- Offer Profile

-

Mobile Industrial Robots is a leading manufacturer of collaborative mobile robots

We are dedicated to developing user-friendly, flexible and safe robots to help companies increase the efficiency of their operations. Our autonomous robots are a new generation of advanced mobile robots which give you a rapid return on investment, often with a payback period of less than a year. These unique, collaborative robots are now used by manufacturers in a wide range of industries and healthcare sectors to automate their in-house transportation.

As a first mover in the field, we have enjoyed a rapid, worldwide adoption of our unique and innovative robots. Mobile Industrial Robots is an international and ambitious company, having dedicated employees who are passionate about making a difference and creating success and innovation within the world of robotics. We are represented worldwide with branch offices and through an extensive distributor network which are dedicated and delighted to receive your inquiry and support you.

Autonomous Mobile Robots

-

The mobile robots from MiR are autonomous mobile robots (AMRs) designed to optimize productivity in logistics and manufacturing operations. The MiR AMRs make your employees more efficient by allowing them to focus on higher-value activities, while shortening lead time, reducing the risk of bottlenecks, and optimizing safety.

The key features of AMRs

Key features of our robots include safe collaboration with people, obstacle avoidance, and compliance with safety standards. We offer customization options, scalability, and efficient fleet management. Our robots excels in route optimization, supports multiple pickup points, and is easy to integrate. It allows for fast and cost-effective deployment with user-friendly programming. Additionally, it fits into diverse environments, including narrow spaces and elevators.

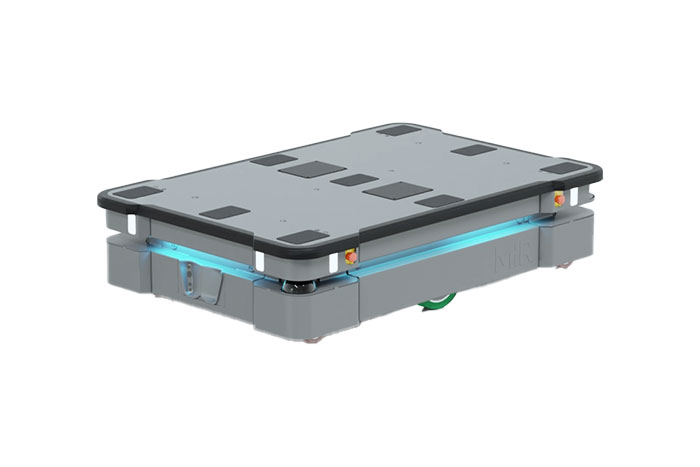

MiR250

- Small and powerful

The MiR250 has a small footprint of just 580 x 800 mm and stands at a mere 30 centimeters tall. Despite its size, it can effortlessly handle up to 250 kg, moving along at 2 meters per second. This agility sets it apart from all other AMRs on the market, making it exceptionally adaptable to demanding environments.

Thanks to its compact design, it can navigate through spaces as narrow as 80 centimeters. This means that doors and elevators, which might pose challenges for other mobile robots, are a breeze for the MiR250.

Built for the long haul, the MiR250 is designed for easy maintenance and can operate around the clock, with the option for swift battery replacement. Moreover, it adheres to the latest safety standards - we therefore believe it is the safest AMR on the market.

If you have the need the MiR250 also comes in an ESD version

MiR600

- Elevate your productivity of pallet movement with MiR600

Equipped with pallet lifts, the MiR600 can pick-up, transport and deliver pallets throughout your facility, completely autonomously. The MiR600 is designed to comply to the latest safety standards and is a safe alternative to forklifts.

With the power to move loads up to 600 kg, speed of 2 m/sec and the ability to quickly maneuver in crowded areas, the MiR600 offers you a way to optimize logistics workflows significantly.

Along with the powerful MiR1350, MiR600 is the first IP52-rated AMR in the market. With increased ability to withstand dust particles and waterdrops the MiR600 can be used in more challenging environments than other AMRs.

