KITO

Videos

Loading the player ...

- Offer Profile

WORK AT THE LIMIT

Our commitment to provide the highest quality products with the most advanced safety features has been the focal point of our work for more than 82 years, from product development to production and service.

Product Portfolio

Electric Chain Hoists

- Engineered to endure. The electric hoists are designed for peak performance—even on the toughest jobs in the most demanding conditions. Their quiet operation and minimal vibration lowers workplace noise pollution, helps reduce worker fatigue and extends the life of the hoist. Practical durability at its best, the hoists let you get the job done safely and worry-free.

CDER2

-

The CDER2 with ergonomic cylinder control

As an addition to its existing product range, KITO offers the Electric Chain Hoist CDER2 with cylinder control. This KITO chain hoist is particularly suited for applications requiring the automation of repetitive transport tasks and is mainly used in the handling technology. The hoist is ideal for the quick operation of travelling a smaller load over a shorter path by operating the grip of the cylinder control integrated with the bottom hook.

Product advantages- Cylinder control with an integrated potentiometer for a variable speed control

- Ideally suited for applications requiring the automation of repetitive transport tasks

- Controlling the lifting or lowering process with only one hand

- Enhanced safety und positioning accuracy with the pioneering inverter technology

- High FEM classification: M6/3m for capacities up to 500 kg and 2 speeds (dual speed)

- Product warranty: 3 years product warranty and 10 years warranty on the brake system. The guarantee is only valid if the operating conditions, inspection and maintenance intervals as described in the owner’s manual are followed

ED

-

The compact one with power from the wall socket

The KITO Electric Chain Hoist Series ED is unsurpassed in its versatility. Anywhere a 220 – 240 V AC connection is available this KITO ED III hoist can be used immediately.

That may, for example, be in smaller workshops and building sites and in storage areas, but, the electric chain hoist is also a dependable tool in dispatch, where larger cardboard packages have to be lifted. Furthermore this small hoist has been tested and has become practically indispensable for the transport of loads inside wind turbine towers.

The unit is designed for loads from 60 – 240 kg. Because of its light weight it can be quickly and individually deployed at different places. The gear casing is made from aluminium and is resistant to weathering and rust.

But heavier loads of up to 480 kg also present no problem. An optional upgrade set, consisting of upper hook, lower block and a longer chain, can be ordered. The upgrade can be carried out quickly and easily. With the corresponding type plate, the ED may then be used with a double chain for higher loads.

This also gives the advantage of a range of load capacities dependent on the lifting speed. In the load capacity range from 60 to 160 kg, the maximum speed is up to 20 m/min. There are also two motor variants, a DC motor with 300 W for the load capacity ranges 60, 100 and 180 kg, and a larger variant with 600-W output for load capacities up to 160, 240 or, with a double chain, up to 480 kg. Safety features include a high-performance mechanical brake with a friction clutch and an upper lift limit switch for increased safety.

The standard equipment includes a plastic chain box for 3 or 6 m lifting height. For lifting heights up to 15, 30 and 70 m, a canvas container is used, while a special receptacle is required for greater heights. As options, the system offers the mini-trolley TMH 25, a plain trolley or a geared trolley up to 500 kg.

Product advantages- Light and compact design

- Low headroom

- Weathertight construction resists dust and water

- Variable high lifting speeds

- Overload protection with built-in slip clutch

- High performance mechanical load brakes

- Degree of protection: IP 54

EDC

-

Easy handling of the load with only one hand

The KITO Electric Chain Hoist Series ED is unsurpassed in its versatility. Anywhere a 220 – 240 V AC connection is available this KITO ED III hoist can be used immediately. KITO offers the Electric Chain Hoist EDC for special applications. This unit is equipped with a cylindrical handgrip control unit and is mainly used in the handling technology. By means of a potentiometer in the cylinder control unit the speed can be adjusted independently.

For ergonomic reasons, its lifting height is limited to 1.8 m. The operator guides the load with one hand, while controlling the lifting or lowering process. This is particularly convenient for repetitive transport procedures. It is possible to vary the preset speed to optimize the working process. Different load holding equipment, such as crate or package grippers, also ensures operator-friendly load handling. The bayonet closure permits quick changing of a wide variety of grippers and hooks.

The unit is designed for loads from 60 – 240 kg. Because of its light weight it can be quickly and individually deployed at different places. The gear casing is made from aluminium and is resistant to weathering and rust.

The EDC is available with dual lifting speed. In the load capacity range from 60 to 160 kg, the maximum speed is up to 20 m/min. There are also two motor variants, a DC motor with 300 W for the load capacity ranges 60, 100 and 180 kg, and a larger variant with 600-W output for load capacities up to 160 or 240 kg. Safety features include a high-performance mechanical brake with a friction clutch and an upper lift limit switch for increased safety. The standard equipment includes a plastic chain container. As options, the system offers the mini-trolley TMH 25, a plain trolley or a geared trolley up to 500 kg.

Product advantages- Light and compact design

- Low headroom

- Weathertight construction resists dust and water

- Degree of protection: IP 44

- Variable high lifting speeds

- Variable speed adjustment

- Overload protection with built-in slip clutch

- High-performance mechanical load brakes

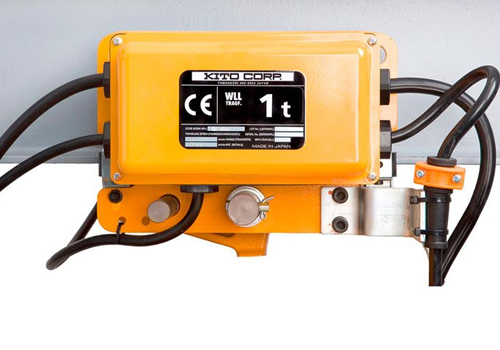

EQ

-

A Milestone on the market for Electric Chain Hoists

Its compactness and its reduced dimensions are some of the special features of KITO’s EQ electric chain hoist. The EQ offers in comparison to KITO’s ER2 series, a considerable reduction in the net weight by 23 %. With the lifting capacities ranging from 250 kg, 500 kg to 1,000 kg the EQ can be used to perform a wide range of commonplace tasks. Furthermore a wide variety of suspensions and lifting heights are available.

The EQ product line is targeted at moderate and heavy duty users, with several unique design features that benefit these customer segments.

The EQ includes an inverter that provides an industry-first “light load high-speed” function that automatically increases hoist speed to 130 % when the load is less than 30 % of WLL. As a result, users can expect the production cycle to improve up to 115% of standard. This unique operating characteristic makes the product ideal for assembly line, work station, and repetitive operation applications.

As well the inverter provides these benefits: cushioned and adjustable speed for ultimate load control as well as electronic thermal and overload protection. The inverter and its unique software also eliminate several wear items typically used in conventional hoists, including a transformer, contactor, or brake coil.

