- Offer Profile

-

Your workpieces impose particular requirements on materials, geometries, raw materials and batch sizes. This is why WINEMA is developing customized transfer machines for the production of long runs, families of parts and component variants, all in optimum batch sizes. The best thing to do is to talk to us at the project planning stage.

Part-oriented production solutions

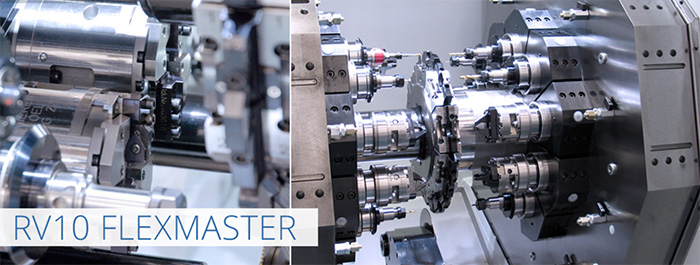

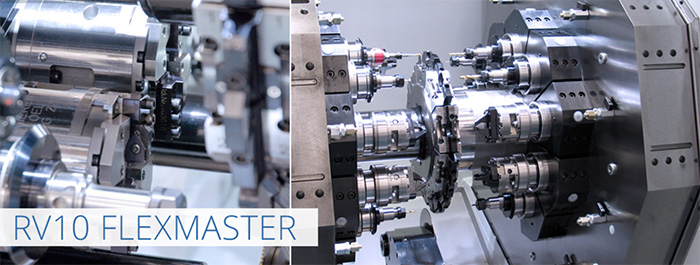

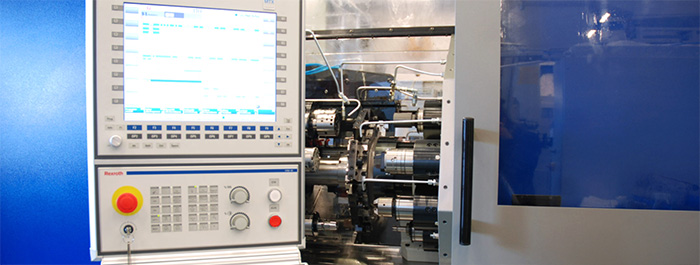

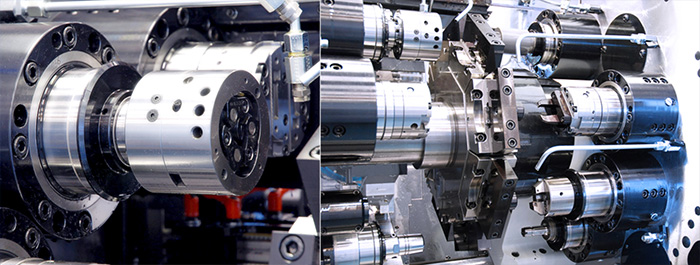

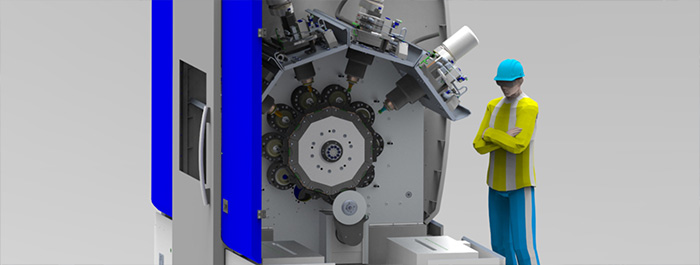

RV10 FLEXMASTER

-

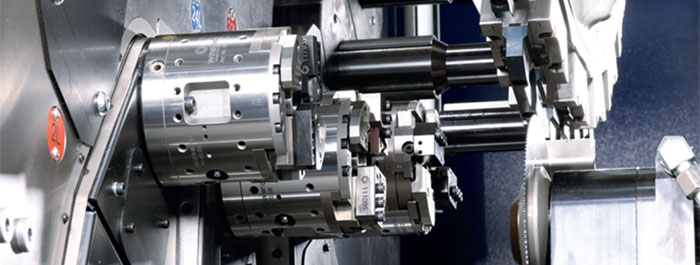

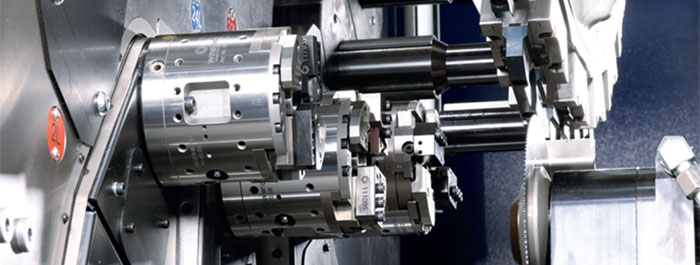

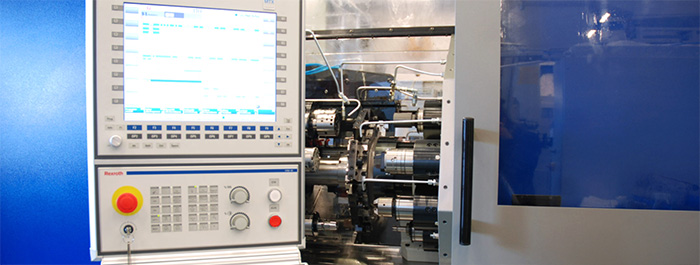

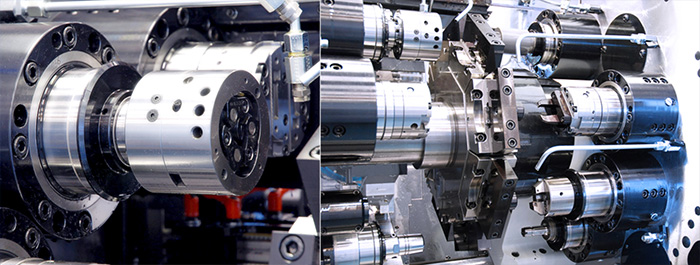

The RV 10 Flexmaster is the further developed Flexmaster concept for smaller parts. This rotary indexing machine is designed for a maximum output with high cycle times and short set-up times. The first glance into the machining area shows a clean and very structured working area with all working units easily accessible for the workers. The RV 10 Flexmaster is the answer to increasing numbers of set-ups needed due to faster changing variations of parts, to shorter life cycles of parts and to new and more difficult materials. With these new rotary indexing machines, you will be able to meet the demands of the changing markets and still achieve the high outputs of mechanical transfer machines.

Specifications- Max. workpiece diameter:

- bar 13 mm

- single part 16 mm

- Max. workpiece length: 80 mm

- Clamping stations: 10

- Output parts per minute: 4-50 pieces

- Double feeding: 10-80 pieces

- Machining units: max. 22 (18 axial, 4 radial)

