IBARMIA

Videos

Loading the player ...

- Offer Profile

- IBARMIA is an advanced technology manufacturer of high added-value solutions adapted to customers needs by highly customized machining centers.

Because IBARMIA would be nothing without the people behind the company, but even less without the trust of those who purchase our products and services. Our house is your house. This is your machine-tool point.

Product Portfolio

MACHINING CENTERS

Specialists in what we make.

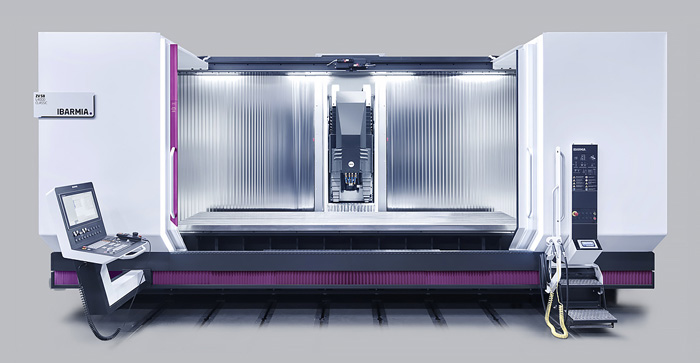

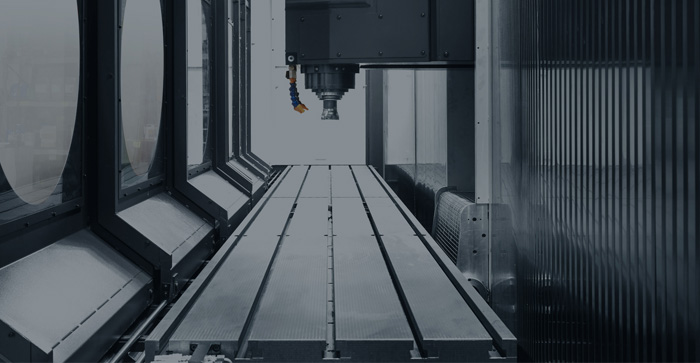

