LINEAR TECHNOLOGY

Precision bearings

-

Precision bearings - Nothing moves, without them

Whether it's in vehicles or machinery - bearings are what keep things moving in virtually all automated processes. The bearing technology used here is as diversified as the range of possible applications.

In the field of precision bearings, Rodriguez can demonstrate the decade-long experience our engineers have when it comes to practical designing. Customers benefit from this when it comes to the development of new products and the application-oriented modification of individual components. At the end we always deliver solutions beyond the standard: Drive components developed according to the maxime "always the right bearing for the corresponding requirement". Thin-section bearings

-

Lightweights with a small cross-section

Compact thin-section bearings by Rodriguez in inch and metric measurements are the right choice for all applications in the mechanical engineering industry, where compact design, low weight and miniaturisation is important.

One of the most important applications of the Rodriguez thin-section bearings is in robotics technology. There they are used, for instance in the hand axes of painting robots in the automotive industry. With more than 250 different types of thin-section bearings up to hybrid versions with ceramic balls, Rodriguez is offering the optimal solution for each constructive problem.

Smaller and lighter - this is a requirement in many modern designs. This requirement is met by thin-section bearings.

Advantages of Rodriguez thin-section bearings

- Thin-section bearings have a large bore diameter with a smaller bearing cross-section.

- Solid shafts can be replaced with hollow shafts.

- The free interior of the thin-section bearings can be used for air ducts, hydraulic piping, electrical wiring or slip rings.

- Thin-section bearings are small, light and compact.

- Despite miniaturisation, the performance of thin-section bearing is comparable to that of normal bearings.

REALI-SLIM® thin-section bearings – Compact and lightweight roller bearings

-

Modern designs rely on a compact design, low weight and miniaturization. This highly engineered bearings, such as the KAYDON REALI-SLIM® thin-section bearings are an ideal solution. Each series of REALI-SLIM® thin-section bearings is based on a single cross-section that remains constant even with increasing bore diameter - that is truly something unique! Thanks to this design novelty, solid shafts can now be replaced with hollow shafts. The interior of the hollow shaft provides space for components such as air or hydraulic lines, electrical wiring or slip rings.

For a large number of applications, a four-point contact REALI-SLIM® thin-section bearing can even replace two bearings. This allows a more compact design and simplifies the installation.

Typical applications for REALI-SLIM® thin-section bearings:- Aircraft and aerospace

- Aerospace

- Assembly and feeder machines

- Food industry

- Rotation tables

- Packaging technology

- Machine tools

- Medical technology

- Optical scanners

- Satellite and communication technology

- Robotics Textile machines

- Pipe-cutting machines

- Semiconductor industry

ULTRA-SLIM® thin-section bearings – Compact and space-saving roller bearings

-

With a cross-section of only 2.5 to 3 millimeters, the ULTRA-SLIM® thin-section bearings are available in boresizes ranging from 35 to 200 millimeters, for an array of applications requiring compact motion control design components.

The precision-engineered ULTRA-SLIM® thin-section bearings are made of stainless steel rings and ceramic balls for corrosion resistant and suitable for vacuum environments.

Rodriguez offers the ULTRA-SLIM® bearings as angular contact bearings (type A), radial ball bearings (type C) and 4-point-contact bearings (type X). Customer-specific solutions are also possible.

Features and benefits of the ULTRA-SLIM thin-section bearings- Low weight

- Space saving

- Small cross-section

- Corrosion resistant

- Vacuum application suitable

- Diameter 35 - 200 mm

- Stainless steel rings + ceramic balls

Metric thin-section bearing - The original in metric dimensions

-

Thin-section bearings in a metric design reduce the design effort. A conversion to metric dimensions is no longer required - which in turn saves time. In addition, they are characterized by the typical advantages of Rodriguez thin-section bearings: their light weight and small cross-section.

All Rodriguez metric thin-section bearings are available either as radial, angular or four-point-contact bearings.

Hybrid thin-section bearings - For clean-room applications

-

Abrasion and high temperature resistant ceramic balls are the rolling elements of hybrid thin-section bearings. Rodriguez offers this special bearing with a cage of metal or plastic, as well as full compliment version without cage. Hybrid bearings are very well suited for applications where lubrication is marginal, therefore the right solution for vacuum and clean room applications.

Features and benefits of the hybrid thin-section bearings- Corrosion resistant

- Lowest contamination

- For poor lubrication and for dry running

- High-temperature range

- Clean room and vacuum suitable

REALI-DESIGN®-Software - Specialized engineering software

-

The REALI-DESIGN® engineering software is available for the bearing selection and design concepts for REALI-SLIM® thin-section bearings from KAYDON®/Rodriguez. The program accelerates and precisely defines the selection and design process. The software provides users with useful tools, information and data. These include a complete, CAD-ready DXF library, a program to create data sheets as well as training modules and a whole lot more. The REALI-DESIGN MM™ is specifically provided for the design and calculation of metric bearings.

