- Offer Profile

- With over a decade of experience and new enthusiasm every day, our mechanical engineers, manufacturing engineers, software developers and electricians from engineer to system supervisor are dedicated to the sophisticated production requirements of our customers from the most diverse industries. Mastering light as a tool - for these tasks we are combining our knowledge, experience and our innovations in order to create engineering and production-oriented solutions for you

RANGE OF SERVICES

ENGINEERING

-

INDIVIDUAL, PRODUCTIVE, LONG-TERM STABLE

highly efficient laser machines at a fair price-performance ratio. We are committed to the engineering tradition in the region Chemnitz / Saxony as well as the laser tradition in Mittweida. This tradition includes the aspiration to develop and manufacture high-end solutions at global scale for solid and reliable technology for your long-term benefit. Conservations of resources and efficiency increase are important factors for the creation of our machine concepts.

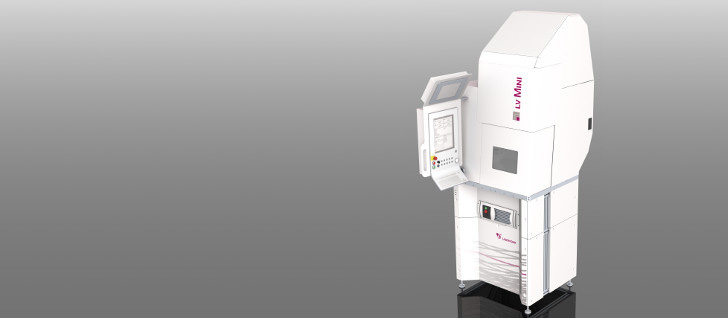

LV MINI

-

PRECISION WELDING AND PRECISION CUTTING ON AN INSTALLATION AREA OF JUST ONE SQUARE METRE

The LV Mini is an ultra-flexible laser processing machine which is particularly suitable for quick and convenient processing of many different small workpieces with complex component geometries or even fine structures.

High-precision linear and rotation axes guarantee highest precision and repeatability – the most important basic requirements for efficient laser processing processes in the range of small and medium-sized quantities. Due to the fact that the LV Mini is particularly suitable for welding and precision cutting applications, it is possible to achieve connections and cuts which have a precise tolerance and are visually appealing.

- Travelling range X x Y x Z: 280 mm x 170 mm x 200 mm

- Workspace X x Y x Z: 600mm x 600 mm x 300 mm

- Dimensions W x D x H: 895 mm x 1,000 mm x 2,560 mm

- Positioning accuracy: <± 0.03 mm

- Repeatability: <± 0.003 mm

Advantages:

- Storage space of only 1m²

- Specifically for applications in medical technology, sensor technology and precision engineering

- Laser marking as practical additional benefit

- Control highlights simplify operation and improve the results

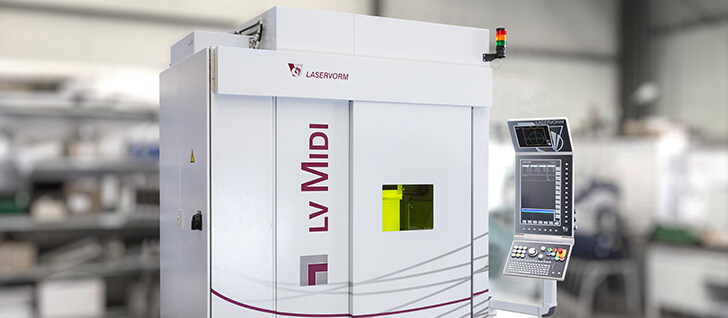

LV MIDI

-

WITH ROTARY AND SWIVEL UNIT FOR HIGHLY SOPHISTICATED 3D PROCESSING PROCESSES IN WELDING, HARDENING AND CLADDING

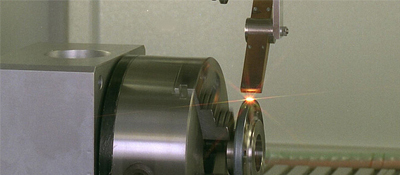

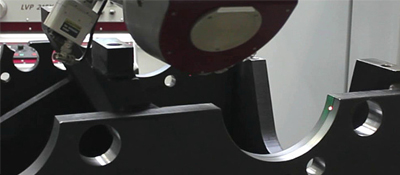

The LV Midi is a CNC machine which can be supplied as 3-, 4-, or 5-axis system. All necessary processing and infeed movements of the processing optics are realized by a 3-axis linear system (X,Y,Z).