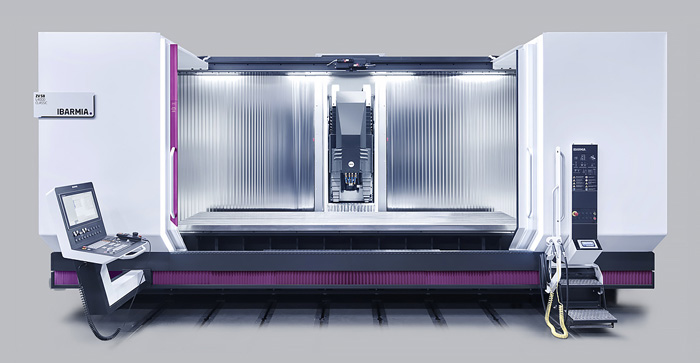

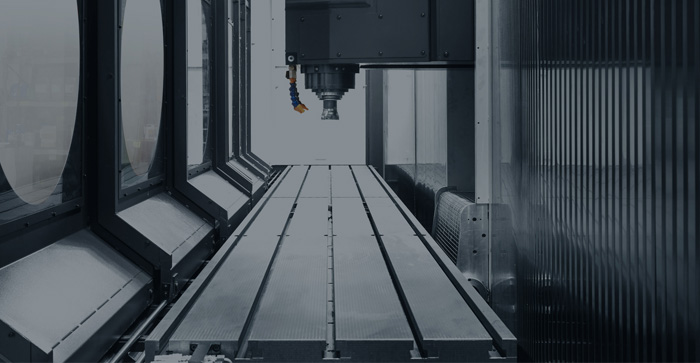

Z SERIES

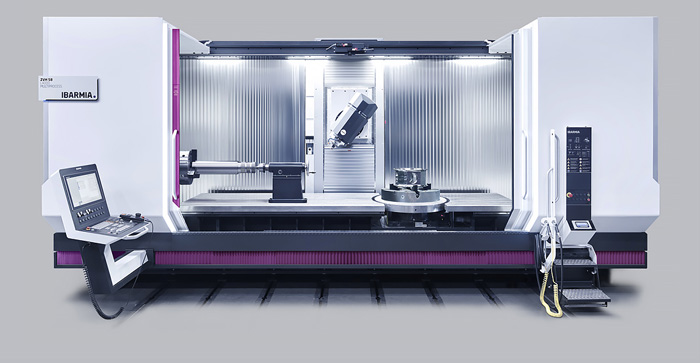

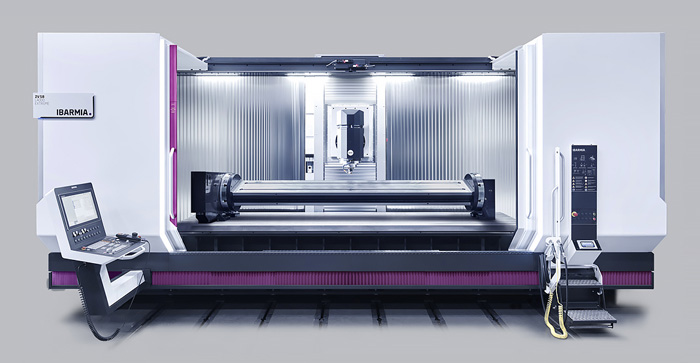

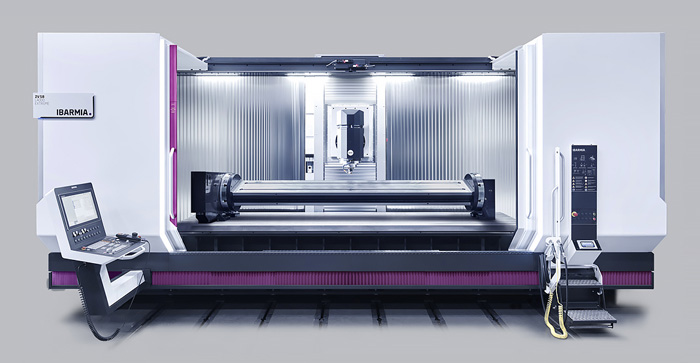

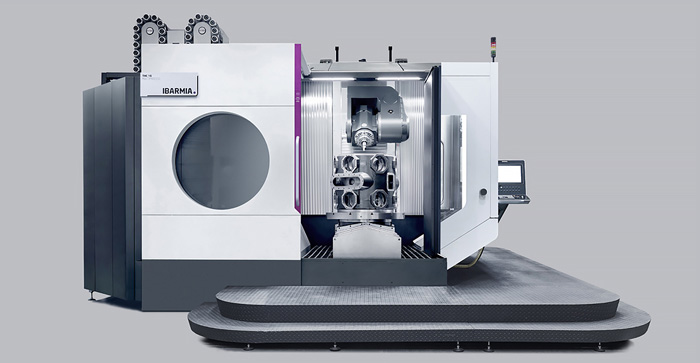

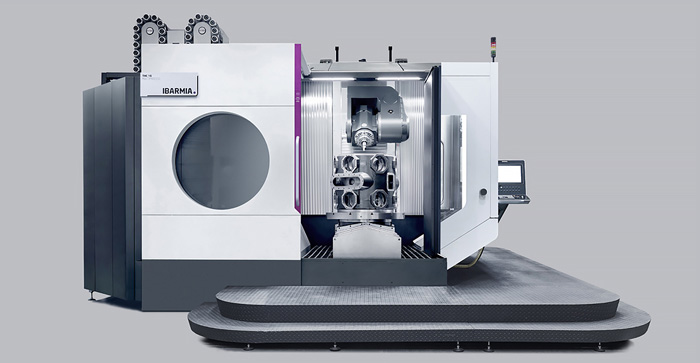

MOVING COLUMN MACHINING CENTERS

The most flexible platform in a wide selection of sizes and axis combinations For the largest variety of sizes and shapes, pendulum work and swing up to ø2000 mm, unlimited flexibility makes this platform a must have for any machine shop.

