- Offer Profile

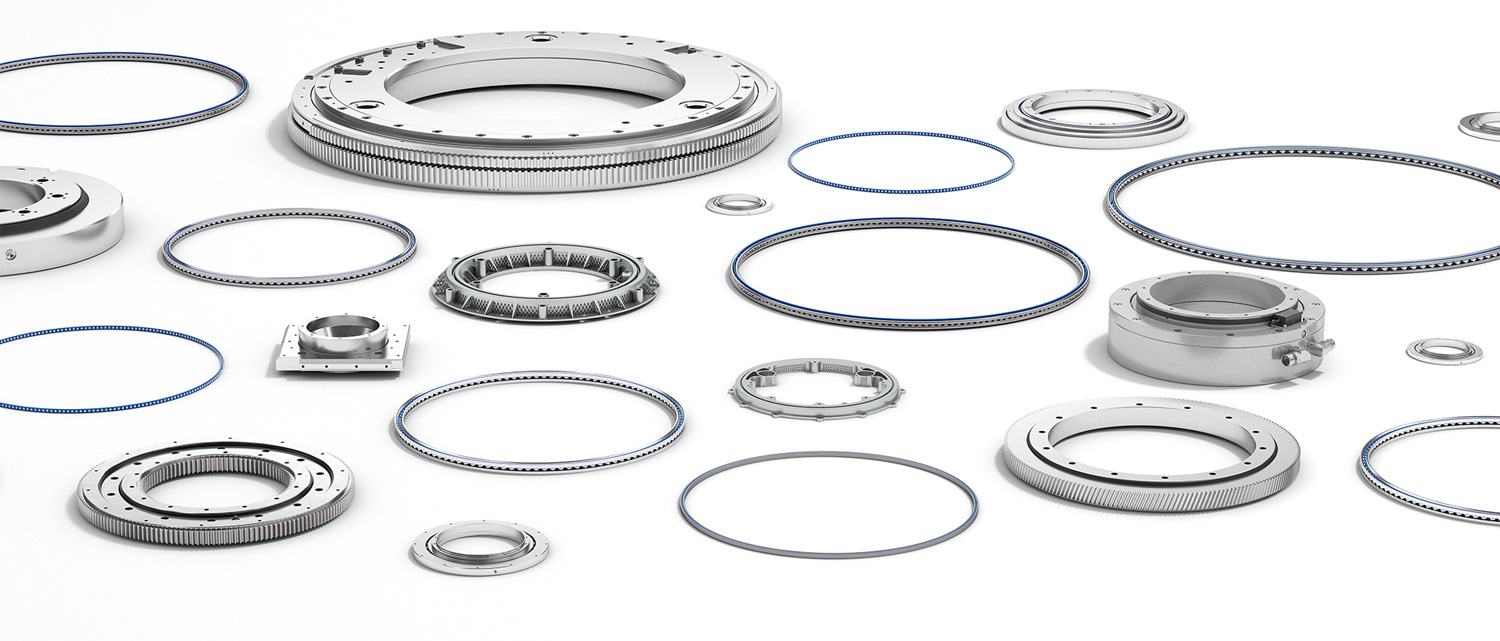

- Franke Wire Race Bearings

and Linear Systems.

We develop and produce Wire Race Bearings and Linear Systems, which are precisely adjusted to suit the needs of our customers. Individuality and quality are our trademarks.

Wire Race Bearings and Linear Systems

Fields of Innovation

-

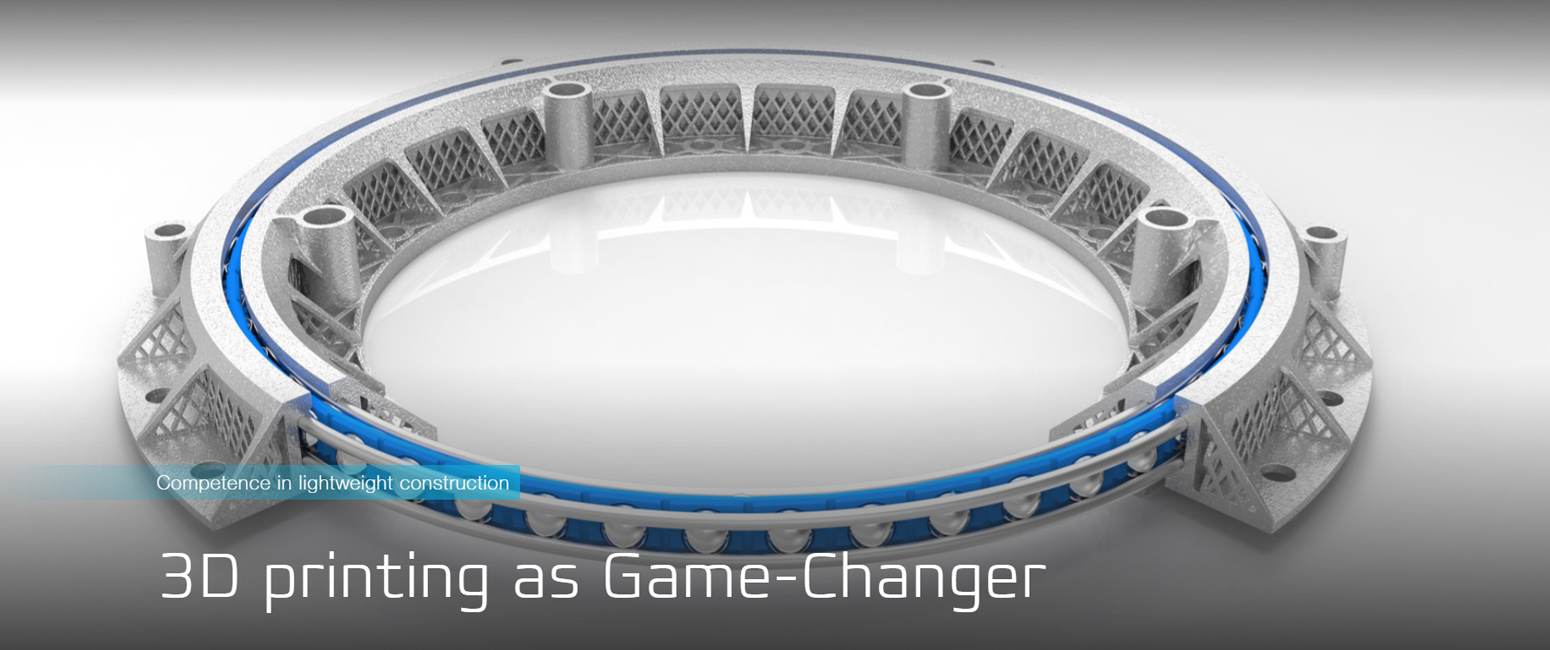

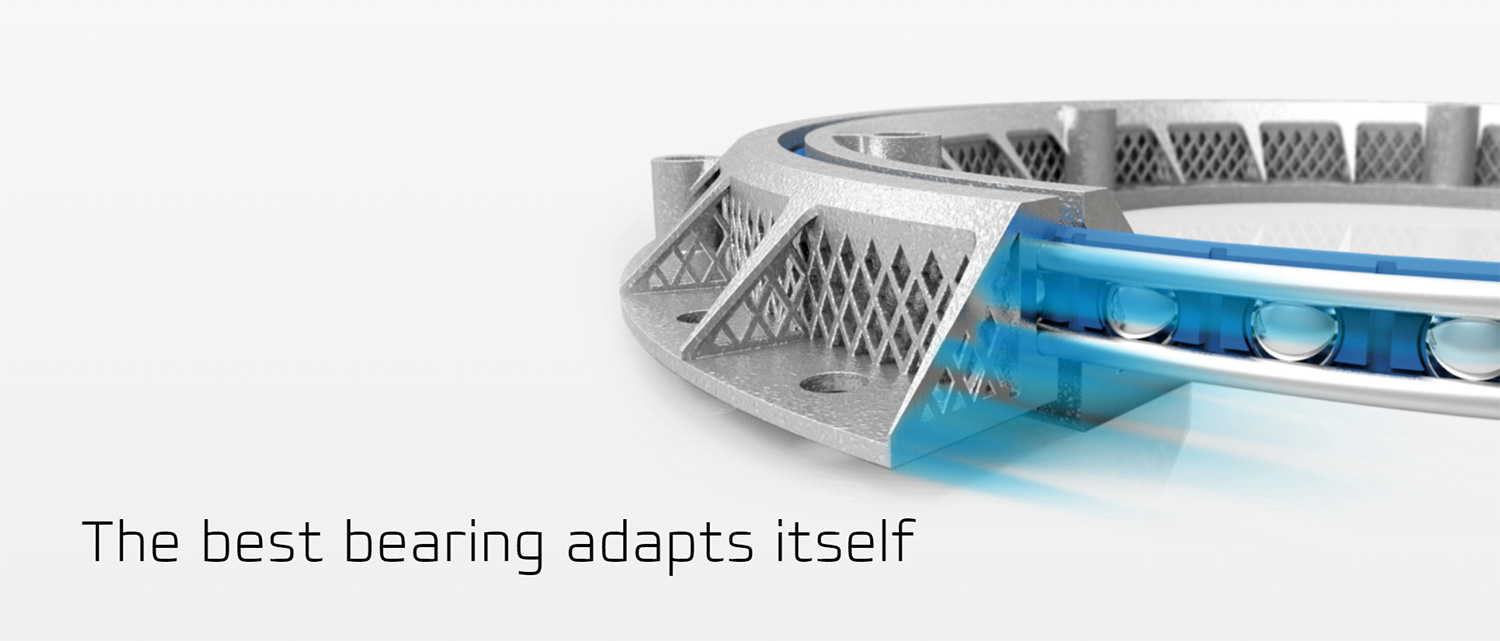

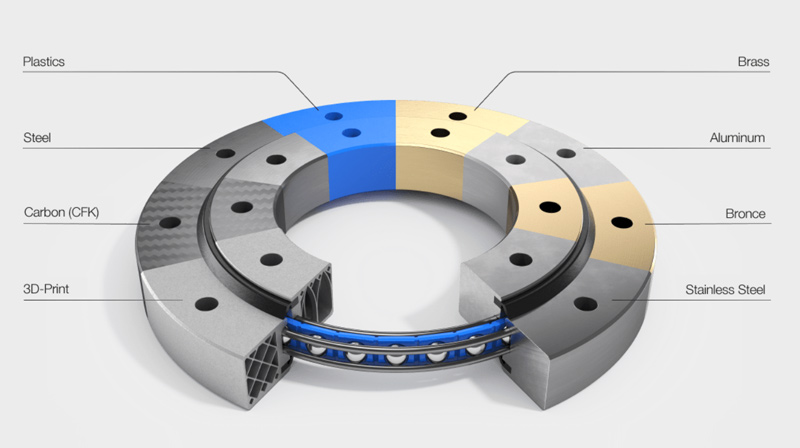

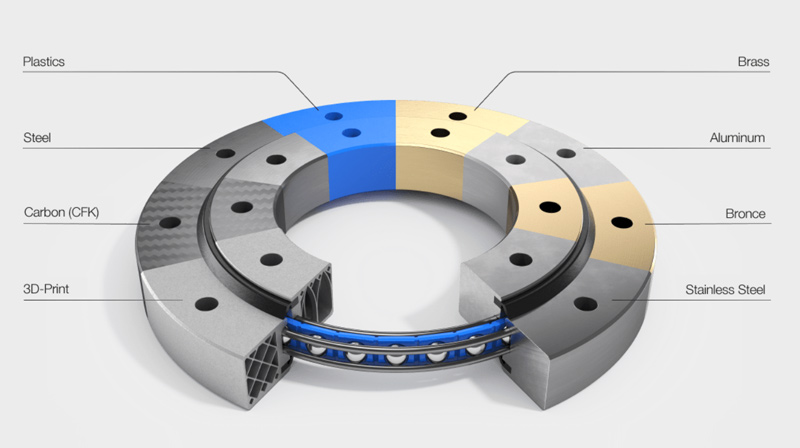

Competence in lightweight construction

Thanks to their patented technology, Franke wire race bearings offer maximum design freedom without compromising load carrying capacity. The enclosing construction can be realized in a variety of lightweight materials and its geometry can be optimally adapted to the respective application. With our many years of experience in the design of individual bearing solutions, we can provide you with optimum support when it comes to lightweight construction - from development to assembly, our experts are always available to provide you with competent support..

Franke bearing assembly with 3D print housing

Franke carbon bearing assembly in angular contact ball bearing design

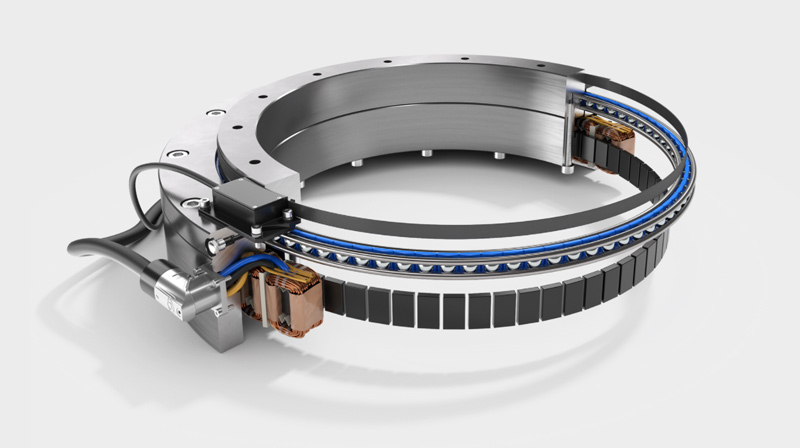

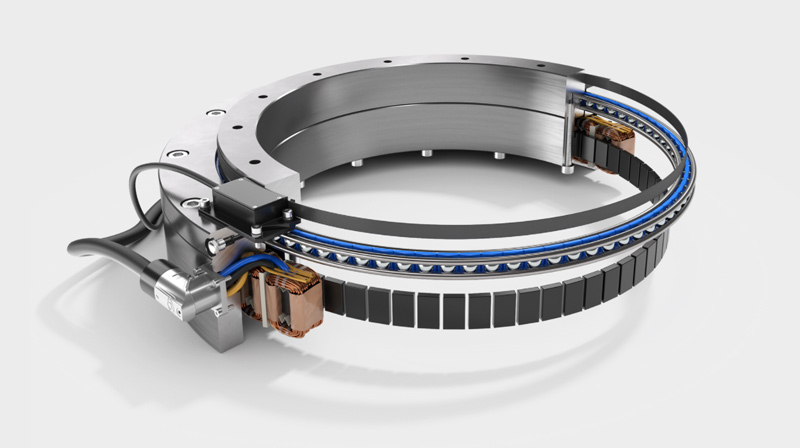

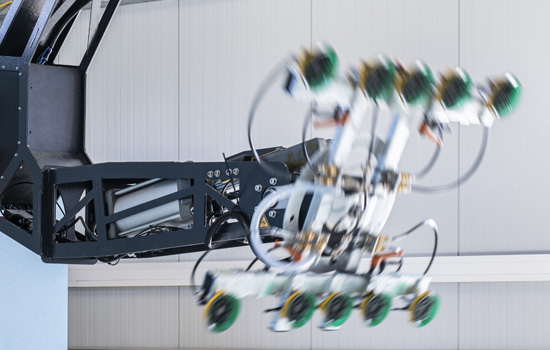

Direct drive - Bearing assembly with Torque-Motor

- Franke bearing assemblies with integrated direct drive (torque motor) are characterized by high dynamics, maximum energy efficiency and a compact installation space combined with center-free design.