- Select the right REALI-SLIM®- thin section bearing

- Find the suitable design

- Expedites and specifies the selection and design process

Precision Bearings

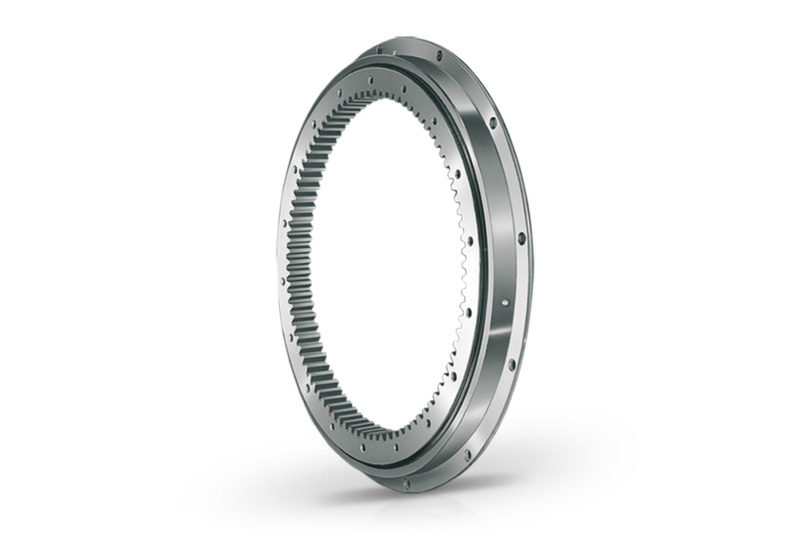

Turntable bearings

-

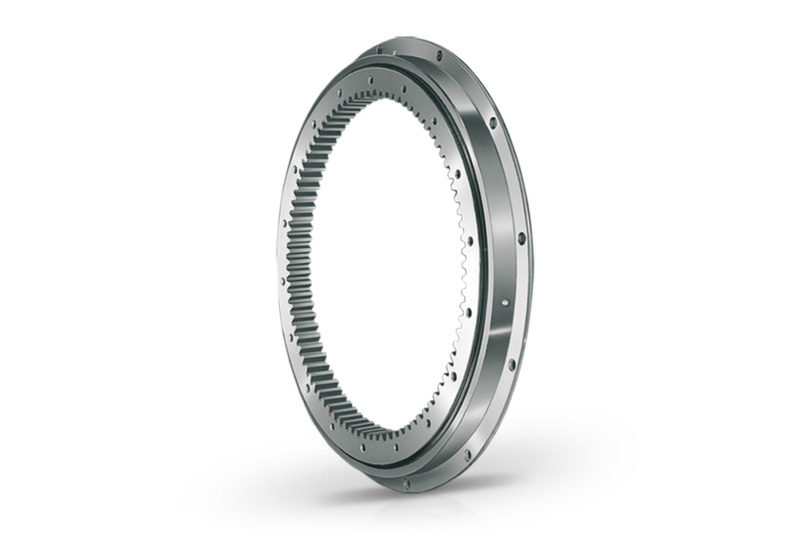

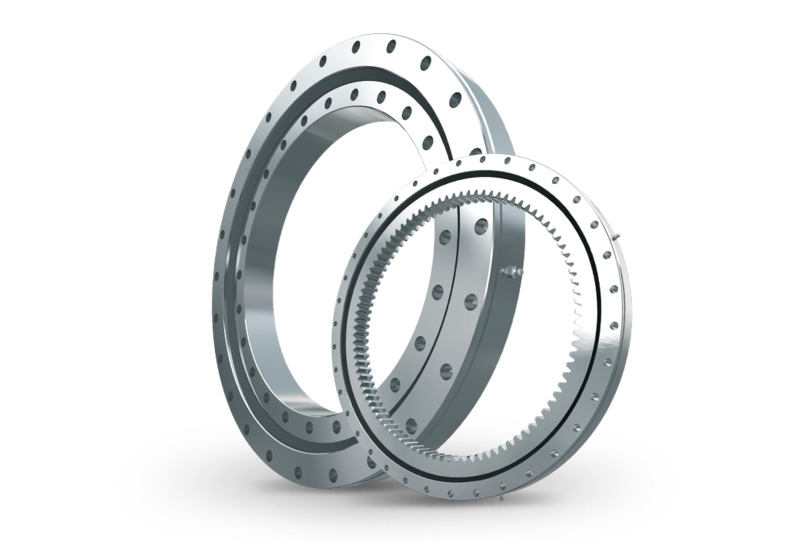

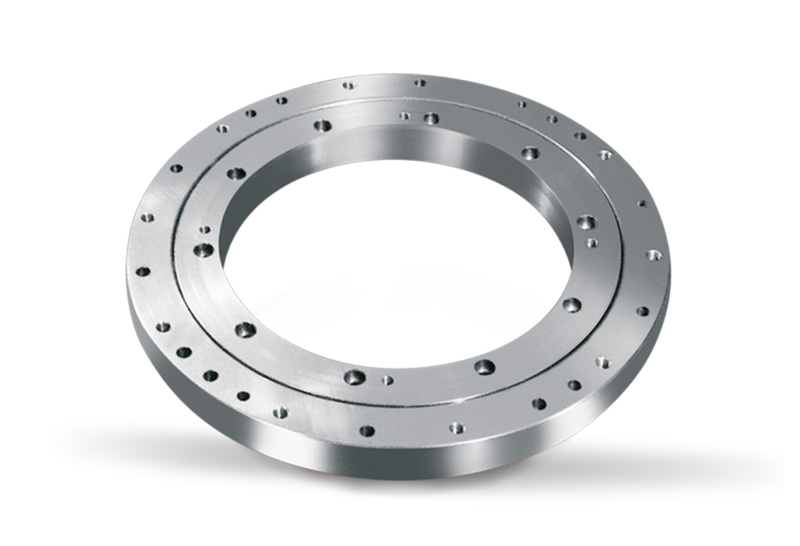

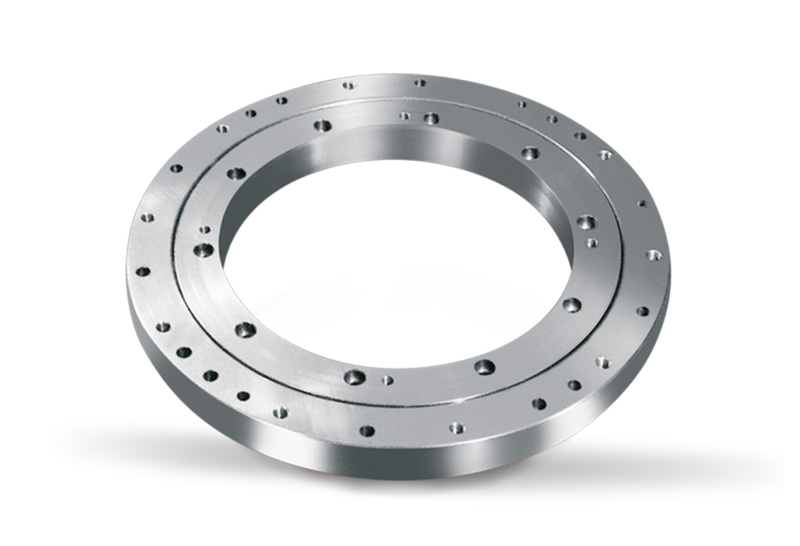

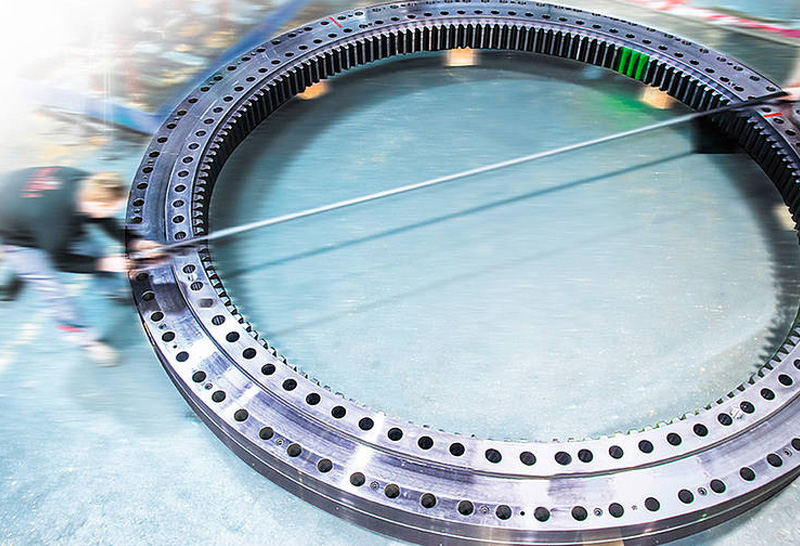

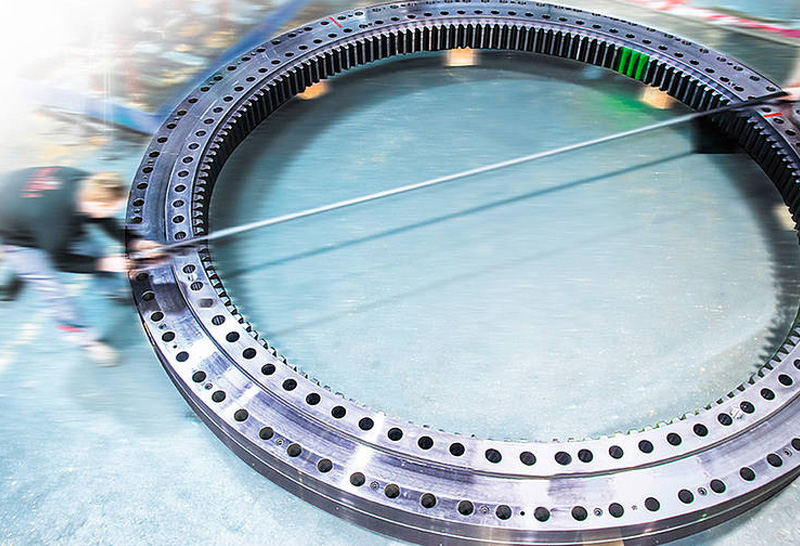

Rugged, multifunctional and weight reductive

For heavy-duty applications

The rugged turntable bearings from Rodriguez are characterized by their large diameter and large bores with only a small cross-section. They were designed for axial, radial as well as combined axial and radial loads. New design concepts and improved manufacturing processes for the turntable bearings, enable our customer's designers to implement completely new solution approaches. The bearings are very easy to assemble and demonstrate their properties particularly in small, sophisticated and high precision applications such as in the aerospace industry or in the special machinery area.

The bore diameter of the Rodriguez turntable bearings is at least 50 millimeters. The bearings are available with and without gear teeth, optionally in a corrosion-resistant or a customer specific tailor-made design.