A robust machine frame in LV CBase special concrete technology provides the basis for highest precision combined with a high level of dynamics. In order to process rotation-symmetrical parts or components, the machine can be optionally equipped with a rotary axis. If the machine is equipped with a rotary and swivel unit, it is suitable for sophisticated 3D processing processes.

The custom-equipped basic machine is the perfect and most efficient solution for your task. The users of the LV Midi often come from the sectors: Automotive, drive engineering, mechanical engineering, medical engineering, precision engineering, sensor technology as well as aerospace engineering. The laser system processes components from micro to macro.

- Travelling range X x Y x Z: 670 mm x 300 mm x 300 mm

- Workspace max. X x Y x Z: 1,500 mm x 600 mm x 700 mm

- Dimensions W x D x H: 2,000 mm x 1,300 mm x 2,600 mm

- Positioning accuracy <± 0.01 mm

- Repeatability <± 0.005 mm

Advantages:

- Laser methods Welding, Hardening or Cladding depending on the configuration

- Intelligent control limits operator intervention to the minimum necessary

- Adaptive processing

- Laser beam formation and deflection with the programmable beam quality

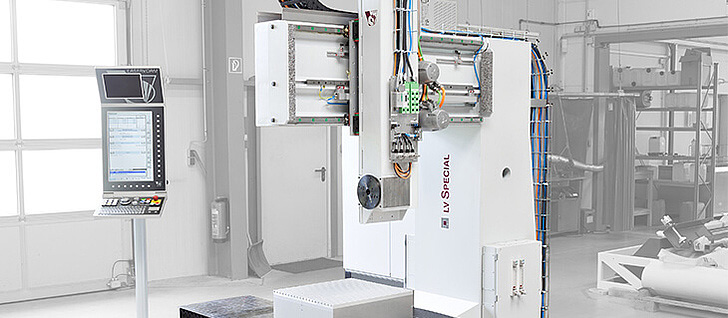

LV SPECIAL

-

YOU HAVE A DIFFERENT TASK? - SINCE 1994, WE HAVE BEEN DEVELOPING SPECIAL MACHINES FOR LASER MATERIAL PROCESSING TOGETHER WITH OUR CUSTOMERS.

We know the requirements of your industry and design a laser system which is precisely tailored to your needs. We will advise you with the selection of the suitable technology and integrate the laser processes into you production line. During the entire lifetime of the system, we will carry out substantial maintenance and service performances on request.

Our machines and components will give you a competitive advantage.

COMPONENTS

JOB ORDER PRODUCTION

-

SAMPLE PRODUCTION, SERIES PRODUCTION LAUNCH, INDIVIDUAL COMPONENTS OR LARGE-SCALE PRODUCTION – WE ARE YOUR PARTNER

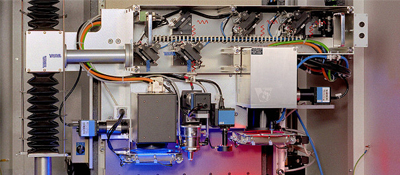

A production planning and control system, and enterprise resource planning (PPC / ERP) used across company borders ensure trouble-free production processes. In addition to laser machines equipped with state-of-the-art lasers for 2D and 3D processing, an extensive portfolio of peripheral technology - such as inductive pre-heating technology, pyrometer controller, image processing systems or various beam formation technology - is available. This equipment is completed by an own metallography laboratory and a wide range of hardware and software for quality assurance and quality documentation.

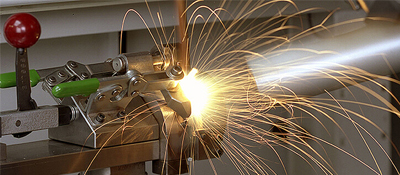

LASER WELDING

-

HIGH-STRENGTH JOIN CONNECTIONS WITH VISUALLY APPEALING WELD SEAMS

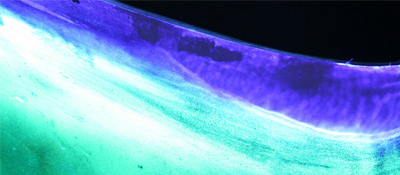

With the process of laser welding, we create precision seams on components made of metal at high speeds. Pulsed and continuously beaming lasers with a high beam quality up to 3.5kW-cw and 7kW-pw capacity are at our disposal. With this, we can achieve, for example, the following welding depths: in steel up to 8 mm, in aluminium alloys up to approx. 3 mm, in titanium up to 8 mm. Here you can find further information on our job order production offers.