Bearing assemblies with direct drive are suitable for applications where high performance and low space requirements are important criteria. The integration of the drive into the bearing housing means that wear-prone assemblies for transmitting drive power, such as toothed belts, shafts or chains, can be dispensed with. This reduces the required drive energy and also benefits more accurate positioning.

Why roller bearings with direct drive?

Franke wire race bearings with integrated direct drive are characterized by highest energy efficiency. The integration of the drive motor into the bearing makes it possible to dispense with components such as gears and drive pinions and thus with complex lubrication circuits. The moving masses are therefore significantly lower and the loss of performance due to factors such as friction and play is minimized.

Functionality of Franke roller bearings with direct drive

Torque motors are integrated directly into Franke bearing assemblies. The customer receives a completely ready to install system. This makes it possible not only to generate a rotational movement, but also to position or execute definable cycle steps.

The torque motor has a high torque at a defined speed range. The distance between the stator and rotor (air gap) is decisive for the magnitude of the torque. The preloaded Franke bearing assembly guarantees a constant air gap. A measuring system can be used to determine the motor position.

Special materials for special properties

-

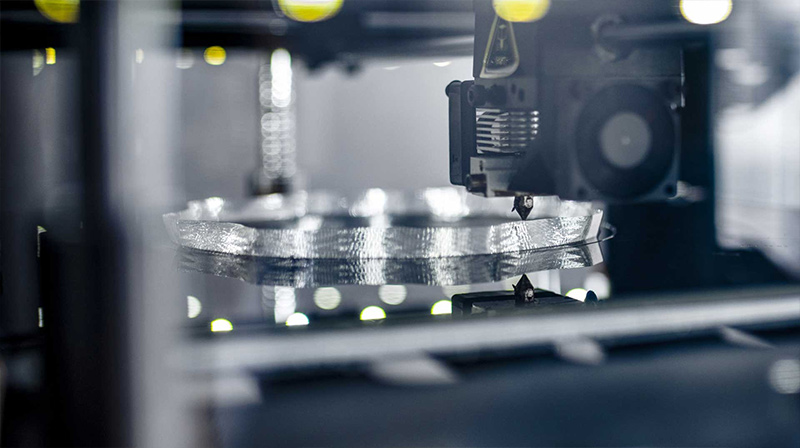

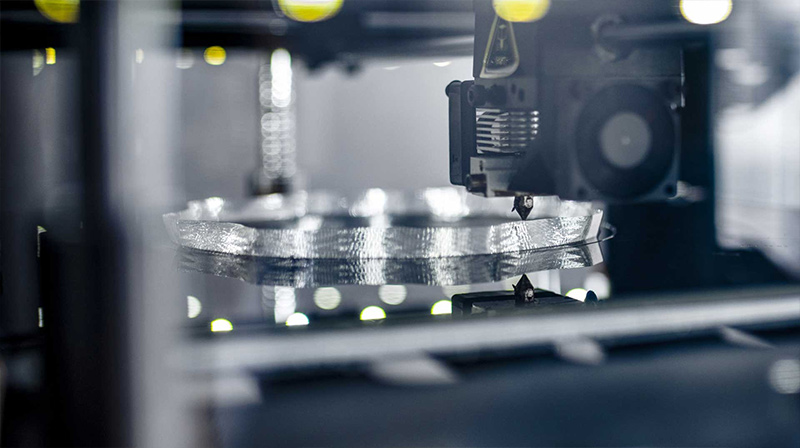

One of the most promising technologies is 3D printing. This opens up completely new possibilities in design. Franke Wire Race Bearings can be easily integrated into 3D printed housings.

Special materials for special properties

The use of alternative materials in bearing constructions as well as state of the art production technologies allow Franke bearings to be optimally adapted to the application. The material used influences properties such as:

- the weight,

- the load capacity and robustness,

- the suitability for certain environments (dirt, humidity, clean room, vacuum, food).

Materials

- Aluminium - over 50 % lighter than steel

- Carbon (CFK) - 75 % lighter and highly resilient

- Plastic - 80 % lighter, durable and quiet

- 3D printing - 90 % lighter and very variable

- Amagnetic steel - for medicine and research

- Stainless steel - for food

News

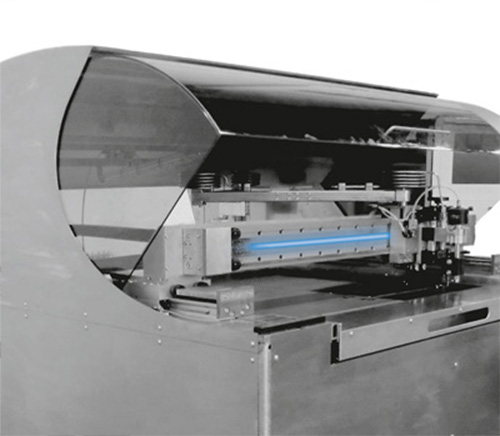

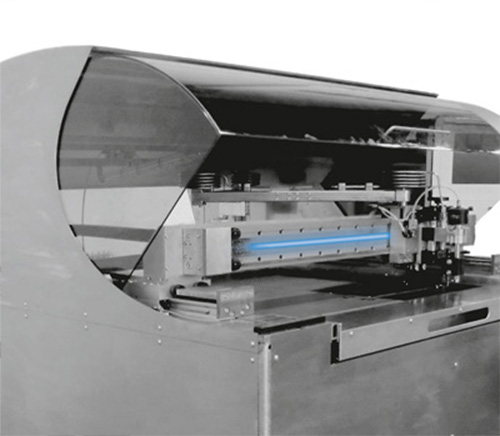

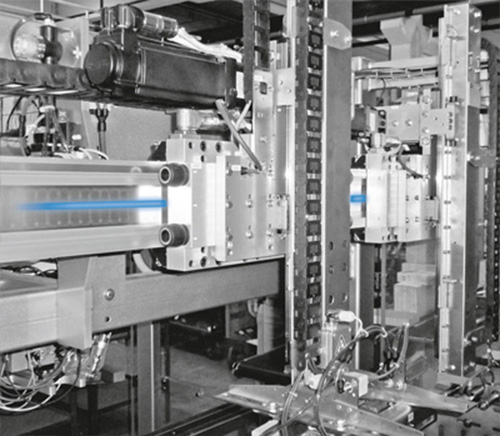

Mespack - masters of flexible packaging

-

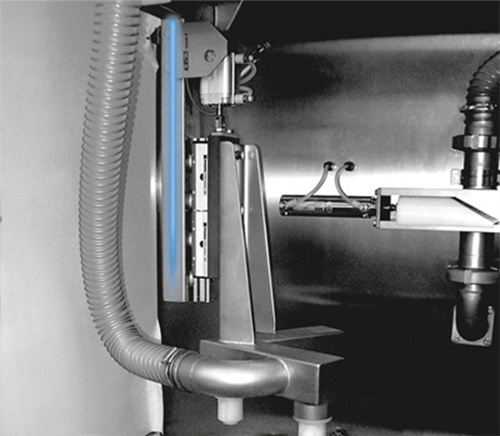

The Spanish packaging machine manufacturer Mespack is a specialist for flexible packaging. Compared to rigid packaging, this not only saves costs and transport volumes, but also protects the environment by using fewer resources. Mespack uses linear guides from Franke in many of its machines for flexible packaging.

"Franke linear guides are made of lightweight aluminium, which is very important for us because it allows us to achieve higher speeds," explains Alonso Marquez. At the same time, he says, process reliability must always be guaranteed. "The durability and resistance of Franke linear systems is crucial for us because they guide fundamental movements and the functioning of the entire machine depends on them," says Marquez. For customers who clean their machines very frequently for hygiene reasons, Franke's completely corrosion-resistant FDC type linear guides are also used. In this version, the inserted raceways and the rollers are made of corrosion-resistant steel, which further improves the resistance.

Making lifting easier: with handling systems from Sachs-Products

-

Easy operation and good design: The young company Sachs Products attaches particular importance to these properties in its handling systems. In its Manipulators Mantis and Vertis, Sachs Products uses bearing assemblies from Franke. Their smooth running, their small installation space combined with high load capacity and their low weight are decisive benefits for Sachs Products.

Designing with Franke products

Roller bearings and linear systems from Franke have been included in Sachs Engineering's design drawings for around 10 years. "We focus on quality in our designs, and we ensure this by using only selected branded products," explains Michael Schubert. If a designer has had good experiences with a product, he recommends it to his colleagues. In addition to the physical requirements, engineering at Sachs includes many other aspects to take into account: First and foremost, the operation, but also aspects such as manufacturing costs or after-sales services. According to Michael Schubert, it is in this context of prudent engineering that the expertise of suppliers such as Franke should be used. "You can't be the best expert in all areas," Schubert notes. With Franke, we have a partner who has extraordinary competence in the field of bearings and whose advice they are happy to rely on in order to consistently design outstanding products.

100 kilometres of fibre on a bobbin

-

The SAHM company from Eschwege is the global technology leader for winding machines for technical yarns, fibres and tapes. Bobbin weights of up to 500 kilograms can be perfectly wound with SAHM winding machines. For the machine types with automatic tube change, SAHM uses slim bearings and linear guides from Franke.

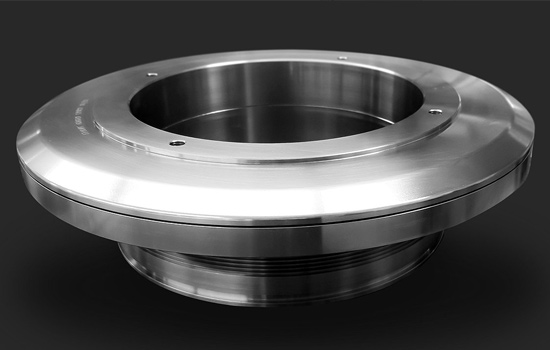

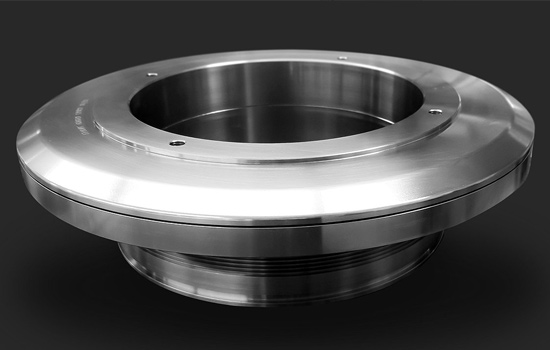

Ball bearing from Franke

For its automatically changing winding machines, SAHM uses thin-section ball bearings and linear guides from Franke. The thin-section bearings for SAHM are customised. By chamfering the races, a defined preload can be set. "This is a clever principle from Franke, because the desired preload is achieved without requiring additional material or space for it," finds André Wegner from the industrial agency AnWeTec, Franke's sales partner in northern Germany.

With the Franke thin-section bearings, a drum is supported in the winding machine, the rotation of which causes the automatic bobbin change. The technical challenge here lies primarily in the compensation of vibrations to which the bearing is exposed: "Wherever winding takes place, micro-vibrations always occur; this can never be completely ruled out," explains Heiko Ebhardt. "In tests with our own design, we had the problem that it broke down because of vibrations and then had too much clearance. With the Franke slim bearings, this no longer happens."

Franke solves challenging rotation task for vegetable spiral cutters from company Kronen

-

A challenge becomes a success story: After previously working on a solution with several suppliers, Kronen GmbH finally found the partner in Franke who mastered a difficult rotation task with a sophisticated bearing assembly.

Franke with a new design approach

Where standard bearings reach their limits due to customer-specific requirements, Franke offers more advanced solutions with its flexibly adaptable wire-race bearings. In the case of the Kronen project, several problems had to be solved at the same time: heat generation, speed, hygiene, tightness, smooth running and long service life. Franke succeeded in meeting all these requirements with a customised bearing assembly using Franke wire-race bearing technology. The Franke bearing assembly guides the rotating cutting tool. The cut product is transported away through the center of the bearing assembly. The Franke solution is "the first that meets all the criteria and also lasts for a long time", explains Sebastian Serrer. "Moreover, the machine is very fast, the speed goes up to 690 rpm. It took some fiddling around and constructive ideas until we found a solution. Especially since we also had to deal with the problem of contamination and cleaning. The bearing had to be tight, otherwise the service life of the machine would be rapidly reduced," explains Michael Bärstecher, technical advisor at Franke.

The great freedom of tube processing - with laser tube cutting machines from Trumpf

-

"Pipes choose Trumpf" is the title of an advertising brochure for Trumpf laser pipe cutting machines. The Swabian flagship company is a global leader in laser processing. Customer-specific wire race bearings by Franke are used in the chucks of its fully automatic cutting artists.

Innovative clamping with Franke bearings

A laser tube cutting machine from Trumpf is a high-tech product packed with innovative ideas. This also includes the clamping technology. It is designed in such a way that the time required for set-up is reduced to zero and tedious reclamping is eliminated. The two chucks of a TruLaser Tube machine are fitted with customised double bearings from Franke. "The chucks are central components of our machines," says development engineer Holger Biener. "They have to ensure that the component is positioned exactly. This is the only way to ensure accurate machining." In this context, the Franke double bearings fulfil an elementary function, because any inaccuracy in the bearing would immediately affect the accuracy of the machining. In addition, high reliability is required of the bearing. They are very satisfied with Franke bearings in this respect, reports Markus Stapf: "The good thing about the Franke product: It works - we have no problems at all during assembly or in the field."

XXL-Franke-Torque Bearing guides laser at new display repair machine

-

A South Korean OLED display manufacturer has developed an innovative machine to correct unavoidable errors in display production more quickly. Franke built an exceptionally large bespoke torque drive for the machine with one meter diameter.

Innovative, high-throughput repair machine

A South Korean OLED display manufacturer has now developed a new type of laser machine to efficiently repair such defective LED displays. The principle: a laser beam is used to repair faulty connections of the conductor paths. Similar devices already exist on the market, but none with a comparable throughput. In principle, the new machine is suitable for all types of LED displays, including micro-LED and OLED displays.

Customised Franke torque drive in XXL design

A central component in the laser repair machine is a very large Franke bearing with torque-motor. Inner diameter: 1,000mm. Weight: 640 kilograms. The bearing is used to rotate several mirrors, which deflect and guide the laser beam. Since the display manufacturer could not find a torque drive of the required size from other suppliers, he turned to the Franke representative in South Korea.

Franke then developed a customised solution. The colossus built by Franke runs very smoothly and precisely due to the damping effects of the integrted wire-race bearing. In order to guarantee the required nominal speed of 150 revolutions per minute, an angular contact ball bearing arrangement was chosen for highly dynamic applications. Precision was also very important in this project. "In terms of accuracy, we have reached a new level with this bearing" says Arne Jankowski from Frankes technical sales. Based on this, the display manufacturer was able to further increase the system accuracy via electronical correction measures.