The hoist employs a highly durable pull-rotor brake system, proven reliable in past KITO products. Up to two million brake cycles can be expected from the system.

Product advantages- Compact hook end approach

- High productivity feature: 130 % speed at less than 30 % WLL

- High duty rating: FEM 3m/ISO M6 rating through 500 kg

- Low maintenance due to: no transformer, no magnetic contactor, no brake contactor, no brake coil

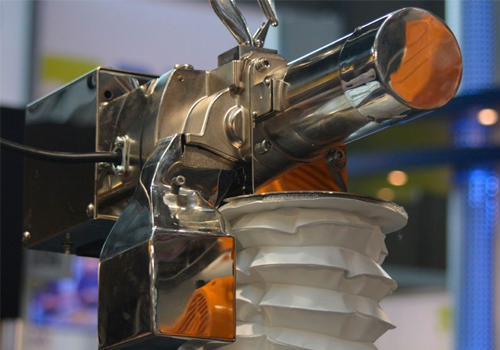

ER2 Food Grade

-

The electric chain hoist engineered for the food industry – the KITO FER2

As an addition to its existing product range, KITO offers the Electric Chain Hoist FER2 which was specifically developed to meet the needs and requirements of the food industry. KITO’s Food Grade ER2 is well-suited for lifting applications in food, beverage, and pharmaceutical processing industries where pristine cleanliness is critical.

Food grade lubricants used on the load chain and in the gearbox are NSF H1 compliant for safe use in any facility where incidental contact with product is a concern. Furthermore, the KITO FER2 hoists fully comply with the provisions of the EU RoHS Directive.

This three-phase electric chain hoist is available in the capacities ranging from 500 kg up to 2 t with a wide array of mounting solutions at the customer’s disposal, from the hook version to the plain trolley or even including the use of a geared or electric trolley. Customer-specified options include a protective silicone pendant cover, stainless steel and nickel-plated hardware, and nickel-plated load chain making this hoist well-suited for contaminant controlled or corrosive processing environments.

Similar to all KITO electric chain hoists, the FER2 hoist comes standard with the KITO brand grade 80 type load chain. This nickel-plated chain is well known for its corrosion resistance, as well as a super-smooth surface that greatly reduces link to link wear.

Product advantages- With CE Certification

- IP55 Environmental Protection

- A Certificate of Conformance is included

- Extended life and reduced operating costs

ER2 Limit Lock

-

The Powerful Electric Chain Hoist with programmable stopping positions

As an addition to its existing product range, KITO offers the Electric Chain Hoist ER2 Limit Lock. The ER2 Limit Lock enables the automatic stopping of the load at preset positions by means of special programmable limit switches for upper most and lower most travel. With the inverter controlled ER2 Limit Lock the hoist can be automatically slowed down and stopped anywhere within the full travel range of the hoist.

In addition, the hoist includes emergency upper and lower travel protection through standard electromechanical limit switches.

The hoist is equipped with an encoder device to detect the hook position within +/- 10mm; and two separate positions can be easily selected using only the push pendant station.

The ER2 Limit Lock is available for a capacity range of 125 kg to 5 ton. Like the other product components of the ER2 Electric Chain Hoist Series, the ER2 Limit Lock Series comprises the “cushioned start and stop” feature based on the ramp-up and ramp-down speed control programmed into the inverter. It is ideal for delicate loads or precise load positioning.

Similar to all KITO electric chain hoists, the ER2 Limit Lock hoist comes standard with the KITO brand grade 80 NP type load chain. This nickel plated chain is well known for its corrosion resistance, as well as a super-smooth surface that greatly reduces link to link wear.

Product advantages- Programmable level limits: easily adjusted using push button control

- Improved productivity and efficiency in operation: the operator can easily lift or lower to the perfect position every time without the need for continuous adjustment

ER2M with motorized trolley

-

KITO’s ER2M Electric Chain Hoist Series – Extremely user-friendly and highly efficient even under the harshest conditions

Everywhere loads need to be lifted and transported safely and precisely the KITO MR2 Motorized Trolley Series is the perfect choice. In combination with the ER2 Electric Chain Hoist Series KITO offers the perfect symbiosis for all sorts of lifting and travel applications. The KITO MR2 trolleys are easily attached to a wide range of beam flange sizes (flat-flanged or tapered beams) up to a beam width of 300 mm. For more information please do get in touch with our Customer Service Support.

The MR2 Trolleys Series offer as standard equipment sealed protection of the trolley (IP55) which contributes towards the utilisation of the hoist also under harsh outside conditions.

As KITO’s motorized trolleys are available from 125 kg to 5 tons capacity you can choose the capacity that meets your individual needs. Higher capacities are available on request. The MR2 is available with single traversing speed and contactor control or with dual traversing speed by means of a frequency inverter. The product variant with the frequency inverter is perfectly suited for handling sensitive loads as it provides for particularly smooth start and stop movements.

The MR2 trolleys feature an extremely durable and reliable pull-rotor motor brake for a higher precision load control, deceleration and a long service life. A heavy-duty motor with high-horsepower, cooling fins and standard thermal motor protection provide top performance and enhanced efficiency of the hoist.

Different kinds of energy supply systems like for instance the KITO cable hanger or the C-rail festoon system are available on request and therefore provide protection to the power supply festooning system. Furthermore the side guide rollers are supported by four ball bearings which smoothes trolley motion and reduces wear of the wheels and beam.

Product advantages- Coverage of a variety of lifting capacities

- Suited to a wide range of applications

- Highly user-friendly

- High-performance even under harsh conditions

- Efficient load handling and precise brake control

- Smooth operation

ER2SG with geared trolley

-

The KITO ER2SG Electric Chain Hoist Series with Geared Trolley configurations – ideal for shorter traversing distances and higher loads

The KITO ER2 Series can also be equipped with a TSG Geared Trolley which will help you manoeuver easily where a motion parallel to the beam is necessary. KITO’s TSG is the ultimate choice, especially for applications with shorter traversing distances and higher loads (up to 30 t). Various capacities can be implemented according to your individual needs at any time without problems.

KITO’s Geared Trolleys feature hardened heat-treated steel wheels that ensure reliable tracking and their sealed ball bearings avoid maintenance hassles and provide smooth operation.

The KITO TSG offers a very simple state-of-the-art design allowing easy configurations and multiple product options. It is also light weight so it requires less labour and time for installation, which contributes to a total cost reduction. Special protective lugs hold the trolley surely on the beam and integrated rubber bumpers guard against damage to the trolley and wheels arising from a collision with the stopper or between two trolleys.

The TSG Trolley wheels are adjustable to work with both tapered and flat-flanged beams, allowing you to use existing equipment without customization. Furthermore KITO offers a variety of trolley hoist suspenders matching the needs of diverse applications. KITO’s Geared Trolleys can be optionally combined with a suspender for close connected suspension and/ or a hook suspension type (from 5 t capacity not necessary).

