- Offer Profile

-

ABUS Kransysteme GmbH

- The ABUS Group is one of the world’s leading overhead crane and hoist manufacturers

- Worldwide Sales and Service

- More than 1100 employees in Europe

- Multiple production sites in Germany

- Product range: Crane systems up to 120 tonnes SWL

- Customer bespoke material handling solutions

Overhead travelling cranes

- ABUS overhead travelling cranes lift loads of up to 120 t making them the ideal solution for particularly demanding tasks and large spans.

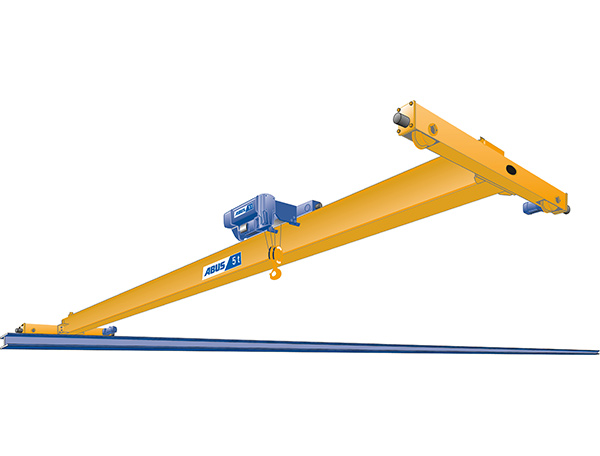

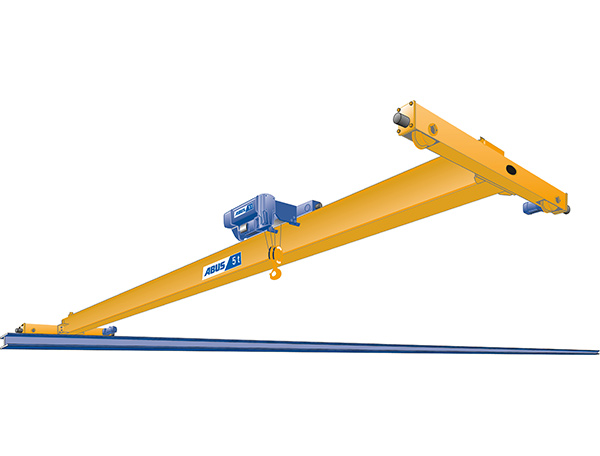

Single girder overhead travelling crane (ELV, ELK, ELS)

-

At a glance

- SWL up to 16 t.

- Spans up to 39 m (SWL dependent).

- Optimised headroom via main girder connection variants.

- Highest possible hook position can be achieved.

- Intelligent functions—an option with the crane control ABUControl

ABUS single girder travelling cranes guarantee optimal material flow even in situations where space is at a premium as in production plants or warehouses where there is little room for crane systems. ABUS single girder travelling cranes are available with rolled section girders or with welded box girders. Thanks to different main girder connection versions, each type of crane can be optimised to minimise headroom and achieve the highest possible hook position.