Advantages of Rodriguez turntable bearings

- Bore diameter starting from 50 mm

- Simple installation

- Available in various, individual versions

- Available with internal or external gear and without gear

- Corrosion-resistant types available on short notice

- Generally short delivery times

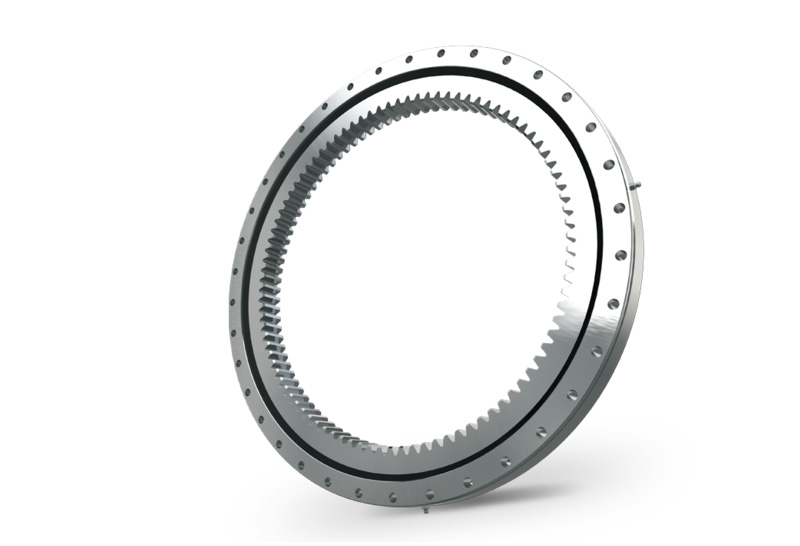

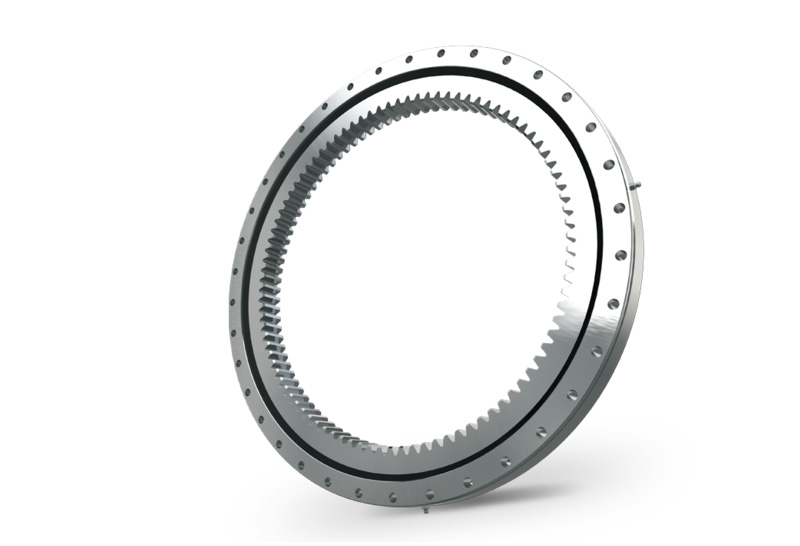

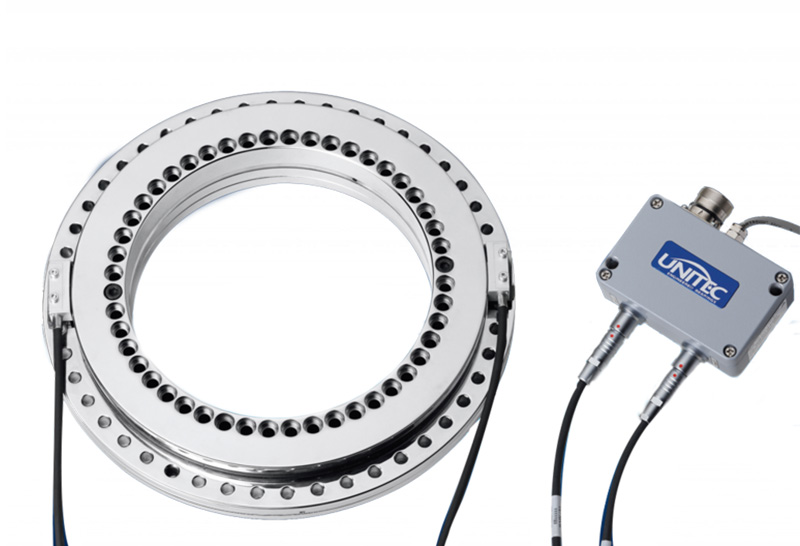

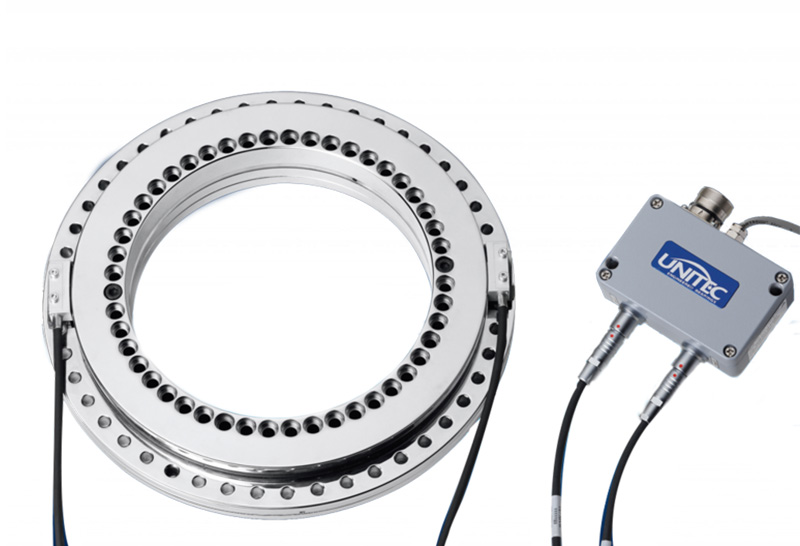

Miniature turntable bearings

-

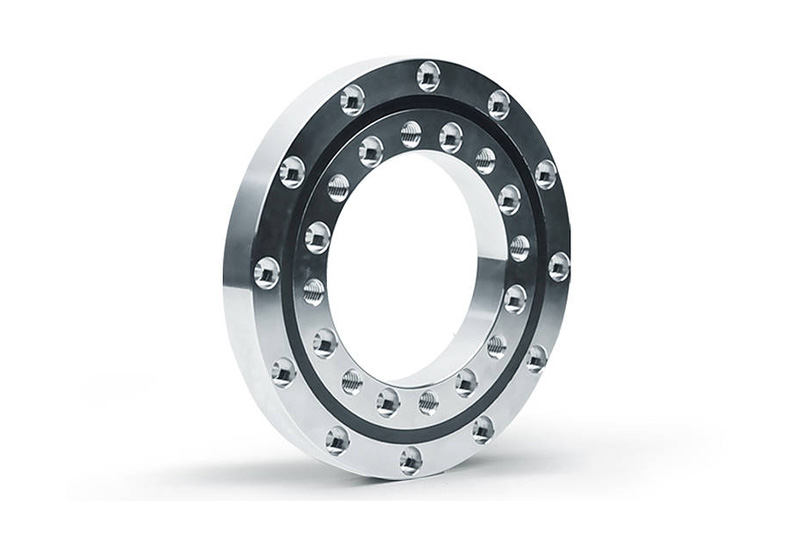

Maximum performance in the smallest space

At Rodriguez, miniature turntable bearings are customized solutions, produced on in-house machining equipment. They are available with internal or external gear and without gear. These innovative bearings convince through a small cross section and a particularly compact design: inner diameters off 30 mm are possible at a cross section of approx. 6.5 mm.

The miniature turntable bearings are made of stainless steel whereby Rodriguez manufactures the bearings according to the individual requirements of their customers – modifications are not only possible in relation to material, but also for the drilling pattern, the seal and the shape of the rings. Corrosion protected versions are also available. Integrating certain functions in the bearing – such as grooves with control functions or mountings and brackets – makes it possible to reduce the number of the needed components. This reduces the number of interfaces, which in turn prevents errors and contributes to a higher system accuracy.

Thanks to their various positive attributes, Rodriguez miniature turntable bearings have proved effective in a variety of sectors such as semiconductor production, optics, medical devices, measurement technology and automation.

Advantages of Rodriguez miniature turntable bearings

- Compact design, low weight, small cross-section

- Customizable

- Also available in small quantities

- Available with internal or external gear and without gear

- Gearing in modular or toothed belt version

- Corrosion protected versions possible

- Simple and thus cost-effective installation

- Partly available from stock

Cross roller bearings

-

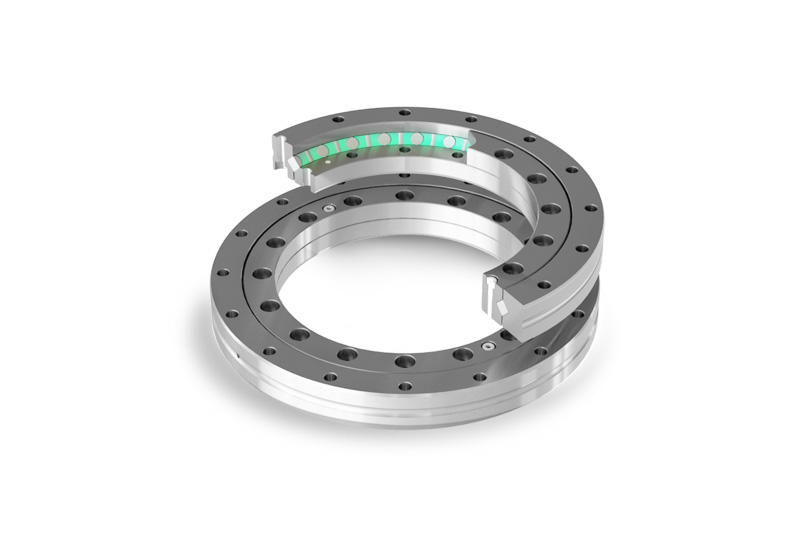

Compact, highly loadable and flexible

For special performance and high precision

Cross roller bearings are highly efficient cylindrical roller bearings. They are characterised by the crosswise layout of the cylindrical rollers, which roll at right angles in ground raceways. The X arrangement of the cylindrical rollers ensures a compact design. In addition, the bearings can support high axial loads in both directions - with radial loads and high tilting moments. By combining loads in cross roller bearings, traditional solutions with radial and axial bearings can often be reduced to a single bearing position.

Rodriguez supplies cross roller bearings for precision applications these are used when high tilting rigidity is required. They excel with their rigidity and high running accuracy and can be supplied with normal clearance, reduced clearance or preload. Key applications include rotary indexing tables and rotary tables with horizontal and vertical axis. All cross roller bearings can be designed and manufactured according to customer requirements.

Space-saving and precise cross roller bearings are part of the wide Rodriguez range of precision bearings for machine tools. With a variety of suitable products, all requirements in this demanding field of application can be met.Advantages of Rodriguez cross roller bearings