- Max stroke machining units (standard): 90 mm

- Clamping: hydraulic jaws/ collets

- Control: CNC Bosch MTX

- Quill feed: CNC

- Weight (depending on equipment): 6.500 kg

- Dimensions (machine only): 2,4m x 1,2m x 2,1m

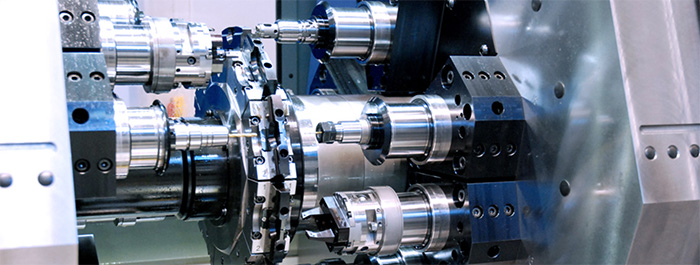

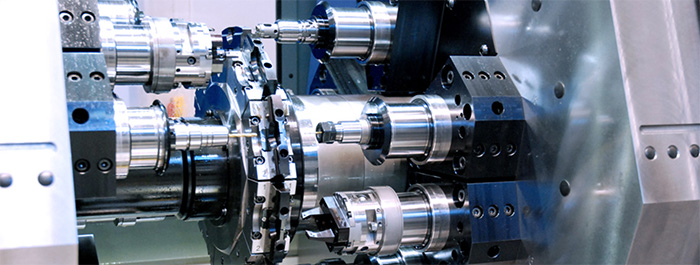

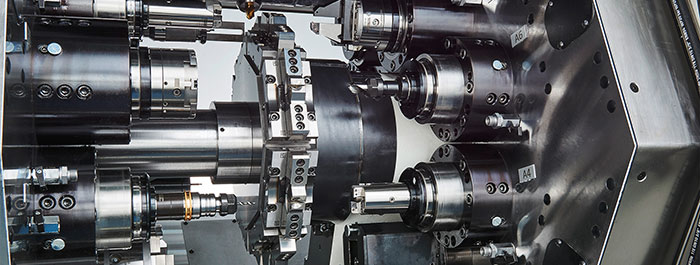

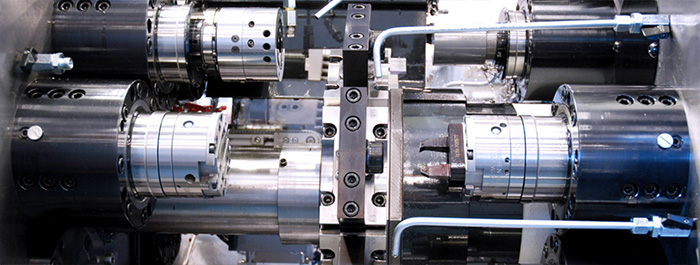

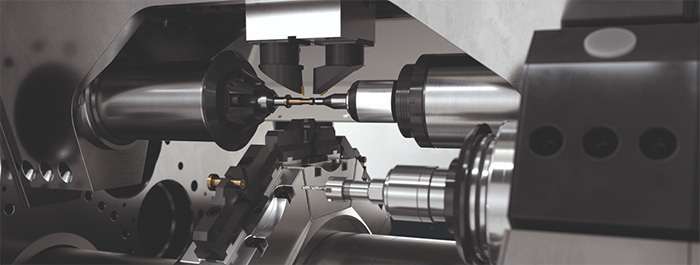

RV10 MULTIMASTER

-

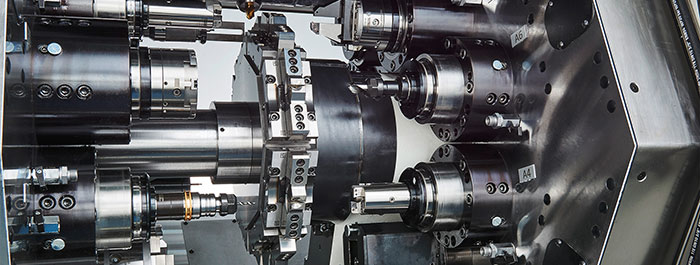

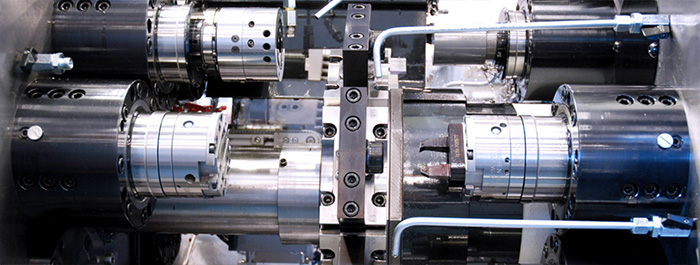

The new RV10 Multimaster enables high-volume production in the diameter range of 2-13 mm.

To this end, all stations are fully CNC-controlled and offer machining from three sides with powerful spindles or high-frequency drives. In addition, the large chip spaces enable optimum machining of long-chipping materials. Another positive factor is the clearly visible machining area, which offers the best possible accessibility and thus simplifies machine setup. During the development of our new machine type, the focus was on visual ergonomics to ensure user-friendly operation.

Machine Specifications:

- Max. Material Diameter Rod Ã: 2-13 mm

- Item: 16 mm

- Max. Workpiece Length: 80 mm

- Clamping Stations: 24

- Output per Minute: up to 200 pieces

- Machining Units: Max. 54 (45 axial, 9 radial)