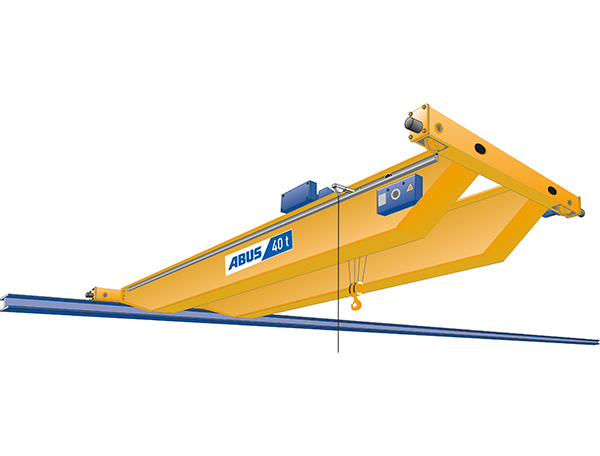

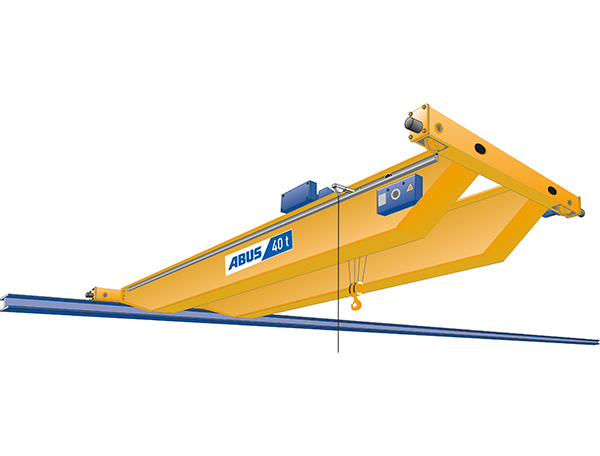

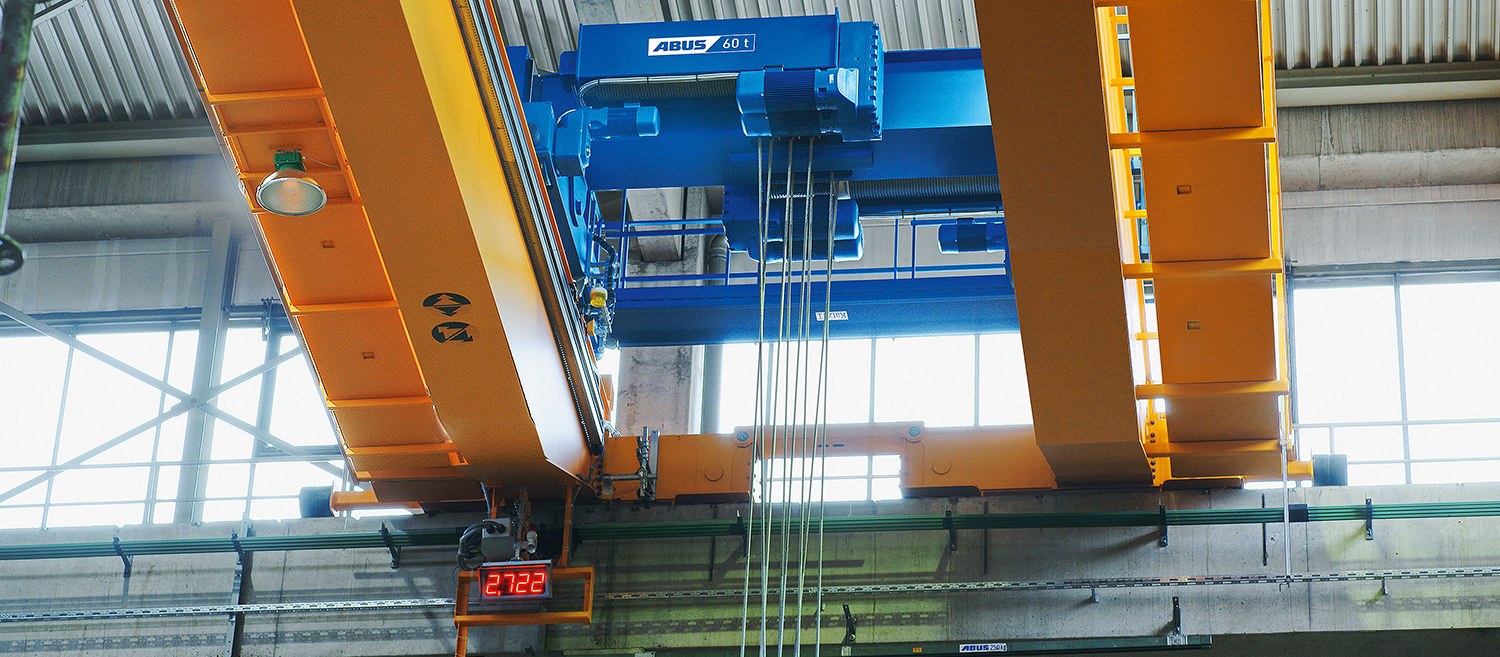

Double girder overhead travelling crane (ZLK)

-

At a glance

- SWL up to 120 t.

- Spans up to 42 m (SWL dependent).

- Additional features can be easily added.

- Fast long and cross travel speeds possible.

- Intelligent functions—an option with the crane control ABUControl

ABUS double girder overhead travelling cranes achieve the maximum load capacity of up to 120 tonnes. They are available in various configurations and feature the versatility required for additional requirements. It is very easy to implement higher crane travel speeds, service platforms, trolleys with walkways, and auxiliary hoists for example.

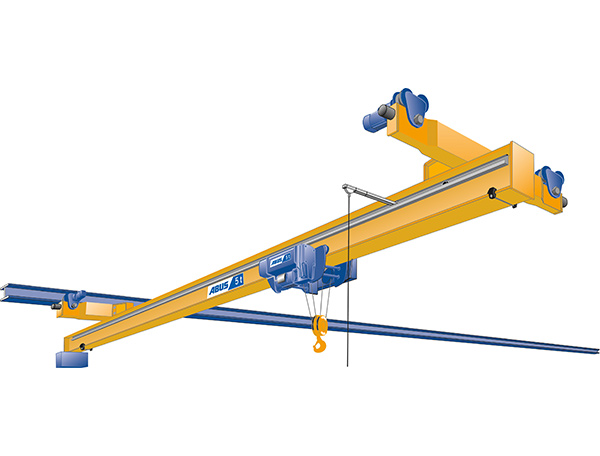

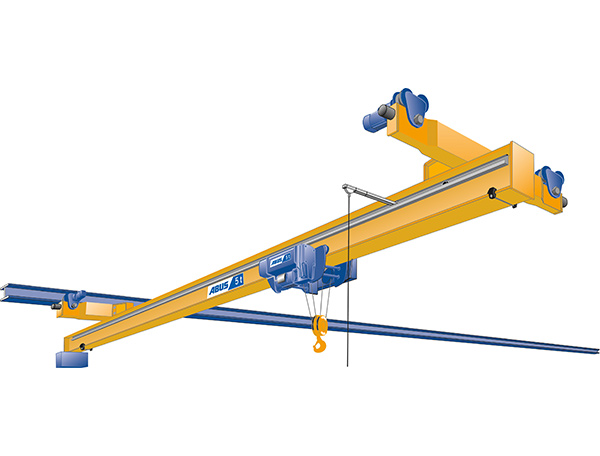

Underslung overhead travelling crane (DLVM, DL, EDK)

-

At a glance

- SWL up to 8 t.

- Spans up to 25m (SWL dependent).

- Crane track suspended from ceiling.

- Ideal for low buildings and complex building conditions.

- Optimal side approach dimensions maximise available building width.

- Intelligent functions—an option with the crane control ABUControl

ABUS underslung overhead travelling cranes offer solutions in applications where gantry tracks are fitted to ceilings rather than free-standing or building columns. Optimal side approach dimensions make it possible to use the maximum available building width.