For more information please do get in touch with our Customer Service Support.

Product advantages- Light and compact design

- Quick and easy handling of the load, better durability

- Smooth operation

- Easy assembly by means of trolley bolts and spacer disks

- Suited to applications involving shorter traversing distances and precise load movement

ER2SP with plain trolley

-

The KITO ER2SP Electric Chain Hoist Series with Plain Trolley configurations: ideal for larger traversing distances

The KITO ER2 Series can also be equipped with a TSP Plain Trolley which will help you manoeuver easily where a motion parallel to the beam is necessary. KITO’s TSP easily bridges larger traversing distances for a load up to 5 t. Various capacities can be implemented according to your individual needs at any time without problems.

KITO’s Plain Trolleys feature hardened heat-treated steel wheels that ensure reliable tracking and their sealed ball bearings avoid maintenance hassles and provide smooth operation.

The KITO TSP offers a very simple state-of-the-art design allowing easy configurations and multiple product options. It is also light weight so it requires less labour and time for installation, which contributes to a total cost reduction. Special protective lugs hold the trolley surely on the beam and integrated rubber bumpers guard against damage to the trolley and wheels arising from a collision with the stopper or between two trolleys.

The TSP Trolley wheels are adjustable to work with both tapered and flat-flanged beams, allowing you to use existing equipment without customization. Furthermore KITO offers a variety of trolley hoist suspenders matching the needs of diverse applications. KITO’s plain trolley series can be optionally combined with a suspender for close connected suspension and/ or a hook suspension type. For more information please do get in touch with our Customer Service Support.

Product advantages- Light and compact design

- Quick and easy handling of the load, better durability

- Smooth operation

- Easy assembly by means of trolley bolts and spacer disks

- Suited to applications involving greater traversing distances

ER2 Stepless Speed

-

Infinitely variable speed control for particularly smooth lifting, lowering and positioning of loads

As an addition to its existing product range, KITO offers the Electric Chain Hoist ER2 Stepless Speed with variable speed control. The speed remains at the discretion of the operator and can be adjusted appropriately for different tasks. Consequently, work processes can be optimised accordingly.

The hoist features an frequency inverter and a special push button control station with buttons that stroke 6.5 mm. The control switch has no pressure points like those in other switches, but works like an accelerator pedal. When the switch is pressed, the chain hoist accelerates and moves to a specified position. At the same time, this speed is saved by the so-called teach-in process. It can later be reduced or increased for other motion sequences. In doing so, lifting and lowering can be accelerated or decelerated from 16% of maximum speed to 100% of maximum speed, simply by depressing the push button.

The ER2 Stepless Speed hoist is ideal for eliminating load-bounce in jib or bridge cranes, making load positioning safe, easy and intuitive for the operator. As well, the hoist is perfectly suited for fine positioning in assembly operations, or in cases where the load is delicate and valuable.

The ER2 Stepless Speed hoist operates with variable lifting speed, and is available for a capacity range of 125 kg to 5 t . The ER2 is well known for its “cushioned start and stop” feature based on the ramp-up and ramp-down speed control programmed into the frequency inverter. It is ideal for delicate loads or precise load positioning.

Similar to all KITO electric chain hoists, the ER2 Stepless Speed hoist comes standard with the KITO brand grade 80 NP type load chain. This nickel plated chain is well known for its corrosion resistance, as well as a super-smooth surface that greatly reduces link to link wear.

Product advantages- Infinitely variable speed control

- Maximum lifting speed range: speed ratio 6:1

- Operation advantages

- Improved work efficiency

ER2 with hook suspension

-

Engineered to perform in the industry’s toughest applications and most extreme conditions

KITO’s high performance ER2 Electric Chain Hoist Series are striving for the first place in the industry when it comes to safety, longevity and maintenance. The ER2 is characterized, in particular, by its high product spectrum, offering the customer an array of choices. Load capacities from 125 kg up to 20 t cover a wide range of applications. Its versatility, from the hook version to the plain trolley up to 5 t and the use of a geared or electric trolley up to 20 t, distinguishes this model as a universal hoist. This is further underlined by the special twin hook version and the variant with an extra-short headroom height. Because of its easy handling, the ER2 is used in almost all sectors, including the paper industry, in shipyards, foundries, and on major construction sites.

In its development of the ER2, KITO has focused on functionality. This means that, without any superficial gimmicks, the robust and solidly constructed hoist, with pioneering inverter technology or with 24-V contactor control, is able to perform its tasks with ease. The production depth offers a further advantage to customers as it guarantees them a high degree of security. Well over 70 % of all the parts we use come from our own production.

An important component of this production depth is the load chain, which differs appreciably from that of its competitors. KITO is the only manufacturer in the world to nickel-plate its load chain. The advantage of this process is that no hydrogen embrittlement occurs as a result of the permeability of the nickel surface to hydrogen molecules. Because of its special properties, nickel is particularly well suited as a surface coating for many applications. This makes the range of applications for this electric chain hoist unparalleled: its advantages ensure that this hoist is even ideal for operations where aggressive media have to be handled.

Product advantages- Product warranty: 3 years product warranty and 10 years warranty on the brake system. The guarantee is only valid if the operating conditions, inspection and maintenance intervals as described in the owner’s manual are followed

- Enhanced safety und positioning accuracy with the pioneering inverter technology or with 24-V control control

- High FEM classification: M6/3m for capacities up to 500 kg and 2 speeds (dual speed)

- Extremely strong and wear-resistant nickel-plated KITO load chain

- Extended life and reduced operating costs

SHER2M low headroom

-

When height becomes an issue – the KITO Electric Chain Hoist SHER2M for low ceiling heights

In situations where every centimetre of headroom is vital, the KITO Electric Chain Hoist SHER2M (Short Headroom ER2 Motorised Trolley Type) is a welcome solution. Apart from use in buildings with low ceilings, it is also ideal where considerable lifting heights are necessary. This is accomplished by means of a special KITO chain guide.

Thanks to this, the load can be raised almost up to the support beam. With its state-of-the-art inverter technology or with 24-V contactor control, the SHER2M is able to perform the tasks assigned to it with ease.

The basic unit is KITO’s evergreen product, the Electric Chain Hoist ER2, characterised by its large bandwidth. Its load capacities from 125 kg to 5 t cover a wide range of applications. Because of its easy handling, the ER2 is used in almost every sector.

On the basis of this diversity of variants, the product can be individually adapted to transport or production sequences as required. This also applies to use on girders, cranes or load carriers.

A further advantage for the customer is the depth of production, which offers the customer a high degree of safety, since well over 70 % of all the parts used originate from our own production.