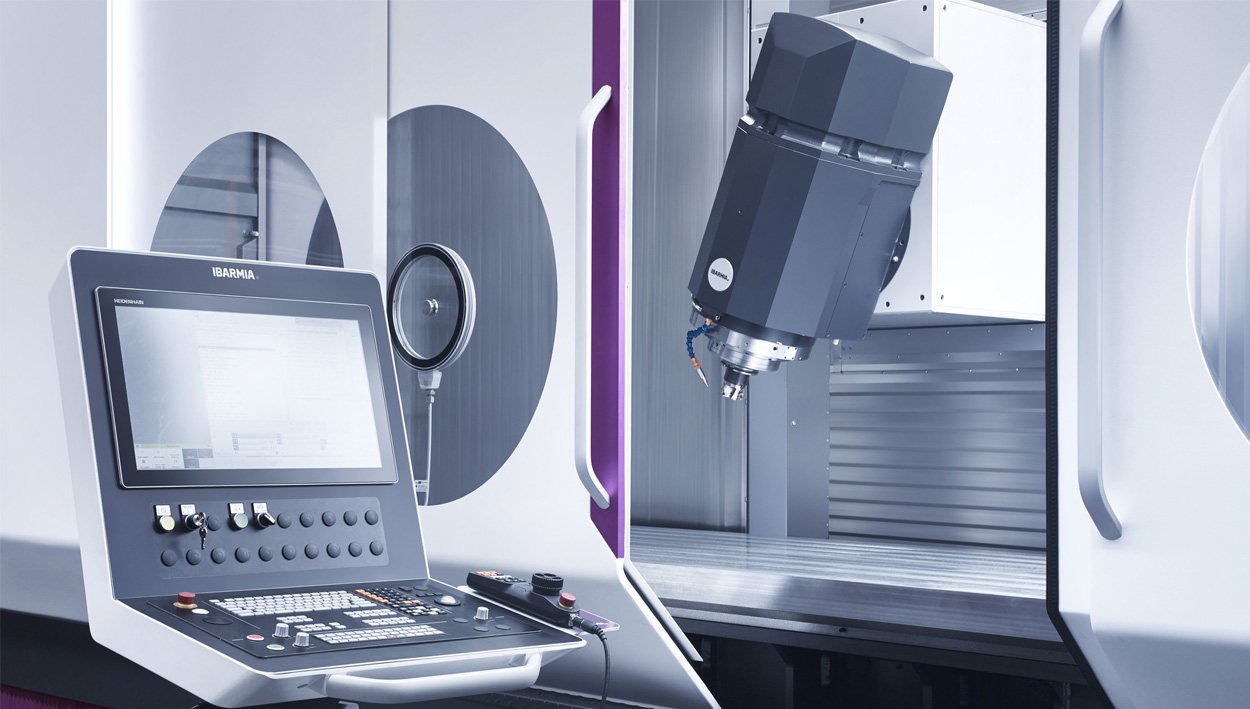

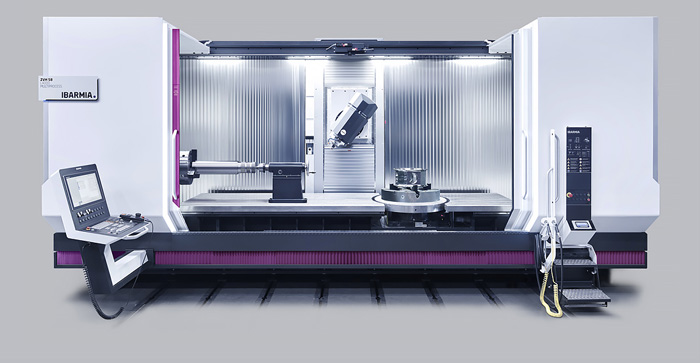

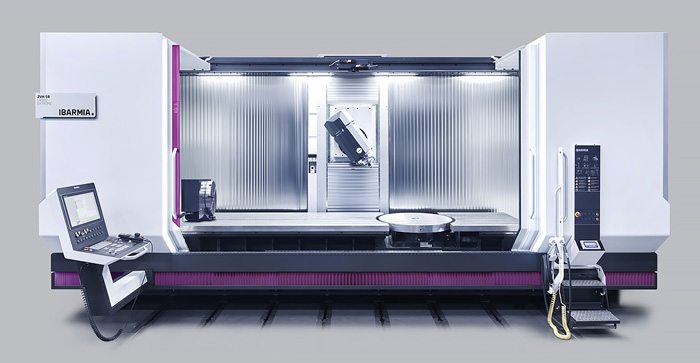

ZVH MULTIPROCESS

- Multitasking machining centers for turning and milling operations

Combine 5 axis vertical and/or horizontal multitasking capacity with a fixed table so you can be ready for any job at the shortest notice.