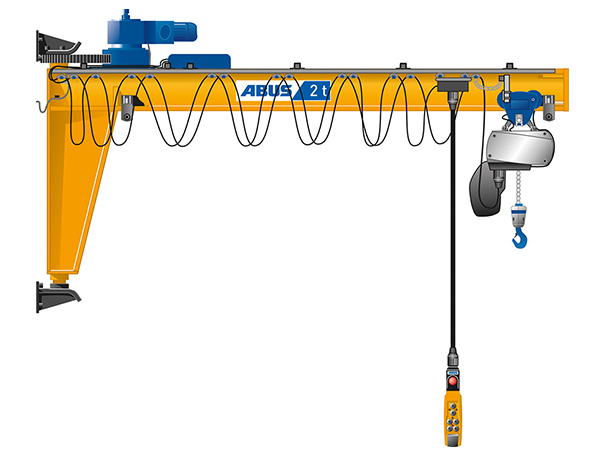

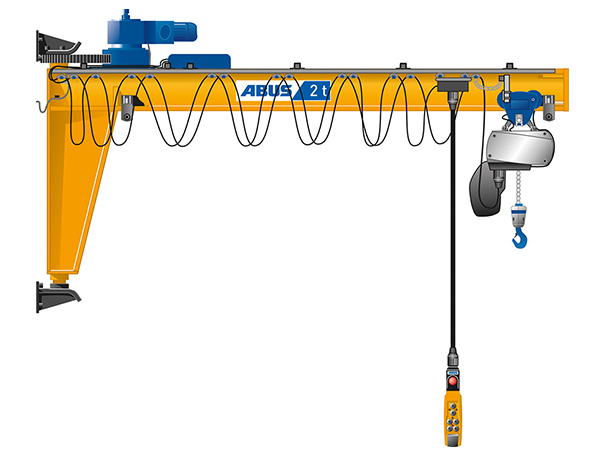

Single-girder wall travelling crane (EWL)

-

At a glance

- SWL up to 5 t.

- Span up to 12 m (depending on load capacity).

- On separate crane track on second level underneath other overhead travelling cranes.

- Ideal as workstation crane for several stations.

- Intelligent functions—an option with the crane control ABUControl

ABUS wall travelling cranes travel on their own crane tracks at building mid-level beneath high-level overhead travelling cranes. They are an ideal solution for covering several workstations with a single installation. ABUS wall travelling cranes type EWL reach spans of up to 12 m and have load capacities of up to 5 t.

Single girder semi-goliath crane (EHPK)

-

At a glance

- SWL up to 5 t.

- Span up to 12 m (depending on load capacity).

- On separate crane track on second level underneath other overhead travelling cranes.

- Ideal as workstation crane for several stations.

- Intelligent functions—an option with the crane control ABUControl

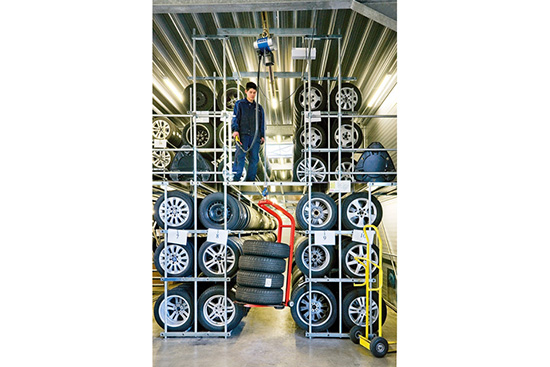

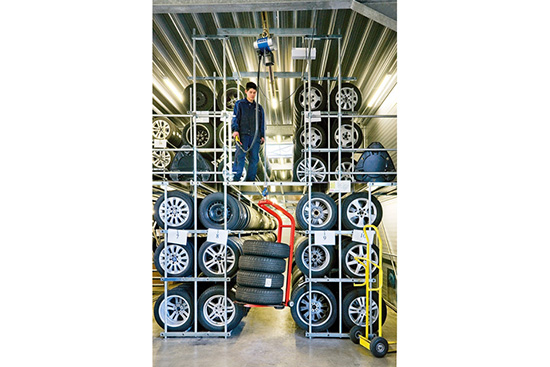

HB-systems

- The HB-System is one of the most successful developments in lifting and material handling technology, combining the effectiveness of a stationary hoist with the mobility of an overhead crane, efficiently and cost-effectively.

Monorail (ESB)

-

At a glance

- Straightforward HB-System for linear point-to-point transport.

- Low headroom.

- Wide suspension spacing.

- Optional electric hoist travel.

The ABUS monorail specialises in lifting loads locally and in linear point-to-point transport. With the help of curved sections your hoist is able to travel through the building exactly as you need it to. Workstations could be linked in this way if required or the crane could be adapted to fit individual machinery locations.

Double-rail system (ZSB)

-

At a glance

- Better load distribution on the suspensions.

- Wide suspension spacing.

- Particularly favourable lifting height with chain hoist suspended between rails.

- Optional electric hoist travel.

- Optional mobile control.

Two crane tracks are suspended in parallel for the ABUS double rail system with the hoist suspended between them. The loads are distributed more evenly meaning less loading for the building structure. Wider suspension spacing is possible.