An important component of this production depth is the load chain, which differs appreciably from that of its competitors. KITO belongs to the few manufacturers in the world to nickel-plate its load chain. The advantage of this process is that no hydrogen embrittlement occurs as a result of the permeability of the nickel surface to hydrogen molecules. Because of its special properties, nickel is particularly well suited as a surface coating for many applications.

Product advantages- Ultra low headroom

- Product warranty: 3 years product warranty and 10 years warranty on the brake system. The guarantee is only valid if the operating conditions, inspection and maintenance intervals as described in the owner’s manual are followed

- Increased safety and position accuracy with the pioneering frequency inverter technology or with 24-V contactor control

- Smooth and silent operation

- Acceleration and stop time of trolley are adjustable

- Extremely maintenance-friendly

TWER2M

-

Safe and synchronous load transport with only one hoist – the KITO Twin Hook Electric Chain Hoist TWER2M

Wherever loads have to be kept horizontal or simultaneously raised or lowered, the KITO Twin Hook Electric Chain Hoist TWER2M (Twin Hook of the ER2M Series) comes into its own.

The synchronised movements required can now be realised with only one hoist. This variant differs fundamentally from the solutions provided by most manufacturers, as these require two hoists to handle the load. Furthermore, no motor runs exactly like any other, so an expensive synchronous regulator has to be used. Following a strategy of conceptual functionality KITO developed the TWER2M with the aim that a 100 % synchronisation can be realised. The secret: One motor drives a twin load chain pinion, so that both chains and both load hooks can be moved synchronously. Fine adjustment presents no problem, should there be a slight variation in synchronisation.

With this technical innovation, KITO possesses a unique selling point, where due to the synchronous variant of the TWER2M, one hoist can be dispensed with. In combination with the electric chain hoist ER2, the twin hook version is even more interesting for the user. A particular feature of the hoist is its high bandwidth, which offers the customer a wide range of options.

The Twin Hook Electric Chain Hoist, which is primarily designed for rolled steel profiles, is especially useful for the handling of long loads such as pipes and steel rods, for example. In this case, the spacing of the hooks can be adapted, according to customer requirements, to the length of the loads to be transported.

The load is moved by operation of the control unit. Additional manual guidance of the load by the operator is not necessary, since rocking of the load is eliminated. By means of the integrated inverter a smooth and precise positioning of the load will be enabled. The hoist can also be fitted with a variety of load holding mechanisms for use in individual cases.

A further advantage is the great production depth, which offers the customer a high degree of security. This applies in particular to the load chain, which is nickel-plated by Kito, which differs appreciably from the load chains of the competitors. The advantage of this manufacturing process is the elimination of hydrogen embrittlement, as the nickel surface is permeable for hydrogen molecules.

Product advantages- Safe and synchronous lift of long goods

- Ideal for lifting loads horizontally and simultaneously, improved positioning accuracy by inverter

- Product warranty: 3 years product warranty and 10 years warranty on the brake system. The guarantee is only valid if the operating conditions, inspection and maintenance intervals as described in the owner’s manual are followed

- Smooth and silent operation

- Acceleration and stop time of trolley are adjustable

- Extremely maintenance-friendly

ER2 WIND

-

KITO ER2 electric chain hoist is a reliable and robust device which is used for all demanding applications such as wind turbines.

KITO’s high performance ER2 Electric Chain Hoist Series are striving for the first place in the industry when it comes to safety, longevity and maintenance. The ER2 is characterized, in particular, by its high product spectrum, offering the customer an array of choices.

An important component of this production depth is the load chain, which differs appreciably from that of its competitors. KITO is the only manufacturer in the world to nickel-plate its load chain. The advantage of these products are higher corrosion resistance and lower wear compared to traditional load chains.

For your wind turbine- Load capacity up to 800 kg fixed. Higher load capacities on request

- Operating voltage: 3 phase 400/690 V, other voltages on request

- Lifting height up to 150 m, other lifting heights on request

- Lifting speed up to 28 m/min

- Classification FEM 1Bm, ISO M3, other classifications on request

- Thermal motor protection PTC

- IP Protection Class IP55

- Fan-cooled motor

- Electromagnetic brake or pull rotor brake

- Load Sheave: 5 or 6 pockets (depending on product model) for very smooth operation

- Device suspension: Top hook or connector can be easily assembled and disassembled

- Die-cast aluminium body with stable structure

- Hook protector to cover the load hook, made of foam, clearly visible

- Load hook pivots by 360° to avoid kinking and twisting of the load chain

- Push button pendant with ergonomic design

- Nickel-plated load chain Grade T, series V (G100) in accordance with standard EN818-7, Strength 1,000 N/mm2

- Chain stopper

HAND CHAIN BLOCKS

- Pull your weight – and way more. The hand chain Blocks prove their unmatched pulling power in the most extreme conditions. Exceptional, heavy-grade components make these long lasting workhorses that tackle severe -40˚ C to +60° C temperatures wether in the coldest northern climates the hottest deserts.

CB steel body

-

Long-lasting and reliable

KITO CB (M3 Model) series manual chain hoists are built with premium-grade components for long life in the toughest industrial and contracting applications. The CB series manual chain hoists are compact and light, yet extremely durable, with industry-leading quality.

The CB manual chain hoists have a shock-resistant gear casing, double ratchet spring, precision gears and double casing to protect against dust and water, secure and reliable mechanical brake, load chain guide and a nickel-plated load chain with long service life. The load chain has a break strength of 1,000 N/mm2 and corresponds to class V according to DIN EN 818-7.

With this high-performance chain hoist series, KITO has extended its product range by offering to its customers a higher degree of functionality, safety and customer utility.

Product advantages- Thanks to their modular construction, the units are suitable for upgrade to greater load capacities.

- TVariable load-bearing capacities are available on request

- TA high-performance precision gearbox ensures that the force which has to be applied to raise the load with the hand chain is kept as low as possible.

- TAs an option an overload limiter is available which limits the degree the hoist is overloaded and increases the safety of the user by means of the integrated slip clutch mechanism. When an excessive overload is detected, the slip clutch engages. The load remains stationary and cannot be lifted anymore regardless of any additional hand force applied.

CB ATEX

-

Long-lasting and reliable also in potentially explosive environments – the KITO CB ATEX

With the manual chain hoist CB ATEX KITO EUROPE extended its product portfolio by a special product variant in explosion-protected design. Especially in areas in production and storage where mixtures of gases, vapours and dust may form an explosive atmosphere in combination with air, KITO has designed a chain hoist for operation in working environments with explosive atmospheres. Hereby KITO ensures the qualified use of the KITO CB ATEX chain hoist series conforming to the ATEX Directive 2014/34/EU. Available for use in T4 temperature environments, the hoist offers safety and security to a wide variety of users.

The essential advantages of the CB ATEX are its easy handling, long service life, and reliability. The product offering covers 500 kg – 3,000 kg capacities, with higher capacities available upon request. The standard lifting height is between 3 and 3.5 m. Variable lifting heights are available on request.

