HEILIG FABRICATION

Videos

Loading the player ...

- Offer Profile

- CUSTOM SPECIALIST IN METALWORKING

Heilig Fabrication offers custom metalworking such as steel constructions and sheet metal and is situated in the province of Noord-Holland. We are part of Heilig Group. An international organization that develops technical solutions for industrial processes such as machines, installations and tools, which are essential for the processing of raw materials to create more valuable products.

As an independent organization, we offer customized products and semi-finished products of various types of alloy steel.

Product Portfolio

SPECIALIST IN METALWORKING

We develop technical solutions for your industrial process. Offering high quality and affordable producs to our customers.

HEILIG FABRICATION

Heilig Fabrication is a major player in the market of metalworking. From our production facilities in Heerhugowaard we provide services such as laser and plasma cutting, CNC press brake bending, welding, metal cutting and solutions for the preservation of steel.

We offer all kinds of metalworking services for machines, equipment and steel constructions and offer high-quality to our customers at affordable prices. We can easily switch from small-scale specialist projects to large-scale projects involving large numbers of staff.OUR METALWORKING SERVICES

YOUR PARTNER IN CUSTOM METALWORKING

Heilig Fabrication is your specialist in metalworking within the Amsterdam and Noord-Holland region. We have gained major experience in cutting and welding for both small and large constructions.

We offer maximum convenience and provide single services or a combination of services at favourable rates. We provide everything. From supplying steel sheet work of various types of alloys to transportation to your customer. We offer fast and flexible deliveries whatever the size of your project.- Laser cutting

- Plasma cutting

- CNC press brake

- Welding services

- Milling and turning (metal cutting)

- Other services (drilling, punching, sawing, wet coating, galvanizing and transport)

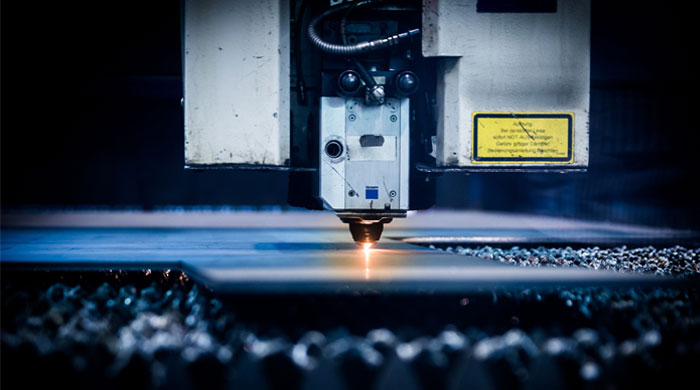

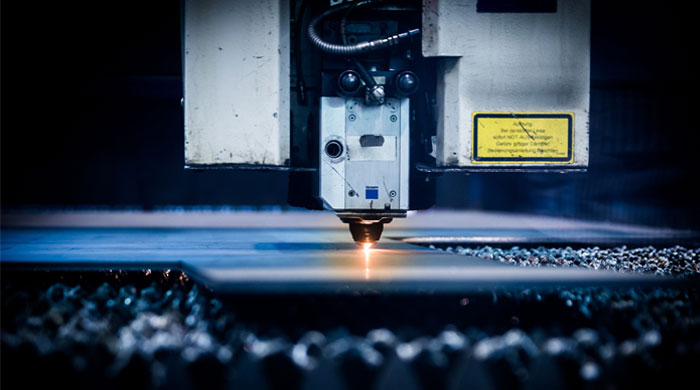

LASER CUTTING

- FOR PRECISE CUTTING SURFACES IN STEEL SHEET

Laser cutting is one of the cutting techniques that is mainly applied when cutting sheet metal, to obtain precise and high-quality cutting surfaces. At Sacred Fabrication We put the laser cutter Trumpf 5060 in front of sheet metal from various alloys up to 6 meters.

The automatic process works so carefully, and the laser so accurately, that the cutting or laser engraving guarantees an extremely high quality. After the metalworking, your product is ready for further machining, such as machining or welding. We can also provide transport to your address or your customer.

THE ADVANTAGES OF A LASER MACHINE AS A CUTTING TECHNIQUE:- High-quality cutting surfaces

- Various metals (steel, aluminium, stainless steel, etc.)

- Accuracy of 0.1 mm

- Sheet metal dimensions up to 6000 x 2000 mm

- Maximum plate thickness up to 25 mm (varies by alloy)

- Precise laser Engraving

PLASMA CUTTING OF THICKER STEEL PLATES

- Plasma cutting is the perfect solution for thicker plates. For cutting metal plates and stainless steel we offer our ESAB 3500 plasma cutter at an affordable price.

A plasma cutter works like a burner. The powerful cutting torch is relatively fast in cutting steel plates of up to 12 meters in length.