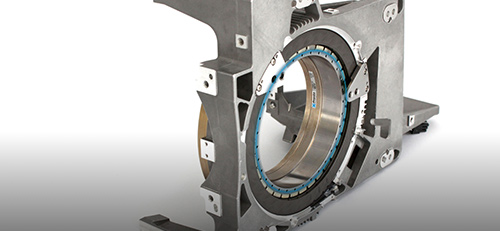

Bearing Elements

-

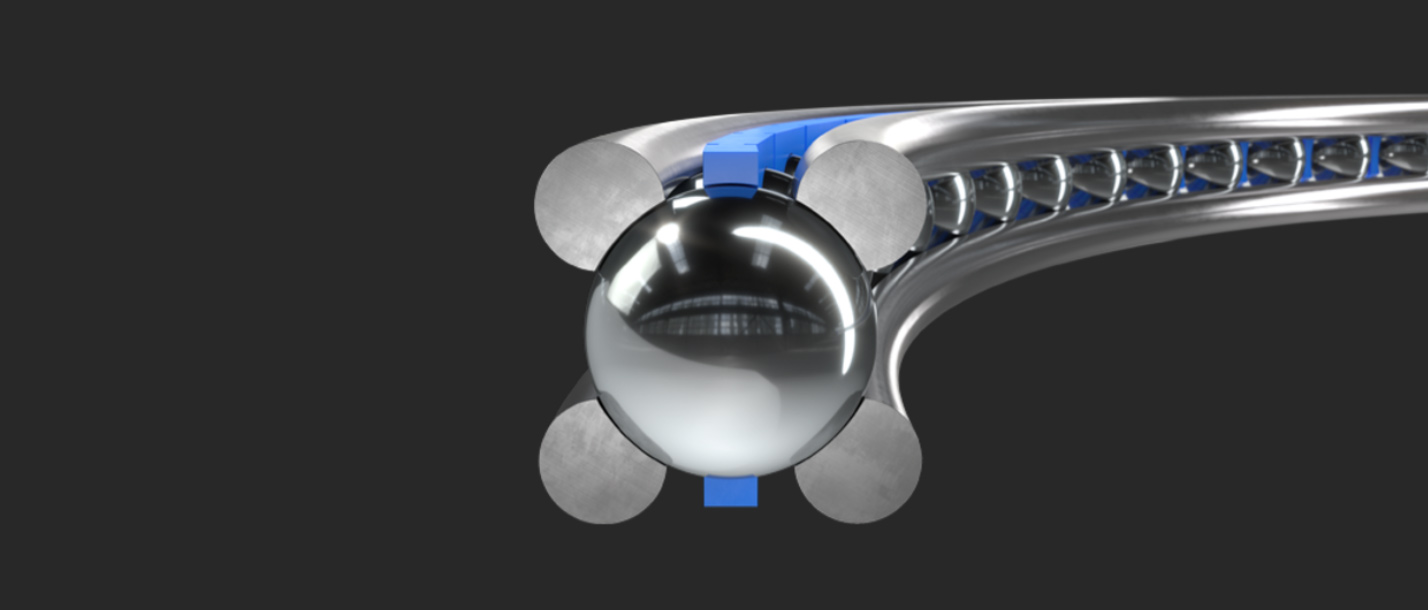

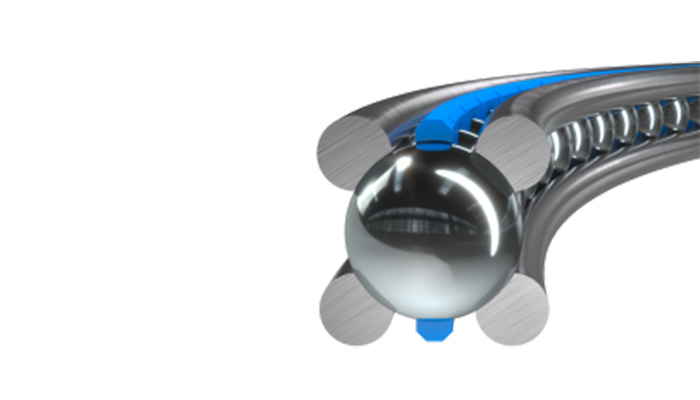

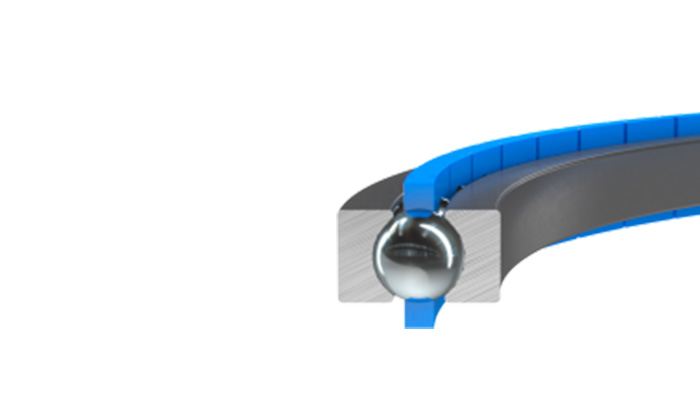

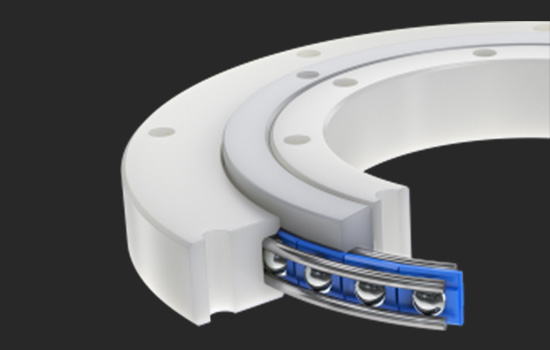

Four wires for better design

The decisive difference between an ordinary ball bearing and a Franke wire race bearing is in the raceways. In a wire race bearing, the rolling elements do not roll on solid housing rings, but on high performance wires. The flexibility of this principle makes it possible to design more freely and simply, in order to develop better products.

Runs precisely. And runs precisely. And runs precisely.

In wire race bearings, the raceways of the rolling elements are precisely matched to the diameter of the rolling elements. This ensures optimum functional characteristics and guarantees both, precise running and a long operating life.

Shock and impact elastic

The races of Franke wire race bearings are made of hardened spring steel. Shocks and vibrations are absorbed by them. The result: a high resistance against such disturbing influences.

Compensates deformations

Slight deformations of the enclosing structures, for example due to temperature changes, are compensated by the flexible Franke bearing element. Where other roller bearings fail, the Franke bearing continues to roll.

No bearing play. Adjustable rotational resistance.

Does your application focus on dynamics or precision? Or does a good compromise have to be found? The rotational resistance of a wire race bearing is adjustable. Suitable for each application. At any time.

Possibilities instead of specifications

Franke bearing elements can be used in a wide variety of designs. The demands on the enclosing construction are low, because it is not directly exposed to the loads. The main load is borne by the wire race bearing. This allows you to determine almost freely the ideal shape and material of your further construction.

- Maximum possible integration capacity

- Series application to meet cost constraints

- Greatest possible flexibility based on preload, runnability and diameter ranges

- Infinitely variable from 70 to 2000 mm

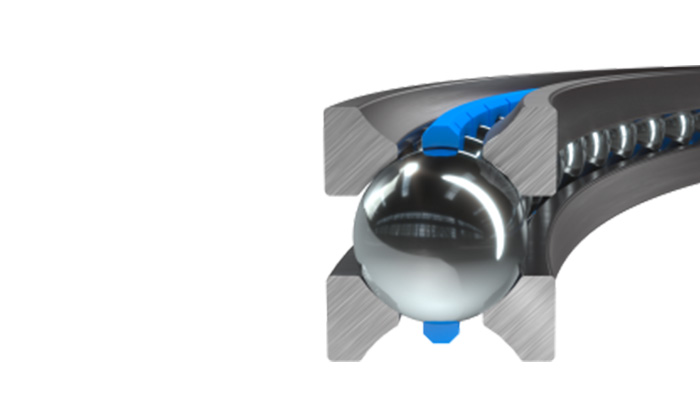

Bearing elements with a ground raceway Type LEL

-

Franke bearing elements type LEL meet the highest demands with regard to running smoothness, accuracy and rotational speed.

Franke bearing elements of type LEL are suitable for high demands on running characteristics and accuracy. Due to the hardened and CNC-ground raceway as well as the ideal geometrical adaptation of ball and raceway radius, they have outstanding bearing characteristics. Bearing elements of type LEL allow the greatest possible freedom of bearing design. The mounting space is between 5.9 mm and 20.9 mm. For special requirements, raceway thicknesses up to 20 mm and ball sizes up to 50 mm are possible.

Technical data

- Material:

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane - Operating temperature: –30 °C to +80 °C, briefly up to +100 °C

- Peripheral speed: Max. 5 m/s, without seals max. 10 m/s

- Lubricant: Klüber Isoflex Topas NCA52 (recommended)

- Material:

Ball race rings: hardened and tempered chrome-silicon steel

Bearing elements with profiled raceways Type LER

-

Franke bearing elements of the type LER are characterized by their compact cross-section and their favourable price.

Franke bearing elements type LER are suitable for medium rotational speeds and accuracies. They convince by smooth running, high dynamics and compact installation space. Due to the straight contact surfaces, they can be easily integrated into the surrounding design and have a high rigidity. The low price makes the bearing element of type LER an economical solution. LER are generally mounted without clearance. The preload can be individually adjusted according to the requirements.

Technical data

- Material: Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane - Operating temperature: -30 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 5 m/s, without seal max. 10 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Material: Ball race rings: hardened and tempered chrome-silicon steel

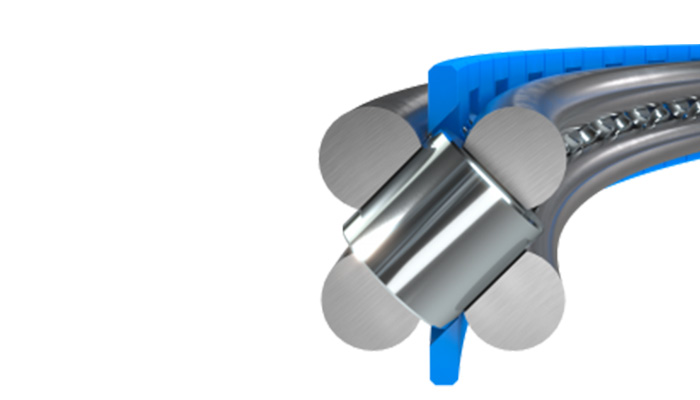

Crossed roller bearings with ground raceways Type LEW

-

Franke bearing elements of type LEW offer maximum rigidity with high running smoothness and accuracy.

Franke bearing elements type LEW are suitable for medium rotational speeds and accuracies. They convince by smooth running even under tilt moment loads, high rigidity and compact installation space. The crosswise arranged rollers can support high loads from all directions. Bearing elements of model LEW are insensitive to shock and vibration. They offer the greatest possible flexibility in terms of preload, running characteristics and diameter ranges.

Technical data

- Material: Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane - Operating temperature: -30 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 4 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Material: Ball race rings: hardened and tempered chrome-silicon steel

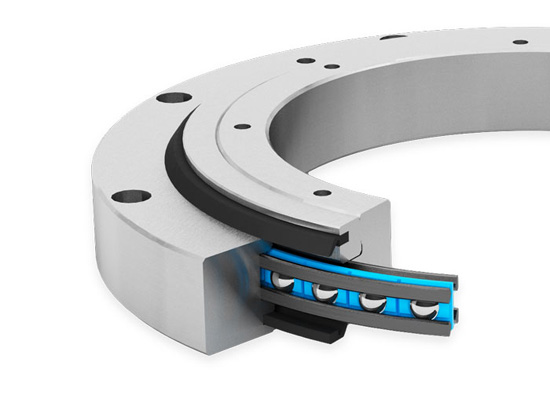

Slim bearings with profiled raceways Type LSA

-

Franke slim bearings of type LSA are a cost-effective alternative to conventional thin-section bearings.

Franke slim bearings of the type LSA convince by their smooth running, extremely compact installation space, simple mounting and favourable price. Slim bearings of type LSA consist of an inner and outer race with hardened and profiled raceways and a plastic cage with retained balls. The rolling elements rest against the raceways at two points each, thus maintaining the 4-point system. The raceways are split and can therefore be changed elastically in diameter for installation.

Technical data

- Material: Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane - Operating temperature: -20 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 5 m/s, without seal max. 10 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Material: Ball race rings: hardened and tempered chrome-silicon steel

Bearing Assemblies

- If required, we can also design and manufacture complete bearing assemblies for you. These can be mounted even more easily than bearing elements. Franke bearing assemblies are available in every size, with individual bores and toothings and in numerous materials such as aluminium, stainless steel, carbon or as a 3D printed housing.

Steel bearing assemblies Type LVA

-

Franke type LVA bearing assemblies offer good load capacity and smooth running - at an attractive price.

Franke Bearing Assemblies Type LVA are ready-to-install bearing assemblies with steel housing rings and integrated bearing element. They are suitable for medium rotational speeds and accuracies. They are available at short notice, some of them even from stock. Designed as 4 point bearings, they can support equally high loads from all directions and are insensitive to shocks and vibrations. Type LVA bearing assemblies are sealed on both sides and adjusted with preload.

Technical data

- Material: Inner / Outer ring: C45N

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane

Sealing: NBR - Operating temperature: -20 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 5 m/s, without seal max. 10 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Relubrication: Via grease nipples to DIN 3405

- Material: Inner / Outer ring: C45N

Aluminium bearing assemblies Type LVB

-

Type LVB aluminium bearing assemblies are characterised by their low weight. They are suitable for medium speeds and some are available from stock.

Franke bearing assemblies type LVB are ready-to-install bearing assemblies with housing rings made of aluminium and integrated bearing elements. Franke LVB are suitable for medium rotational speeds and accuracies and convince by their light weight. LVB bearing assemblies are available at short notice, some of them even from stock. Designed as 4-point bearings, they can support equally high loads from all directions and are insensitive to shocks and vibrations. LVB bearing assemblies are sealed on both sides and are set with preload.

Technical data

- Material: Inner / Outer ring: aluminium, anodized

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane

Sealing: NBR - Operating temperature: -20 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 5 m/s, without seal max. 10 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Relubrication: Via grease nipples to DIN 3405

- Material: Inner / Outer ring: aluminium, anodized

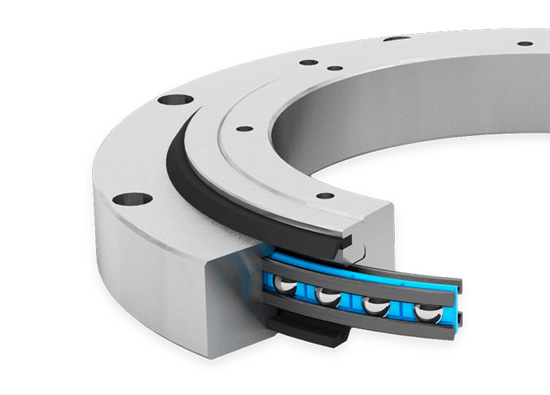

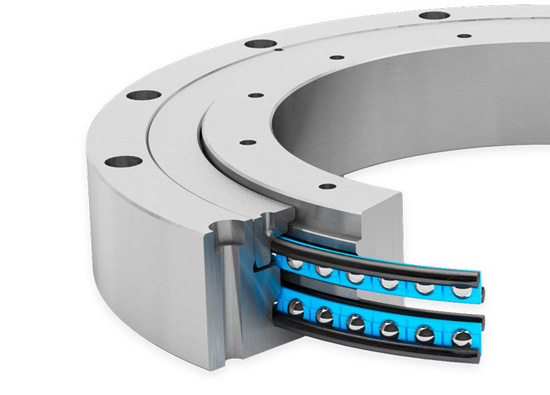

Double row steel bearing assembly, highly dynamic Type LVC

-

Double row bearing assemblies LVC are suitable for the highest circumferential speeds. Excellent dynamics and very low rotational resistance are the outstanding characteristics of this type.