This chain hoist series is primarily targeted at heavy duty users, with several unique design features benefitting these customer segments. Ideal applications include use in petrochem, offshore oil and gas rigs, chemical, mining, paint booth and similar environment applications.

Suspension types include top hook, plain trolley and hand geared trolley configurations. When supplied with a trolley suspension, the CB ATEX line includes solid bronze wheels through 2,000 kg capacity, and bronze coated wheels in the 3,000 kg model. With a hand geared trolley, stainless steel hand chain is standard.

One of the most unique features is the robust body size compared to lighter-duty competitor’s models which is fitted with double-reduction gearing. Moreover, KITO’s CB ATEX series stands out with a brake design twice the size and durability of competitive units, resulting in less heat buildup and allowing longer lift lengths than other models. Furthermore, the hoist offers a special mechanism of sealed ball bearings, that increase mechanical strength. The CB ATEX series has a copper coated bottom hook and latch, super-premium nickel plated load chain, and a stainless steel hand chain.

Product advantages- Allows the operation in potentially explosive atmospheres conform to ATEX Directive 2014/34/EU

- Increased safety for temperature limit range: maximum equipment temperature 135 °C, according to temperature class T4

- Safe operation in potentially explosive atmosphere, protected against explosive gases, vapours and dust

CB High Speed

-

The Strong One for Heavy-Duty Applications

Increases in lifting / lowering speed by seven times the normal speed – that is the KITO Manual Chain Hoist Series High Speed CB. The High Speed CB is ideally suited for applications where a load is repeatedly placed, and the empty hook is returned. The revolutionary load-sensing mechanism provides the user with significant time and cost savings (reduced manpower by 3.5 times), improved worker productivity, reduced worker fatigue and higher worker safety.

The most common applications are power plant maintenance, heavy construction sites, large commercial construction, petrochemical and chemical plants, offshore & onshore oil, shipbuilding, heavy steel fabricating, and other temporary or jobsite uses.

Product advantages- Planetary gear system enables 7 times faster lifting and lowering speed

- Reduced manpower of the user by 3.5 times

- Maintenance-free sealed bearings

- Heat-treated gears and load bearing parts are hardened for long, trouble-free life

CF aluminium body

-

Extremely resistant – also in agressive environments – the KITO CF

The KITO CF is a manual chain hoist with an extremely robust closed Aluminium die-cast body that particularly features a long service life and reliability. This also suggests its special areas of application, since the CF is mainly used where there is exposure to aggressive environments. Thus you will find this hoist in operation in industry sectors like heavy construction, maintenance operations, repair and refurbishment, piping installation, and similar applications. For the user this means significant time and cost savings, an increase in productivity and a considerably smaller workload.

KITO’s CF is CE marked and conforms to all applicable machinery directives. The product offering covers 500 kg – 3 t capacities, in the lift lengths of 3 and 6 meters. Weighting just up to 28 kg the CF stands up for its ease of handling und portability.

The KITO CF is unique with its single reduction gearing that results in lifting speeds up to 28 % faster than typical manual chain hoists. Moreover it is built with double pawl springs, and heavy duty heat-treated pinion and gears. The gear shafts with ball bearings minimize the friction forces so that the pulling forces from the user on the hand chain reaches the load without some of it being lost. This optimized force transmission guarantees ease of operation.

The hoist is also extremely maintenance-friendly. Only four screws have to be removed to gain access to the gearing, the load chain pinion and the braking mechanism. So maintenance can be carried out quickly and precisely.

Like all KITO chain hoists, the CF comes standard with highly corrosion resistant KITO brand grade 100 load chain. The chain is nickel plated and has an ultra-smooth surface that results in reduced link-to-link wear, and increased lifetime.

Product advantages- Step up to KITO quality and safety

- Increased productivity

- Significant time and cost savings

- Less hand force through maintenance-free ball bearings

- Durable with a lightweight and extremely robust design

- High protection against dust, water and other external influences

CX mini hoist

-

Compact, lightweight and simple design

With a weight of 2.4 kg, a minimum height of 217 mm and a load capacity of 250 kg, the KITO CX003 manual chain hoist is one of the smallest and lightest chain hoists available. Followed by CX005 with a weight of 4.5 kg, minimm height of 260 mm and 500 kg load capacity. What is more, with its advanced industrial design the CX received the sought-after price of the “Good Design Awards”, which was awarded by the Japan Industrial Design Promotion Organisation in October 2008.

The small CX003 is the size of a beer coaster and is the preferred choice wherever repair work has to be carried out and the fitter has to carry the unit with him. This could be in the area of mechanical engineering, for the replacement of defective parts, or for stage construction.

The aluminium casing is finely worked and fitted with countersunk bolts. The manual chain hoist is fitted with overload protection as standard equipment. The mechanical braking system, the load chain guide and the nickel-plated load chain for longer service life are other special features. Further advantages are easy handling, durability and reliability.

The unit has an operating force of only 14.7 daN, making it one of the easiest hoists in the world to operate. Both, CX003 and CX005, naturally feature overload limiters as standard equipment and these come into effect at 130 to 170 % of the maximum load capacity. In other words, when an attempt is made to lift a load which exceeds the load capacity, the hand chain slips through so the load cannot be raised.

The load chains, with a diameter of 3.2 mm, and the fine chain pitch allow adjustment of the hoist in a unique manner, permitting lifting movements with millimetre precision. The unit can be operated at temperatures from −40 °C to +60 °C. Another special feature of this hand chain hoist is the excellent chain guidance, thanks to an improved chain pass.

Product advantages- Easy and smooth operation with minimal hand-pull force

- Light-weight with the size of a beer coaster

- Ideal for work in tight quarters

- Overload limiter as standard

- Abrasion and corrosion resistant, extremely durable

SHB ultra-low headroom

-

The KITO Manual Chain Hoist Series SHB – High performance even in tight spaces

With the SHB (Short Headroom Block) KITO EUROPE has created one of the shortest trolleys offered on the market to date. With a hook dimension of only 115 mm, in the one ton load capacity range, this hoist permits its use also in extremely reduced spaces with low head rooms. The trolley with cast trolley wheels distinguishes itself by its swift and reliable operation.

As customers were repeatedly facing the problem of there being absolutely no more headroom for upward movement, KITO responded to the needs of its customers and the market and

developed a chain hoist with ultra-low headroom. As with the other KITO products the focus was directed at functionality bearing in mind the technical requirements of the individual customer.

Closer investigation showed that the problem of restricted lifting height often arose, for example, where machines had to be lifted for maintenance purposes, but the extremely small

space between the machine and the ceiling did not permit this. Another application is in the paper industry, to shorten the down time needed for essential maintenance work and to get

production going again quickly. The short trolley is permanently installed, so it is always available for this purpose. Naturally, there are various other application problems which could be solved with the short trolley SHB.