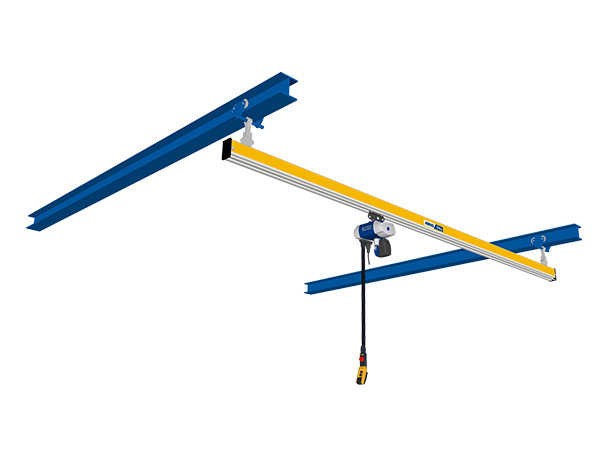

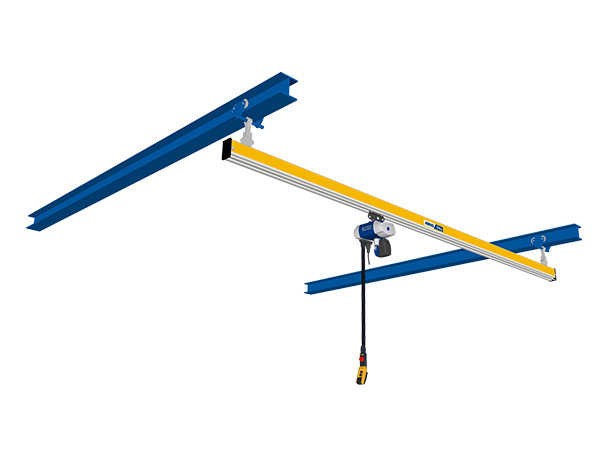

Single girder crane (EHB)

-

At a glance

- Area-coverage materials handling.

- Very light crane; ideal for use in lightweight buildings.

- Easily moved manually.

- Short end approach dimensions.

- Wide suspension spacing.

The ABUS single girder crane EHB is the most straightforward HB system solution for area-coverage materials handling within buildings. The EHB is a very light crane due to the simple construction of two crane tracks and one crane girder which makes it easy to move the EHB manually. This crane is ideal to be installed in lightweight buildings with low load-bearing ability.

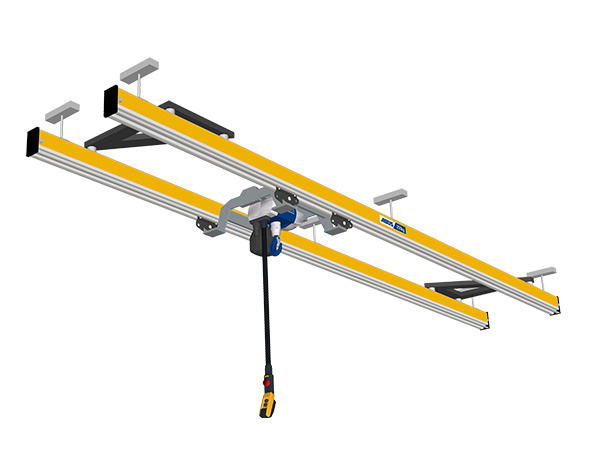

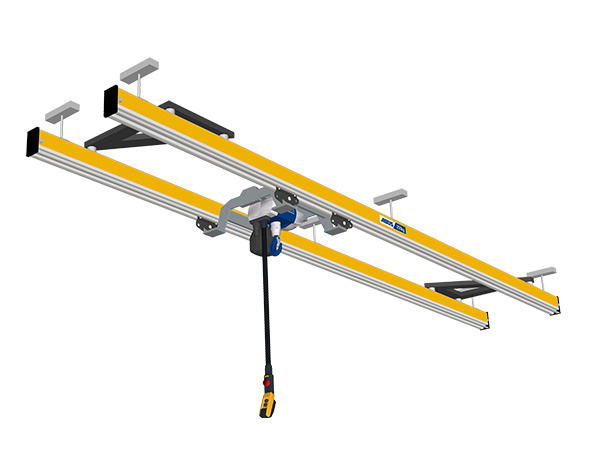

Single girder crane (EHB-X)

-

At a glance

- Optimal use of available room height thanks to stooled up crane.

- Easily moved manually.

- Extremely low profile.

- Short end approach dimensions.

- Wide suspension spacing.

- Optional electric hoist travel.

- Optional mobile control.

The EHB-X is your answer should the building height of the EHB prove to be insufficient. The crane girder of this single girder crane does not run underneath the crane tracks but between them. The total height of the crane is equal to the height of a single profile. A vastly improved lifting height is achieved. This can be very useful if high machinery in the transport area needs to be negotiated.

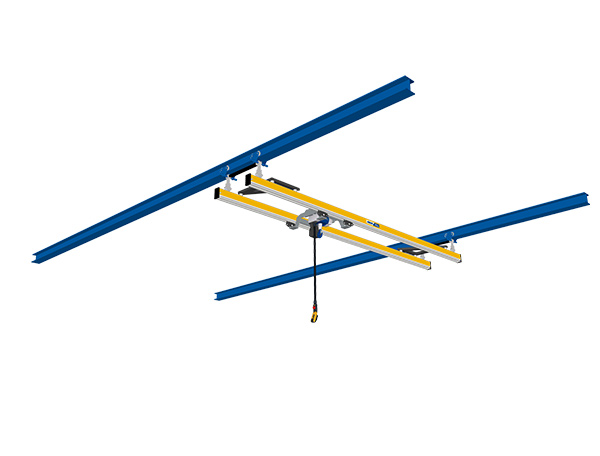

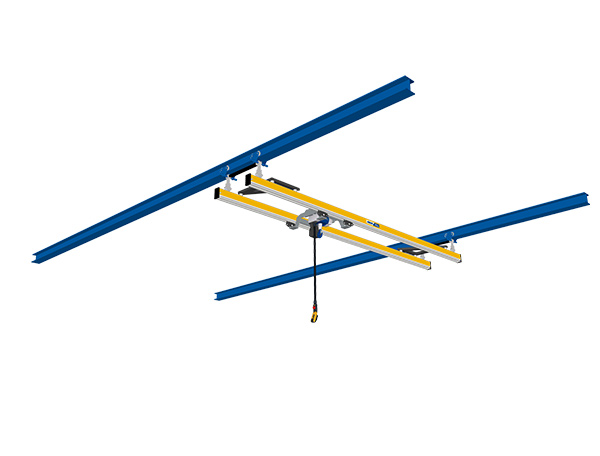

Double girder crane (ZHB)

-

At a glance

- High load capacity.