Franke bearing asseblies type LVC are bearing assemblies made of steel, designed as double row angular contact ball bearings with integrated bearing elements. Franke LVC are suitable for highest circumferential speeds. They convince by very high dynamics and a very low rotational resistance. The double row angular contact ball bearings in a 4-point arrangement are preloaded. They are insensitive to shocks and vibrations. The low rotational resistance and the minimal breakaway torque reduce the required drive power. Due to the low coefficients of friction, Type LVC bearing assemblies operate almost maintenance-free and achieve a long service life.

Technical data

- Material: Inner / Outer ring: C45N

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane

Sealing: NBR - Operating temperature: -20 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 20 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Relubrication: Via grease nipples to DIN 3405

- Material: Inner / Outer ring: C45N

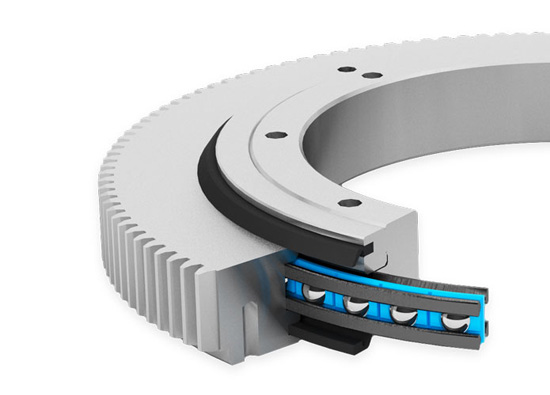

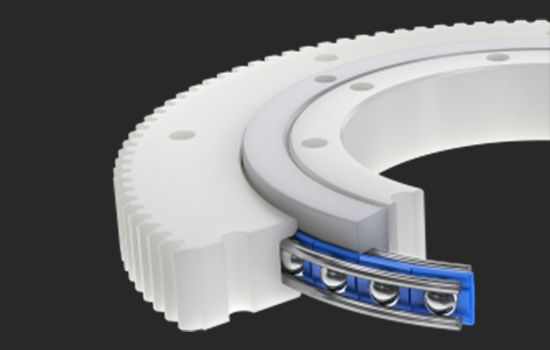

Steel Bearing assembly with external gear Type LVD

-

Franke LVD bearing assemblies with external gear offer high load capacity and are suitable for medium-high speeds.

Franke bearing asseblies type LVD are ready to install bearing assemblies with external gear, steel housing rings and integrated bearing elements. Franke bearing assemblies type LVD are suitable for medium rotational speeds and accuracies. They can be supplied at short notice, in some cases even from stock. Designed as 4-point bearings, they can support equally high loads from all directions and are insensitive to shocks and vibrations. The bearing elements are sealed on both sides and adjusted to preload.

Technical data

- Material: Outer ring: 42CrMo4V

Inner ring: C45N

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane

Sealing: NBR - Gear: DIN 3967, quality 8e25, straight toothed, module see table below

- Operating temperature: -20 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 5 m/s, without seal max. 10 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Relubrication: Via grease nipples to DIN 3405

- Material: Outer ring: 42CrMo4V

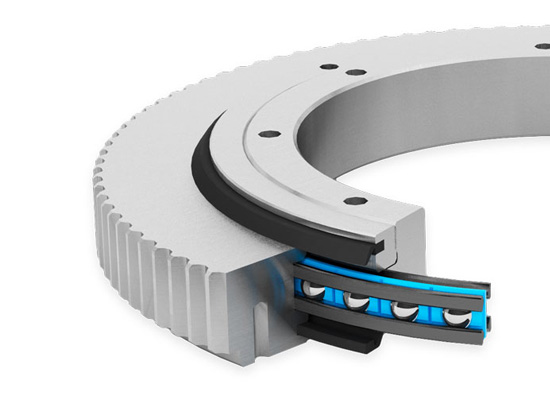

Aluminium Bearing assembly with external gear Type LVE

-

Franke LVE bearing assemblies with external gear are made of weight-saving aluminium. They offer a high load capacity and are suitable for medium-high speeds.

Franke bearing assemblies type LVE are bearing assemblies with toothed belt gearing, aluminium housing rings and integrated bearing elements. Franke bearing assemblies type LVE are suitable for medium rotational speeds and accuracies. They convince by their low weight and are available at short notice, in some cases even from stock. Designed as 4-point bearings, they can support equally high loads from all directions and are insensitive to shocks and vibrations. The bearing assemblies are sealed on both sides and adjusted to preload.

Technical data

- Material: Inner / Outer ring: aluminium, anodized

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane

Sealing: NBR - Gear: AT10

- Operating temperature: -20 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 5 m/s, without seal max. 10 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Relubrication: Via grease nipples to DIN 3405

- Material: Inner / Outer ring: aluminium, anodized

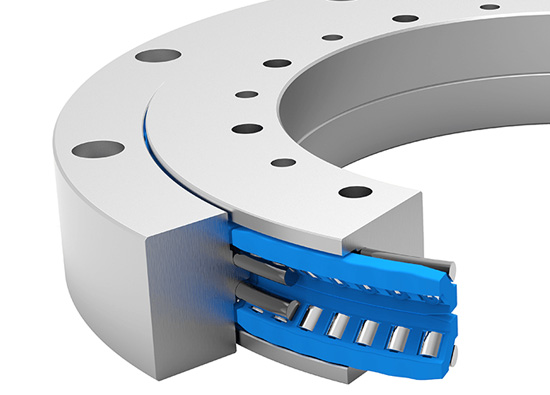

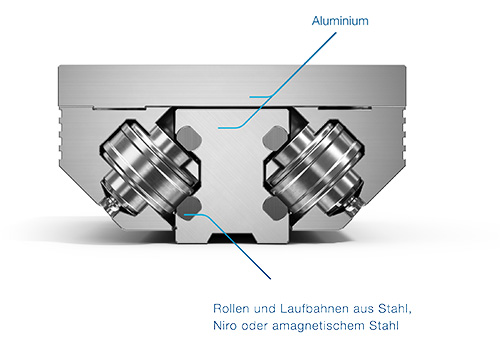

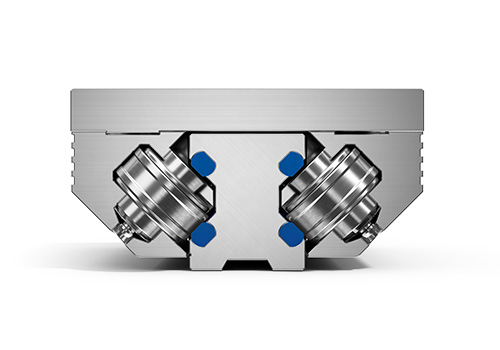

Drehverbindung aus Aluminium mit Rollen, hochbelastbar Typ LVG

-

Franke LVG bearing assemblies are suitable for the highest load capacities and convince with excellent running smoothness and rigidity.

Franke bearing asseblies type LVG are bearing assemblies made of aluminum, designed as double row angular contact roller bearings with integrated bearing elements. LVG bearing assemblies are suitable for the highest load ratings. They convince by high rigidity, low rotational resistance and low weight. Designed as roller bearings, they can support high loads from all directions and are insensitive to shocks and vibrations. Franke LVG are sealed on both sides and are set with preload. By using aluminum, Franke beaing assemblies type LVG are 60% lighter than comparable steel bearings.

Technical data

- Material: Inner / Outer ring: aluminium, anodized

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Cage: polyamide or thermoplastic polyurethane

Sealing: NBR - Operating temperature: -20 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 4 m/s

- Lubricant: Shell Gadus S3 V220 C2

- Relubrication: Via grease nipples to DIN 3405

- Material: Inner / Outer ring: aluminium, anodized

Bearing assemblies made of plastic (POM)

Type LVK-

Franke LVK type bearing assemblies offer all the advantages of wire race bearing technology combined in a lightweight plastic housing.

Franke LVK type bearing assemblies are ready-to-install bearings with housing rings made of plastic (POM) and integrated bearing elements. Franke LVK are suitable for medium rotational speeds and accuracies and are available from stock. Designed as 4-point bearings, they absorb equally high loads from all directions and are insensitive to shocks and vibrations. LVK bearing assemblies are insensitive to environmental influences and can also be used in food technology and pharmacy

Technical data

- Material:

Inner/Outer ring: Polyoxymethylene (POM)

Ball races: Non corrrosive Steel (1.4310)

Rolling elements: Non corrosive Steel

Cage: Polyamid (PA12) - Operating temperature: -10 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 4 m/s

- Lubricant: Klüber UH1 14-151

- Relubrication: Via grease nipples to DIN 3405

- Material:

Bearing assemblies made of plastic (POM), external gear

Type LVL-

Franke LVL type bearing assemblies offer all the advantages of wire race bearing technology combined in a lightweight plastic housing with external toothing.

Franke LVL type bearing assemblies are ready-to-install bearings with housing rings made of plastic (POM), integrated bearing elements and external toothing. Franke LVL are suitable for medium rotational speeds and accuracies and are available from stock. Designed as 4-point bearings, they absorb equally high loads from all directions and are insensitive to shocks and vibrations. LVL bearing assemblies are insensitive to environmental influences and can also be used in food technology and pharmacy.

Technical data

- Material

Inner/Outer ring: Polyoxymethylene (POM)

Ball races: Non corrrosive Steel (1.4310)

Rolling elements: Non corrosive Steel

Cage: Polyamid (PA12) - Gearing: DIN 3967, quality 8e25, straight toothed, module see table below

- Operating temperature: -10 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 4 m/s

- Lubricant: Klüber UH1 14-151

- Relubrication: Via grease nipples to DIN 3405

- Material

Bearing assemblies made of plastic (POM), toothed gear

Type LVM-

Franke LVM type bearing assemblies offer all the advantages of wire race bearing technology combined in a lightweight plastic housing with external toothing.

Franke LVM type bearing assemblies are ready-to-install bearings with housing rings made of plastic (POM), integrated bearing elements and external toothing. Franke LVM are suitable for medium rotational speeds and accuracies and are available from stock. Designed as 4-point bearings, they absorb equally high loads from all directions and are insensitive to shocks and vibrations. LVM bearing assemblies are insensitive to environmental influences and can also be used in food technology and pharmacy.

Technical data

- Material:

Inner/Outer ring: Polyoxymethylene (POM)

Ball races: Non corrrosive Steel (1.4310)

Rolling elements: Non corrosive Steel

Cage: Polyamid (PA12) - Gearing: AT-10

- Operating temperature: -10 °C to +80 °C, short-term up to +100 °C

- Peripheral speed: Max. 4 m/s

- Lubricant: Klüber UH1 14-151

- Relubrication: Via grease nipples to DIN 3405

- Material:

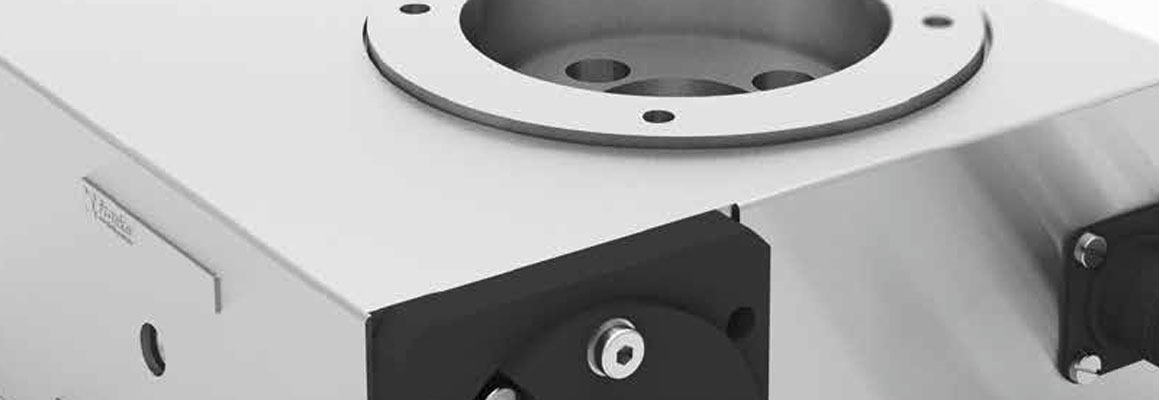

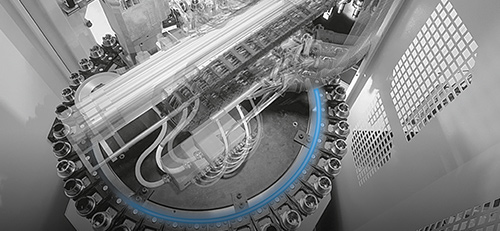

Rotary Tales, Rotary Systems, Worm drive/highly dynamic

- You prefer a complete solution from one source? Franke offers complete customized positioning and drive units, optionally with proximity switch, coupling and motor. Systems with direct drive are a particular strength of Franke. They are used, for example, in many computer tomographs of renowned manufacturers.

Rotary table, high dynamic Type LTA

-

Franke rotary tables LTA are particularly suitable for dynamic applications in the fields of machining, handling and assembly.

Franke rotary tables type LTA are light, compact, ready to install positioning units for speeds up to 100 rpm. They are highly loadable and have excellent concentricity and axial run-out accuracy. Rotary tables LTA are versatile and are particularly suitable for light machining tasks as well as dynamic handling and assembly applications.

Technical data

- Material: Base plate: Aluminium

Housing: V2A

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Worm wheel: Wear-resistant bronze alloy

Worm shaft: CK45N hardened and grinded - Operating temperature: -10 °C to +80 °C

- Rotational speed: Max. 100 min-1

- Mounting position: Any, preferably horizontal

- Lubricant: With bearing grease via grease nipples

- Options: Inductive proximity switch, flange/coupling to mount the motor, motorization

- Material: Base plate: Aluminium

Rotary table, high precision Type LTB

-

Franke rotary tables LTB impress with their excellent angular accuracy and high resolution. This makes them particularly suitable for tasks in the fields of measuring, testing and orientation.

Franke rotary tables of type LTB are centerless, ready to install positioning units. The housing is made of light aluminium. Franke LTB are highly loadable and have an excellent angular accuracy and resolution. They can be used in a wide range of applications and are particularly suitable for movement and positioning tasks in the field of measuring, testing and orientation.