The basic unit is a hand chain hoist, the well-known model M3 from the CB Series. The SHB works with two load chain falls. Four falls are only needed for the load capacities of 7.5 t and 10 t. The basic unit has an impact-resistant gear housing, double ratchet springs, a precision gearbox and double casing for protection against dust and water, a safe and reliable load pressure braking system, load chain guidance and a nickel-plated load chain

for long service life. In short, its easy handling, long service life and reliability make the short trolley SHB the obvious choice.

Product advantages- Extremely low-profile hoist: ideal for demanding industrial lifting applications where space is extra tight, small cornering radius

- Easy and maintenance-free operation

LEVER HOISTS

- The lever hoists forged an entirely new, industry-leading benchmark by being smaller, lighter and stronger than any other lever hoist on the market. Its proven strength and durability stand up in an endless array of gruelling applications, including environments where temperatures drop to a bone-chilling -40 C and soare to a scorching and unbelievable 60° C.

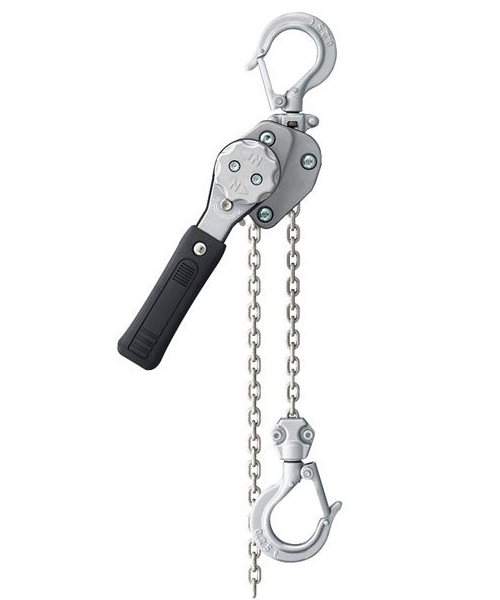

LB

-

KITO’s Lever Hoists LB – the work-horse of the manual chain hoists

Ideal for pulling, lifting or tensioning the KITO Lever Hoist Model LB stands out with its high performance and can handle even the most difficult challenges facing the industry. This is for instance the case in sectors like ship-building where sheet metal plates are pulled into place or where beams and girders have to be connected together and everywhere where precision work in very confined spaces is particularly important.

What is more, with its advanced industrial design the LB received the sought-after price of the “Excellent Product Awards”, which was awarded by the Japan Society of Mechanical Engineers (JSME) in 2009.

The Lever Hoist LB is available with load capacities from 800 kg to 9 t. For loads of up to 3.2 t, it operates with one chain fall, at the 6.3 t with two chain falls, and the 9 t hoist with three chain falls. The graduation of load capacities ranges from 0.8 t to 1.0 t, 1.6 t, 2.5 t, 3.2 t, 6.3 t and 9 t. This makes KITO one of the few firms to supply hoists with load capacities of 1.0 t and 2.5 t.

By using double reduction gearing and a patented induction hardening process on load bearing parts, the hoists weight and size is reduced while improved overall strength. As a result, you can use less hand force to operate and enjoy improved portability.

With a steel body frame, forged carbon steel hooks and corrosion resistant nickel-plated load chain the LB Lever Hoist stands up in the most demanding industrial and contracting applications. Since load gearing parts, at rated capacity, are only stressed to 25% of their limit, you can operate the hoist with confidence over a long period of time.

A unique feature is the freewheel mechanism with overload protection. In conventional variants, it is possible that due to inadvertent operation of the lever by the operator, the freewheel function is accidentally activated, leading to, in the worst case, to the load being dropped. This is impossible with the KITO Lever Hoist LB, as it is fitted with a freewheel knob. This has to be engaged by gentle pulling to activate the freewheel function and release the chain for adjustment.

Product advantages- Suitable for continuous operation under the most severe conditions

- Maintenance friendly: The LB’s open body design allows for easy inspection and cleaning without dismantling the unit.

- Through its light weight and reduced headroom: ideal for the use in confined spaces

LB-OF

-

More Safety with the KITO Lever Hoist LB-OF without freewheel chain adjusting mechanism

With the lever hoist LB-OF (without freewheel chain adjusting mechanism) KITO EUROPE extends its product portfolio by another safety variant where the freewheeling mechanism is generally deactivated.

A key consideration in the product design for KITO was the safety aspect. This also bears fruit in the outward appearance of the hoist. As a visually recognizable difference to the Lever Hoist Series LB, which has an ocre-coloured freewheel knob, the LB OF is fitted with a blue knob that shows that this hoist is equipped without a freewheeling function. A change in the lifting height can then only be adjusted by operating the lever.

Especially for complicated and dangerous applications where dynamic forces can occur, for instance in overhead line construction, the KITO Lever Hoist particularly the LB-OF is a suitable and safe installation aid. Furthermore the hoist proves advantageous in aircraft production and maintenance where slippage of the load during the fitting or removal of aircraft parts such as engines or turbines could have incalculable consequences including huge costs or delays.

Beyond that the LB-OF offers all of the various advantanges of the KITO Lever Hoist Series LB.

Product advantages- Suitable for continuous operation under the most severe conditions

- Maintenance friendly: The LB’s open body design allows for easy inspection and cleaning without dismantling the unit.

- Through its light weight and reduced headroom: ideal for the use in confined spaces

LB-OLL

-

KITO’s Lever Hoist LB with Overload Limiter – Convenient and safe

With the lever hoist LB-OLL (Overload Limiter) KITO EUROPE extends its product portfolio by another product variant revolving around safety. The LB-OLL comes into its own wherever, under horizontal or vertical load tension, the forces arising cannot be precisely defined. For instance in shipbuilding, where sheets have to be dragged or in surface mining where the chains need to be replaced in an excavator.

So this lever hoist, with its integrated slip clutch mechanism which prevents lifting during overloading, represents a proven preventive measure. Even before the hoist starts working, the operator has a feeling of security. In the case of an overload, the overload protection allows the lever to slip. When overloaded the operator is only able to lower the load. The load is held stationary without the need for further securing and preventing the load from dropping.

A unique feature is the freewheel mechanism with overload protection. In conventional variants, it is possible that due to inadvertent operation of the lever by the operator, the freewheel function is accidentally activated, leading to, in the worst case, to the load being dropped. This is impossible with the KITO Lever Hoist, as it is fitted with a freewheel knob. This has to be engaged by gentle pulling to activate the freewheel function and release the chain for adjustment.

As a visually recognizable difference to the Lever Hoist Series LB which has an ocre-coloured freewheel knob, the LB OLL has been designed with a black freewheel knob that shows that this hoist is equipped with an overload limiter. Additionally KITO placed a special name plate on the lever of the hoist with the bilingual reference: Overload Limiter or Überlastsicherung.