- High precision

- High rotation accuracy and rigidity

- Compact design

- Absorption of radial and axial loads from both directions

- High tilting moment load capacity

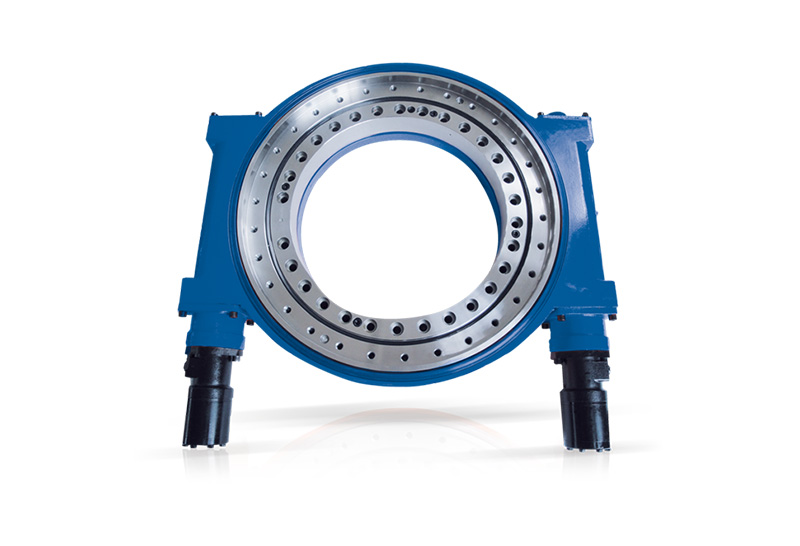

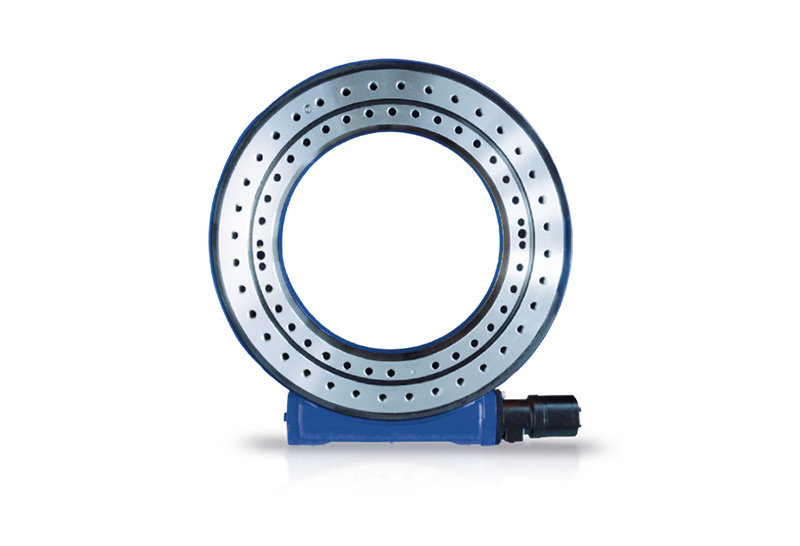

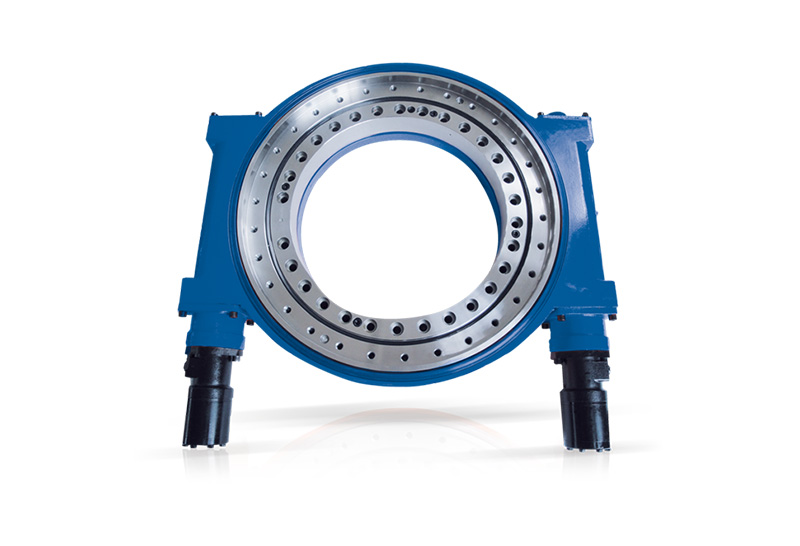

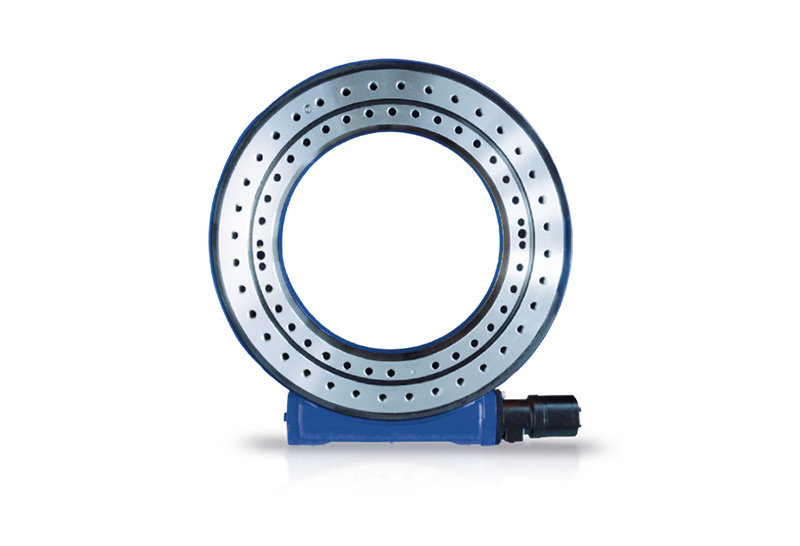

Slew drives

-

Ready-to-install and compact

The ready-to-install solution for your application

Beyond our rugged turntable bearings, the Rodriguez slew drives are the compact system assemblies for your application: They ensure an optimum transmission of forces and high torques in a closed unit with long lifetime and high reliability.

The modular design of Rodriguez slew drives guarantees high flexibility. On demand, our slew drives are available in hydraulic or electric versions and with brake and sensors for location feedback. Moreover, they are easy to integrate into current constructions.

Housings, turntable bearings and worm drives do perfectly match and render a complicated single part assembly unnecessary. Rodriguez slew drives are available in many standard dimensions as well as with motor connections.

Advantages of Rodriguez slew drives

- Protected and ready-to-install system assembly

- High torques in compact constructions

- Easy to install in current applications

- Lower effort of mounting and maintenance

- Available with many current standard connections

- On demand with electric and hydraulic version, brake and sensors available

- Customized solutions

- Short delivery times

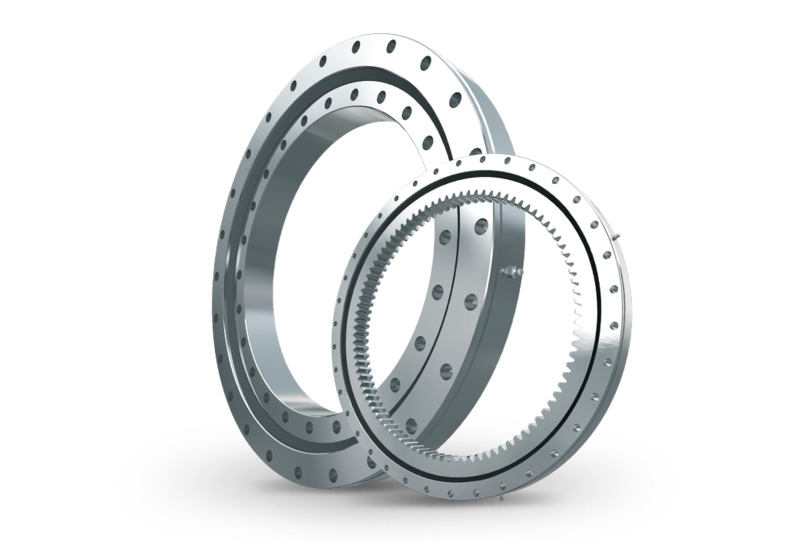

Large diameter slewing bearings

-

Flexible and robust

Precision in big dimensions

As a result of their flexible capabilities, the rugged large diameter slewing bearings from Rodriguez are already operating in a large number of application areas.

Difficult ambient conditions, significant high load cases, specific turning characteristics and high lifetime benchmarks require suitable solutions: We at company Rodriguez are well prepared for your requirements.

Our scope of supply in the field of large diameter slewing bearings contains ball- and roller slewing bearings, geared rims and customized solutions with integrated drives.

No matter if you are interested in a new design or an urgently required spare part, with internal or external gearing, even tooth belt or helical gearings: with a diameter up to 240 inch (6.100mm) Rodriguez offers a suitable drive solution for nearly every application.

Advantages of Rodriguez large diameter slewing bearings

- Maximum outer diameter of 240 inch (6.100 mm)

- Internal and external gear up to module 30

- Ground gears, tooth belt gearings and other specialized gears on request

- Certified to meet EN 10204 requirements for materials, dimensions and operating specifications

- Corrosion protected version

- Customized engineering

- Rapid construction of prototypes

- Identical replacement parts for your operating ball and/or roller Slewing Bearings

- Short delivery times

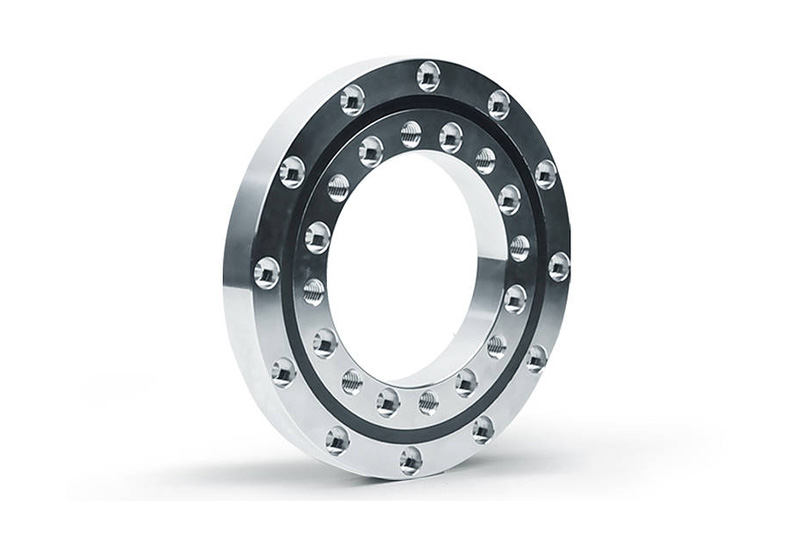

Axial-radial precision roller bearings

-

For precise rotation

If you want things to turn smoothly

The Rotary Table Bearings (RTB) from Rodriguez are bidirectional axial-radial precision roller bearings. They are especially designed for the application in rotary tables and spindle heads of machine tools. The ready to use and compact RTB bearings convince through high stiffness and high axial and radial capacity.

Advantages of Rodriguez RTB-bearings

- Precision bearings up to class P4

- Compact and ready to use bearing units

- High axial and radial load capacity

- High stiffness

- Bearing design according to customer's request

Special customized bearings

-

Bearings for customer specific applications

Made-to-order for the customer

Standard ball bearings are not suitable for many ball bearing applications. This can have economic reasons or reasons relating to the design. For these reasons, Rodriguez is also offering a wide range of individual and customized solutions.

The special customized bearings can be manufactured from various materials and in different surface qualities. The client has the choice between turned or grounded bearings and designs in roller bearings steel, stainless steel, plastic or a mix of stainless steel and plastic.

With the special customized bearings, the user also benefits from the know-how of our engineers in the made-to-order development for the customer’s application and the system integration.

Advantages of Rodriguez special customized bearings

- Bearings made of different materials: bearing steel, stainless steel, plastics, steel/plastic mixture

- Turned or grounded

- System integration

- Customer specific applications

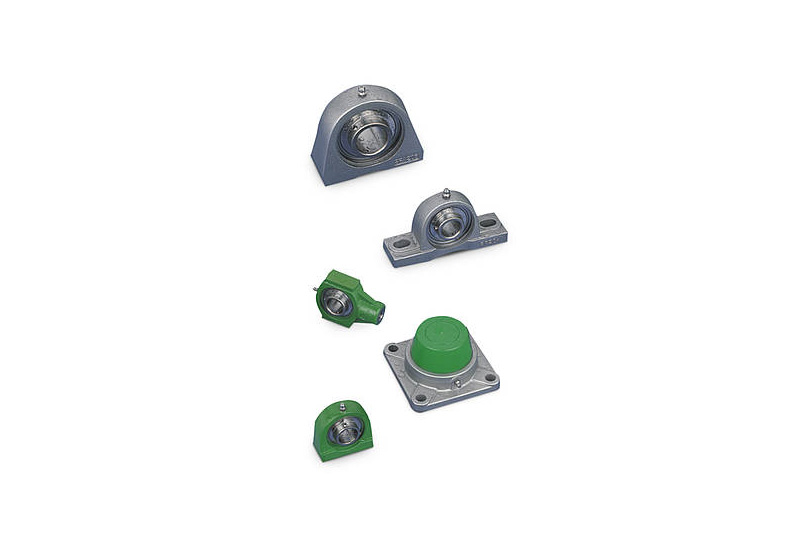

Stainless steel & thermoplastic bearing housings

-

Hygienic bearings for simple cleaning

Lightweight and hygienic

Machines and components used in the pharmaceutical or the food industry must be easily cleanable and resistant to aggressive cleaning agents as well as damp environments. That is exactly what the Rodriguez stainless steel and thermoplastic bearing housings offer: They are corrosion resistant, easily cleanable and on top of that especially light.