In fine welding, we achieve seam widths of as low as 0.1 millimetres. Joints on welding-critical materials (such as sinter materials or ceramic) as well as high-quality welding joints (e.g. helium-proof) can be effected on a wide range of materials. Examples for weldable materials: copper alloys (also coated), platinum, zinc-coated steel sheet, tungsten, aluminium oxide ceramics, plastics and others. We are welding in compliance with DIN, e.g. according to the Pressure Vessels Directive and we have available a comprehensive range of possibilities for process documentation such as performance transcripts, weld beam monitoring and quality monitoring by means of modern image processing.

LASER HARDENING

-

We carry out surface hardening processes (hardening depths 0.1mm up to max. 2mm) on finished (e. g. ground) workpieces with Nd:YAG, fibre and diode lasers with almost no deformations. We are using different NC systems with 3 to 6 axes. Through the use of a 6-axis robot, we are able to manufacture large quantities of small components effectively in series. Here you can find further information on our job order production offers.

A high efficiency and process security are ensured with the help of special hardening optics, and optimum control and monitoring of the hardening process is ensured by the use of pyrometers.

We carry out metallographic cross-section polishing and hardness measurements for you.

LASER CLADDING

-

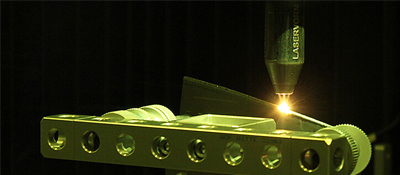

Laser cladding is used for the production of partial wear-protection areas made of different metals / alloys or for the production of functional layers for friction bearings, heat protection, for the creation of new component areas.

Since 1994, we have been using these processes from "Micro" to "Macro", with the spectrum of components ranging from medical devices with wall thicknesses of few 0.1mm up to applied surfaces of a few square decimetres and layer thicknesses of several millimetres.

Besides an extensive wealth of experience with the technology of laser cladding with wire and powder feed, we have also developed solutions for quality assurance in high-volume applications.

We are qualified by SIEMENS AG / Power Generation for regeneration welding on power plant turbine blades. The new dimension of technological freedom: Laser cladding beads vary in terms of welding cross-section width and height in wide ranges in real time thanks to LV LineScan and broad beam powder nozzle. For tool and mould making, we carry out correction and repair work on components with the filler materials powder or wire.

OTHER LASER PROCESSES

-

LASER CUTTING AND PERFORATION

- With this procedure, we process plastics (technical) textiles, ceramics and glasses - and in special cases, metals.

LASER DRILLING- For some special applications, we offer the procedure laser drilling. Please ask us whether we have the right technology for your task at our factory.

SKINNING

- Flat cables can be skinned on e.g. one or both sides, all-over or only on single conductors.

QUALITY ASSURANCE

-

TIME and TEMPERATURE MEASUREMENT

- Laser-assisted heat treatment processes are recorded and controlled with contactless and non-contact measuring sensors up to a pyrometer matrix camera and a time resolution of less than one millisecond.

LENGTH MEASUREMENT- With the help of various manual and electrical measurement and testing devices we are able to determine lengths, positions, shapes, concentricity and other values associated with length measurement.

METALLOGRAPHY EQUIPMENT- A complete metallography equipment from wet separating cutting, embedding to grinding and polishing grades, etching processes and the evaluation with different microscopes is an important requirement for development tasks but also for routine tests.

HARDNESS MEASUREMENT- With stationary (Vickers micro and small load) and portable (dynamic) measuring technologies, we are able to determine measuring values. Especially for surface hardening processes, a spatially resolved micro load hardness measurement is necessary in order to obtain clear statements on the hardness profile.

FORCE MEASUREMENT TECHNOLOGY- Various devices for the testing and measuring of component with regard to compressive and tensile strength - typically used for yield force measurements on welded joints.

DYE PENETRATION TEST (PT)- In order to detect pores or cracks, our qualified testing staff makes use of dye penetration tests (red-white test, UV).

CROSS-LINKED AND DATABASE-ASSISTED DOCUMENTATION- Measurement and analysis results are archived together with process data and can be assigned - in the long term - to batches or even individual workpieces through the PPC and ERP.

SERVICE AND MAINTENANCE

- Already during technology development and machine construction it is ensured that our engineering customers will later have to contact our service department as rarely as possible. In order to minimise downtimes in case of damages, we use carefully selected as well as mostly standardised and replaceable components. Our PLC and NC controlled machines are delivered with the possibility of remote diagnostics and remote maintenance.