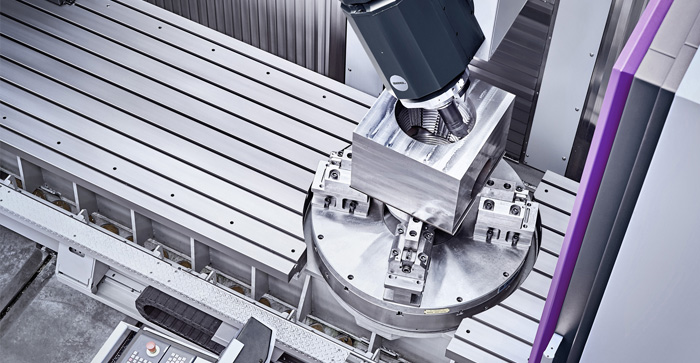

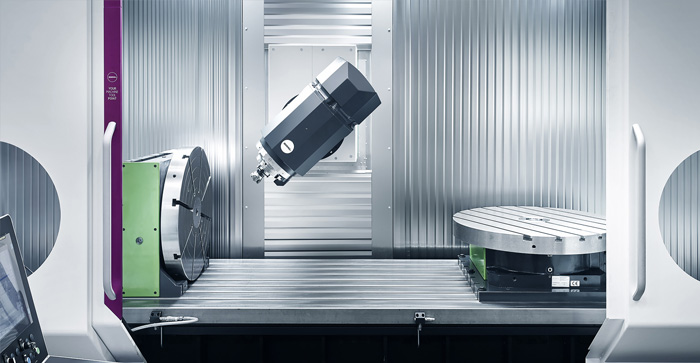

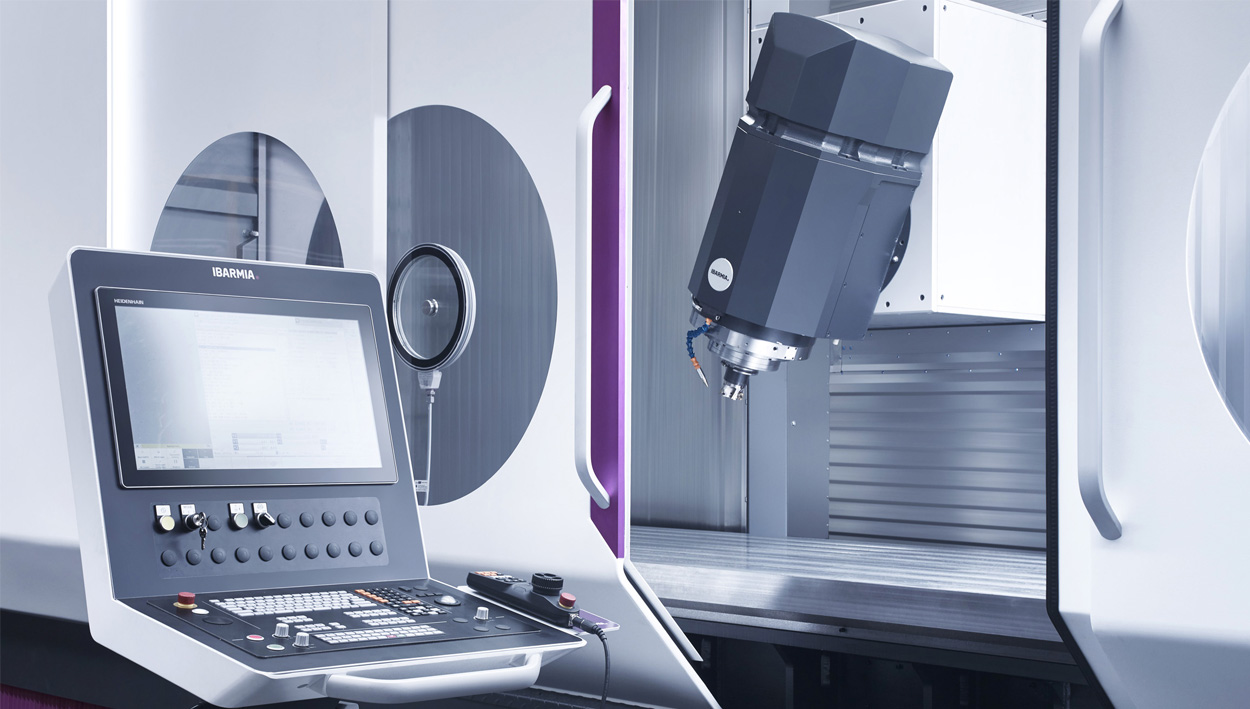

ZVH spindle head

4 axis movement. Continuous tilting head with torque motor. +/- 105º Up to 20.000 rpm

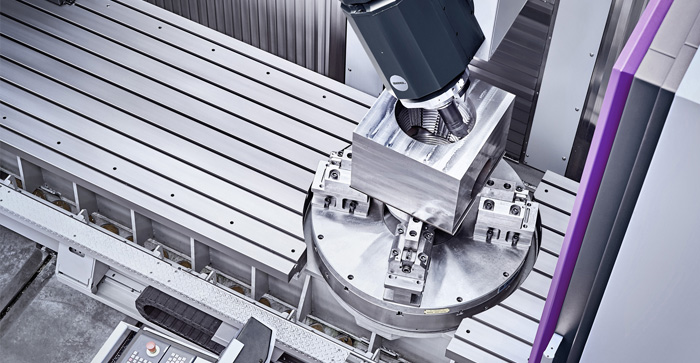

Main advantages- Vertical mill-turn

Built-in rotary table for 5 axis multitasking operations.

Table diameters from ø800 mm to ø1200 mm.

Max load up to 6000 kg. Max speed

up to 800 rpm. - Horizontal mill-turn

Horizontal multitasking with chucks up to ø630 mm. Wide range of turning swings and lengths with speeds - Internal diameter machining

Automatic changer of long boring bar for internal diameter turning operations with high rigidity and stability. - Pendulum work

Serve two jobs simultaneously with our ÂNon Stop Machining solution. It includes a central division wall, independent blocking of front doors and management software.