Therefore, next to their utilization in the food and pharmaceutical industry, they are also ideally suited for the application in the chemical industry as well as in bottling and paper treatment systems. In addition to standardized components Rodriguez primarily offers need-based and customer-specific solutions. Just ask us!

Advantages of Rodriguez stainless steel & thermoplastic bearing housings

- Low weight

- Easy to clean

- corrosion-resistant

- hygienic surface

- antimicrobial

- chemical resistant

- relubricatable

Linear Technology

-

Linear technology from Rodriguez – precise guidance for every motion

Linear guides and linear actuators are used in diverse industrial applications. Linear technology is used for example in loading and unloading processes, pick & place applications or for numerically controlled processes in machines and systems.

Linear motion processes vary widely and generally require individual solutions on the basis of linear guides and linear actuators. Rodriguez offers a broad range of linear guides, profiled rail guides and linear actuators in many different sizes and types. In addition to individual custom solutions, we also develop complete linear systems with different drive variants on the basis of our linear guides.

LINEAR GUIDE COMPONENTS

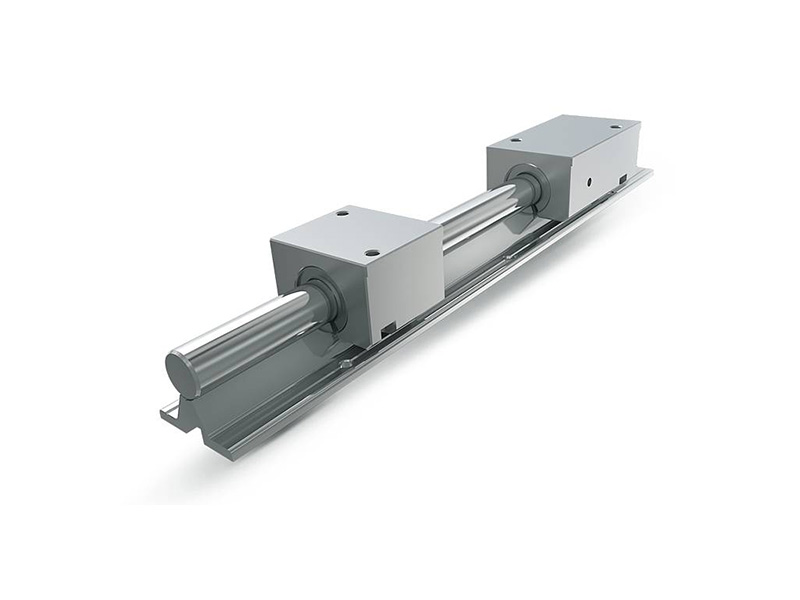

Linear roundrails

-

Linear roundrails are reliable and powerful - Classic components for reliable linear motion

Linear roundrails are long established as machine elements for the execution of linear motions and have optimally withstood the test of time in industrial applications. They can be used for example as adjusting units in automation tasks.

Linear roundrails are robust, reliable, powerful and – due to their simple construction – very economical. The construction of the roundrails, which is based on hardened guide carriages in combination with different linear-motion bearings or linear-motion bushes, allows many possibilities for variation. Rodriguez also offers sliding bearing variants.

In addition to the type of bearing, there is also a broad spectrum of guide elements to choose from. Mounting the guide shaft on different shaft supports and the use of open guide elements create additional possibilities for variations. Linear roundrails with shaft support provide an economical and robust alternative to profiled rail guides.

Advantages of Rodriguez linear roundrails

- Precision shafts made of different materials

- Linear ball bushings for all performance levels

- Linear slide bushings (ceramic/self lubricating)

- Linear housings and components

- Shaft support blocks and shaft support rails

- Customer specific applications

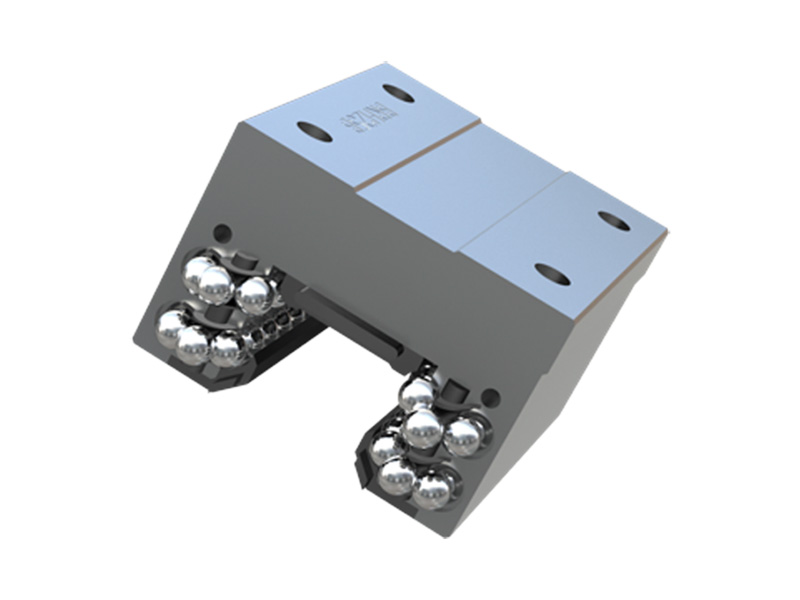

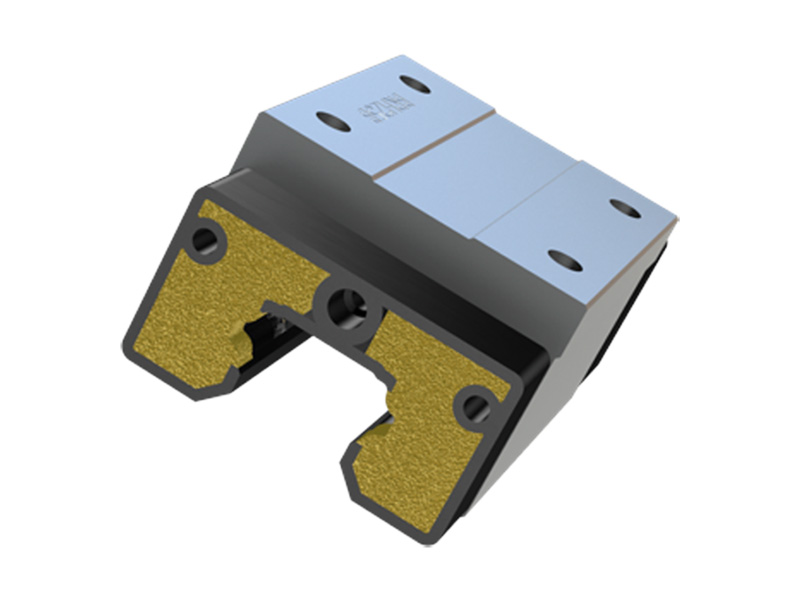

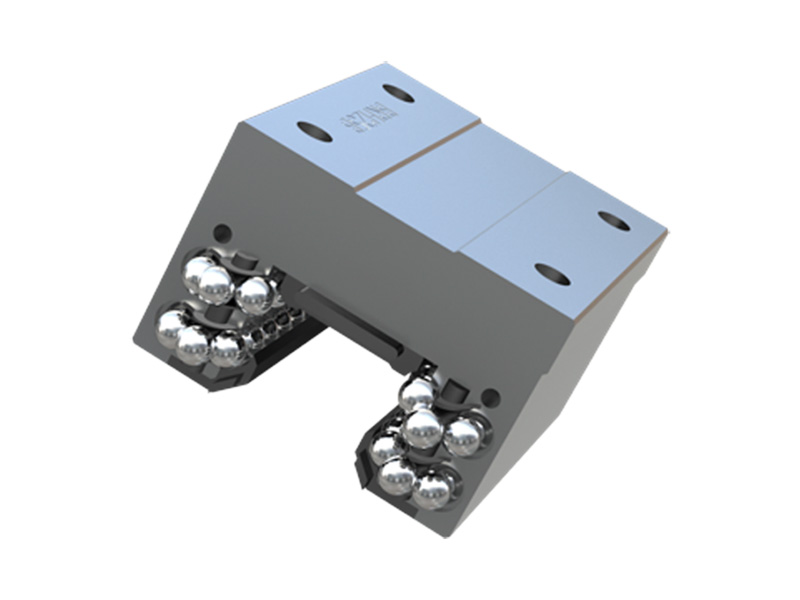

Linear guideways

-

Linear guideways can carry heavy loads

Linear guideways with four rows per carriage (in X-arrangement and 45° contact angle) can handle forces from all main directions. The X-arrangement of the raceway enables easy preload installation. Moreover, the system is less sensitive for misalignment. Linear guideways of this version are usually used for adjusting and loading equipment as well as traversing units in production machines or for robot applications.

An integrated lubrication system extend the service intervals and made the linear guideways extremely low-maintenance. Moreover, linear guideways of Rodriguez are available with ball cage. The carriages can also be delivered in different versions.

Upon request, Rodriguez linear guideways are available with a metal cover strip for protection against contamination. An external lubricant tank is available for further extension of a maintenance interval.

For particularly compact designs, Rodriguez can also provide the linear guideways in the miniature versions.