- Particularly favourable lifting height thanks to the chain hoist being placed between the crane girders.

- Optional electric hoist travel.

- Optional mobile control.

The ABUS double girder crane ZHB is our answer for heavy loads combined with area-coverage transport. The ZHB is also characterised by long crane spans. The ABUS chain hoist is also suspended between the crane girders making for an optimised lifting height.

Stooled-up double girder crane (ZHB-X)

-

At a glance

- Optimal use of available room height thanks to stooled up crane.

- Extremely low profile.

- Wide suspension spacing.

- Optional electric hoist travel.

- Optional mobile control.

The ZHB-X is your answer should the building height of the ZHB prove to be insufficient. The crane girder of this double girder crane does not run underneath the crane tracks but between them. The total height of the crane is equal to the height of a single profile. A vastly improved lifting height is achieved. This can be very useful if high machinery in the transport area needs to be negotiated.

Single girder crane (EHB-I)

-

At a glance

- Area-coverage materials handling.

- Very light crane; ideal for use in lightweight buildings.

- Easily moved manually.

- Crane track consisting of standard rolled-section girders.

- Short end approach dimensions.

The ABUS single girder crane EHB-I is a good solution for area-coverage material transport in buildings that have existing rolled-section girders fitted at a distance appropriate for crane tracks. The lightweight crane girder consists of a hollow profile suitable to run directly on this rolled-section girder crane track when combined with the two underslung trolleys.

Double girder crane (ZHB-I)

-

At a glance

- High load capacity.

- Particularly favourable lifting height thanks to the chain hoist being placed between the crane girders.

- Crane track consisting of standard rolled-section girders.

- Optional electric hoist travel.

- Optional mobile control.

The ABUS double girder crane ZHB-I is our answer for heavy loads combined with area-coverage material transport. The ZHB-I is also characterised by long crane girder lengths. The crane travels directly on crane tracks consisting of rolled-section girders. The ABUS chain hoist is also suspended between the crane girders making for an optimised lifting height.

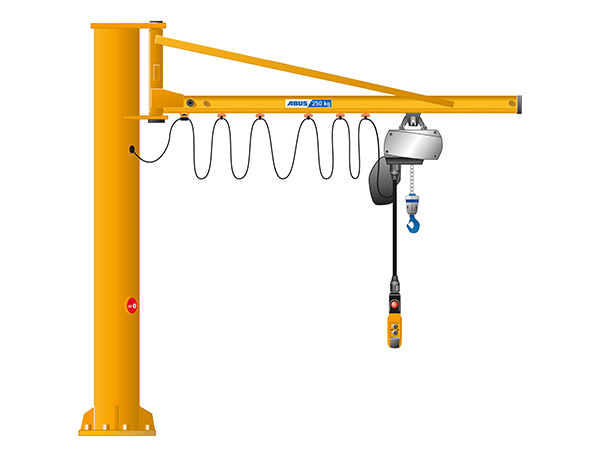

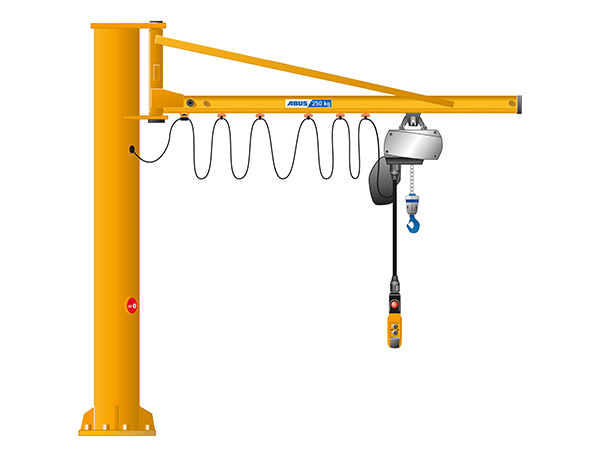

Jib Cranes

-

Working in a team combines the potential of the individual to the overall strength of the company. ABUS slewing jib cranes are powerful and reliable team workers, which make your work easier. With its extensive range of slewing jib cranes, ABUS offers especially flexible and cost-effective material flow solutions all around the workplace.

ABUS slewing jib cranes allow individual adaptation to your application through a choice of hoists, fixing methods and other additional features – all to the highest quality you would expect from ABUS.

They can handle loads up to 6.3 t easily and accurately, all at the push of a button. There are many options available whether the jib cranes stand on their own column or are mounted on the wall or pillar of your building. Whether loading machines, changing heavy tools or lifting workpieces onto work tables - ABUS slewing jib cranes make lifting easier, safer and more economical.

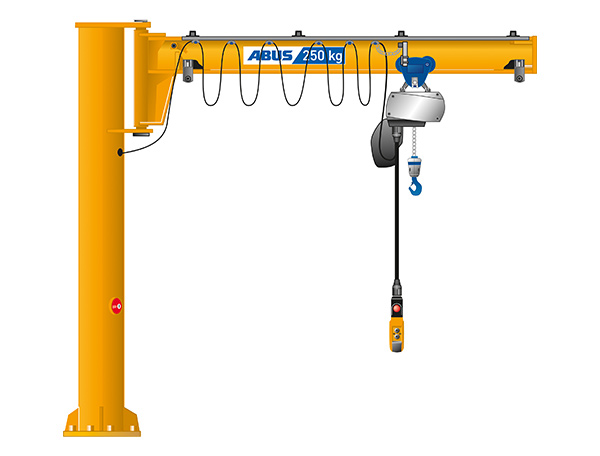

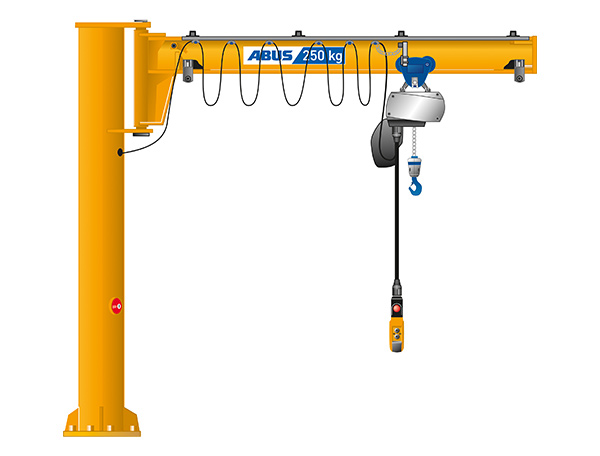

Pillar jib crane (VS)

-

At a glance

- SWL up to 6.3 t.