Technical data

- Material: Housing: Aluminium ribbed

Ball race rings: hardened and tempered chrome-silicon steel

Rolling element: hardened rolling bearing steel

Worm wheel: Wear-resistant bronze alloy

Worm shaft: CK45N hardened and grinded - Operating temperature: -10 °C to +80 °C

- Rotational speed: Max. 7 min-1

- Mounting position: Any, preferably horizontal

- Lubricant: With bearing grease via grease nipples

- Options: Inductive proximity switch, flange/coupling to mount the motor, motorization

- Material: Housing: Aluminium ribbed

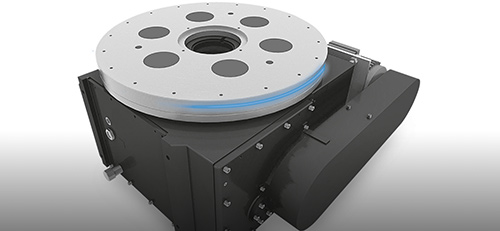

Bearing assembly with Torque-Motor Type LTD

-

Franke bearing assemblies with integrated direct drive (torque motor) are characterized by high dynamics, maximum energy efficiency and a compact installation space combined with center-free design.

Bearing assemblies with direct drive are suitable for applications where high performance and low space requirements are important criteria. The integration of the drive into the bearing housing means that wear-prone assemblies for transmitting drive power, such as toothed belts, shafts or chains, can be dispensed with. This reduces the required drive energy and also benefits more accurate positioning.

Technical data

- Material: C45N (optionally aluminium)

- Operating temperature: -10 °C to +80 °C

- Mounting position: Any

- Lubricant: With bearing grease via grease nipple

- Options: Absolute measuring system, axial cable outlet, control units incl. cables, water-cooling

Applications

- Our customers are as diverse as our product program. They are at home in fields such as mechanical engineering, medical technology or the textile industry. The trust that our customers place in us and our products confirms: Our Wire Race Bearings are convincing thanks to their high performance and flexibility - irrespective of the machine or the industry in which they are used.

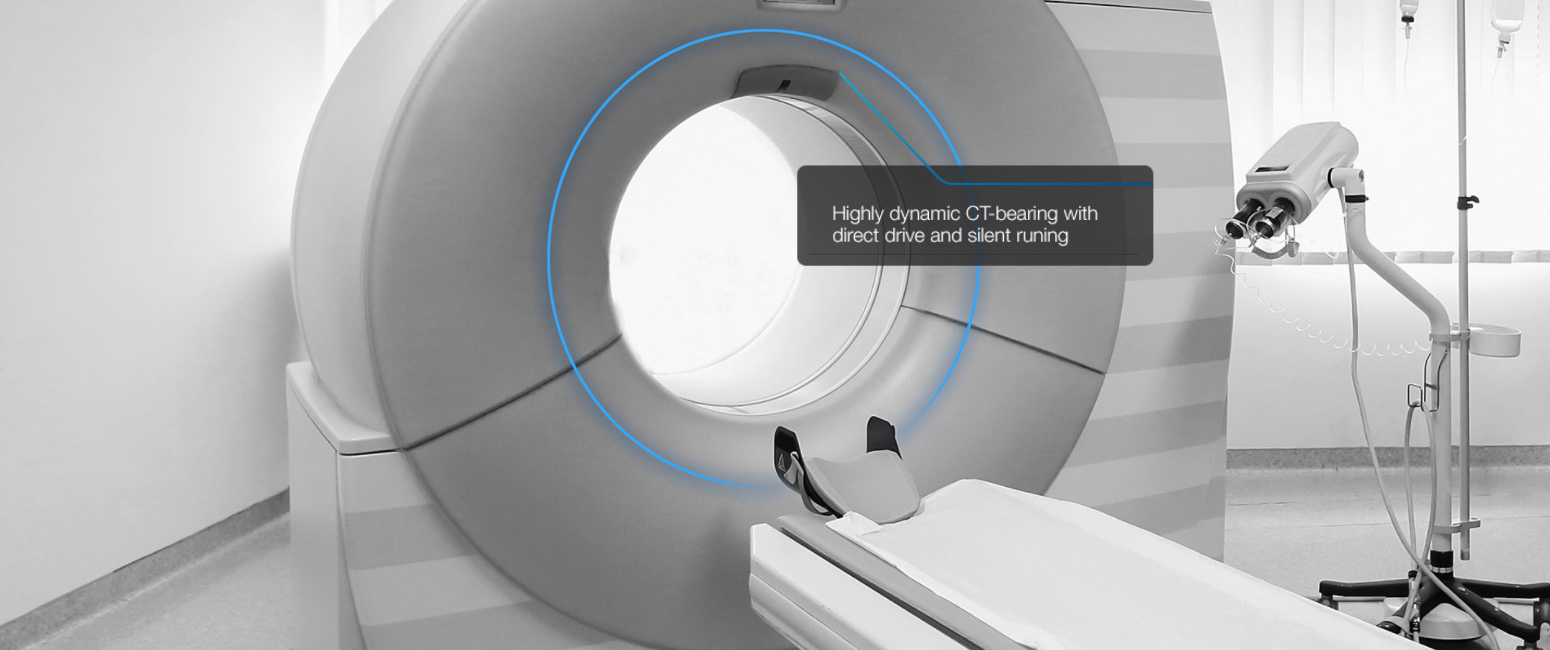

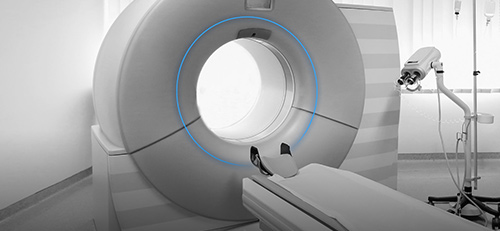

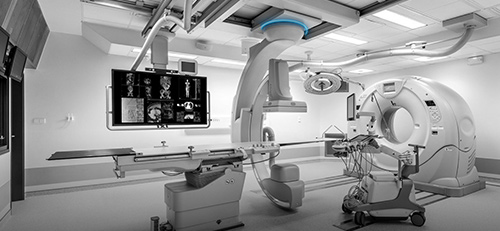

Computer tomograph

-

Requirements

The main bearing of the computer tomograph is partly responsible for ensuring that accurate images are delivered. Even at high speeds, it must run quietly and with low vibration. Exact radial and axial runout must be guaranteed.Solution

A customer specific patented Franke whisper bearing with elastomer. In addition to the high running smoothness, Franke CT bearings have an optimal rotational resistance. The radial and axial runout is a few hundredths of a millimetre, depending on the design and diameter. All Franke CT bearings are adjustable according to customer requirements. The internal elasticity makes the bearing extremely robust even under the toughest operating conditions.Bearing solution used

Double row angular ball bearing (customized)Advantages

Extremely quiet running at up to 300 rpm. Noise is dampened by the elastomer (60 dBA). The bearing has a low rotational resistance (< 20 Nm) and electrical insulation between the inner and outer ring. Loads of more than 1,000 kg are possible.

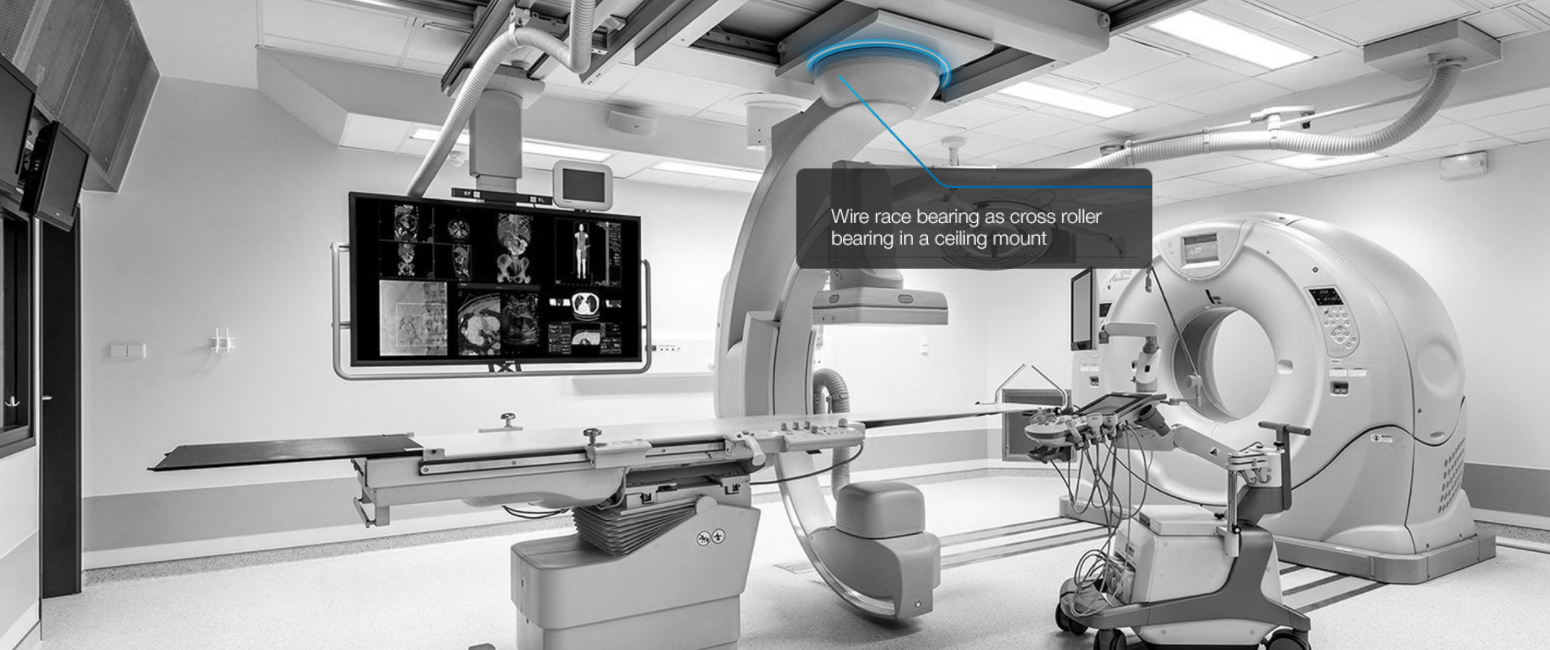

Ceiling Light

-

Requirements

Heavy equipment for medical examination should be mounted on the ceiling in a swiveling manner. The bearing is exposed to high weight and lever forces. Short-term deformations of the bearing housing due to high moment loads during movement cannot be excluded. The unit should be quiet and easy to move, both electrically and manually.Solution

Franke bearing element type LEW with cross arranged rollers for high load capacity and smooth running even under difficult external conditions.Bearing solution used

Baering element type LEWAdvantages

Product advantages include high load capacity, compact installation space and uniformly low rotational resistance at high torque loads.

In addition, the strongly dimensioned bearing element reliably compensates for the lack of rigidity of the surrounding design.

C-arm x-ray machine

-

Requirements

The imaging unit of an X-ray machine encloses a patient in an arched shape. The so-called C-arm should be easily and uniformly tilt-able by hand.Solution

Franke wire race bearings as segment bearings.Bearing solution used

Bearing element type LELAdvantages

The direct integration of the raceway segments into the housing parts saves space and costs. The segment bearing is adjusted backlash-free and can be moved by hand with defined resistance. The movement is quiet and uniform. The high torque forces are safely absorbed by the four-point bearing in any travel position.

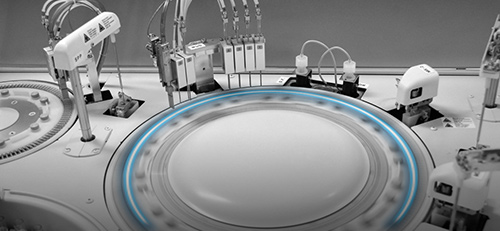

Centrifuge

-

Requirements

The rotating drum of a centrifuge for blood samples should be stored simply and inexpensively. Only low loads occur. Small installation space and high speeds are further basic conditions of the application.Solution

Bearing Element Type LER with Torque-MotorBearing solution used

Bearing Element Type LERAdvantages

Franke bearing elements type LER are suitable for medium rotational speeds and accuracies. They convince by smooth running, high dynamics and compact installation space. Due to the straight contact surfaces, they can be easily integrated into the surrounding design and have a high rigidity. The low price makes the bearing element of type LER an economical solution. LER are generally mounted without clearance. The preload can be individually adjusted according to the requirements.

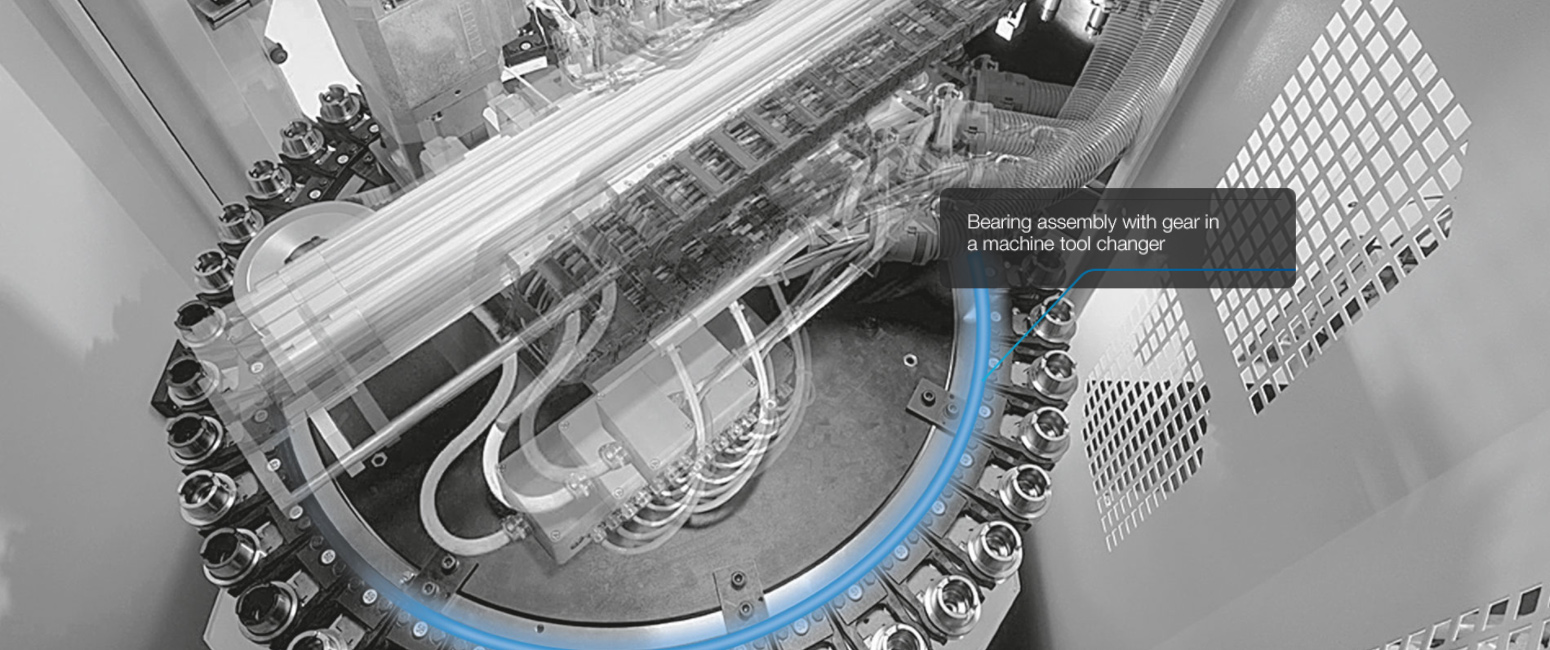

Tool Changer

-

Requirements

In the tool changer of the machining centre a rotary joint is used to feed the various tools to the machining head. A high degree of precision is required in order to be able to grip the tools securely at all times.Solution

Franke bearing assembly with toothing in the diameter range 630 to 1092 mm.Bearing solution used

Bearing assembly type LVD (customized)Advantages

Due to the large center clearance of the Franke slewing rings, the complete drive system can be moved inwards. A labyrinth seal and a lip seal protect the raceways from chips and coolant. The tool holders are mounted directly on the outer ring. The selected preload ensures high accuracy and a uniform rotational resistance for smooth running and precision.