Advantages of Rodriguez linear guideways

- Low-maintenance

- No additional lubrication system required

- Extension of the maintenance intervals

- Lubricant saving

- Clean and media resistant

- Also available in a miniature version

- With a metal coverstripe

- Available with an external lubricant tank

Ball transfer units

-

Heavy duty rollers for friction-free material transfer - Friction-free heavy goods transport

Rodriguez is one of the world's largest supplier of ball transport systems. A total of 146 different variations of ball transfer units with carrying capacities from 10 to 5000 kg and ball diameters from 4.8 up to 120 mm will probably be a solution for almost any kind of transportation problem.

The product range includes universal, flange and miniature versions as well as heavy duty and high-tech versions. Depending on the application the precision balls are made of steel, stainless steel or nylon.Rodriguez ball transfer units especially prove themselves in the material flow technology - whether it's in the glass industry, metal processing, the assembly line or in the container handling. Their low friction resistance allows an easy and precise transport of even the heaviest cargo in all directions.

The typical applications of the ball caster systems are cargo-handling and conveyor systems. They always work - no matter if they are in wet or dry environments.

Advantages of Rodriguez ball transfer units

- Low friction resistance

- Large selection of standard and special ball casters

- Precision balls made of steel, stainless steal and nylon

- Ball diameter: 4.8 mm – 120 mm

- Hollow balls and specific solutions on request

Float-on™ castors

-

Castors for the easy handling of flat sheet materials - Transport made simple

The float-on™ castors from Rodriguez which were originally designed for transporting glass elements are also very well suited for transporting goods made of granite, wood, plastic, paper or cardboard. The castors can move light to heavy loads with minimal effort and allow fast as well as flexible changes of direction. They are suitable for use in wet as well as dry environments.

Rodriguez offers application-oriented versions of the float-on™ castors in a right and left alignment, and currently also two sizes with ball diameters of 35 mm and 50 mm. For standard applications, ball holders made of galvanized BZP steel are available. The stainless steel version is suitable for more demanding applications. The mounting is performed via a 14 mm bore hole. The height of the ball can be adjusted after the fixation of the base.

Advantages of Rodriguez float-on™ castors

- Easy transporting of sheetmaterials such as glass, granite or paper

- Flexible

- Rapid directional changes possible

- Designed to be used in wet and dry conditions

LINEAR DRIVE COMPONENTS

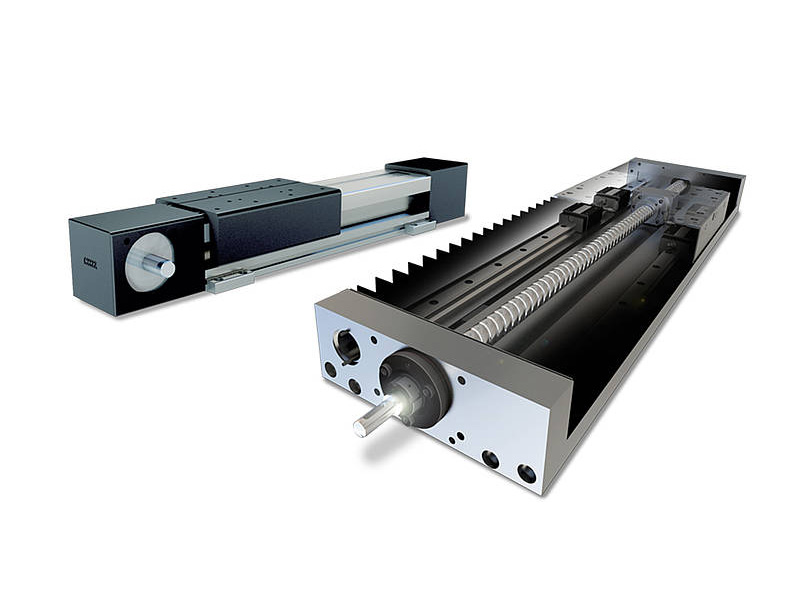

Ballscrews

-

Ballscrews transform rotational into longitudinal motions - For dynamic positioning applications

Ballscrews and trapezoidal screw drives transform a rotational into a longitudial motion and vice versa. Rodriguez offers both types of threaded spindles in both metric and imperial dimensions and in all major industry standards. Thereby, ballscrews, which work with balls as rolling elements, offer a higher efficiency than trapezoidalscrews which is exposed to a sliding friction.

Similarly, a ballscrew is preferably used for dynamic positioning applications during a continuous operation. Trapezoidalscrews on the other hand are ideal for slow movements or clamping tasks with a short duty cycle.

Ballscrew with driven ballnut AMFH

For conventional ballscrews speed is an obstacle for the implementation in many industrial applications. The longer the ballscrew spindle, the higher the risk will be that the required speed cannot be achieved due to the critical revolution-speed of the spindle. In these cases we recommend the use of a ballscrew with a driven ballnut.

The combination of custom ballscrew nut, axial angular contact ball bearings and and a precision threaded nut will yield a powerful, toothed belt driven unit that delivers optimum results even at high speeds. Upon request, a corresponding drive wheel can also be integrated.

Advantages of Rodriguez ballscrews

- Rolled, ground and whirled ballscrews

- Preload and accuracy as determined

- Individual endmachining

- Superfinished for highest loads

- Long service life and smooth running

- Fully certified and guaranteed

- Systemintegration possible

Rollerscrews

-

Permit high axial loads - High speed, high acceleration

Rodriguez rollerscrews are only used for transferring axial forces. They consist of a ground spindle and the threaded nut which is equipped with rollers. The special geometry of the thread and the rollers characterize the rollerscrews. The use of rollers with grooves on their outside diameter and the hereby resulting contact areas as well as the number of contact points permit a high axial load capacity.

Rodriguez rollerscrews are available in two basic versions: With satellite rollers or with roller feedback.

Rollerscrews with satellite-rollers or with rollercirculators consist of a ground spindle, the threaded nut and the satellite rollers. Hereby, the spindle and nut have a multiple thread profile with a slope angle of 90°. The satellite rollers are guided on both sides by geared rings and thus a distance parallel to the axis is maintained. This version of the rollerscrew is available with and without preload. To protect against coarse contaminants the threaded spindle drive nuts can be equipped with dirt wipers made of PA66.

Rollerscrews with rollercirculators do not use satellite-rolelrs, but instead rollers with grooves in their outer diameter. These are spaced according to the distance of the respective pitch. For relatively high spindle diameters they offer small pitches and thus achieve a high positioning and repetition accuracy and a high efficiency.

Advantages of Rodriguez rollerscrews

- High axial load capacity by the use of thread-rollers and the resulting contact areas, as well as the amount of contact points

- High speed, high acceleration

- High axial rigidity

- High positioning-accuracies and repeatabilities with short strokes

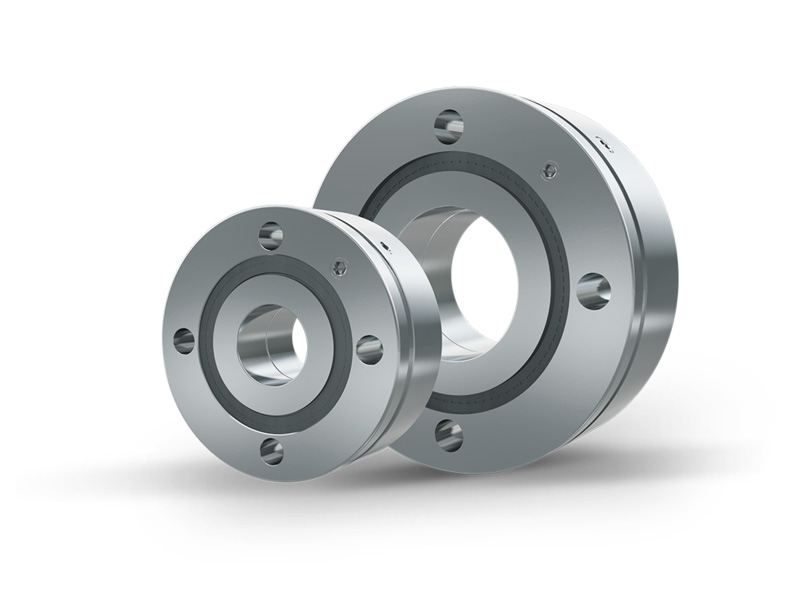

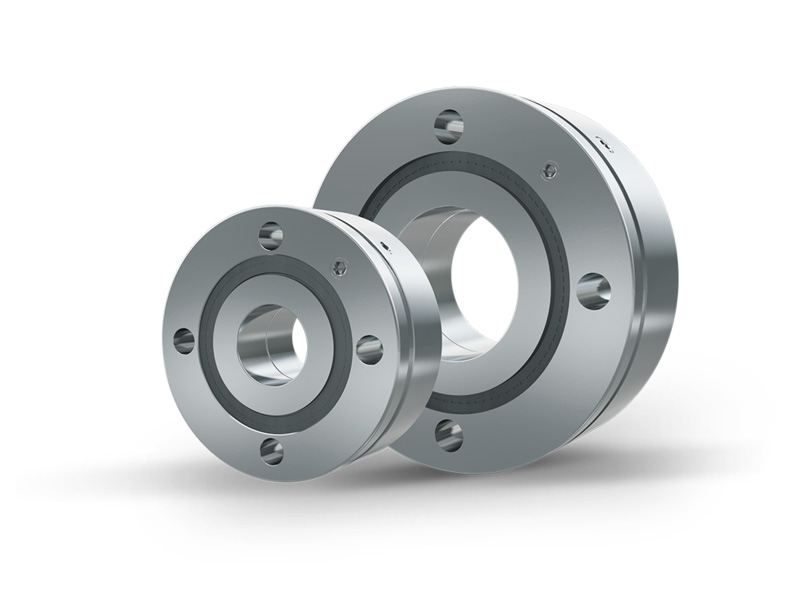

Axial angular contact bearing DRF/DRN

-

For high speeds - Guaranteed precision

The double row DRF/DRN-bearings are particularly suitable as a bearing for threaded spindles in modern machine tools. Their high rigidity and minimum runout guarantee a precise tool positioning and a reliable repeatability.