- Jib length up to 10 m.

- Slewing range n x 360°.

- Up to 4 t with ABUS electric chain hoist.

- Up to 6.3 t with ABUS electric wire rope hoist.

The pillar jib crane LS has been designed for freestanding installation on the building floor. This workstation crane provides a slew range of 270° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 1.0 t. Slewing stops allow you to adapt the slewing range to your individual needs.

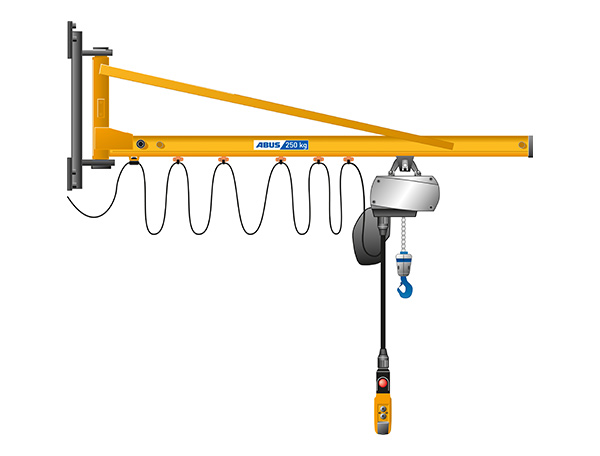

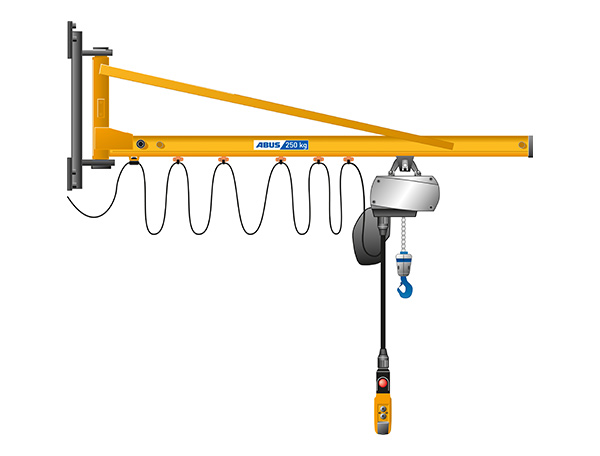

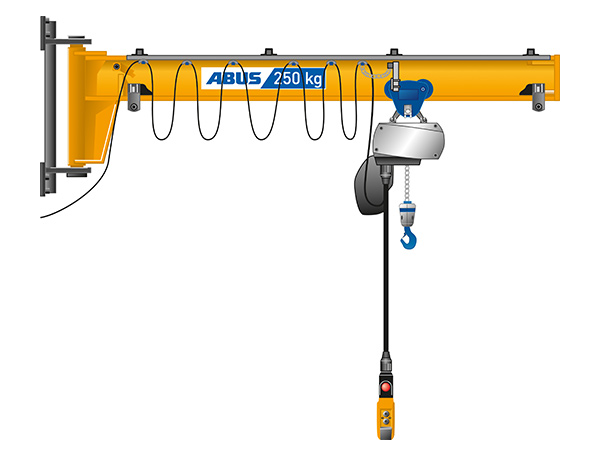

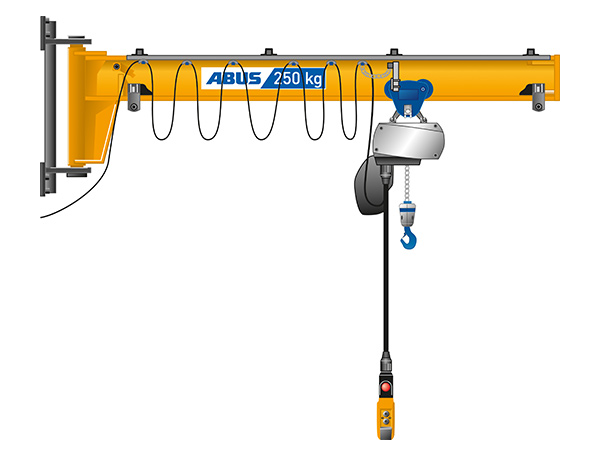

Wall jib crane (VW)

-

At a glance

- SWL up to 5 t.

- Jib length up to 10 m.

- Slewing range 180°.

- Up to 4 t with ABUS electric chain hoist.

- Up to 5 t with ABUS electric wire rope hoist.

The wall jib crane VW has been designed to be mounted on a wall or column. This workstation crane provides a slew range of 180° with jib arm lengths of up to 10 m and Safe Working Loads (SWL) of up to 5 t. The design of the wall jib crane VW enables the given building dimensions to be used to the fullest extent, so that the transfer of the load is achieved at the highest possible lift height.

Pillar jib crane (LS)

- At a glance

- SWL up to 1 t.

- Jib length up to 7 m.

- Slewing range 270°.

- With ABUS electric chain hoist.

