- Offer Profile

-

Pneumatic Hoists with Permanent Excellence

At JDN we want to be more than just your hoist supplier. We are striving for a long lasting trustful partnership. We want to help you to move loads in a sustainable and digitalized world. That is our goal.

Every pneumatic hoist and crane we produce is designed with the guiding principle of “permanent excellence”. We have been cultivating our values and our claim since 1745.

We want to help you to move loads in a sustainable and digitalized world.

Pneumatic hoists, crane systems and custom solutions

-

J.D. Neuhaus is the world’s leading manufacturer of pneumatic hoists, crane systems and custom solutions – Made in Germany.

For over 50 years, J.D. Neuhaus has been building hoists with compressed air as a drive medium and is today world-wide market leader in this technology. This proven JDN technology is also used in JDN Air Crane systems.

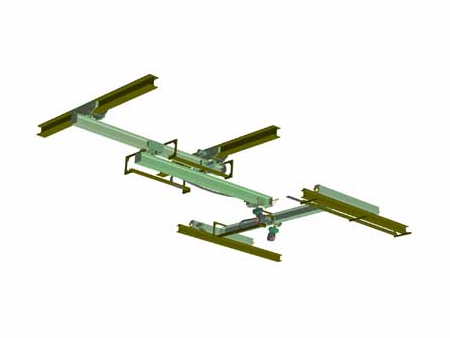

Crane Systems and Kits

- JDN Hoists are very robust and therefore suitable for tough industrial applications even in continuous working processes.

Crane Systems

-

Crane Systems for the harshest environments, with pneumatic or hydraulic drive.

The program includes:

- Overhead traveling cranes

- Suspension cranes

- As well as jib cranes / slewing cranes

Crane Kits for explosion-proof air cranes

-

With these crane kits overhead travelling cranes up to 10 t load capacity can be manufactured easily and economically, also for use in hazardous areas.

The crane builder provides the main girder and JDN supplies all the components requiredfor the construction of an air-operated crane ready for connection:

- Endcarriage with pneumatic travel drive

- Energy supply systems

- Various accessories

- And of course the corresponding pneumatic hoist with trolley

JDN Accessories

-

Our wide range of accessory products makes it possible to tailor JDN series products precisely to your individual areas of application.

Whether you need to meet special safety requirements, adapt performance or increase operating comfort – we have the right solution for you.

- Filter silencers

- Filter regulators

- Maintenance unit

- Main air emergency stop

- JDN lubricant for oil-free operation, quantity 250 ml

Hoists & Trolleys

- JDN Hoists are very robust and therefore suitable for tough industrial applications even in continuous working processes.

Air Hoist mini

-

Your Air Hoist with NFC sensor and service app

The Air Hoist mini is the most compact hoist, with a carrying capacity of up to 980 kg and an integrated NFC sensor with service app that makes it truly unique in the industry.

The mini’s profile of use shows it is capable of meeting demands for a manageable and flexible compressed air hoist. This means the mini is perfectly suited for use in various areas of application, such as the automotive, chemistry, pharmaceutical, and food industries.

- Carrying capacities: 125 kg, 250 kg, 500 kg, 980 kg

- Air pressure: 6 bar

- Heights of lift: 3 m, 5m, 8 m

- Length of control: 2 m, 4 m, 7 m, max. 10 m

Air Hoists mini Food Grade

-

Food Grade Hoist

Many industrial areas require special demands on extreme cleanliness and hygiene. For example the food and beverages industry, the chemical and pharmaceutical industry. The food industry hoist JDN Air Hoist mini Food Grade comes with additional features, that will ensure a smooth, hygienic and most importantly safe operation.

- Carrying capacities: 125 kg, 250 kg, 500 kg, 980 kg

- Air pressure: 6 bar

- Heights of lift: 5m

- Length of control: 4 m

Compared to electric hoists, due to the mechanical drive no short circuits or salt bridges can occur which can lead to failure of the hoist.

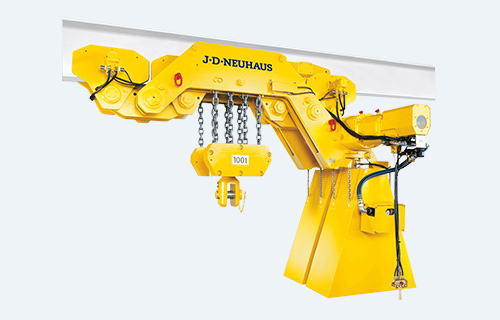

JDN Air Hoist PROFI

-

Carrying capacities: 250 kg up to 100 t

Air pressure: 4 bar or 6 barJDN Air Hoist PROFI Series are superior in all places where safety has priority. The PROFI Series scores well with its 100 % duty rating and explosion protection as standard. This important advantage ensures JDN Air Hoists are especially suitable for applications in hazardous areas. JDN Air Hoists PROFI Series are very robust and therefore suitable for tough industrial applications even in continuous working processes.

- suitable for application in hazardous areas (ATEX)

- sensitive infinitely variable speed control for the precise positioning of loads

- easy operation

- suitable for lube-free operation

- 100% duty cycles – no downtimes

- frequent switching and extended duty cycles

- sound absorption

- insensitive to dust, humidity and temperatures ranging from -20°C up to +70°C

For traversing loads there are different trolleys to meet your special demands.

Hydraulic Hoists PROFI

-

Carrying capacities: 3 t up to 100 t

As an alternative to compressed-air drive, we can supply you with Hydraulic Hoists with carrying capacities up to 100 t.