Circular knitting machine

-

Requirements

The main bearing in the knitting machine plays a decisive role in the quality of the knitted fabric. Despite high mechanical and thermal loads, the highest demands are placed on both the accuracy and the running performance of the bearing. The required speeds are up to 60 rpm.Solution

A ground bearing element of the LEL series with a ball pitch diameter of 400 to 1,500 mm made of chrome silicon ensures smooth, quiet running in the smallest installation space. High accuracy of the bearing in axial and radial run-out (< 0.03 mm) as well as the high surface quality of the raceways ensure a consistently high quality of the machine.Bearing solution used

Bearing element LEL (customized)Advantages

LEL with wire diameter of 4 mm, ball diameter of 3/8'', 8, 10 or 12 mm The support angle is 45°, in special cases 53° due to the predominant axial load. Standard speeds are 30 rpm, for small KK diameters up to 60 rpm. The axial load by the machine cylinder is around 4,000 N, depending on the machine type.

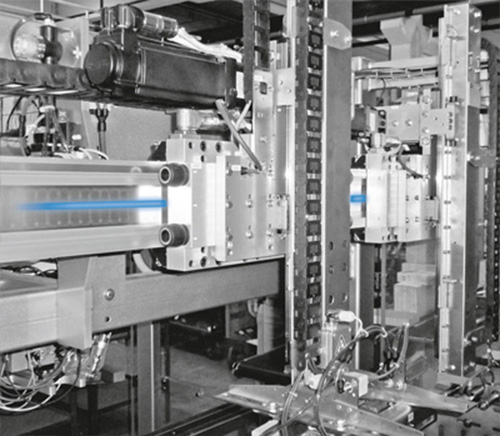

Mounting head for circuit board production

-

Requirements

Bearing for a high-performance placement head for printed circuit board production with a clock frequency of 18 start/stop movements per second and up to 120 million revolutions within five years. The service life is set at ten years. The bearing arrangement must be preloaded at 70 °C in all directions without clearance so that the components can be assembled precisely.Solution

Franke special bearing assembly LDB0110. Aluminium (Dispal) is used as material for the inner and outer ring. It has almost the same coefficient of thermal expansion as steel and thus enables constant unit settings over the entire temperature range.Bearing solution used

Bearing Element Typ LVB (customized)Advantages

Customer-specific design that meets all requirements with regard to dimensions, material and connection dimensions. The integrated bearing element has a small cross section and enables the customer to achieve a compact, light but nevertheless rigid design. Franke is the only manufacturer worldwide that can meet such requirements.

Thread testing of pipeline pipes

-

Requirements

Testing the threads of pipeline tubes is a dynamic and high-precision process. For exact positioning of the measuring device, a high positioning accuracy as well as a radial and axial runout of 0.02 mm is required. An existing SEW servo controller provided by the customer is to be reused.Solution

Franke bearing assembly with torque motor LTD-385-Z in special design.Bearing solution used

LTD-385 (customised)Advantages

The integrated torque motor meets all requirements for dynamics and precision. The compact design and the large center clearance allow ideal placement of the measuring equipment. In the special version, the torque motor is equipped with 2 measuring heads and a temperature sensor as a feedback transmitter.

Pivot bearing for camera crane

-

Requirements

A mobile camera crane, which is mounted on vehicles, is to be swivel-mounted. The bearing must be able to withstand high tilting moments due to the boom. Lightweight construction and robustness against shocks and vibrators are further requirements for the bearing.Solution

Bearing assembly with weight-reducing bore holes and a round wire without raceway.Bearing solution used

Bearing assembly type LVB (customer-specific)Advantages

The bore holes reduce the weight by almost 50%. The round wire cannot tilt under load and ensures full function of the bearing even if the basic construction twists.

Articulated robot

-

Requirements

The lightweight robot is used as a service and mobile robot. The dead weight of the robot is 10 kg with a nominal load of 3 kg. It is made of lightweight CFRP materials with good stiffness and low mass. Bearings are to be used for the movement axes. Their main requirements are also high stiffness, low weight and a small installation space.Solution

Bearing elements in the LER64 and LER84 series.Bearing solution used

Bearing element type LERAdvantages

Bearing elements require only minimal installation space and are integrated directly into the robot's design. The material of the enclosing construction is therefore not dependent on the bearing and can be freely selected. High load capacity of the bearing from all directions.

Rotary index table

-

Requirements

The bearing used must ensure a jerk-free and shock-free motion sequence of the rotary tables for the respective applications as well as high repeatability and high positioning accuracy in the end positions. High payloads are moved.Solution

Bearing elements LEZ with ball pitch diameter 400 to 1500 mm. Designs with a wide variety of raceway wires and ball combinations are used.Bearing solution used

Bearing element type LELAdvantages

The Franke bearing elements LEZ used are precisely matched to the various loads and thus guarantee the required jerk-free and shock-free movement of the turntables. Due to the four-point system, the bearings easily absorb the occurring loads.

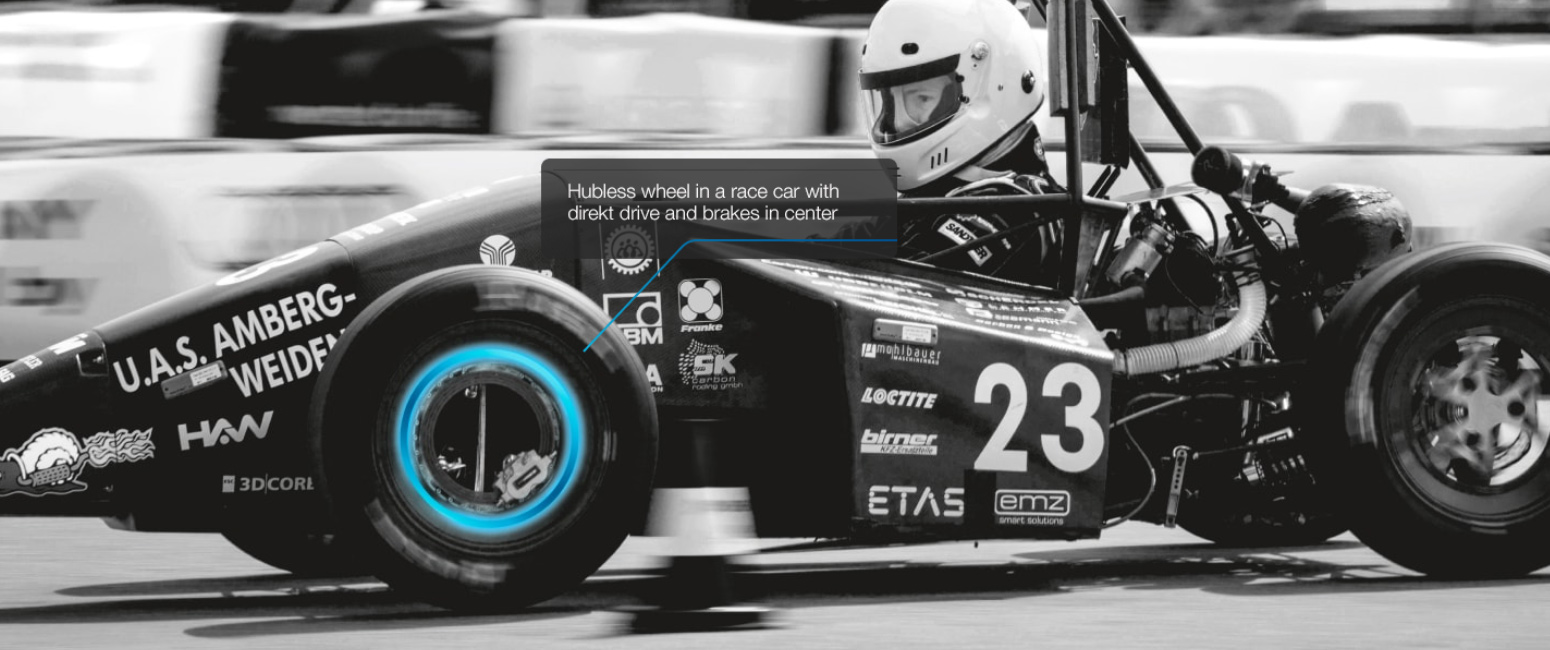

Hubless rim of a Formula Student racing car

-

Requirements

The aluminium-carbon rim of an electric racing car is intended to accommodate drive and braking devices in its centre. The bearing used should require extremely little installation space and offer great central clearance. At the same time, large forces and torques must be reliably transmitted.Solution

Franke wire race roller bearings as double row angular contact ball bearings directly integrated into the housing parts of the rim. The wire race roller bearing absorbs the loads that occur and operates independently of the material of the surrounding parts. Wires and rolling elements require minimum installation space.Bearing solution used

Bearing element type LEL (customized)Advantages

Space-saving bearing solution with a high degree of freedom in the centre. Due to the arrangement as a double row angular contact ball bearing, extremely dynamic motion processes can be implemented.

Wheel hub with Torque-Motor

-

Requirements

A concept vehicle is to be driven with one direct drive per wheel. For this purpose, a space-saving bearing with sufficient load capacity is sought The maximum speed is 1,000 rpm. The balls must be non-magnetic due to the proximity of the direct drive.Solution

Four LES0380 – 5/9.525, including ceramic balls.Bearing solution used

Bearing Element LEL (customized)Advantages

Customer-specific bearing arrangement for direct integration into the customer's design. Support of forces from all directions including tilting moments. Installation space designed in cooperation. Joint assembly of the prototype at Franke.

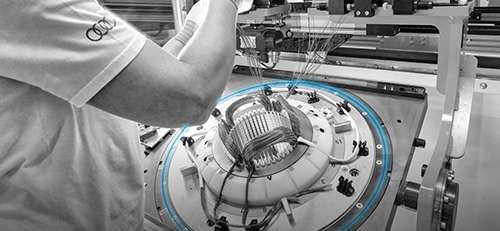

Bearing arrangement of stator winding machines

-

Requirements

To ensure homogeneous windings of the stators, the winding head must be precisely supported. A uniform, homogeneous rotational resistance and lightweight construction to reduce mass inertia are further requirements. The high running performance of the bearing is the guarantee for high economic efficiency.Solution

Franke wire-race bearings type LER-3 in diameters from 300 to 700 mm.Bearing solution used

Bearing element type LER-3 (customised)Advantages

Franke wire-race bearings can be integrated directly into the existing system. Their small installation space and the homogeneous rotational resistance that can be installed ensure a precise, uniform bearing arrangement of the winding head with a long service life.

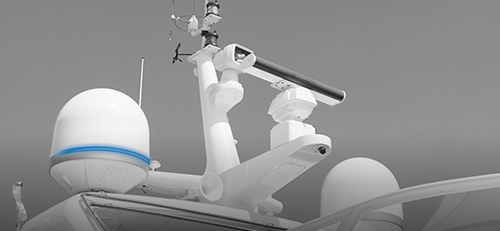

Mobile Satellite Antenna

-

Requirements

The main bearing for a mobile satellite antenna must not exceed a total weight of 1 kg. Smooth running with high tilt stiffness must be ensured.Solution

Franke bearing assembly LDB200 made of aluminium, with outer gear.Bearing solution used

Bearing assembly type LVB (customized)Advantages

Complete ready-to-install bearing assembly made of aluminium with toothed belt. Large centre clearance and low space requirement due to the compact design.

Satellite Antenna on Vessels

-

Requirements

The bearing must have a high rigidity over the complete service life (shock loads due to shaft movement). Corrosion resistance and constant rotational resistance over a temperature range from -25 °C to +60 °C must be ensured.Solution

The slewing ring LDA166 in steel version with threaded ring including coating and LER bearing elementBearing solution used

Bearing assembly LVA (customized)Advantages

The steel solution has a constant rotational resistance over the entire temperature range. The high stiffness over the entire service life is ensured by an additional running-in process and readjustment.

Suspension of an aerial camera

-

Requirements

Light custom bearings are required for the swivel joints of the suspension, which have a high rigidity and at the same time are smooth running with low breakaway torque and rotational resistance. Forces and moments occur from all directions. The bearing must not impair the camera's recording quality.Solution

LDB155 on high-strength aluminium with customized bore pattern. Anodized-orange by request of the customer.Bearing solution used

Bearing assembly type LVB (customized)Advantages

Bearing material, design and coating are made according to customer requirements. The four point bearing can support forces from all directions and is insensitive to temperature fluctuations and vibrations. Smooth-running bearing with high stiffness at a reasonable price.

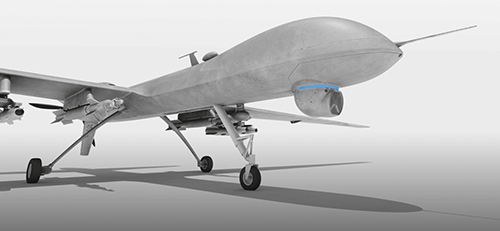

Laser optics on aircraft

-

Requirements

Roller bearings with high rigidity and highest accuracy are required for use in aircraft protection. The bearings must be able to compensate for thermal expansion.Solution

Slewing ring LDB80/295 as cylindrical roller bearing made of aluminium with a diameter of 295 mm. A further bearing assembly in the form of a three-point bearing is also used.Bearing solution used

Bearing assembly type LVB (customized)Advantages

The LDZ bearing assembly has a radial and axial runout of 0.03 mm. A weight saving is achieved by the light aluminium construction. The load ratings, rigidity and accuracy of the bearing are determined by the raceways. The second bearing has a load angle of 45° (three-point bearing). The outer ring is movable in order to optimally compensate for the thermal expansions that occur.

Aerial bearing aviation

-

Requirements

Rolling bearings with high rigidity, highest accuracy and lowest weight are required. The bearings must be able to compensate for vibrations and thermal expansion.Solution

Slewing rings with housing parts from the 3D printer can be individually adapted to the application and impress with their low weight.Bearing solution used

To the innovation field "lightweight construction"Advantages

Extreme lightweight construction is an important feature for aerospace components. Franke special bearings from the 3D printer impress with their extremely low weight.