- Moves 600kg payloads at speed of 2 m/s in demanding environments

- IP52 - improved ability to withstand dust and fluids

- Designed to comply with latest safety standards - ISO3691-4

MiR1350

- The MiR1350 is compliant with the highest available robot standards making it superior to other AMRs on the market.

Maximize efficiency with MiR1350, the robust AMR featuring a 1350 kg payload capacity.

This AMR excels in automating heavy load and pallet transportation, eliminating the need for traditional, potentially hazardous forklifts.

Equipped with state-of-the-art technology and 13 TüV certified safety features, MiR1350 ensures optimal safety and is designed to comply with the latest safety standards.

With MiR600, this is the first IP52 rated AMR, designed to withstand dust particles and waterdrops, for navigating challenging environments where other AMRs cannot enter.

- High payload enabling transportation of pallets and heavy goods

- IP52 rated - improved ability to withstand dust and waterdrops

- Designed based on present safety standards - ISO3691-4 and with 13 TüV certified safety features

MiR1200 Pallet Jack

- Smarter moves, faster results; MiR1200 Pallet Jack dominates pallet handling

The MiR1200 Pallet Jack revolutionizes internal pallet transportation, automating detection, transport, and delivery of EU pallets up to 1200 kg at 1.5 m/s. Its groundbreaking AI-based perception system sets it apart, reducing pick-and-place cycle times significantly and elevating throughput.

This agile robot operates continuously, with shift-long battery capacity and seamless opportunity charging for uninterrupted performance. Navigating tight spaces effortlessly, it optimizes logistics efficiency, ensuring timely pallet delivery without additional infrastructure.

Perfectly integrating into various value streams, from warehouse operations to core production processes, the MiR1200 complies with the latest safety standards. It safely navigate around people and other obstacles and constitutes a safe alternative to traditional forklifts and pallet trucks. With user-friendly software and quick scaling through MiR Fleet, deploying and managing this solution is straightforward, making it the ultimate blend of precision, performance, and productivity.

- AI-based perception for fast, precise and reliable pallet detection

- High battery-capacity and fast charging for working in 24/7 workflows

- Complies to present safety standards - ISO3691-4

Features:

- Pallet Detection

- Safety

- Signal lights

- High battery capacity

- Ease of use

MiR Applications - MiR top modules for MiR250

-

MiR robots are open platforms, designed to be incredibly versatile and adding top modules to them can make them even more useful for your business.

If you need a robot that can tow carts or lift and transport shelves or pallets, MiR has you covered with our pre-made solutions.

