- Offer Profile

-

FOOKE has been manufacturing large and very large 5-axis milling machines for over 30 years. These machine tool systems are often used as gantry and overhead gantry machines for large-area and large-volume workpieces from the rail, aviation, aerospace and automotive industries, where model and prototype building as well as tool and mould construction are common application areas.

OVER 119 YEARS OF EXPERIENCE "MADE IN GERMANY"- Mechanical engineering at its best

MILLING MACHINES

-

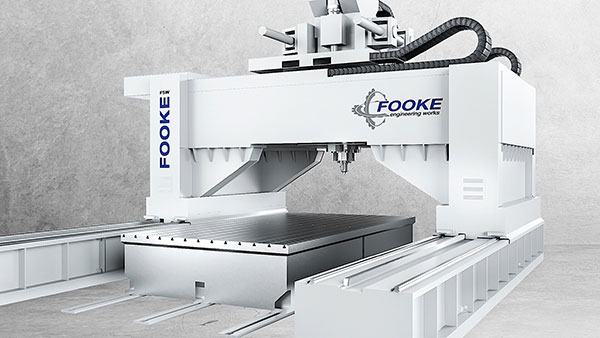

GANTRY MILLING MACHINES.

The right 5-axis gantry milling machine from FOOKE for every application.

Milling machnines - Hightech for highest demands

Experience maximum accuracies and highest precision on a new level.Our solutions increace efficiency, productivity and quality of our customers machining processes

ENDURA® GANTRY MILLING MACHINES

- The features of ENDURA® high-speed milling machines, whether designed as 5-axis milling machine or as special solutions based on customer requirements, are outstanding. They are characterized by excellent machine dynamics with high acceleration rates and constantly high feed rates

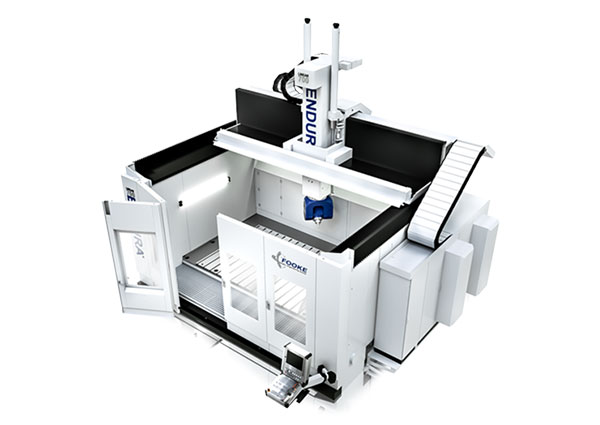

ENDURA® 400 LINEAR - Compact Gantry Milling Machine

- We have designed and constructed the FOOKE compact portal milling machine ENDURA® 400LINEAR especially for demanding customers who are primarily at home in the world of plastics; And indeed for those whose task it is to produce large workpieces precisely.

ENDURA® 600 LINEAR - Gantry Milling Machine

- The ENDURA® 600LINEAR gantry milling machine is equipped with linear motor drive technology, which has especially established for high-speed machining of large workpieces. Acceleration values of up to 3.0 m/sec² classify this series in the category of high-speed milling machines.

ENDURA® 700 LINEAR - Compact Gantry Milling Machine

- The compact 5-axis milling machine ENDURA® 700LINEAR is characterized by high structural rigidity, features maximum dynamics and achieves highest accuracies. These properties result in optimum motion control and maximum productivity.

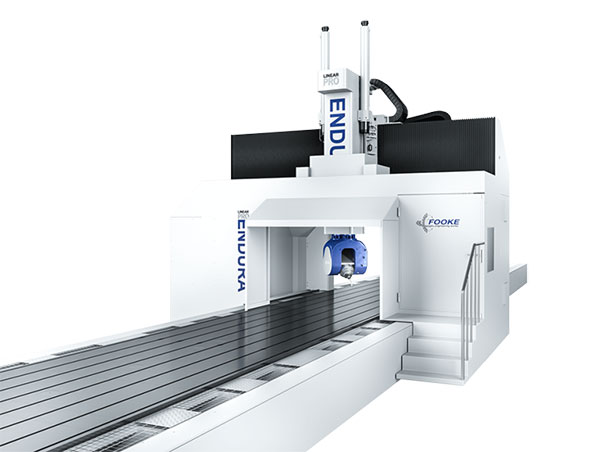

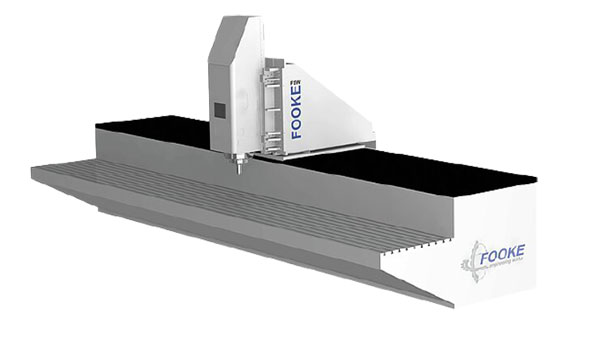

ENDURA® PRO LINEAR - Long Bed Milling Machine

- The ENDURA® PRO LINEAR is a 5-axis gantry – Long bed milling machine, especially designed for high-performance cutting of aluminum and composites profile structure elements. Its monoblock machine bed construction ensures a uniform load distribution.