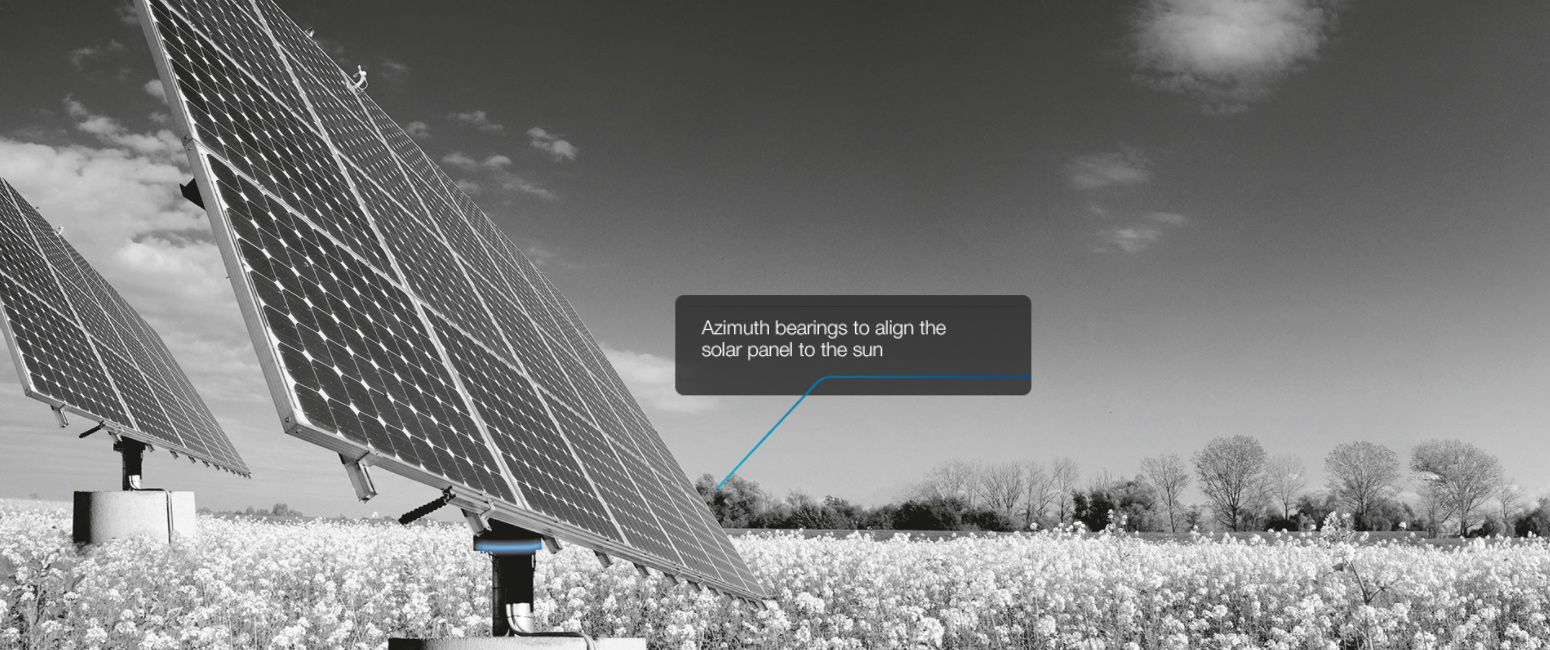

Azimuth bearing for solar panel

-

Requirements

Bearing assembly for pivoting the solar sail. Very slow worm drive to follow the course of the sun. High stiffness, as high wind pressure is possible.Solution

Wire race bearings as bearing elements. Wire diameters of 7 mm and ball diameters of 20 mm are used to achieve the required load ratings and rigidity. Further adaptations: Special forging and full ball design.Bearing solution used

Bearing element type LEL (customized)Advantages

Low space requirement due to direct integration into the cast housing of the rotary actuator. High load ratings and high rigidity as well as attractive series price are further advantages.

Fan

-

Requirements

For the fan of a living room ventilator an absolutely silent bearing must be found. The bearing must compensate for certain manufacturing tolerances of the injection-moulded housing. The housing has a compact design; only a small installation space is available for the bearing used.Solution

Bearing element LEZ367 with 2.5 mm wire and 6 mm balls.Bearing solution used

Bearing element LEL (customized)Advantages

To further minimize noise, the ball cage of the bearing is only fitted with every second ball. To facilitate series assembly by the customer, the injection-moulded housing has been optimised. A threaded ring is used to adjust the bearing seat.

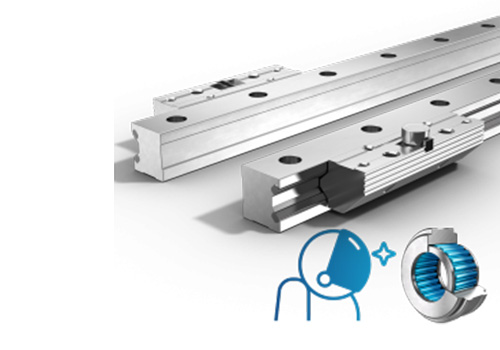

Linear Movement

-

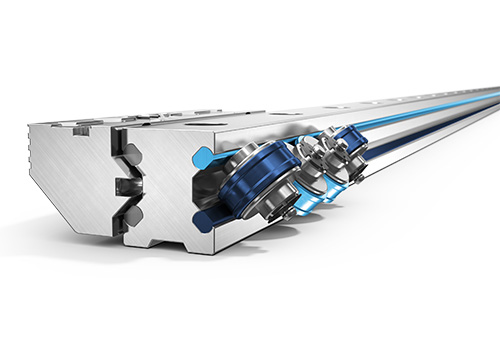

Uniquely dynamic. Uniquely individual.

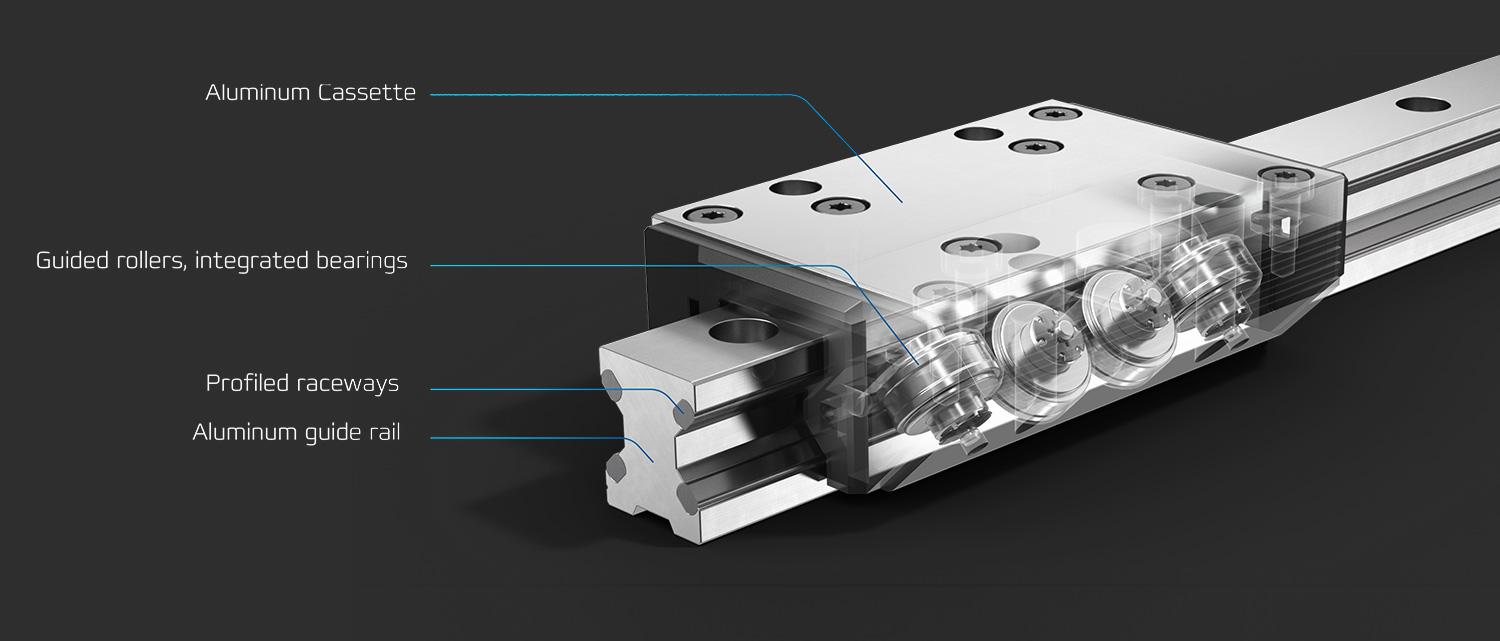

Franke linear systems transfer the ingenious principle of the wire-race bearing to linear movements. Inserted raceways ensure the load capacity on all sides. The rest of the construction can therefore be made of lightweight aluminum. Large guided rollers ensure smooth running - maintenance-free over the entire service life. Thanks to their modular design, Franke linear systems can be individually adapted to requirements.

Accelerate more easily

- Franke linear systems are the first choice when highest dynamics are required. The large rollers are mounted very smoothly. They run with low friction and precisely guided on the inserted tough and hard steel wires. Because almost exclusively light aluminum is used for the entire construction, the moving mass is low. The result: Highest dynamics and energy efficiency.

Designing homogeneously with aluminum

- The main components of Franke linear systems - rails and cassettes - are made of aluminium. Franke linear systems are ideally suited for constructions made of aluminum, because the homogeneous materiality excludes temperature-related distortions.

The quieter the better

- Where Franke linear systems are used, you hear almost nothing from them. Only a quiet, homogeneous noise can be heard. This makes them ideally suited for noise sensitive applications. Furthermore, the whisper-quiet operation is an audible quality feature.

Highly accurate and durable

- Franke's core competence lies in the high-precision manufacture and machining of wire raceways. The pursuit of precision determines every single step of our work. The result is bearing solutions with outstanding accuracy values and an excellent service life.

Patented guidance

- Franke track rollers have a groove adapted to the wire tracks. This patented type of guidance prevents the rollers from sliding on their bearing pins and rubbing against the housing. The advantage: a lower friction, more controlled movement.

Loadable on all sides

- The rollers are arranged crosswise and run on one of the four wires each. In this way, forces are absorbed on all sides and the installation position can be freely determined. Depending on the profile rail used, the bearing can be designed with an external guide in an O arrangement (figure right) or with an internal guide in an X arrangement.

Maintenance-free - carefree

- The needle or ball bearings used in the rollers are lubricated for life. This means that no maintenance is required over the long life of a Franke linear guide. For applications in the food industry we also offer lubricant-free roller bearings.

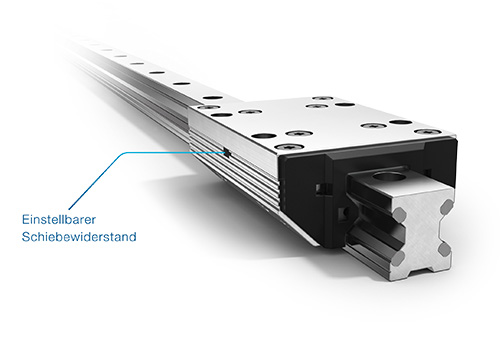

Always the right sliding resistance

- The sliding resistance of Franke linear guides can be adjusted to the application at any time using an adjusting screw. Very fine adjustments are possible. This allows the system to be adapted to the load - in the direction of smooth running or in the direction of stiffness and vibration resistance.

Linear Guides

-

- Aluminium roller guides in various designs (e.g. non-corrosive, lubricant-free, LowCost)

- All variations with inserted steel raceways

- Large rollers for smooth and quiet running

- Individually adjustable slide resistance

- Infinitely variable from 200 to 4000 mm in one piece, infinitely coupled for longer stroke lengths

Double rail with Cassette

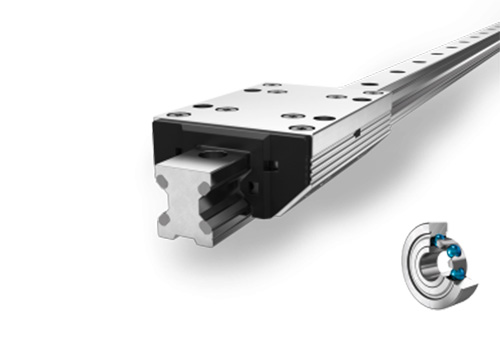

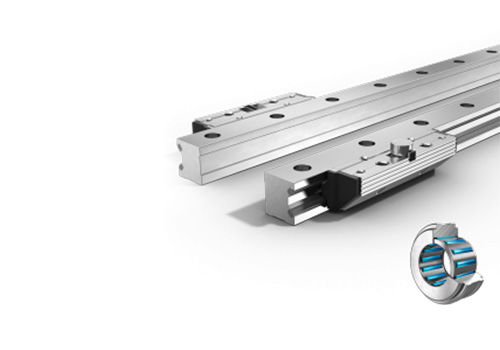

Linear Guides Type FDA-K- Double rail and Cassette - Standard

-

Aluminum roller guides of type FDA convince with the highest load capacity of all Franke linear guides as well as very good dynamics.

Franke FDA linear guides are equipped with very quiet and smooth-running, high-quality needle bearings and consist almost entirely of lightweight aluminium. The sealed roller bearings enable maintenance-free operation over the entire service life. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be endlessly coupled.

- Stroke length: One-piece from 200 mm to 4000 mm, endless coupling

- Material:

Cassette plate, roller shoes,

Rail body: anodised aluminium

Running tracks: Spring Steel

Rollers: Rolling bearing steel - Operating temperature: -20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: lubricated for life, maintenance-free

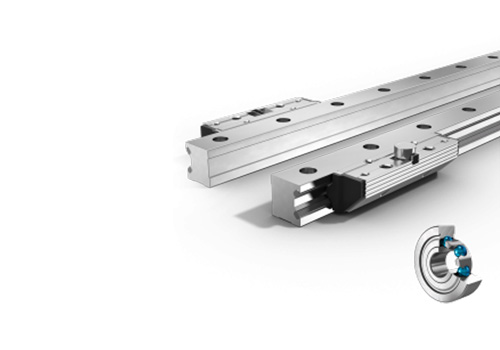

Linear Guides Type FDB-K - Double rail and Cassette - Low cost

-

Aluminum roller guides of type FDB are equipped with ball bearings and convince with a particularly low price.

Franke FDB linear guides are suitable for linear motion tasks in almost all industries. They are particularly convincing in cost-sensitive applications with reduced demands on load capacity. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: spring steel

Rollers: bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

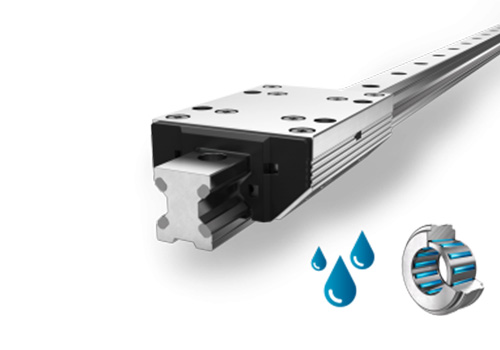

Linear Guides Type FDC-K - Double rail - Non-corrosive

-

FDC aluminum roller guides are insensitive to harsh environmental conditions.

Franke FDC linear guides are equipped with very quiet, smooth-running, high-quality needle bearings and are made almost entirely of lightweight aluminum. Inlaid raceways made of corrosion-resistant steel make them insensitive to environmental influences as well as moisture or cleaning agents. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: corrosion resistant steel

Rollers: corrosion resistant bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

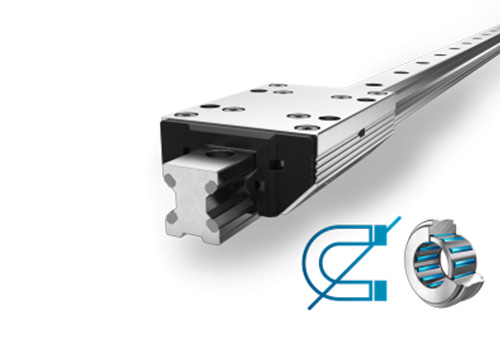

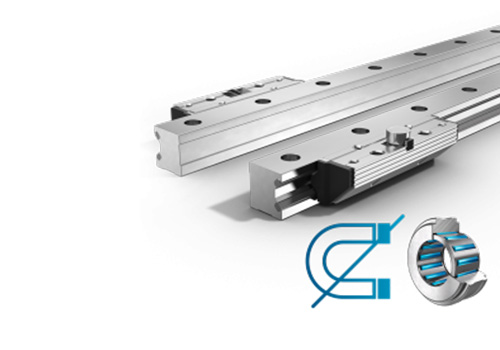

Linear Guides Type FDD-K - Double rail and Cassette - Non-magnetic

-

Aluminum roller guides of the type FDD in non-magnetic design convince by magnetic neutrality and by a light and quiet running.