- Stroke of Machining Units: 90 mm

- Clamping System: Centrically clamping 2-jaw chuck

- CNC Control Unit: Bosch XM 42

- Quill Feed: Yes

- Weight (depending on equipment): 27,000 kg

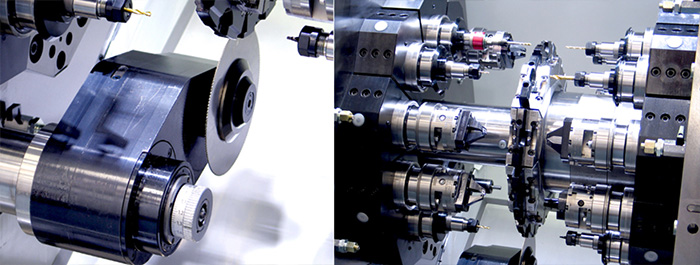

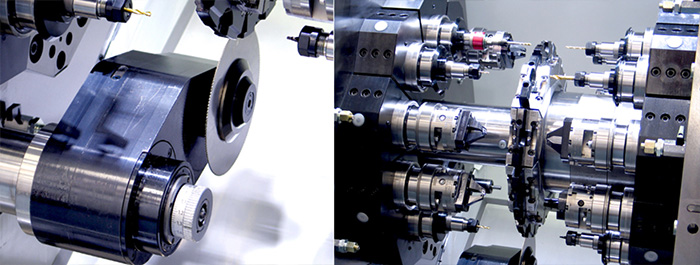

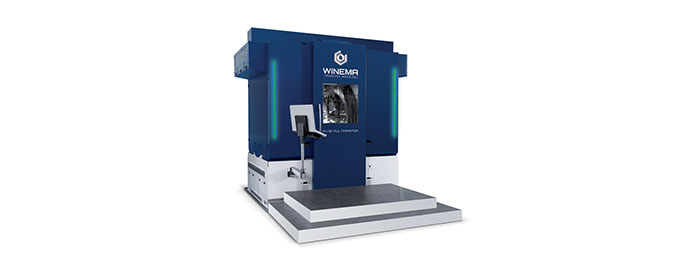

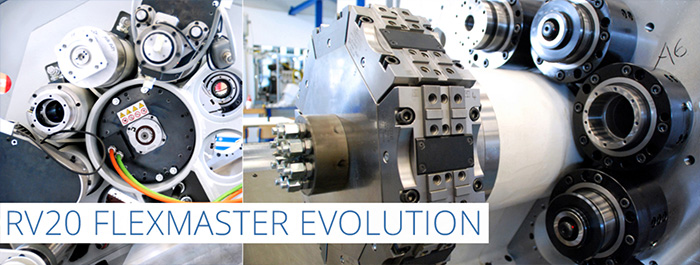

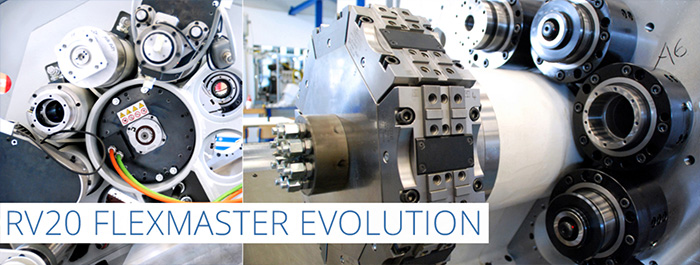

RV20 FLEXMASTER EVOLUTION

-

The WINEMA RV 20 Flexmaster Evolution is the further developed RV 20/8 Flexmaster. This CNC controlled rotary indexing machine is designed for the machining of parts in one setting. The typical diameter is between 4 and 30 mm, from the bar up to 42 mm. The RV 20 Flexmaster Evolution has a indexing table with 8 clamping stations. The workpieces can be machined by maximum 14 axial units and 3 radial units.

Specifications- Max. workpiece diameter:

- bar 42 mm

- single part 50Ã50 mm

- Max. workpiece length: 180 mm

- Clamping stations: 8

- Output parts per minute: 10-15 pieces

- Machining units: max. 17 (14 axial, 3 radial)