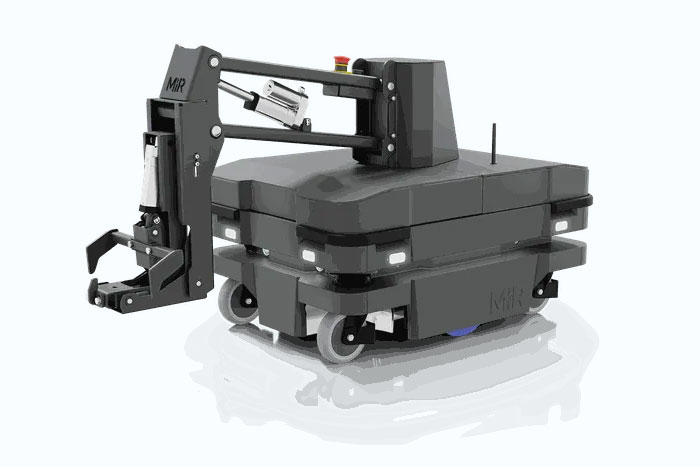

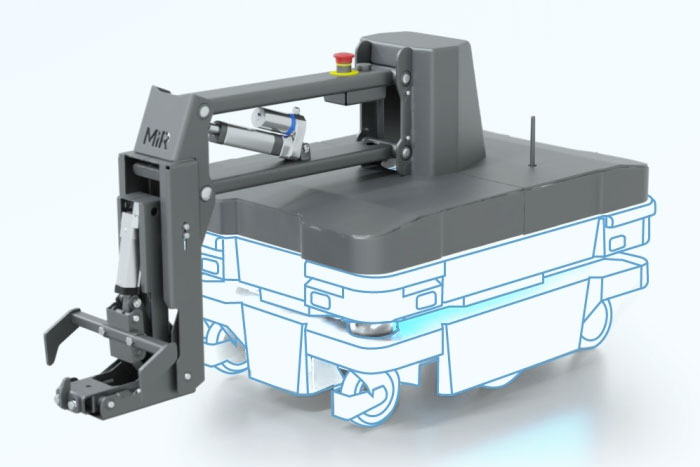

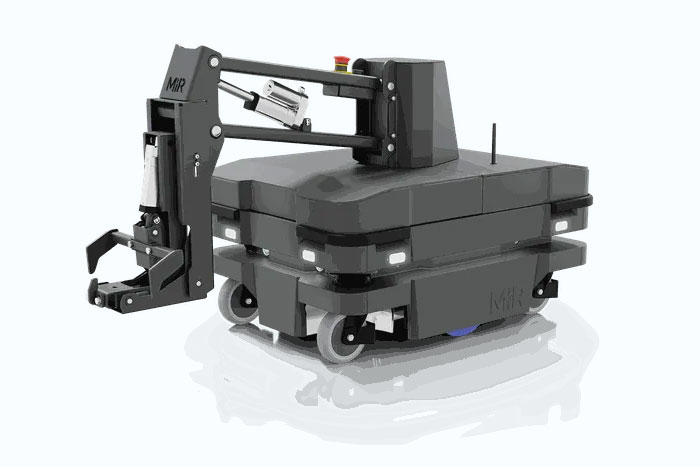

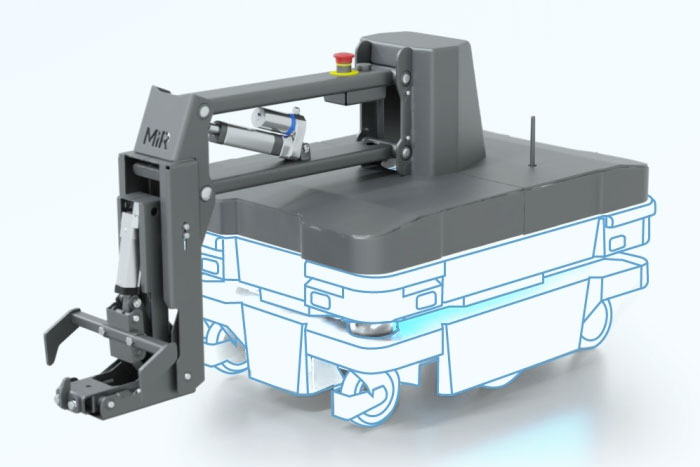

MiR Hook 250

-

Looking to streamline your internal transportation tasks?

Meet the MiR Hook 250 - a game-changing mobile robot solution for the MiR250 robot that can help you achieve maximum efficiency! With its patented extended-payload design, this user-friendly and highly efficient robot top module can pick up and tow carts in production, logistics, and healthcare settings with ease.

The MiR250 Hook robot identifies carts by April Tags and it can pick up carts with different heights, and autonomously transports them as you define. This means that you do not have to change your existing carts, you just need to add an April Tag and the MiR250 Hook solution will be able to transport them effiently.

Thanks to its leading-edge software and advanced MiR250 base, the MiR250 Hook is fast and agile, making it the perfect solution for those looking to boost their performance.