Franke FDD linear guides are suitable for linear motion tasks in almost all industries. Non-magnetic tracks without influencing the prevailing magnetic fields make them ideal components e.g. in medical technology or in electronics manufacturing. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: non-magnetic steel

Rollers: non-magnetic bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 1 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

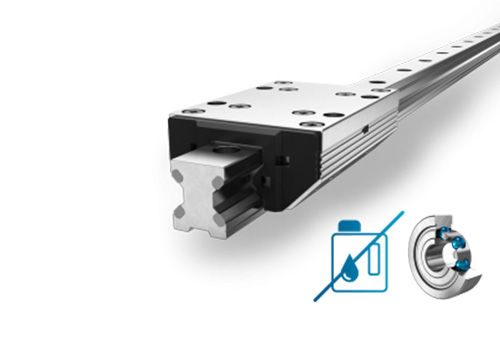

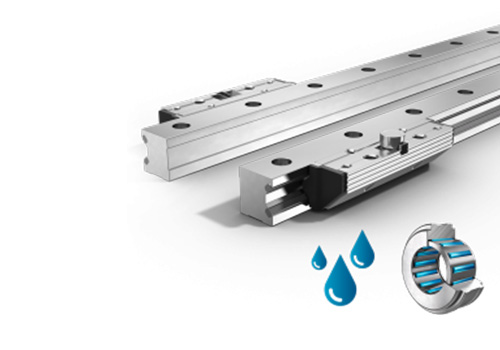

Linear Guides Type FDE-K - Double rail and Cassette- Lubricant free

-

Aluminum roller guides of type FDE are equipped with lubricant-free and needle-bearing rollers.

Franke FDE linear guides are equipped with lubricant-free, high-quality needle bearings and are made almost entirely of lightweight aluminum. They are suitable for linear motion tasks in almost all industries, especially for use in food production or in clean rooms. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: spring steel

Rollers: bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 1 m/s

- Mounting position: Any

- Lubrication: Lubricant free, maintenance free

Linear Guides Type FDG-K - Double rail and cassette - Non-corrosive Low cost

-

Aluminum roller guides of type FDG are equipped with stainless steel raceways and ball bearings. They offer insensitivity to environmental influences at an affordable price.

Franke FDG linear guides are suitable for linear motion tasks in almost all industries. They are particularly convincing in cost-sensitive applications in harsh environments and with reduced demands on load capacity. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: corrosion resistant steel

Rollers: corrosion resistant bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

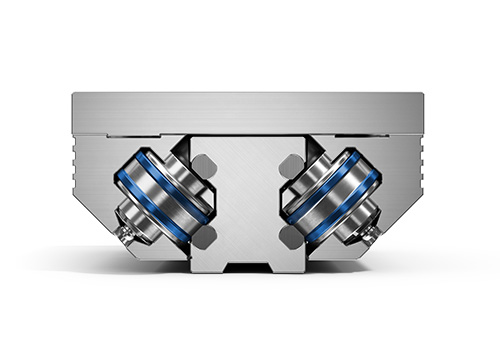

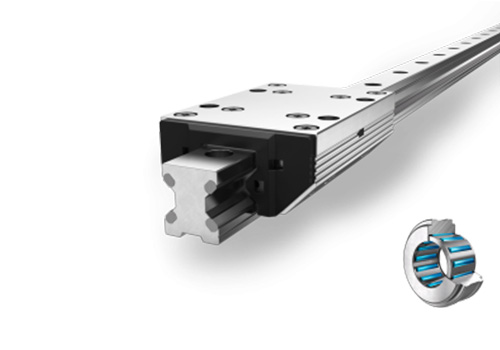

Linear guide type FDH-K - Double rail and cassette - Highly dynamic

-

Aluminum roller guides of type FDH convince with their particularly quick response and smooth running even at high acceleration.

Franke FDH linear guides are suitable for linear movement tasks, especially in dynamic pick-&-place applications. They have rollers with angular contact ball bearings for the highest acceleration and speed values, for example when using linear motors as the drive source. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke lengt: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: spring steel

Rollers: bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear guide type FDI-K - Double rail and cassette - Suitable for vacuum

- Description

Pair of Single rails and pair of Roller shoes

Linear Guides Pair of single rails Standard Type FDA-R

-

Aluminum roller guides of type FDA convince with the highest load capacity of all Franke linear guides as well as very good dynamics.

Franke FDA linear guides are equipped with very quiet, smooth-running, high-quality needle bearings and are made almost entirely of lightweight aluminum. The sealed roller bearings enable maintenance-free operation over the entire service life. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: spring steel

Rollers: bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear guides Pair of single rails Low cost Type FDB-R

-

Aluminum roller guides of type FDB are equipped with ball bearings and convince with a particularly low price.

Franke FDB linear guides are suitable for linear motion tasks in almost all industries. They are particularly convincing in cost-sensitive applications with reduced demands on load and noise. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes, rail body: aluminum, anodized

Raceways: spring steel

Rollers: bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear guides Pair of single rails Non-corrosive Type FDC-R

-

FDC aluminum roller guides are insensitive to harsh environmental conditions.

Franke FDC linear guides are equipped with very quiet, smooth-running, high-quality needle bearings and are made almost entirely of lightweight aluminum. Inlaid raceways made of corrosion-resistant steel make them insensitive to environmental influences as well as moisture or cleaning agents. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: corrosion resistant steel

Rollers: corrosion resistant bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear guides Pair of single rails Non-magnetic Type FDD-R

-

Aluminum roller guides of the type FDD in non-magnetic design convince by magnetic neutrality and by a light and quiet running.

Franke FDD linear guides are suitable for linear motion tasks in almost all industries. Non-magnetic tracks without influencing the prevailing magnetic fields make them ideal components e.g. in medical technology or in electronics manufacturing. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: non-magnetic steel

Rollers: non-magnetic bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 1 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear Guides Pair of single rails Lubricant free Type FDE-R

-

Aluminum roller guides of type FDE are equipped with lubricant-free and needle-bearing rollers.

Franke FDE linear guides are equipped with lubricant-free, high-quality needle bearings and are made almost entirely of lightweight aluminum. They are suitable for linear motion tasks in almost all industries, especially for use in food production or in clean rooms. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke lengt: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: spring steel

Rollers: bearing steel - Operating temperature: −20 °C to +80 °C

- Maximum speed: 1 m/s

- Mounting position: Any

- Lubrication: Lubricant free, maintenance free

Linear Guides Pair of single rails Non-corrosive Low-cost Type FDG-R

-

Aluminum roller guides of type FDG are equipped with stainless steel raceways and ball bearings. They offer insensitivity to environmental influences at an affordable price.

Franke FDG linear guides are suitable for linear motion tasks in almost all industries. They are particularly convincing in cost-sensitive applications in harsh environments and with reduced demands on load capacity. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: NIRO steel

Rollers: NIRO steel - Operating temperature: −10 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear Guides Pair of single rails Highly dynamic Type FDH-R

-

Aluminum roller guides of type FDH convince with their particularly quick response and smooth running even at high acceleration.

Franke FDH linear guides are suitable for linear movement tasks, especially in dynamic pick-&-place applications. They have rollers with angular contact ball bearings for the highest acceleration and speed values, for example when using linear motors as the drive source. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material;

Cassette plate, roller shoes,

Rail body: aluminum, anodized

Raceways: spring steel

Rollers: steel - Operating temperature: −10 °C to +80 °C

- Maximum speed: 10 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear Guides Pair of single rails Vacuum suitable Type FDI-R

-

Aluminum roller guides of type FDI are special guides for use in vacuum. The full needled bearings are equipped with vacuum-compatible lubricant.

Franke FDI linear guides are equipped with vacuum-compatible needle bearings and are made almost entirely of lightweight aluminum. Special design, material and lubricants prevent outgassing in a vacuum. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

- Stroke length: One piece from 200 mm to 4000 mm, endlessly connectable

- Material:

Cassette plate, roller shoes,

Rail body: aluminum

Raceways: spring steel

Rollers: non-corrosive bearing steel, full needled - Operating temperature: −20 °C to +80 °C

- Maximum speed: 1 m/s

- Mounting position: Any

- Lubrication: Lifetime-lubricated, maintenance-free

Linear Systems Applications

-

Leading along the entire line

Franke Linear Systems are used across a broad variety of different industries – among them the food and packaging sectors. In many cases, their smooth and quiet running is essential to achieve trouble-free operation.

Water jet cutter

-

Requirements

Numerous so-called slider systems are available on the market to move video cameras. The system by the firm SlideShot from Great Britain is a recent addition, which uses Franke linear guides. These systems have the following requirements: smooth and quiet operation, homogeneous movement and low weight.

SolutionFranke Linear Systems in a special design with accessories for photographers.

Advantages

Available from www.slideshot.co.ukLightweight aluminium design for low carrying weight, large-scale rollers for smooth and quiet running and a broad range of accessories to adapt in a variety of shooting situations.

Requirements

Cutting with a water jet calls for exact and rapid movements of the cutting head above the work piece to create even and smooth edges and to travel along even more complex geometries.

SolutionFranke linear motor module FTH Drive with integrated direct drive.

AdvantagesLightweight aluminium design for low weight and dynamic movement. The linear motor is integrated in the rail profile. This makes the module extremely flat and ensures it requires very little mounting space. The aluminium body and the non-corrosive running bars make the system insensitive to moisture.

Food packaging

-

Requirements

The packaging machine works at high speeds. The linear guides used here must be resistant to aggressive media (e.g. salt, sugar, spray water). The machine has stroke lengths of 1500mm to 2100mm. The average mileage of the packaging machine is 30,000km per year.

SolutionThe aluminium roller guides in series FDA20.

AdvantagesThe aluminium roller guides FDA enable speeds of up to 10m/s. The stroke lengths are infinitely variable. Central lubrication on the cassette achieves a high service life and substantial mileage. Grease nipples fitted to the front allow for convenient lubricant replenishment while the guides are fitted.

Cheese production

-

Requirements

A linear guide is to be used to hold a cheese wheel in place for the subsequent cutting process. The guides must satisfy the hygienic requirements for use in the food industry. There must be no leakage of lubricant. The system has relatively weak motorization.

SolutionThe aluminium roller guides in the system FDA25 with tracks from the series FDC25.

AdvantagesThe Franke aluminium roller guide operates cleanly and maintenance-free thanks to the food industry-compatible non-corrosive design. It comes with food industry lubrication. The guide can be set to the desired low slide resistance using a grub screw fitted to the side of the cassette. This is used to reduce the drive power applied to the guide.

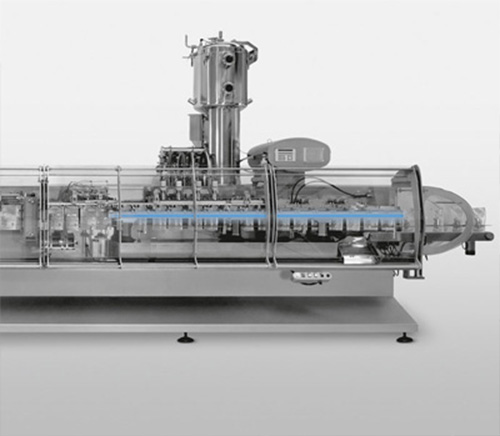

Packaging machine

-

Requirements

Bonding points to bond the mattresses are positioned in the center of the gantry. The guides are used to travel to the gantry along the x and y axes. The assembly surfaces of the guides are not processed in order to save costs.

SolutionThe aluminium roller guide FDA25 in a length of 2000mm.

AdvantagesThe guide unit, motorized by a toothed belt, travels at a speed of 50m/min. The guide is fitted directly to the unprocessed aluminium substructure. This involves mounting aluminium on aluminium, which means there is no bi-metal effect in the event of temperature fluctuations. This cost efficient solution makes the system competitive. Customers achieve maximum drive culture using the aluminium roller guide. The system preload is infinitely variable to suit the requirements.

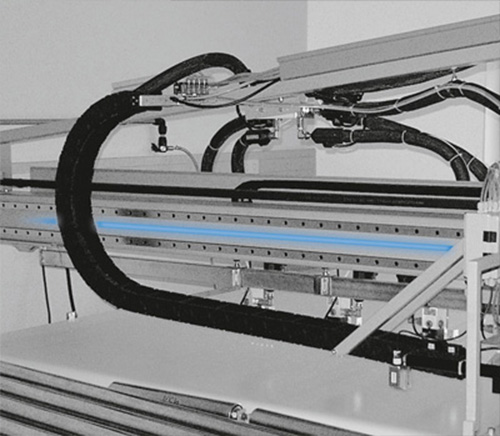

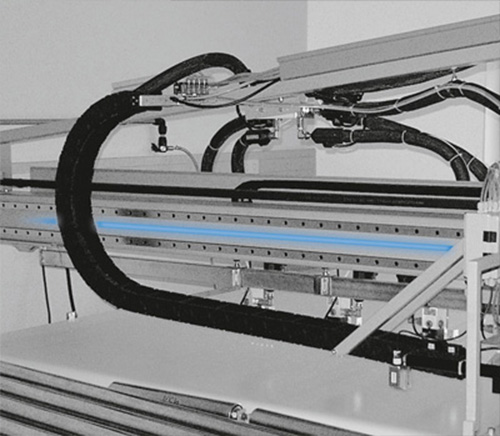

Requirements

Machine units in a packaging machine need to travel quickly and safely. High clock rates necessitate dynamic movement patterns. Two units are moved on one module.

SolutionFranke linear motor module FTH Drive with two motors.

AdvantagesFranke linear motor modules in type FTH Drive come with linear motors fitted to the guide rails. This engineering reduces the mounting space and enables compact designs. The module bodies are made of aluminium and harmonize perfectly with the aluminium profiles used to assemble the machine. Two motors, controlled separately, ensure highly dynamic movement.

Dental X-ray device

-

Requirements

The linear guide is used in the secondary panel of the dental X-ray device. The purpose of the panel is to enable exact X-ray imaging. Here it is important that the unit travels without any oscillation whatsoever. The linear guide must run easily and smoothly.

SolutionThe Franke roller guide FDL12 is integrated directly in the customized carriage mount. A lateral grub screw is used to set the slide resistance and hence the stiffness of the entire system. This guarantees movement without any oscillation whatsoever.

AdvantagesThe guide FDZ12 runs evenly, quietly and cleanly. The elevated preload (0.6 to 0.8N) ensures that the secondary panel travels free from oscillation. The guide comes with lifetime lubrication. The sealed, single-row ball bearings mean that no lubricant can leak to the outside.