- Vertical mill-turn

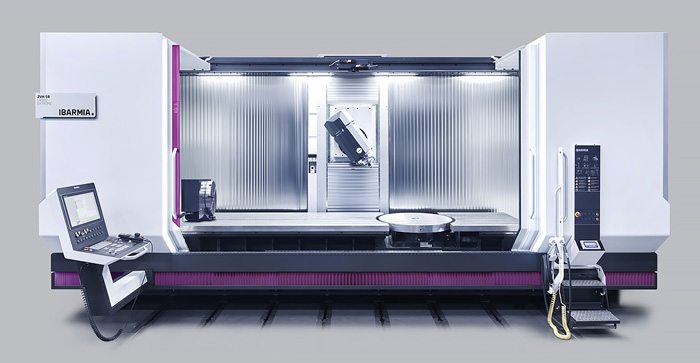

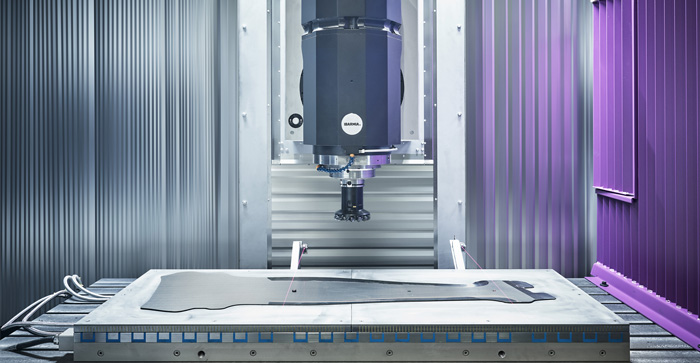

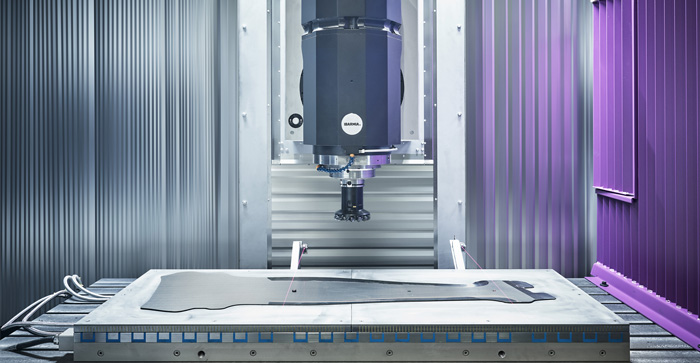

ZVH EXTREME

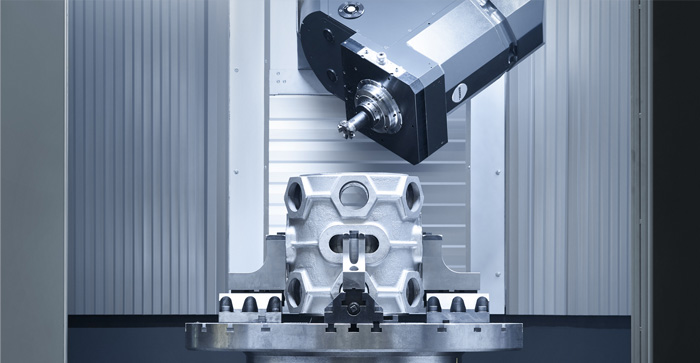

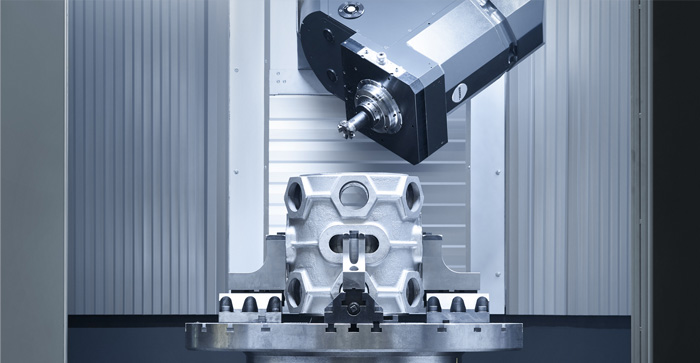

- 5 axis capacity combined with a fixed table

Combine 5 axis vertical and/or horizontal machining capacity with a fixed table so you can be ready for any job at the shortest notice.