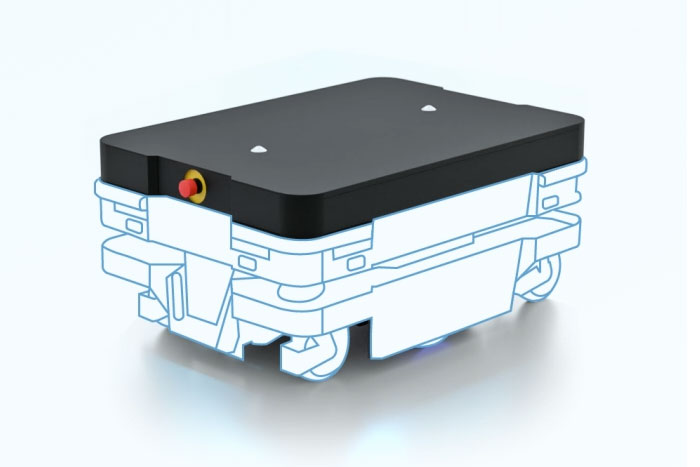

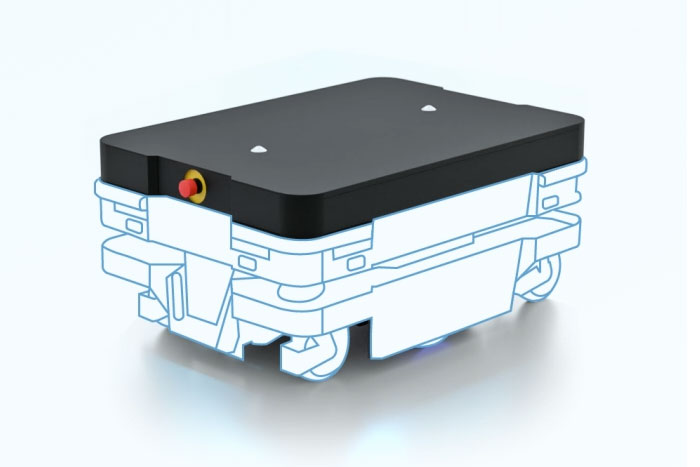

MiR Shelf Carrier 250

-

Ensure maximum utilization of your MiR250 robots with the MiR Shelf Carrier 250.

The MiR Shelf Carrier 250 top module is a standard module, which fits to the MiR250, enabling the robot to collect and deliver shelves, carts and other applications.

With the MiR250 Shelf Carrier solution, you can efficiently transport and deliver multiple carts and shelves across your facility. This approach optimizes the utilization of your MiR250 robots, surpassing the limitations of fixed shelves directly mounted on the robot.

MiR top modules for MiR600

MiR EU Pallet Lift 600

-

Looking to make your pallet handling more efficient?

MiR EU Pallet Lift 600 for the MiR600 AMR is your solution. This system empowers the MiR600 to autonomously lift and transport EU pallets, offering stable handling with payloads up to 500 kg. This enables you to optimize pallet transportation effortlessly without the need to alter your facility layout.

The MiR600 operates at 2 m/sec (7.2 km/hour), ensuring efficient transport times while still navigating completely safely in your environment, with no need for wires, magnets or QR codes.

MiR Shelf Lift 600 - Autonomous Cart Handling

-

Looking to optimize your heavy load transportation?

Experience streamlined heavy load transportation with the MiR Shelf Lift top module for the MiR600 and MiR1350. This enables MiR’s heavy-duty robots to autonomously pick up and deliver carts and shelves.

This solution ensures flexibility in transporting loads of various sizes and pallets without the need for a pallet rack. One robot can efficiently handle multiple carts, offering a versatile solution for your logistics needs.

MiR Pallet Lift 600

-

Looking for a flexible way to transport your pallets?

A MiR600 equipped with the MiR Pallet Lift 600 top module is your solution! The MiR Pallet Lift 600 top module securely handles different sizes on pallet, e.g. 40" x 48" pallets, and other loads, enabling MiR600 to autonomously lift and transport payloads up to 500 kg.

This solution will help you optimize pallet transport without the need for facility changes. MiR600 with Pallet Lift 600, autonomously moves pallets at 2 m/sec ensuring a fast throughput, and frees up staff for higher valuable tasks.

MiR top modules for MiR1350

-

It is easy to mount your top modules on the MiR robots. It is also easy to find different top modules via the worlds’ largest eco-system for AMRs, MiR Go. Here you’ll find +160 solutions for our versatile AMRs – check it out, maybe you see just the solution you need to optimize your workflow.

MiR EU Pallet Lift 1350

-

Need a stable solution for transporting heavy pallets?

The MiR EU Pallet Lift 1350 top module ensures stable handling and transport of your pallets. It enables the MiR1350 to lift pallets autonomously from the MiR EU Pallet Rack and lowers the pallet for stable transportation of payloads up to 1250 kg.