Beyond that the LB-OLL offers all of the various advantanges of the KITO Lever Hoist Series LB.

Product advantages- Suitable for continuous operation under the most severe conditions

- Maintenance friendly: The LB’s open body design allows for easy inspection and cleaning without dismantling the unit.

- Through its light weight and reduced headroom: ideal for the use in confined spaces

- Equipped with an overload limiter

LX

-

The small one with undoubted benefits

With the ultralight and compact ratchet hoists of the KITO LX Series, demanding tasks like fastening, fixing and positioning of loads in the light-load range can be solved easily and effectively.

The LX is designed for loads of 250 kg and 500 kg, respectively. The ratchet hoist is mainly used where delicate parts have to be joined together: for example, in apparatus installation, where control cabinets are to be connected and have to be brought within a few millimeters of each other, or in the automobile workshop, for fitting and removing engines or for fitting engines and gearboxes together. This ultra-compact ratchet hoist can be used almost anywhere.

In this hoist, the focus is on its compact form, small dimensions and light weight, thanks to its aluminium housing. The LX003 weighs 1.7 kg, the LX005 2.7 kg. That means that the ratchet hoist, together with the belt pouch in which it can be stowed and carried, is always available and immediately ready for use. Another advantage is the fine tolerance load chain, in the LX003, for example, with a load capacity of 250 kg and a diameter of only 3.2 mm. This allows extremely precise lifting. When the lever is operated, a lifting movement of approx. 2 mm takes place for each click. The hand lever has a length of only 150 mm, so that, where there is absolutely no more space available, this device can still demonstrate its functionality.

A further feature is the chain overrun mechanism with load drop protection. When a load is suddenly applied in freewheel mode, the brake engages instantly and reliably.

Considering their many advantages, the high performance, the dimensions, the weight, the aluminium housing, the low lever force, the load drop protection and the wide range of uses, the ratchet hoists LX003 and LX005 are unique in the market.

Product advantages:- Extremely compact, lightweight, portable design

- Ease of use in tight quarters or in elevated work locations

- Ideal for the fastening, fixing or positioning of light loads

- Maintenance-friendly, corrosion-resistant and highly durable

- Free chain adjusting mechanism for highly reliable lifting

TROLLEYS & ACCESSORIES

-

Trolleys play an integral role when moving loads from one location to another. This is done using three main methods, i.e. push, geared and electric trolleys. In many cases it is also important to have a fixed anchor point for example on a beam using a clamp.

Please come in and view our state of the art electric MR2 trolley.

MR2 motorized trolley

-

KITO’s Motorized Trolley Series MR2 – Extremely user-friendly and highly efficient even under the harshest conditions

Everywhere loads need to be lifted and transported safely and precisely the KITO MR2 Motorized Trolley Series is the perfect choice. In combination with the ER2 Electric Chain Hoist Series KITO offers the perfect symbiosis for all sorts of lifting and travel applications.

The KITO MR2 trolleys are easily attached to a wide range of beam flange sizes (flat-flanged or tapered beams) up to a beam width of 300 mm. For more information please do get in touch with our Customer Service Support.

The MR2 Trolleys Series offer as standard equipment sealed protection of the trolley (IP55) which contributes towards the utilisation of the hoist also under harsh outside conditions.

As KITO’s motorized trolleys are available from 125 kg to 5 tons capacity you can choose the capacity that meets your individual needs. Higher capacities are available on request. The MR2 is available with single traversing speed and contactor control or with dual traversing speed by means of a frequency inverter. The product variant with the frequency inverter is perfectly suited for handling sensitive loads as it provides for particularly smooth start and stop movements.

The MR2 trolleys feature an extremely durable and reliable pull-rotor motor brake for a higher precision load control, deceleration and a long service life. A heavy-duty motor with high-horsepower, cooling fins and standard thermal motor protection provide top performance and enhanced efficiency of the hoist.

Different kinds of energy supply systems like for instance the KITO cable hanger or the C-rail festoon system are available on request and therefore provide protection to the power supply festooning system. Furthermore the side guide rollers are supported by four ball bearings which smoothes trolley motion and reduces wear of the wheels and beam.

Product advantages- Coverage of a variety of lifting capacities

- Suited to a wide range of applications

- Highly user-friendly

- High-performance even under harsh conditions

- Efficient load handling and precise brake control

- Smooth operation

TK beam clamp

-

Safe and robust – the KITO Beam Clamp TK Series

Another highlight under the load handling accessories is the extra durable KITO TK series heavy duty beam clamp. It is available in capacities ranging from 1 t to 10 t, and is adjustable to fit a wide range of beam flanges. In 3 t and 5 t models, two different flange ranges are available. It can be used to suspend a hoist, or attached directly to the top flange of a structural beam for lifting purposes.

This product shows strong appeal to users such as heavy construction, plant maintenance, power generation, shipbuilding, general steel fabrication and offshore industries.

Independent tests have shown evidence that the new TK series represents a unique selling point in the hoisting industry because it is suitable for angle pulling up to 45° with no reduction in WLL. With its extremely flexible handling the beam clamp is suitable for a broad range of applications.

As well, the clamp features a self-centering shaft design, corrosion resistant galvanized hardware, and a shackle that can be used for load suspension, or easily pivoted away for direct connection to the load hook.

The specially designed jaws spread the load over a larger area of the beam compared to competitive designs, reducing beam stress, and offering more security and load control.

The KITO Beam Clamp TK is the perfect accessory when a permanent or even temporary suspension point is required. It offers efficiency, cost effectiveness and a high degree of safety for various fields of application.

Product advantages- Certified for angle pulling with no reduction in WLL (for cross-beam applications up to 45 °, for applications longitudinal to the beam up to 15 °)

- Adjustable to fit a wide range of beam flanges

- Light and robust design

- Easy and flexible handling

- Increased safety and load control

- Optimized handling for textile slings

TMH mini trolley

-

The KITO TMH Mini Trolley Series – The Small one with reduced Headroom

As on option to the electric chain hoist series ED/EDC KITO offers the reliable and very robust TMH Mini Trolley Series. With a net weight of just 1,9 kg this extremely compact trolley features a lifting capacity of up to 250 kg.

Specifically designed to work with the high-speed KITO ED hoist the TMH can be used for all single-fall models of the ED. Here the user can choose between a range of flange widths from 50 up to 100 mm. The user-friendly design provides for a headroom which has been improved by 25 % compared to hook mount.

Product advantages- Easy maintenance

- Light and compact design

- Better durability

- Smooth operation

- Improved headroom by 25 %

- Reduced rolling resistance

TSG geared trolley

-

The KITO TSG Geared Trolley Series – ideal for shorter traversing distances and higher loads

The KITO TSG Geared Trolleys will help you manoeuver easily where a motion parallel to the beam is necessary. KITO’s TSG is the ultimate choice, especially for applications with shorter traversing distances and higher loads (up to 30 t). Various capacities can be implemented according to your individual needs at any time without problems.