The double row axial angular contact bearings are preloaded high precision bearings with a 60° contact angle. They can absorb radial and axial forces from both directions, are low maintenance, quick to install and allow very high revolution speeds.

Advantages of Rodriguez axial angular contact bearing DRF/DRN

- High axial rigidity

- High resolution speeds

- Highest precision

- Low-maintenance

- Reduced installation times

Bearings for ball screw drives

-

For each application a perfect solution - Always the best bearing solution

For screw drives, the bearing of the threaded spindle is most important for the kind of use. The RODRIGUEZ® modular design system provides best possible bearing solutions for your application.

Double row bearings, like the bearings of the series DRF/DRN of Rodriguez are always a good solution if you need the highest dynamic und precision f.ex. in the main axis of machine tools. DRF/DRN are double row high precision bearings with 60° contact angle. They can absorb radial as well as axial loads in both directions and due to high runout accuracy and high stiffness these bearings guarantee precise positioning and repeatability. The bearings can be offered with and without fixing holes in the outer ring.

SFT support units are developed for the use in transport ball screws. The bearing units and flange bearings are robust, precise and most cost-effective. The preloaded angular contact bearings are installed in a solid steel housing with a contact angle of 30°, 45 ° or 60°. Thereby a good stiffness and precision is guaranteed. Depending on the application, bearing units can be supplied in block or flange design. In addition, the customer can choose between floating bearings, provided with double sealed standard bearings, and fixing bearing units.

Spindle roller bearings like the SRB-bearings from the Rodriguez modular design system are used when maximum rigidity and durability are most important – f.ex. in precision balls screws in machine tool applications. The bidirectional operating high precision needle-axial cylinder roller bearings are compact and absorb high axial and radial loads. Their special bearing design where the outer ring faces are acting as raceways in both axial directions and are centred on the inner ring, guarantees high precision and stiffness combined with compact bearing dimensions.