With the MiR EU Pallet Lift 1350, the MiR1350 picks up, transports and unloads pallets autonomously, freeing up employees for more valuable tasks.

Quick facts about MiR1350 EU Pallet Lift:

- 1.2 m/s Max speed

- 10.5 Hours Run time

- 1250 kg Payload

MiR Shelf Lift 1350

-

Looking to optimize your heavy load transportation?

Experience streamlined heavy load transportation with the MiR Shelf Lift top module for the MiR600 and MiR1350. This enables MiR’s heavy-duty robots to autonomously pick up and deliver carts and shelves.

This solution ensures flexibility in transporting loads of various sizes and pallets without the need for a pallet rack. One robot can efficiently handle multiple carts, offering a versatile solution for your logistics needs.

- Use MiR Shelf Lift for MiR600 and MiR1350

- Payload: Move carts up to 500 kg with MiR600 and up to 1250 kg with MiR1350

- Carts: One robot can handle multiple carts with MiR Shelf lift

- Navigation: No need to alter your facility layout thanks to autonomous navigation

- Safety: Works safely in dynamic environments

MiR Pallet Lift 1350

-

Looking to optimize safety and efficiency of your pallet handling?

Look this way! Facilitating transportation of various pallet sizes, including 40" x 48", the MiR Pallet Lift 1350 top module empowers the MiR1350. This autonomous system efficiently lifts and lowers pallets from the MiR Pallet Rack, ensuring stability during transportation of payloads weighing up to 1250 kg.

This solution with enable your employees to focus on more valuable tasks, as the MiR Pallet Lift 1350 allows the MiR1350 to autonomously handle the pickup, transport, and unloading of 40" x 48" pallets, taking over the dull, dirty and dangerous tasks of the workforce.

Quick facts about MiR1350 EU Pallet Lift:

- 1.2 m/s Max speed

- 10.5 Hours Run time

- 1250 kg Payload

MiR Accessories

MiR Charge 48V

-

Looking to streamline your internal transportation tasks?

MiR Charge 48V is a fully automatic charging station that lets MiR250, MiR600 and MiR1350 robots autonomously reload their batteries as needed. This small, non-intrusive charging station uses standard power and can be easily integrated into almost any environment. Keep robots running around the clock

Your MiR250, MiR600 and MiR1350 robots will never run out of power in the middle of a job. MiR Charge 48V is a fully automatic charging station that offers flexible deployment options to meet your needs.

Collaborates with MiR Fleet

The robot autonomously returns to the charging station and connects when its battery falls under established limits. It can also be programmed to regularly recharge between deliveries, such as when it returns to a stockroom or depot, which can allow the robot to run nearly continuously. MiR Charge 48V fully charges a MiR250, MiR600 or MiR1350 robot in about one hour. When multiple robots are deployed using MiR Fleet, the system evaluates battery levels and job loads, optimizing utilization and recharging to keep the fleet on the job around the clock.

MiR Pallet Rack

-

Optimize pallet transportation

MiR Pallet Rack is the delivery station for your 40" x 48" pallets and other sizes of pallets. It enables the MiR600 and MiR1350 to autonomously collect and deliver pallets with the MiR Pallet Lift, for stable transportation of payloads up to 1250 kg.

Optimize pallet transportation without changing facility layout

When equipped with MiR Pallet Lift, the MiR600 or MiR1350 can drive into the delivery station MiR Pallet Rack to pickup or deliver pallets safely, efficiently and in a completely autonomous way, freeing up employees for more valuable tasks.There is no need to change the facility layout when operating MiR robots as the function of wires, magnets or QR codes is replaced by sophisticated navigation software.

Simply download CAD files of the facility to the robot or use its laser scanners to create a map - that’s all it takes to ensure a fast and cost-efficient implementation.

MiR Go

-

Extend the functionality with MiR Go top modules

In the fast-paced world of manufacturing, MiR offers a strategic advantage to forward-thinking organizations.

At our core, MiR is an open robot platform, finely tuned for seamless integration into daily operations. We leverage our extensive knowledge of internal logistics automation and our expertise in software, navigation, and workflow optimization.