KITO’s Geared Trolleys feature hardened heat-treated steel wheels that ensure reliable tracking and their sealed ball bearings avoid maintenance hassles and provide smooth operation.

The KITO TSG offers a very simple state-of-the-art design allowing easy configurations and multiple product options. It is also light weight so it requires less labour and time for installation, which contributes to a total cost reduction. Special protective lugs hold the trolley surely on the beam and integrated rubber bumpers guard against damage to the trolley and wheels arising from a collision with the stopper or between two trolleys.

The TSG Trolley wheels are adjustable to work with both tapered and flat-flanged beams, allowing you to use existing equipment without customization. Furthermore KITO offers a variety of trolley hoist suspenders matching the needs of diverse applications. KITO’s Geared Trolleys can be optionally combined with a suspender for close connected suspension and/ or a hook suspension type (from 5 t capacity not necessary).

For more information please do get in touch with our Customer Service Support.

Product advantages- Light and compact design

- Quick and easy handling of the load, better durability

- Smooth operation

- Easy assembly by means of trolley bolts and spacer disks

- Suited to applications involving shorter traversing distances and precise load movement

TSP plain trolley

-

The KITO TSP Plain Trolley: ideal for larger traversing distances

The KITO TSP Plain Trolleys will help you manoeuver easily where a motion parallel to the beam is necessary. KITO’s TSP easily bridges larger traversing distances for a load up to 5 t. Various capacities can be implemented according to your individual needs at any time without problems.

KITO’s Plain Trolleys feature hardened heat-treated steel wheels that ensure reliable tracking and their sealed ball bearings avoid maintenance hassles and provide smooth operation.

The KITO TSP offers a very simple state-of-the-art design allowing easy configurations and multiple product options. It is also light weight so it requires less labour and time for installation, which contributes to a total cost reduction. Special protective lugs hold the trolley surely on the beam and integrated rubber bumpers guard against damage to the trolley and wheels arising from a collision with the stopper or between two trolleys.

The TSP Trolley wheels are adjustable to work with both tapered and flat-flanged beams, allowing you to use existing equipment without customization. Furthermore KITO offers a variety of trolley hoist suspenders matching the needs of diverse applications. KITO’s plain trolley series can be optionally combined with a suspender for close connected suspension and/ or a hook suspension type. For more information please do get in touch with our Customer Service Support.

Product advantages- Light and compact design

- Quick and easy handling of the load, better durability

- Smooth operation

- Easy assembly by means of trolley bolts and spacer disks

- Suited to applications involving greater traversing distances

SPECIAL APPLICATIONS

- The requirement to design in-house processes favorable, flexible and economical is, in principle, independent of the industry. The key is that each solution is optimally tailored to the needs of the individual company. KITO is one of the few manufacturers able to offer a comprehensive range of hoists.

Electrical

-

- Electric hoist with radio remote controls, festooned wire harnesses for bridge crane retrofits, your preferred brand of pendant control, etc.

- Electric hoists with ultra-slow or ultra-fast lifting/lowering speeds

- Electric hoists with extremely long lift, such as wind tower or elevated platform

- Electric hoist and trolley for inclined monorail operation (rack & pinion drive)

- Electric hoist with secondary brake (such as molten metal applications)

Safety start-up systems (lights, sirens, PLC interface outputs)

Our normal process starts with the highest quality KITO products, customized in-house at Kito, or with the support of our network of specialized local sub-suppliers. Our technical, engineering and production departments provide to you quick and precise product solutions under any working condition.

Contact us via sales@kito.net to find out more details.

Mechanical

-

- Parking / holding brakes for trolleys

- Remote mounted hand wheel for manual chain hoists

- Special witness testing & inspections

Our normal process starts with the highest quality KITO products, customized in-house at Kito, or with the support of our network of specialized local sub-suppliers. Our technical, engineering and production departments provide to you quick and precise product solutions under any working condition.

Contact us via sales@kito.net to find out more details.

Corrosion protection and environmental

-

- C5M and other marine grade painting systems

- Stainless steel chain or hooks for manual or electric hoists

- Clean room hoists (manual or electric)

- Very high / very low temperature extremes

Our normal process starts with the highest quality KITO products, customized in-house at Kito, or with the support of our network of specialized local sub-suppliers. Our technical, engineering and production departments provide to you quick and precise product solutions under any working condition.

Contact us via sales@kito.net to find out more details.

SPARES

-

Nobody throws a KITO hoist away. In off shore applications the average life cycle of a KITO hoist is often spread over more than a decade. Where others are buried in the hoist graveyard, often becoming an environmental hazard, KITO hoists are refurbished to battle turn after turn. Spare parts guarantee a long fulfilling and satisfying life working hard for their users.

KITO Spare Parts – Ensure long service life of your KITO hoist

KITO’s genuine replacement parts and load chains are critical for the safety, durability and performance of KITO hoists.

Strict quality controls and testing conditions by our mother company, KITO Corporation, as well as carefully selected materials of all the KITO Spare Parts ensure the longest possible life for your KITO hoists. In order to ensure warranty terms and perfect operation, we recommend you use only KITO high-quality nickel-plated load chains. LOAD CHAIN

-

With the KITO load chain you’re always in safe hands. A quality that delivers what it promises!

KITO is one of the few companies that manufactures both its hoists and its load chains. On top of that – KITO is the only manufacturer worldwide that nickel-plates its load chains. This combination provides the hoists with the unique benefit of safety and functionality, and excellent reliability.

The precise manufacturing quality of KITO products is realized through following demanding production and inspection procedures that exceed the highest existing International safety standards. Therefore KITO load chains are in demand on all parts of the world.

KITO’s nickel-plating process prevents hydrogen embrittlement, as the chain material can be penetrated by hydrogen molecules. Thanks to its special properties, nickel is especially well suited as a surface coating for many applications, such as the windmill and offshore industries.

The load chains are electroless nickel-plated and feature an increased corrosion and abrasion resistance in comparison to zinc-plated load chains. The nickel-plated load chains characterize a breaking strength of 800 or 1000 N/mm2 respectively and bring additional advantages to the user such as wear resistance and a long service life. The load chains comply with the quality class DAT or V, respectively.

KITO’s load chains fully comply with the standard EN 818-7 and have been certified by the trade association BGHM (Institution for Statutory Accident Insurance and Prevention in the Woodworking and Metalworking Industries). Furthermore KITO received for all of its produced load chains the official certification stamp H23.

Product advantages- Only company that manufactures both its hoists and its nickel-plated load chains

- According to norm DIN EN 818-7

- Longer service life

- High reliability

- Minimal maintenance