THE BENEFITS OF PLASMA CUTTING:- customized metal cutting at affordable prices

- sheet metal formats up to 12,000 x 3,000 mm

- plate thickness from 6 to 40 mm (varies per alloy)

CNC PRESS BRAKE

- FOR BENDING SHEET AND PLATE MATERIAL

CNC bending machine is an essential tool for metalworking. Heilig Fabrication has CNC press brake (Computer Numerical Control) for bending your sheet metal.

We are capable of bending steel in series utilising our press brake machines which are also capable of bending heavy steelwork:- Press brake BAYKAL APHS NEO 31200

- Press brake BAYKAL APHS 6100 x 600

Both machines can generate a compression force of 200 to 600 tons for the folding (or press brake bending) of edges and radius bends.- computer controlled machines (CNC) for precision edges

- single sheet metal of heavy steel or production in series

- edges and radius bending

- sheet metal format up to 6 meters

- sheet metal thickness up to 15 mm

WELDING SERVICES

- PROFESSIONAL WELDING INSPECTION AND WELDING RESEARCH

Heilig Fabrication provides high-quality welding services in the province of Noord-Holland. Besides laser cutting and CNC folding, we provide welding services for metal, welding inspection services (IWT/IWE) and welding testing services (NDT).

For processing your carbon steel, aluminium or stainless steel to the highest standards we invest in the qualification, skills and certification of our welders. During planning and execution we adhere to strict standards of quality.

We provide all MIG/MAG and TIG welding services in a professional, flexible and fast way. Besides these activities we conduct all kinds of welding tests (NDT) in accordance with industrial standards.

The most important NDT techniques:- Visual testing

- Magnetic testing

- Penetrant testing

- Radiographic (X-ray) testing

- Ultrasonic testing

In order to avoid any mistakes our activities are guaranteed in accordance with the following procedures and researches:- Inspection and Test Plan / ITP)

- Material certification

- Traceability o material

- Inspection of doubling plates / lamellar tearing

- Procedure Qualification Record / PQR

- Welding Procedure Specification / WPS

- Welder Performance Qualifications / WPQ

Our professional welders, the accuracy, the correct procedures and machine settings in combination with material – process – conditions of use (pressure, temperature, environment) are linked with each other in order to prevent any mistakes.

All our activities are executed in accordance with strict predetermined procedures. Results are measured and documented for evidence as proof for quality and reference.