ZVH spindle head

4 axis movement. Continuous tilting head with torque motor. +/- 105º Up to 20.000 rpm

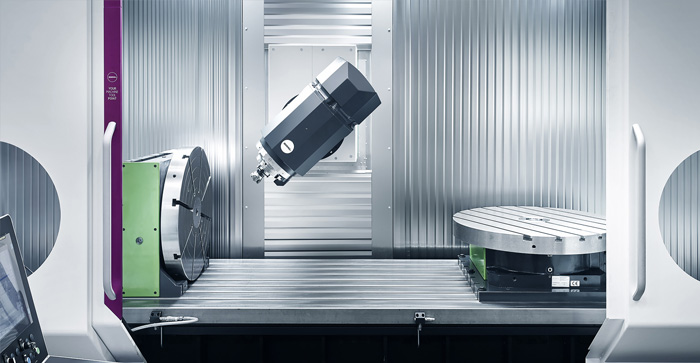

Main advantages- 5 axis simultaneous machining

The combination of the highly dynamic B axis head with the horizontal and/or vertical rotary tables allows 5 axis machining of complex parts. - B axis head (ZVH +/-105º)

Machine various angles of complex parts in one set-up and increase the productivity by using customized sliding tables, special working - Rotary tables

Integrated rotary tables with large diameters and high load capacity. Bolt-on rotary tables to work in vertical and/or horizontal orientation, customized extra-long trunnion fixtures etcÂ

- 5 axis simultaneous machining

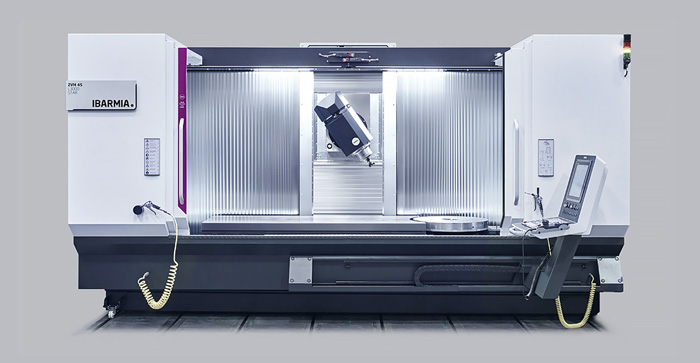

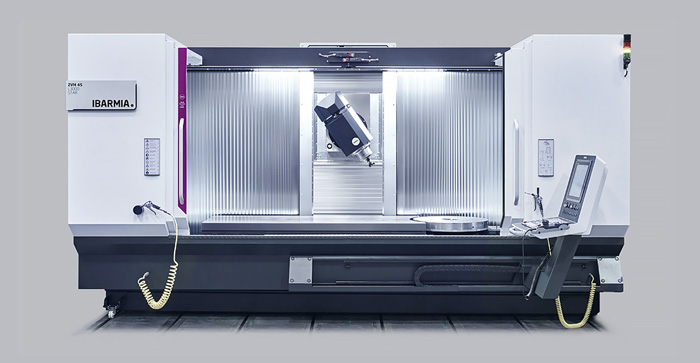

ZVH STAR EDITION

- IBARMIAÂs Âready to go standard configuration

The most aggressive moving column 5 axis machine, high technology in a combination of elements to meet a wide range of requirements for the quickest ROI. Available in two models: L1500 and L3000.

ZVH spindle head

4 axis movement. Continuous tilting head with torque motor. +/- 105º Up to 20.000 rpm

Main advantages- Moving column

Designed to cover the widest range of machining requirements. The generous working area allows an unlimited range of applications. - Rotary tables

Combined with the B axis head, they allow 5 axis machining of complex parts. Bolt-on rotary tables can be positioned to work either in vertical and horizontal axis. - Electro-spindle: Superior Technology

Powerful and high-speed spindle for all materials. - Latest generation CNC controls

Specially developed for high speed and 5 axis machining.

- Moving column

ZV EXTREME

- Capacity and superior ergonomics in 3 axis machines

3 axis models or in combination with horizontal rotary tables, IBARMIA can achieve the highest productivity by customizing working areas to specific production systems.

ZV spindle head

3 axis movement. High Dynamics spindle. Up to 20.000 rpm

Main advantages- 3 axis vertical machining

An endless range of solutions for efficient working areas, quick change over of parts etc... combined wit high speed spindles with the highest feed rates. - Trunnion fixtures

Custom made trunnion fixtures with specific clamping systems, possibility to work in pendulum etc.. excellent chip evacuation by removing the fixed table allowing a clear passage to the chip extraction system.

- 3 axis vertical machining

ZV CLASSIC

- Rigidity and reliability with no limits in 3 axis centers

Moving column centers for 3 axis milling operations or in combination with horizontal axis rotary tables, for works along the table or in pendulum cycle. Medium speed ranges for great material removals.

ZV Classic head

Belt and pulley transmision: high torque with the highest reliability Uo to 821 Nm

IBARMIA launched the firts CLASSIC model in 1986, and the fundamental concepts have not been modified: we continue using cast iron to build the moving structures, the main spindles are provided with generous bearings to ensure the maximum rigidity and material removing capacity...

T SERIES

UNIVERSAL 5 AXIS MACHINING CENTERS

For large diameters up to ø3600 mm and automatic pallet changing

Universal machining centers for 5 axis machining of big diameter parts focused on high productivity by integrating multitasking technology and automation systems.