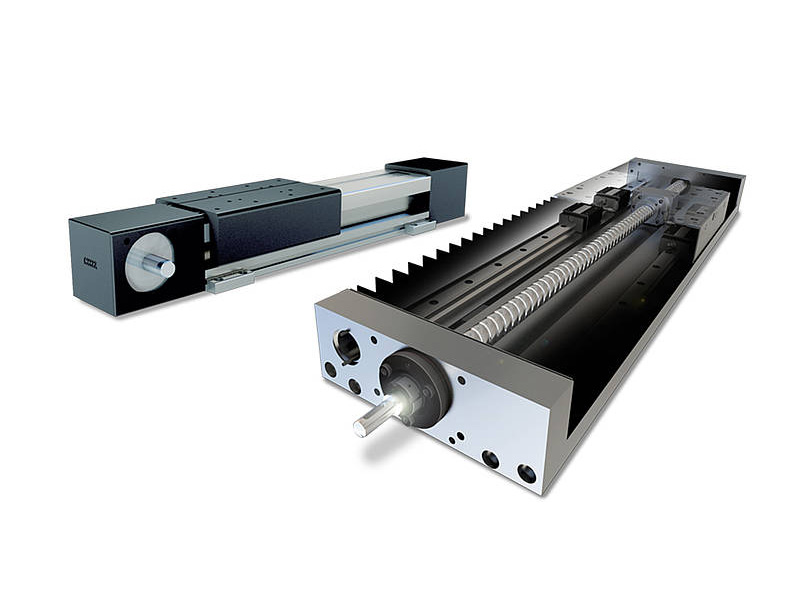

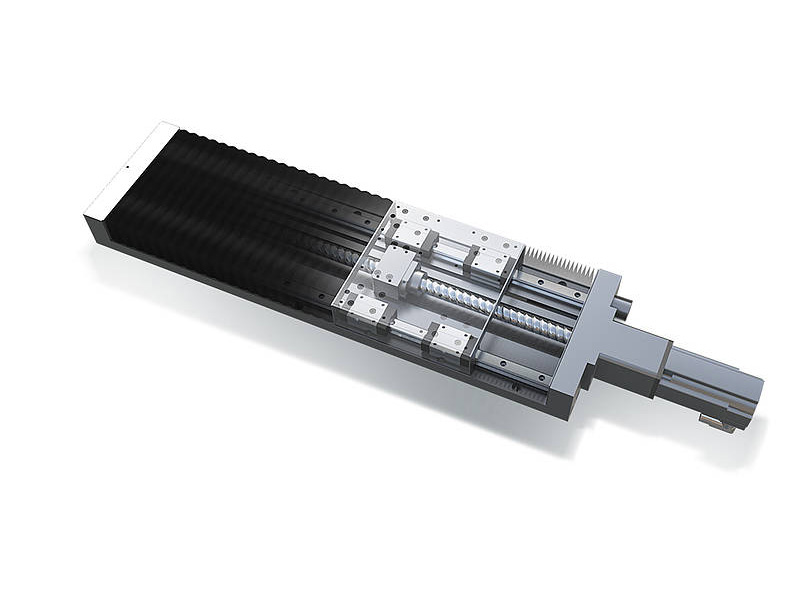

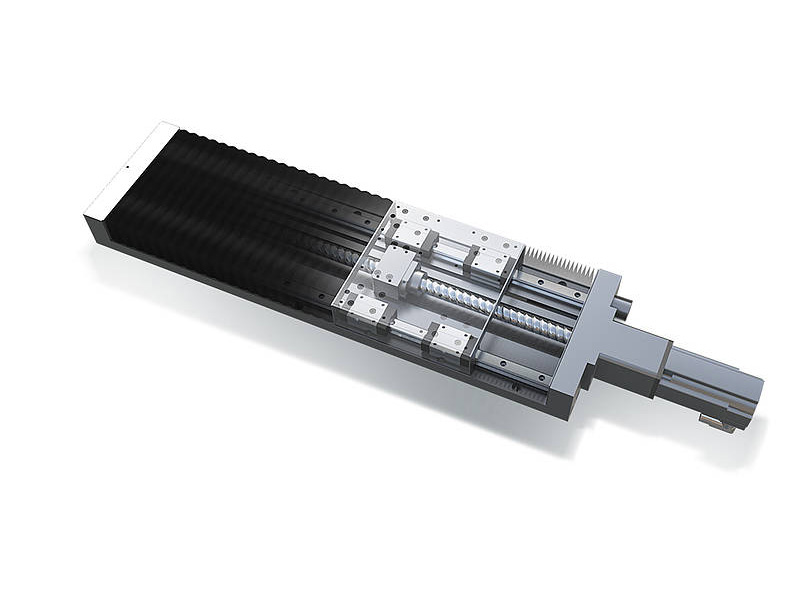

LINEAR SYSTEMS AND SUB-ASSEMBLIES

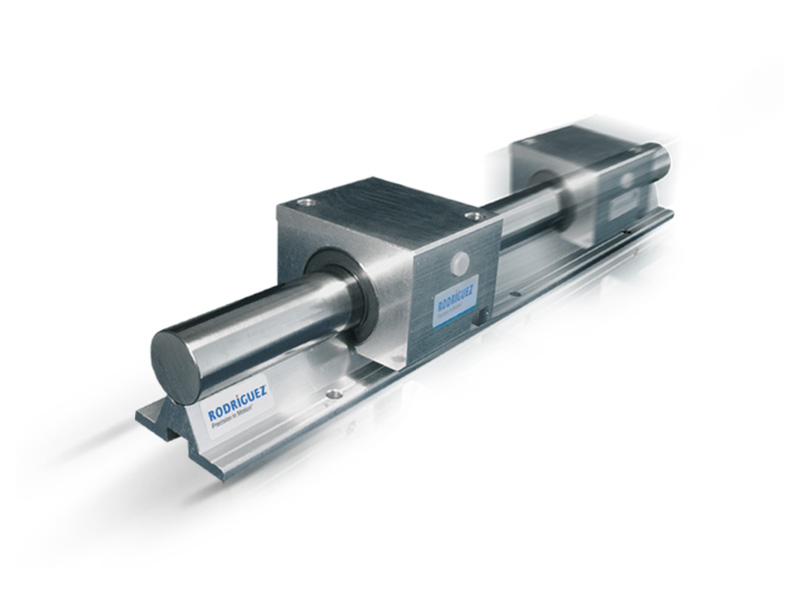

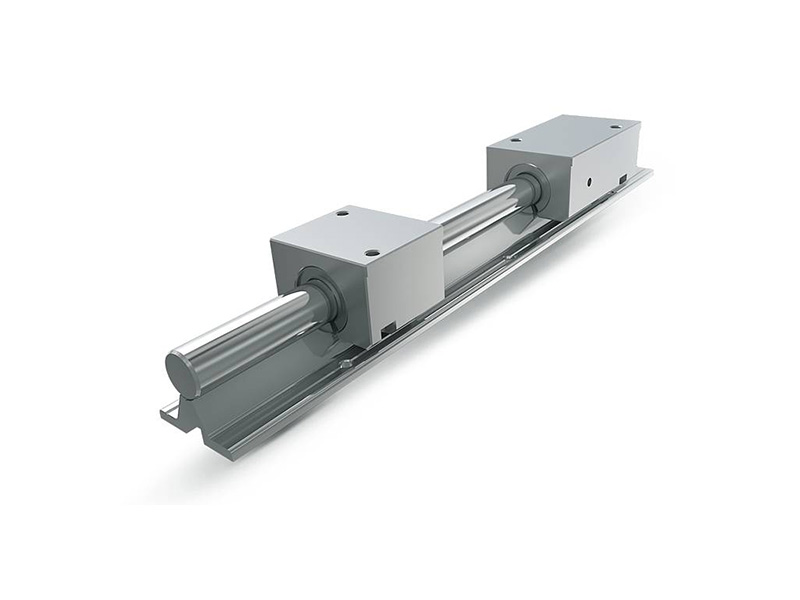

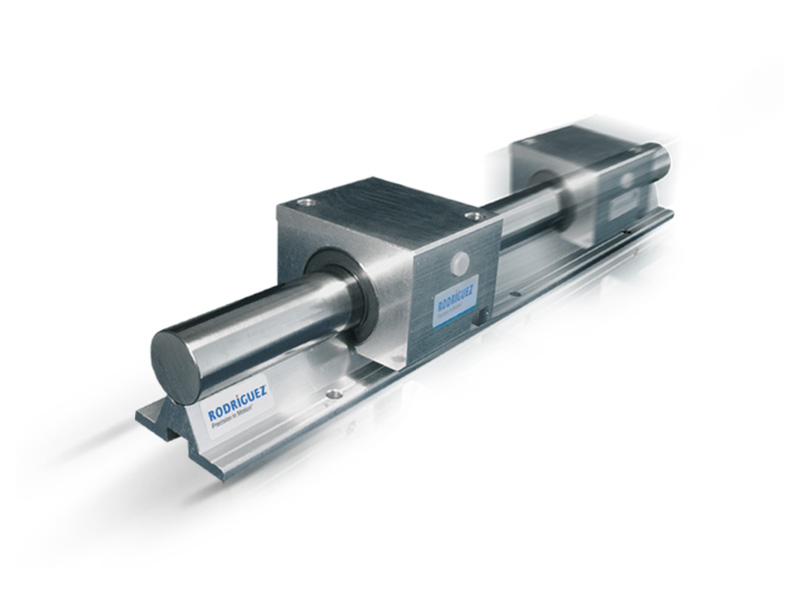

Linearsystems

-

Linearsystems for automation - The ideal combination of guidance and drive

Linearsystems from Rodriguez combine the advantages of linear guiding systems and mechanical drive mechanisms in a compact and simple way. Rodriguez ALS series linear slides are equipped with precision guide shafts.

Selfaligning linear ball bushings as well as standard versions or fullsteel linear ball bushings are available as rolling bearings. Additionally these units can be equipped with selflubricating linear slide bushings.Rodriguez linear slides offer the user a choice between the movable (version A) or the fixable slide (version B). Both variants are available with or without bellows (option F). If extremely high loads should exert an influence on the linear slide, the use of supported precision shafts is recommended. Ballscrew-driven systems (ALSK), trapezoidalscrew-driven systems and beltdriven units are available.

In addition to the linear slides, the Rodriguez portfolio also includes linearsystems with linear guideways as guides, sliding guides and roller-bearing guideways. Connected to an aluminium profile, this is a very compact and high-performance linearsystem. These systems can be driven by ballscrews or belts.

Also in the program: Linear guideway-tables are the ideal system for linear motions with high rigidity requirements. The base plate of the rail guide tables consists of machined aluminum profiles or steel with stop angles. The Rodriguez ball rail guides built into the stiff axis with four long guide carriages per table part. The drive is optionally performed either with a ballscrew drive (RSTK), linear motors (RSTL) or a belts (RSTZ).

Advantages of Rodriguez linearsystems

- Various guiding and drive options

- Great variety

- Covering almost all industrial requirements

- Compact design

- Movement length of up to 12000 mm possible

Linear actuators

-

The efficient alternative for hydraulic and pneumatic systems - For improved machine performance and reduced energy consumption

Linear actuators are used in a wider range of applications. Apart of industrial applications, these products are also operated in agriculture, construction-works and medical industry. Wherever loads have to be lifted, sunken, pushed, pulled, turned or positioned, the use of linear actuators is an option.

Usually one target by using linear actuators is the electrification. The adoption of electro-mechanical drive-components instead or hydraulic or pneumatic elements improves the performance of the machine. Aside of better controllability, the system-precision is increased, lifetime is extended by reducing stand-still-times and the cost of the system are reduced. In addition environmental problems and costs, i.e. by avoiding leakages and emission of hydraulic liquids, are avoided.

Advantages of Rodriguez linear actuators

- Reduced maintenance

- Dyn. Load up to 40kN

- Strokelength up to 2000mm

- Wide speed-range, 5,8mm/ s up to 2000mm/ s

- IP69K

- Various options available

Automotive

-

Rodriguez Automotive – Driving ahead of the competition

Based on our long standing knowledge and experience with different products, applications and industries, we are well equipped to satisfy any demands by the industry.

We are able to supply anything from the manufatcuring of basic components to the assembly of complete systems according to all required specifications. We can supply special parts and assemblies in small quantities as well as very high quantities for the commercial and automotive industries. To meet the requirements of our customers, we make use of various raw materials, components and standard parts.

A particular focus is placed on the reliable securing of cargo. The statutory requirements for the components used in the automotive sector are very strict. Therefore, Rodriguez together with the DEKRA Technology Center has developed an additional quality assurance and certification system with steel testing profiles for tarpaulin and roof rollers. Compared to the usual testing performed by the vehicle manufacturers, the new system ensures reproducible results.

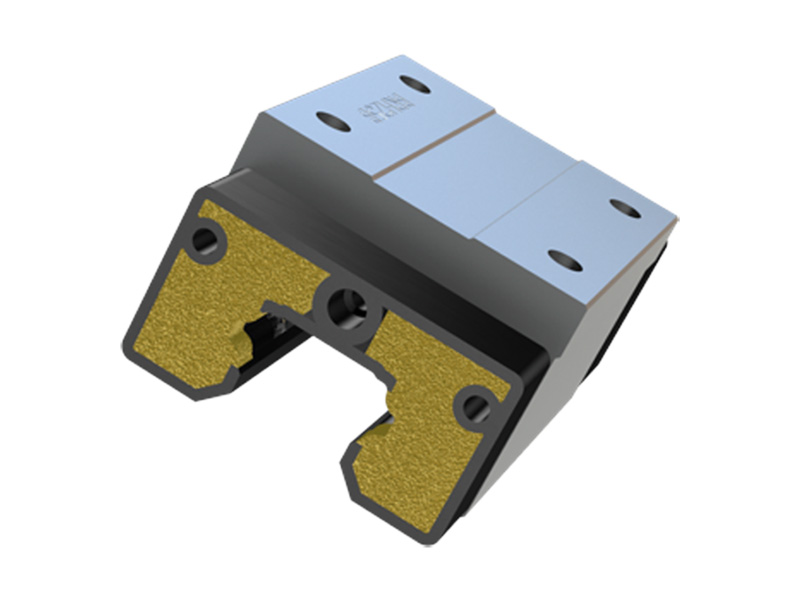

Side curtain and roof rollers

-

DEKRA-tested - Side curtain and roof rollers

For 20 years, Rodriguez has been developing and manufacturing components for the automotive industry. The range of products includes side curtain and roof rollers for aluminum truck roof systems. These sliding side curtain components are important for a safe transportation as well as fast loading and unloading. Rodriguez offers these as a single and as a tandem version for higher loads in the respectively suitable designs for the different rail systems.

All Rodriguez side curtain and roof rollers are DEKRA-tested and they are rechecked and certified regularly. This guarantees safety and quality.

Features and benefits of the Rodriguez side curtain and roof rollers- Single as well as tandem versions for higher load capacities

- Designs for different rail systems

- Best running characteristics

- Guaranteed quality

OCS buckle®

-

OCS buckle® of the newest generation - Fasten simply

For advanced quality and safety choose the new and patented OCS-buckle® of Rodriguez. The unique EASY-OPEN – function sets a high standard in practice and efficiency, without loosing sight of profitability. The OCS-buckle® of Rodriguez is DEKRA tested and approved for the securing of a load.

Advantages of Rodriguez OCS buckle®- Unique EASY-OPEN function

- DEKRA certified quality

- Patented system

- High efficiency

VALUE ADDED PRODUCTS

-

Focussed on your requirements: Customized solutions

Customer requirements, technical feasibility as well as economic efficiency are the main focus of our work. Together with our customers, we are looking at their demands and implement this one in innovative ideas for current and future business areas. Thus new product visions and verified product concepts are created even before the real engineering starts.

Customized solutions are one of Rodriguez core competencies. We develop, manufacture and supply complete customized solutions based on our thin section bearings and linear technology products. For these applications it is important to choose carefully the individual components and ensure their precise production and correct mounting. This is very essential for the proper functionality of customized solutions which are developed by Rodriguez. Thus you are benefitting from our entire technology- and system know-how.

As a specialist for bearings we take care of every process step from the development and construction via manufacturing and mounting right up to quality inspections, field tests and setting into operations in order to provide you the best customized solution. To maintain our high standards we continuously invest in latest production technologies and in the qualification of our employees.

Customers who obtain sub-assemblies or complete customized systems from Rodriguez benefit from a relief in procurement. The administrative input for the purchasing of several small components is no longer required reducing processing costs, which allow the customer to concentrate on their core competencies. This also applies especially for small quantities. The integrated functionality does include gears, grooves with control functions, mountings, brackets as well as integrated ball races at shaft or housing.

Advantages of Value Added Products

- Customized solutions

- Small number of components

- Integrated functionality

- Lower effort of mounting

- Lower total costs

- Concentration on core competencies

Integrated solutions with thin-section bearings

-

Rodriguez developed a driven rotary table with customized stainless steel KAYDON thin-section bearings for a cleanroom application. The end result was a high-precision positioning system. The scope of service included the manufacturing of aluminium components, the sourcing of measuring modules, the upgrading of the thin-section bearings with a special cleanroom grease, the assembling of the complete unit including the measurement system as well as complete quality and functionality testing, even for the measuring module. This involved all values being logged and passed on to the customer.

The compact precision rotary tables are characterised by excellent repeatability, high resolution and outstanding running accuracy. The use of angular contact bearings enables high load capacity and freedom from clearance.

Bearing system for a cable camera system

- In this project Rodriguez developed a special bearing system for a small direct-drive motor. The motor was adapted directly to the bearing system. The use of two identical bearing systems reduced the number of interfaces and components significantly.

Flange bearing system in semi-conductor technology

- One of Rodriguez’s system solutions/value added products was used in a flange bearing system for wafer handling. Integrating flanges on the thin-section bearing facilitated easier mounting for users and an improved system performance.