TECHNOLOGY ADVICE

BRANCHES

-

SECTORS AND FIELDS OF APPLICATION FOR LASER MATERIAL PROCESSING

Material removal through corroding or evaporating, creating alloys through melting, mixing and fast solidification, creating high-strength joints through melting-metallurgically clean processes, achieving highest wear-resistances through local hardenings or hardfacing - laser material processing offers these and many more processes.

Light is our universal tool. Well-bundled and precisely controlled in terms of time and space it is possible to use it very profitably. As a never-breaking drill, as a never-blunting saw, as a fire melting any material

DRIVE ENGINEERING

-

Stability, accurancy of fit and consistancy are requirements during the drive engineering of components. Today, laser technology sets new benchmarks for the quality of gears, turbine parts and drive elements. Wether large scale production or individual blanks, the developmental expertise of LASERVORM is the catalyst for the success of your company.

COMPONENTS- blisks and turbine blades - aircraft turbine (cladding)

- powertrain components (welding with inductive preheating, hardening)

- Coupling components (welding, hardening)

AUTOMOTIVE ENGINEERING

-

Efficiency, innovation and a resource-saving production are the main factors for the success in Automotive Engineering. Laser technology offers many different possibilities for automotive engineers and suppliers to optimise production. Whether cars, motorcycles, utility vehicles or agricultural engines - LASERVORM is your partner for laser processing, technology development and laser engineering.

COMPONENTS- Shift forks, gearshift lever shafts (welding, cutting, hardening)

- Coupling components (welding, hardening)

- Power-transmitting components (welding, also with wire or powder feed)

- Baulk rings (welding)

- Exhaust gas components (welding)

SENSORS

-

Precision laser welding applies very thin membranes or foils to solid components, longitudinal seams with a wall thickness of only a few µm are developing on pipe systems. The laser enables the replacement of medically questionable materials (e.g. solders), creates visually appealing welded joints or gas-tight welding on sensors or parts of the housing.

COMPONENTS- Pressure sensors, sensors (welding)

- Filter discs (welding)

- Valves (welding, hardening)

- sensor housings (welding)

- Electric motors (welding, cutting)

PHARMACEUTICAL INDUSTRY

- A clean matter - safety and cleanliness are the priorities in pharmaceutical production. This is why the contactless laser offers many possibilities for this industry. As the only supplier worldwide, we are offering to pharmaceutical producers a special-purpose machine solution for the sterile opening of eggs. Use the innovating potential of the laser: we will assist you from the first idea up to the realisation of the project.

MEDICAL TECHNOLOGY

-

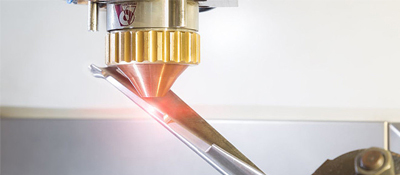

Laser material processing for the medical technology sector constitutes a special challenge for the contract manufacturers and mechanical engineers: Smooth surfaces ensuring clinical cleanliness and non-breaking connections.

The laser beam as tool is ideally suited for processing sophisticated components. Minimum production tolerances ensure a constantly high level of product quality. As a result of the low energy input, the components can be processed with almost no distortion.

However, in order to achieve the optimum when processing the workpiece, new, innovative control solutions are necessary. At Laservorm, we are constantly working on new control concepts and thus on the solution of problems.

COMPONENTS- Surgical instruments - forceps, retractors, bone saws (welding, smoothing)

- Instruments of the minimally invasive surgery - endoscope components (welding)

- (Neuro-surgical) implants (welding, smoothing)

- Battery cases (welding)

- Surgery needles (welding)

- Suction tubes (welding, caldding)

ENERGY

-

As a precise tool, the laser is more and more frequently used when producing heat exchangers, battery cases or even electric motors. The possible applications and variations are versatile.

COMPONENTS- Turbine blade - power plant (hardening, cladding)

- Heat exchangers (welding)

- Battery cases (welding)

- Parts of fuel cell (welding)

RESEARCH AND TEACHING

- Whether test stand for teaching or laboratory equipment for research. We realise customer-specific requirements for universities, institutes of higher eduction and research facilities. The modular design of our laser machines allows, for example, the changeover to another laser method or the integration of additional axes for more options.

MACHINE CONSTRUCTION

-

Innovation through technology - Whether delicate small parts or large heavyweight components - Innovative laser surface treatment methods improve the properties of individual components and extend their service life. With only minimum heat input at selected points, laser hardening or cladding enhances the performance of the components and thus improves the quality of the products.

COMPONENTS- Forming and embossing tools (hardening, cladding)

- Bearing seats (hardening, cladding)

- Flywheels and cam discs (welding, hardening)

- Bellows (welding)