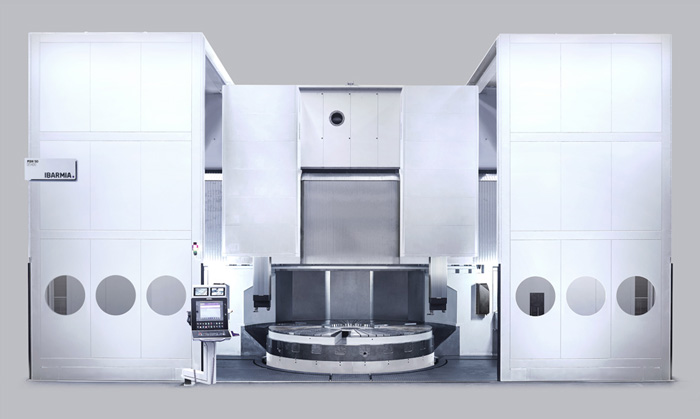

T MULTIPROCESS

- 5 axis Multitasking machining centers (turning and milling)

IBARMIA can provide two types of spindle heads to adapt the machine to specific jobs. A wide range of options allow tailoring solutions to each requirement.

Tool holders

HSK 100 Â CAPTO 8

Axis travels

X  From 1200 to 3600 mm / Y  From 1100 to 2300 mm Z  From 1000 to 1900 mm B  -15º/+195º / A  -45º/+135º

Spindle

Up to 84 kW - 12.000 rpm

Spindle heads

Two available models: THC / THR

Continuous tilting heads with torque motor and direct measuring systems in the axes.

THC_ B axis head

Maintain the same tool center point across the full range -15º/+195º

THR_ A axis head

Fork type spindle head ideal for negative angles -45º/+135º

Main advantages- 5 axis turning and milling: vertical turning

Turning tables from ø1000 mm to ø2200 mm. Max loads up to 16.000 kg for turning operations and turning speeds up to 500 rpm. - 5 axis turning and milling: Multi - face milling

Complete in one set up complex parts that require approaches in many different angles. - Machine Automation:

Pallet management

Various pallet changing and storage systems adapted to each size and loads for an effective production system. - Machine Automation:

Advanced tool management

Automatic tool changing solutions for special heads and their tools, angle heads and large size tools.

- 5 axis turning and milling: vertical turning

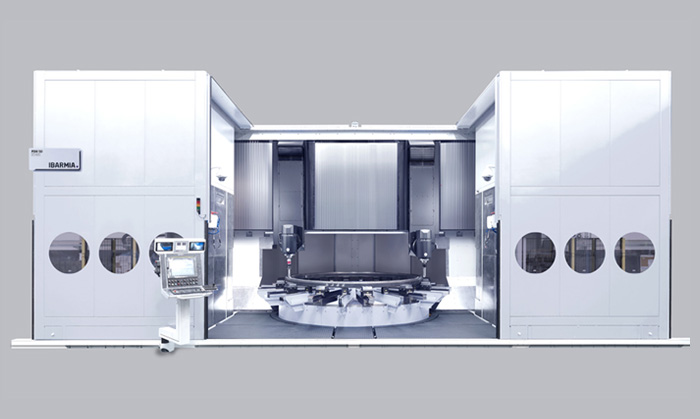

T EXTREME

- High performance 5 axis universal machining centers

Power, accuracy and dynamics combined with excellent chip evacuation, ergonomics and intelligent production functions.

Spindle tapers

SK-50 Â BT-50 Â HSK 100 Â CAPTO 8

Axis travels

X  From 1200 to 3600 mm / Y  From 1100 to 2300 mm Z  From 1000 to 1900 mm B  -15º/+195º / A  -45º/+135º

Spindle

Up to 84 kW - 12.000 rpm

Spindle heads

Two available models: THC / THR

Continuous tilting heads with torque motor and direct measuring systems in the axes.

THC_ B axis head

Maintain the same tool center point across the full range -15º/+195º

THR_ A axis head

Fork type spindle head ideal for negative angles -45º/+135º

Main advantages- Multi-face machining

Accurate tilting heads and heavy-duty rotary tables allow machining various angles of complex pieces in one set up. - Machine Automation:

Pallet management

Various pallet changing and storage systems adapted to each size and loads for an effective production system. - Machine Automation:

Advanced tool management

Automatic tool changing solutions for special heads and their tools, angle heads and large size tools.

- Multi-face machining

C SERIES

LARGE DIAMETER RING PRODUCTION CENTERS

Turning, drilling and grinding centers for flange and bearings up to ø8500 mm

The program, composed by turning centers and drilling centres, offers integral solutions (machines and fixturing devices) as well as optimal management of the big volumes of chips and coolant generated and used in the process.