The pillar jib crane LS has been designed for freestanding installation on the building floor. This workstation crane provides a slew range of 270° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 1.0 t. Slewing stops allow you to adapt the slewing range to your individual needs.

Wall jib crane (LW)

-

At a glance

- SWL up to 1 t.

- Jib length up to 7 m.

- Slewing range 180°.

- With ABUS electric chain hoist.

The wall jib crane LW has been designed to be mounted on a wall or column. This workstation crane provides a slew range of 180° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 1.0 t.

Pillar jib crane (LSX)

-

At a glance

- SWL up to 0.5 t.

- Jib length up to 7 m.

- Slewing range 270°.

- With ABUS electric chain hoist.

The pillar jib crane LSX has been designed for freestanding installation on the building floor. This workstation crane provides a slew range of 270° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 0.5 t.

Wall jib crane (LWX)

-

At a glance

- SWL up to 0.5 t.

- Jib length up to 7 m.

- Slewing range 180°.

- With ABUS electric chain hoist.

The wall jib crane LWX has been designed to be mounted on a wall or column. This workstation crane provides a slew range of 180° with jib arm lengths of up to 7 m and Safe Working Loads (SWL) of up to 0.5 t.

Lightweight mobile gantry

-

At a glance

- Load capacity (SWL) up to 2000 kg

- Total height up to 5000 mm

Total width in accordance with load capacity (SWL):

Load capacity (SWL)

max. total width

250 kg

500 kg

800 kg

1000 kg

1250 kg

1600 kg

2000 kg7900 mm

7000 mm

6500 mm

6300 mm

5650 mm

5000 mm

4000 mm

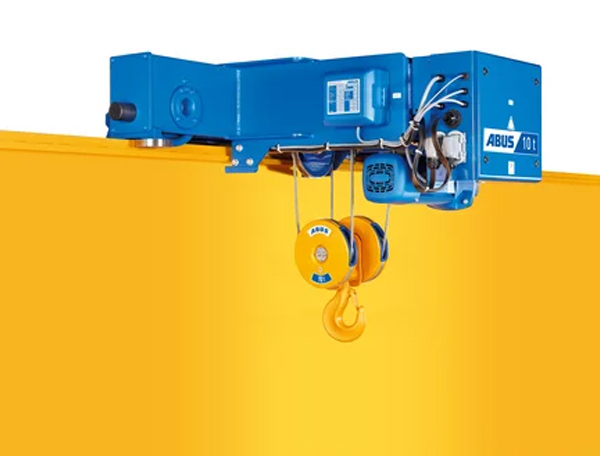

Wire rope hoists

- ABUS electric wire rope hoists are the core element of our crane systems. They are also the result of many decades of research and development by ABUS. Our wire rope hoists are produced at the ABUS production plants at Gummersbach using the most advanced technology available and continue to bear witness to the reliability, and durability of our products. The SWL range of ABUS electric wire rope hoists extends from 1 t to 120 t. Our customers can choose from a wide range of models depending on application and requirements - starting with the standard wire rope hoist in the lower SWL range up to special crab unit designs incorporating additional features at the higher SWL range. However, all wire rope hoists have these characteristics in common: highest levels of uptime availability and safety within materials handling operations.

Type E – monorail hoist

-

At a glance

- SWL range 1 t - 16 t

- Compact design.

- Two direct drive cross travel motors.

- Cross travel trolley adjustable to suit various flange widths.

Monorail hoist as economic choice in compact design with favourable dimensions. Safe Working Load range between 1 t and 16 t. Two direct drive cross travel motors. The cross travel trolley is adjustable to suit various flange widths.

Type S – side-mounted hoist

-

At a glance

- SWL range 1 t - 10 t.

- Hook positioned beside the crane girder.

- Optimised highest hook position.

- Allows building heights to be reduced.

The side-mounted hoist with the hook positioned beside the crane girder achieves an optimised highest hook position. Safe Working Load range between 1 t and 10 t. The combination of optimised highest hook position and the option to design cranes with spans of up to 35 m or more as single girder cranes results in cost advantages when investing in buildings.

Type U – monorail hoist with twin trolleys

-

At a glance

- SWL range 6.3 t - 25 t.

- Cross travel trolley with direct drive.

- No exposed reduction gearing.

- Load is distributed over 8 wheels.

Monorail hoist with twin trolleys type U for high load capacities and long hook paths. Safe Working Load range between 6.3 t and 25 t. Direct drives without exposed reduction gearing for cross travel trolleys. Cranes with higher load capacities yet smaller spans can be designed as single-girder cranes when using this hoist.

Type D – standard crab unit

-

At a glance

- SWL range 1 - 63 t.

- Articulated end carriage joints.

- No hook wander or rotation with true vertical lift units.

- Maintenance platform as an option.

Compact double rail crab unit for medium SWL applications up to 63 t. The articulated end carriage joints ensure positive contact of all four wheels with the track. Hoist trolley features two direct drive cross travel motors.

Type DQA – ultra low headroom crab unit

-

At a glance

- SWL range 1 t - 40 t.

- Ultra low headroom design.

- Articulated end carriage joints.

- Two direct drive cross travel motors.

Compact crab unit for SWL of up to 40 t. Ultra low headroom design with rope drum axis in the direction of cross travel; with articulated end carriage joints to ensure positive contact of all four wheels with the track and with two direct drive

Type Z – twin barrel crab unit

-

At a glance

- SWL range 8 t - 120 t.

- Compact design.

- Articulated end carriage joints.

- Two direct drive cross travel motors.

Compact twin hoist crab unit for Safe Working Loads of up to 120 t with articulated end carriage joints to ensure positive contact of all four wheels with the track and with two direct drive cross travel motors.

Type DA - low headroom crab unit

-

At a glance

- SWL range 1 - 40 t.