- predestined for application in explosion-endangered areas (ATEX)

- sensitive, variable speed control

- super-silent

- encapsuled and robust gear motor

- integrated overload switch-off

Trolleys

-

Trolleys are available for all hoists of the PROFI and M series.

- as manual trolleys (LN) for pushing or pulling the trolleys by hand

- as reel chain trolleys (LH) for moving the trolleys by unwinding the reel chain

- as motorised trolleys (LM) powered by an air motor

Standard Features:

- easy to install

- with anti-climb and anti-drop devices

- robust and with little maintenance

- able to negotiate curves

The energy can be fed by various different systems.

Integrated Systems

- JDN Integrated Systems are available with air or hydraulic drive for the offshore industry and also where heavy loads in reduced spaces have to be moved.

EH Series pneumatic

-

Carrying capacities: 10 t up to 115 t per unit

With pneumatic or hydraulic driveThe pneumatic EH Series is predestined for moving heavy loads in low rooms.

Depending on the application the pneumatic EH Series can be used as a double hoist. Parallel, for example in BOP handling systems or connected in series by a coupling rod as used in the cement industry for the transport of the grinding mills.

- ideally suited for working in hazardous areas (ATEX)

- insensitive to humidity dust and temperatures from -20°C to +70°C

- low headroom, compact design

- favourable air consumption

- world wide service

EH Series hydraulic

-

Carrying capacities: 20 t up to 100 t

Alternatively, to the pneumatic drive the hydraulic EH Series is available with capacities up to 100 t.

- predestined for application in explosion-endangered areas (ATEX)

- sensitive, variable speed control

- super-silent

- encapsuled and robust gear motor

- integrated overload switch-off

LMF Series

-

Carrying capacities from 0,5 t up to 6,3 t

The LMF Series, with carrying capacities from 0,5 t up to 6,3 t, is designed for areas where headroom is restricted.

If only low headroom is available and the standard trolleys do not meet the requirements we recommend the LMF Series with low headroom where the air hoists are mounted horizontally.

- ideally suited for working in hazardous areas (ATEX)

- insensitive to humidity, dust and temperatures from -20°C up to +70°C

- extremely low headroom

- favourable air consumption

UH Series

-

Carrying capacities: 4 t up to 100 t

Where hoists with extremely low headroom are required for lifting and moving loads in very low spaces the UH Series is used.

- ideally suited for working in hazardous areas (ATEX)

- insensitive to humidity, dust and temperatures from -20°C up to +70°C

- extremely low headroom

- favourable air consumption

BBH Systems

-

Carrying capacities: 1100 kg and 2200 kg

Air pressure: 6 barFor big bag handling applications, J.D. Neuhaus offers innovative system solutions and thus meets the special requirements of this range of use.

Designs with one or two load hooks

With one load hook for cross beams. The large distance between the hook and the chain box is particularly advantageous. This guarantees that there is no danger of collision between the load and the chain box. With two load hooks for more complex multi-point cross beams or simple rod cross beams with two means of suspension.

- Particularly suited for use as big bag handling hoists and for the movement of all kinds of bulky loads due to the extreme low construction height.

- Usable as synchronised hoist in two-hook design.

- Very economical and reliable due to the use of proven JDN serial components.

- Fewer parts for operation free of maintenance and wear.

- Chain box included in standard equipment.

- Adjustable to various I-profiles; the hook distance can be adjusted later.

Cryogenic Systems

-

Not only for the BOP Handling

under arctic conditionsJDN has developed hydraulic cryogenic systems for applications in a temperature range from -45°C to +40°C.

- Smooth starting of the drives due to preheating device

- Operation with cryogenic hydraulic oil

- Tested under real conditions and in operation in Siberia

Subsea Systems

-

The ultimate tool for every professional diver

PROFI subsea hoists are a versatile and indispensable tool for professional divers and are suitable for horizontal work as well as for oblique pulling.

- Air or hydraulic drive

- Infinitely variable speeds can be regulated sensitively

- With overload protection

- Very versatile, also suitable for horizontal and oblique pulling thanks to hook suspension

JDN Global Service

-

Maximise the potential of longevity

Is it possible to increase the profitability of an investment and simultaneously reduce the risk of production downtime? Yes, it is! By carefully planning ahead. With JDN Service at your side, you ensure the continuous operational availability of your JDN hoists. And: With regular maintenance, you simultaneously ensure the maximum longevity of your JDN products.

Benefit from the advantages of the manufacturer

Long downtimes and a lack of operational safety of a system are absolutely the worst case scenario for every conscientious manager. Your best defence in this case is a service partnership with J.D. Neuhaus, since nobody knows JDN products better than their designer and manufacturer, which means us. Nobody can supply you with original spare parts or replacement products quicker and cheaper than we can.

Use the expertise of the world’s market leader

So what does it mean to you to purchase products and services from a single provider, the world’s market leader in pneumatic and hydraulic hoists? This means one less thing to worry about. We manage your JDN products during their entire life cycle, we are certified according to ISO 9001 and ISO 14001, and we are a master of every export routine. That’s quality of service that takes away your fears and helps you relax.

Experience the strength of the service team

What if something happens? You can contact JDN Global Service to help you every day, around the clock with experienced JDN technicians, who have the best training and operate around the world. We diagnose, find a solution, and fix the problem. In any remote corner of the world. We’re JDN Global Service. We’re prepared for extremes.