- Max stroke machining units (standard): 90 mm

- Clamping: hydraulic jaws/ collets

- Control: CNC Bosch MTX

- Quill feed: CNC

- Weight (depending on equipment): 8.500 kg

- Dimensions (machine only): 2,8m x 1,4m x 2,5m

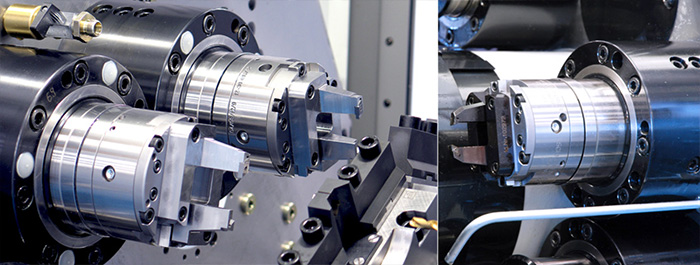

RV30

-

WINEMA’s RV30 Flexmaster expands the Flexmaster concept for the production of medium and large workpieces with diameters between 20 – 50 mm. Just like the entire RV series, the new RV30 is also constructed for maximum output with exemplary equipping capabilities. The 10 clamping stations combined with the optional 3 axle units situated horizontally and axially offer the best prerequisites for the machining of more complex components. A growing number of models, shorter product life cycles, modifications of the component, new materials: With the Winema RV30 Flexmaster you can adjust to the changing requirements of the market and still produce quantities which used to be exclusively achieved by cam-controlled machines.

Specifications- Max. workpiece diameter:

- bar 15mm

- single part 50mm

- Max. workpiece length: 200 mm

- Clamping stations: 10

- Output parts per minute: 4-50

- Machining units: max. 22 (18 axial, 4 radial)

- Max stroke machining units (standard): 90 mm

- Clamping: hydraulic jaws/collets

- Control: CNC Bosch MTX

- Quill feed: CNC

- Weight (depending on equipment): 17000 kg

- Dimensions (machine only): 3,07m x 1,85m x 3,04m

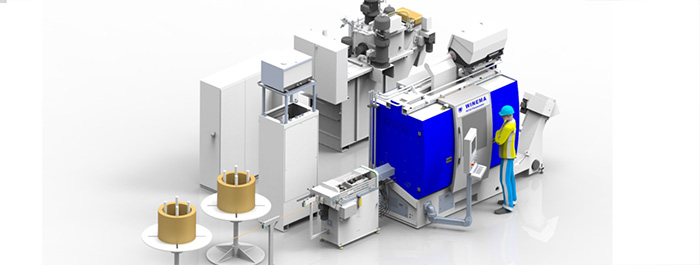

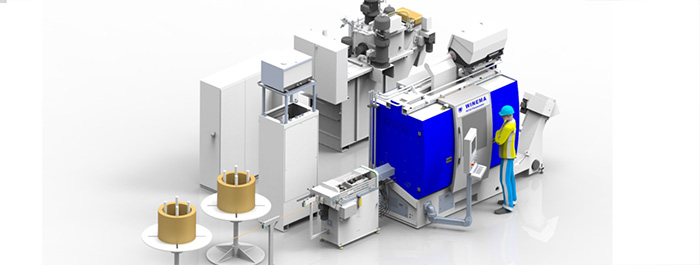

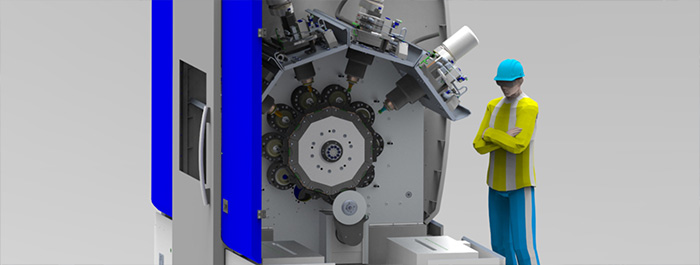

WINEMA precision turning cell (PTC)

-

GENUINE FLEXIBILITY DURING COMPONENT PRODUCTION

Your workpieces impose particular requirements on materials, geometries, raw materials and batch sizes. This is why WINEMA is developing customized transfer machines for the production of long runs, families of parts and component variants, all in optimum batch sizes. The best thing to do is to talk to us at the project planning stage.

WINEMA precision turning cell (PTC) Â the fourth dimension in rotary transfer machining

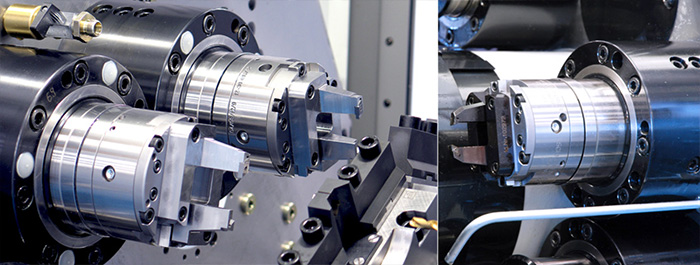

The WINEMA PTC enables you to machine the entire external contour of the workpiece without positioning errors, accurate to a micron level. The robust WINEMA PTC is integrated in the machine as a disconnected turning cell and it is free of the drive and machining factors that affect the other stations. With the PTC, you can achieve the highest levels of concentricity precision with internal and external turning.