- Minimum overall headroom dimensions.

- May be used where very little space is available above the crane.

In contrast to the type D unit, the cross member supporting the hoist between the end carriages is fitted with articulated joints. The hoist headroom is therefore reduced to a minimum. This is the option to use where very little space is available above the crane, as an alternative to type DQA, also a low headroom option.

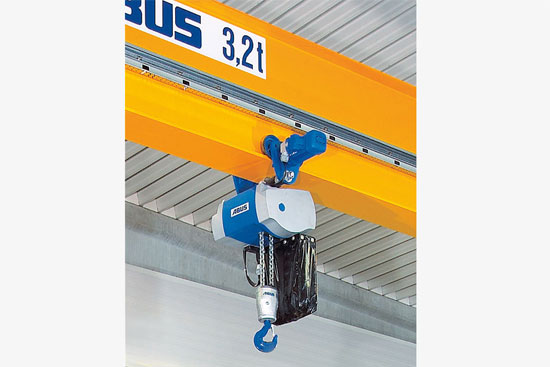

Electric Chain Hoists

-

No crane without hoists - they are the heart of all crane systems.

Chain hoists in daily use at workstations have to be robust, reliable and low-maintenance. The ABUCompact range of ABUS electric chain hoists offer solutions for up to 4 t SWL featuring the high build quality for which ABUS is well-known. The modular design allows a huge range of lifting speeds of up to 20 m/min for hook paths of up to 50 m.

Precision lifting, safety slipping clutch and quick plug-type connectors are as integral a part of the standard configuration as is the tried and tested durable direct control for sizes GM2, GM4 and GM6.

Chain Hoist ABUCompact (GMC)

-

At a glance

- SWL up to 200 kg.

- Hook path up to 20 m.

- Mains connection 230 V / single-phase (standard power socket).

A standard power socket with 230 V suffices for the power supply of the ABUCompact GMC. The GMC is particularly suited to mobile use due to its low weight. The GMC is available with single or double falls and is able to lift loads of up to 100 kg / 200 kg. The lifting speed is infinitely variable. Feasible hook paths reach lengths of up to 20 m / 10 m.

Chain Hoist ABUCompact (GM2)

-

At a glance

- SWL up to 630 kg.

- Hook path up to 32 m.

- Lifting speed up to 20 m/min.

The ABUCompact GM2 is available with 1 or 2 falls. The GM2 lifts loads of up to 320 kg / 630 kg. The hooks paths reach lengths of up to 32 m / 16 m. Different lifting speeds are available depending on the load capacity.

Chain Hoist ABUCompact (GM4)

-

At a glance

- SWL up to 1250 kg.

- Hook path up to 50 m.

- Hoist limit switch with up to 4 shut-down points.

The ABUCompact GM4 is available with 1 or 2 falls. The GM4 lifts loads of up to 630 kg / 1.25 t. The hooks paths reach lengths of up to 50 m / 25 m. Different lifting speeds are available depending on the load capacity.

Chain Hoist ABUCompact (GM6)

-

At a glance

- In single or double fall design.

- SWL up to 1.25 alt. 2.5 t.

- Hook path up to 35 / 17.5 m.

- Extensive additional equipment available.

The ABUCompact GM6 is available with 1 or 2 falls. The GM6 lifts loads of up to 1.25 t / 2.5 t. The hooks paths reach lengths of up to 35 m / 17.5 m. Different lifting speeds are available depending on the load capacity.

Chain Hoist ABUCompact (GM8)

-

At a glance

- In single or double fall design.

- SWL up to 2 alt. 4 t.

- Hook path up to 32 / 16 m.

- Extensive additional equipment available.

The ABUCompact GM8 is available with 1 or 2 falls. The GM8 lifts loads of up to 2 t / 4 t. The hooks paths reach lengths of up to 32 m / 16 m. Different lifting speeds are available depending on the load capacity. The ABUCompact GM8 features a 48V electronic control as standard.

Components & Accessories

- Komponenten und Accessories

Radio control ABURemote

-

ABURemote gives you the freedom you need when transporting heavy loads. The load can be moved from the safest available standing position which offers the best overview.

Optimised specifically to be used with ABUS crane systems, the ABURemote is characterised by high quality. Choose between two types of transmitters: the hand-held transmitter ABURemote Button or the joystick transmitter ABURemote Joystick.

End Carriages & Wheel blocks

-

- End carriages and wheel blocks

Installation Components

-

- Safety conductor KBH

- Universal components

- Festoon cable system

- Electric installation material

Control Components

-

- Central control system

- Crane anti-collision device

- Star limit switches

- Load measuring system LIS

- Pendant control ABUCommander

- ABUS spring reels

- Operating direction signs

ABUS calibrated hook block

-

- Calibrated commercial scale of accuracy class III with CE-M approval, incl. Declaration of Conformity

- Durable DMS ring torsion load cell made of stainless steel sensor

- The indicated load is always in the field of vision of the operator, either on the remote control or, as an option, on the crane

- Weighing module is optimally integrated into the bottom block of ABUS wire rope hoists

- Radio data transmission via the Teledata evaluation unit

- Calibrated hook block scale can also be retrofitted

LED lighting

-

- Immediate brightness

- Operating temperature: -30°C to +50°C

- Input voltage AC 100 - 240 V, 50 / 60 Hz

- Protection class IP 55

- Colour temperature 5000 K

- Over 50,000 hours of service life

- Over 100,000 switching cycles

- Energy efficiency class A+

Lightweight mobile gantry

-

With our lightweight mobile gantry (LPK) you can easily lift loads of up to 2 t. The ABUS LPK can be moved easily and is therefore always available wherever you need it, quickly and efficiently.

- Load capacity (SWL) up to 2000 kg

- Total height up to 5000 mm