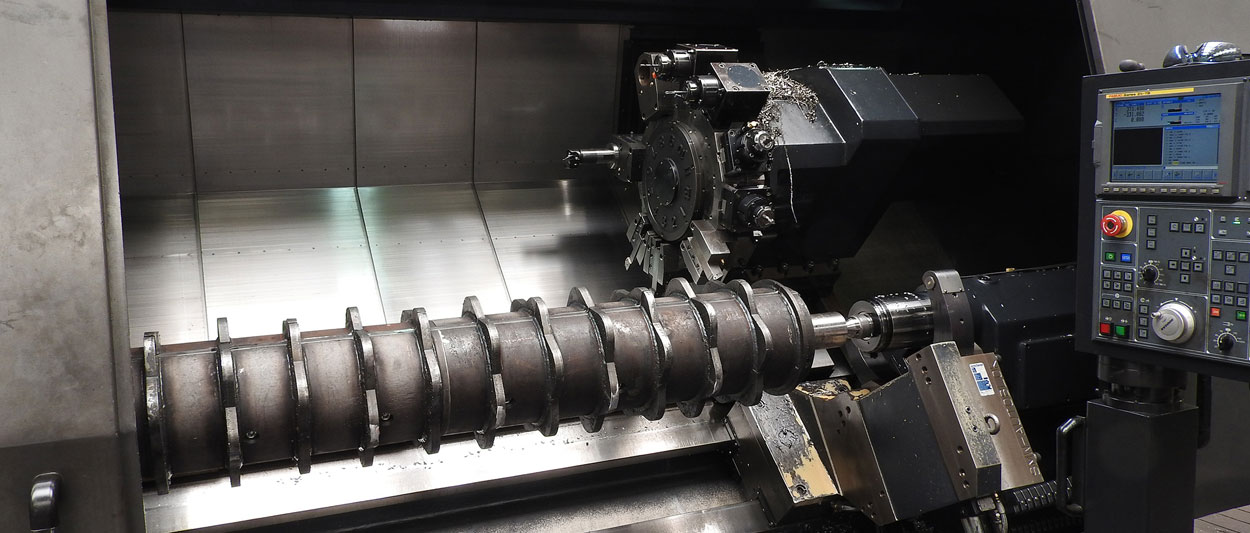

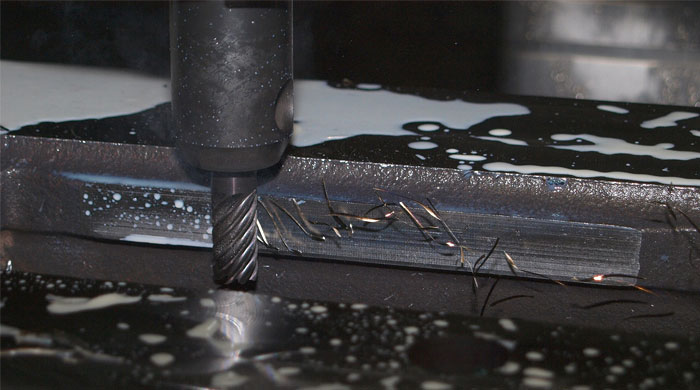

MACHINING: CNC MILLING AND TURNING

- Within the extensive service package of Heilig Fabrication, of course, there is also milling and turning. In this metalworking technique, we machin out your metal products very accurately according to your specific drawing.

Our machines include:- A CNC bed milling machine with a working width of 1,000 mm, a working length of 3,800 mm and working height of 1,600 mm.

- A CNC machining centre with a working width of 1,000 mm, a working length of 550 mm and a working height of 500 mm.

- A CNC lathe with a ø540 mm rotary diameter between the centers of 1,500 mm.

- A CNC lathe with a turning diameter of Ø 900 between the centers of 3,200 mm.

The combination of our CNC milling machines and lathes, the right tools and the experienced professionals ensure a perfect finish to your product or series. A combination with laser laser or plasma cutter cutting and welding can save you time and financial advantage. plasmasnijder

We provide machining work for companies in mechanical engineering, shipbuilding and construction. With our fast service and competitive rates, customers for CNC metalworking in the Amsterdam, Alkmaar, Haarlem and Den Helder region know where to find us.

PRESERVATION

- WET COATING, POWDER COATING AND GALVANIZING

At Heilig Fabrication we know that proper preservation of metal products provides long-term durability. The protection of semi-finished products, components and complete products will increase the lifespan of metal.

In order to reach the proper protection and lifespan levels it is essential to choose the right preservation method. Just as choosing the appropriate metal finishing process.

With our vast expertise Heilig Fabrication is able to choose the right finishing method for a durable protection against corrosion during the manufacturing process.

COMPLETE SERVICE OF SURFACE TREATMENTS

As part of our complete service our products are supplied with a surface treatment, such as blasting, wet coating, powder coating and thermal galvanizing. At Heilig Fabrication we perform quality controls. If you require any specific quality report we can provide you with this.

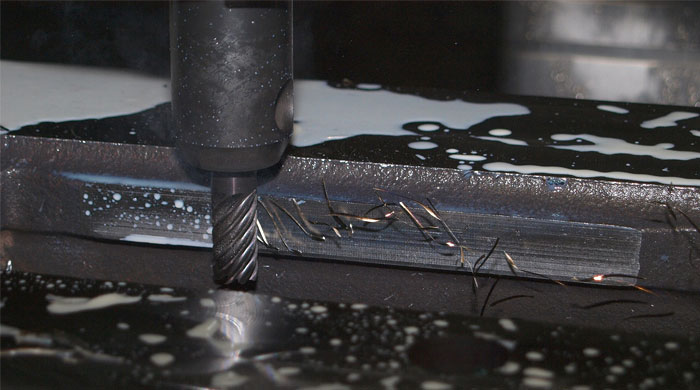

PUNCHING, DRILLING AND SAWING OF METAL

- At Heilig Fabrication we provide everything. We offer additional services such as drilling, sawing and the preservation of your metal products or semi-finished products. We can also arrange for the transportation to your address or to your customer’s address.

Besides welding, cutting and shaping of various types of alloy metal, our staff is also very experienced in other metalworking technologies. In our production facilities we work with state-of-the-art machines to drill, punch and saw single products or product series.

PRESERVATION

After these primary metalworking services we provide protective coatings to preserve your metal products and guarantee a long life.

GALVANIZING

We offer galvanizing services at affordable prices. Maximum formats: 15,500 x 2,500 x 1,600 mm and maximum weight of 15 tons.

WET COATING

Wet coating technology gives a superior finish and better protection. This provides us to improve the look and durability of your product. We offer quality coating at the best price. Maximum formats: 15,500 x 1,200 x 3,000 mm and a maximum weight of maximum 5 tons.

PICK-UP OR DELIVERY

You will receive a confirmation when your products are ready. You can pick up your products at Newtonstraat 17, 1704 SB Heerhugowaard, the Netherlands. For delivery to your address or the address of your customer we can arrange the transportation. We have favourable price agreements with several transport companies.