ENDURA® 800 LINEAR - Plate Milling Machine

- The ENDURA® 800 plate milling machine in GANTRY portal design with two CNC-controlled axes is particularly suitable for the efficient and precise machining of plate material for various alloys of aluminum. Machine table moving in X-direction. The ENDURA® 800 produces optimum milling results in one single cut.

ENDURA® 900 LINEAR - Gantry Milling Machine

- The latest generation in ENDURA® gantry milling machines has been designed with an overhead travel portal and is based on already extremely successful conventional ENDURA® products.

ENDURA® 1000 LINEAR - Travelling Column Milling Machine

- The easy loadability of an ENDURA® 1000LINEAR travelling column milling machine, even with the largest workpieces, is also an enormous advantage of this machine concept. Due to its design, this travelling column milling machine can be manufactured in almost any length (X travel).

ENDURA® 7000 LINEAR - Compact Gantry Milling Machine

- This compact tool milling machine ENDURA® 7000LINEAR was specially developed for the tool and mould construction, for a highly productive roughing, semi-finishing and finishing application of the customary high-strength material

FSW - TECHNOLOGY

-

Our know-how for your process:

- Many years of experience in mechanical engineering.

- High vertical range of manufacture including tool development, joining and clamping technology.

- Turnkey solutions from one source.

- Comprehensive, worldwide service and fast help on site.

Your advantages at a glance:

- Detailed consultation in advance.

- Intensive exchange with our FSW engineers.

- Modular machine structure enables individual adaptability of the FSW systems.

- Best possible integration into existing production processes.

- High return of investment.

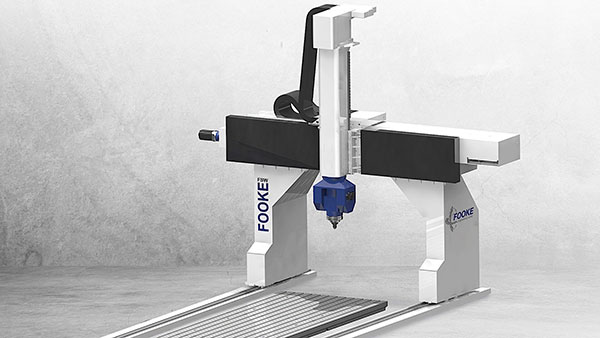

FOOKE FSW SMALL - FRICTION STIR WELDING MACHINE

- The FOOKE FSW Small series is a machine tool for the machining of smaller components in the automotive industry, rail technology, aerospace, heat sinks and many more. It allows you to easily produce simple welding seams on plane surfaces with sheet thicknesses of up to 30 mm at high axial forces and torques for almost any application.

FOOKE FSW MEDIUM - FRICTION STIR WELDING MACHINE

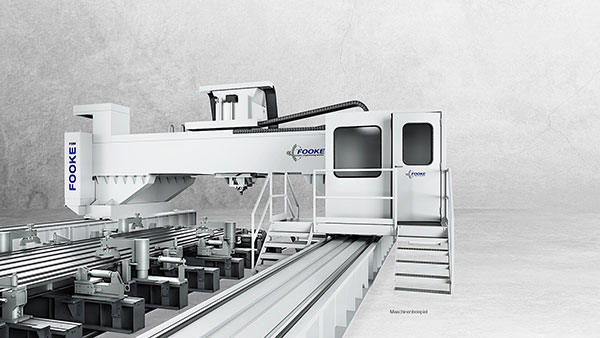

- The FOOKE FSW Medium series offers machine tools for the hybrid processing of large-scale workpieces of low-melting metals, especially manufactured for friction stir welding of profiles, used in the rail vehicle, aerospace, shipbuilding and automotive industries.

FOOKE FSW LARGE - FRICTION STIR WELDING MACHINE

-

FRICTION STIR WELDING WITH HIGH PROCESS FORCES.

Our standardized FOOKE FSW Large series offer machine tools for hybrid machining of large to very large components in aerospace, rail, shipbuilding and many more.

FOOKE FSW 10 │ 20 │ 30

-

UNIVERSAL 3-AXIS FRICTION STIR WELDING MACHINE FOR THE PRODUCTION OF LINEAR WELDS

The FOOKE FSW 10 is a 3-axis machine tool for linear friction stir welding of aluminum workpieces or similar materials. It represents an optimal entry into the technology of friction stir welding.