As a closed, internally rigid design, the PTC can transfer the workpiece into an independent coordinate system where it can conduct a turning process in isolation. The vibration-damped cast design disconnects the turning process from the machining factors that affect the other stations. By turning between tips, concentricity requirements that used to be critical can be manufactured without any problem down the entire length of the workpiece.

If the workpiece is held in a collet chuck by the PTC, tight positional tolerances can also be maintained between external and internal contours, all within a reliable process context. Two turning tools with Capto interface are integrated in every PTC. Three PTCs can be used in each machine (WINEMA RV10 Flexmaster).

Use the latest turning trick in the transfer machine!

- Complete machining of the external contour

- Internal machining is possible

- Optimum concentricity position when turning between tips

- Up to 3 modules can be used in a machine

ALBATROZZ

-

ACHIEVE MOREÂ with less energy!

Although albatrosses, who can weigh up to 12 kg, are considered among the heaviest flying birds and because their wingspan exceeds 3.5 meters, they are considered larger than any other bird species, they are surprisingly energy efficient. These extreme flyers glide for days over the oceans and accumulate tens of thousands of kilometers without becoming exhausted. A clever combination of anatomy and technique gain this Albatros energy saving records.

WINEMA ENERGY BALANCE

WINEMA Maschinenbau GmbHÂs new ALBTROZZ-line offers energy-efficient technology based on the Albatros principle: Existing energy is optimally used and combined with the latest technology. This provides an enormous savings potential and opens up new horizons.

This was realized just recently with a Bosch Rexroth, at a hydraulic power pack on our drive station. Equipped with a frequency converter and an intelligent program control, the engine only generates as much power as is needed for the current processing. Without renouncing necessary power reserves, this system regulates so efficiently that the drive unit requires up to 25 % less energy.

This type of energy management is DIN ISO 50001 compliant and can help you obtain your power savings goals. Talk to us  together we can reach new horizons with less energy!

- Valuable contribution to energy management according to DIN ISO 50001

- Optimal use of existing energy

- Example: a new energy-efficient hydraulic unit

- Intelligent control of the pump power at the optimum operating point by load-dependent controlled power output.

- Reduction of noise emission

- Fast amortization due to considerable electricity savings

Our industries

- With our products, you can react flexibly to the demands of the market and still achieve quantities that were previously reserved for cam-type machines. Our range of products offers you customized solutions for the production of customized parts in different industries, including:

AUTOMOTIVE INDUSTRY

- The automotive industry is one of the key technologies of the German economy, that produces around 5.5 million cars a year. The car production in Germany is third in the world behind China and Japan as well as the first place in Europe. With its suppliers, the automotive industry is one of the largest employers in Germany. Our machines are used by numerous suppliers in the automotive industry. Our machine concepts, high output, high availability and reliable precision of the workpieces meets the expectations of our customers.

ELECTRICAL INDUSTRY

- Based on the number of employees, the electrical industry is the second largest industrial sector in Germany with a turnover of around 170 billion Euros in 2014. This industry includes numerous applications for rotary indexing machines and also well-known manufacturers in the electrical industry with their own products, who are already part of our customer base.

GAS / WELDING TECHNOLOGY

- The high-precision rotary indexing machines by Winema support the production of high quality and professional welding equipment, suction equipment, welding accessories, wear parts and welding tools in industrial quality. This way we are able to contribute largely to a great result – the work of our customers.

FASTENING TECHNOLOGY

- To solve different fastening problems, our customers use the Winema rotary indexing machines. They are used to produce a variety of applications for the realisation of fastening solutions. Precision, maximum safety, fast and convenient processing and long-term guarantee of functionality are important criteria for our customers that Winema fulfills.

FITTINGS / HYDRAULICS

- Hydraulics are used wherever movements and forces need to be controlled. Through optimized planning with our customers, we are able to support them in the production of parts and applications that are necessary for the realisation of complete hydraulic systems.