TURNING CENTERS

- For large circular pieces up to ø8500 mm

The new range of IBARMIA turning centers can be configured to accommodate all the processes required in the complete machining of large circular pieces: turning, milling, drilling, threading, boring and grinding. The finishing operations in this type of pieces are critical, reducing the number of set-ups avoiding errors is vital. The new IBARMIA turning centers have been designed to respond to these real market needs.

Main advantages- Turning tables

Turning plates with Hydrostatic design developed by IBARMIA. Pinion-crown transmission driven by a double motor system. - Fixed cross-beam

High rigidity fixed coss-beam made of casting GG-30 for hydrodinamic guiding system or in steel-welded for hydrostatic guiding system as option. - Fixture devices

A wide range of clamping fixtures to facilitate the loading and unloading operations as well as the clamping and unclamping operations updated to the demands of turning and/or grinding operations. - Powerful RAM concept

High precision RAM head with high cutting capacity. Equipped with prismatic and hidrostatic guides on X and Z axes for maximum reduction of vibrations. Travels up to 1500 mm. - Maximum flexibilit

Automatic change system of turrets and tool holders for turning. In the top level of the range (MULTIPROCESS), live RAMS are added to the high performance lathes, so apart from turning operations, the machine can also do drilling, tapping, milling, boring and even grinding operations. - Customized tool magazines

Next to the standard tool magazines, IBARMIA offers tool magazines for the range of interchangeable heads and individual solutions for all the manufacturing needs.

- Turning tables

DRILLING CENTERS

- In portal structure or moving column architecture

Drilling centers in portal structure with one or two heads in option over a central rotary table which allow to cover any range of work from the center of the table to a maximum diameter ø8000 mm.

Main advantages- CP Structure

Portal structure with double column, fixed crossbeam and different headstocks in option. Rotary tables available in bearing and hydrostatic rotation systems. - Automatic clamplig fixtures

For machining big flanges and bearings up to ø8000 mm and 600 mm tall. Jaw blocks are manually adjusted radially along a rack surface with teeth facing up or down (two systems). - Power transmissions

Classic belt & pulley and electrospindle transmission types. - Automatic tool changer

Tool magazines up to 40 positions located at the sides of the machine which are equipped with a double gripper arm system for a quick and smooth tool selection. - Vertical & horizontal drilling capacity

Drilling capacity up to 80 mm. B axis continuous tilting head in option (+/-105ª). - M Tapping capacity up to M60

Threading by Interpolation. - High performance

Milling capacity / Axis interpolation. (Depending on the rotary table characteristics).

- CP Structure

IBARMIA TECHNOLOGIES

All our know-how to find the best solution.

Manufacturing Technologies

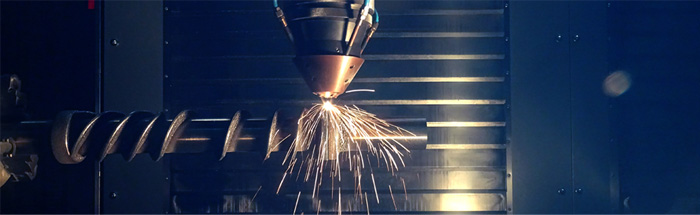

ADD+PROCESS

- ADVANCED MANUFACTURING

ADD+PROCESS incorporates a technology in which metal powder is injected into the focused beam of a high-power laser so its surface is melted into a pool of base material, powder delivered into this same spot is absorbed in the melt pool generating a deposit while the LMD moves around the working area creating the required shape layer by layer.

MULTIPROCESS

- Multiprocess machining: Milling, Turning and Grinding.

5 AXIS MACHINING

- Advanced 5 axis machining technology.

3 AXIS MACHINING

- Efficient 3 axis machining technology.

Service Technologies

AUTOMATION SYSTEMS

- FLEXIBLE MANUFACTURING

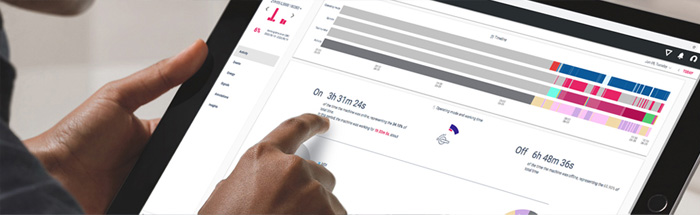

SMART POINT

- CONNECTED MANUFACTURING

Connectivity and data monitoring: The new industrial era.

SMART POINT is a cloud-based data monitoring system. Its web-based platform allows accessing the data from any connected device making it easier to take effective and smart decisions resulting in improvements in productivity.

TECH-CYCLES

- ADVANCED MANUFACTURING

v

IBARMIA developments integrated in the machine CNC for advanced assistance and optimization of production processes.

IBARMIA SERVICES

Performance and profitability for your machine.

In IBARMIA, we build a special lasting relationship with our client that lasts the lifespan of the machine.