In manufacturing facilities, where the demand for heightened efficiency, productivity, and innovation is ever-present, MiR Go serves as a powerful resource and inspiration hub. It houses applications and top modules tailored for seamless integration with MiR's suite of robots, delivering a substantial operational boost.

MiR Go is an exclusive ecosystem of over 160 off-the-shelf applications, designed and engineered to enhance the capabilities of MiR robots. With MiR Go Certified, a supplementary to MiR Go, you can rest assured that these applications have undergone testing by us, encompassing functionality, safety, and mutual change control. This ensures that MiR Go Certified products integrate seamlessly with MiR robots, upholding our high quality standards.

The key benefit of MiR Go is its ability to seamlessly customize MiR robots with off-the-shelf solutions, providing flexibility that empowers your company to excel in automation, embrace the future with confidence and a competitive edge by harnessing the full potential of MiR and MiR Go.

Find all of our MiR Go top modules:

Nord Modules Wheel Gate

-

Automation simplified: Click, pick, go

The Wheel Gate merges with the Quick Mover, creating a fully automated system. The Wheel Gate can receive or hold an object, connecting the MiR robot with production lines and storage systems.

An integrated stop function and manually controlled wheels on the gate make it easy for employees or the mobile robot to push payloads to the pickup point or into the production line. The purpose is to further automate internal logistics and increase productivity. Due to the optimized distance between the arms, the modules deliver great flexibility in terms of load sizes – from small to large items.

Nord Modules QM220, Quick Mover

-

Quick Mover: Efficient material handling made simple

The Quick Mover is capable of transporting goods as well as picking up and delivering the Shelf Cart SC200. The top module is mounted on top of the mobile robot and functions by a lifting mechanism integrated into the module.

Nord Modules - Pallet Lift EU

-

Streamline your logistics and elevate your productivity

Optimize your internal logistics by automating the internal transportation of pallets with the Nord Modules EU Pallet Lift Top Module. Nord Modules EU Pallet Lift autonomously picks up and delivers pallets in the Pallet Rack.

Stable handling and transport of EU size pallets. It enables the MiR AMRs to lift pallets autonomously from the Pallet Rack and lowers the pallet for stable transportation of payloads up to 1250 kg.

Enabled Robotics - MC600

-

Maximize productivity with the versatile MC600

The MC600 mobile cobot helps companies to automate internal logistics processes. The integrated software for developing smart applications means companies can use the MC600 for many different tasks, such as:

- Machine tending in a loop sequence (24/7-365) to reduce downtime;

- Line-site delivery

- Transporting and handling materials to reduce the burden of repetitive tasks and ensure traceability; and

- Replenishing supplies so employees can spend their valuable time solving other tasks.

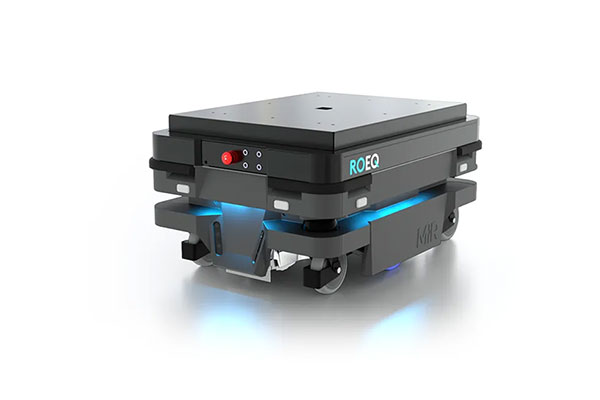

ROEQ - TMS-C300 Ext

-

Increased payload handling with the TMS-C300 Ext Cart

Developed as part of a full ROEQ cart solution to collect, transport and deliver pallets, skids, boxes etc. in free space. The ROEQ TMS-C300 Ext top module works together with the ROEQ S-Cart300 series on the MiR250 for payloads up to 300 kg.

The extended top module has been designed with safety in focus, with easy access to the emergency stop even when carrying pallets and other loads up to 120 cm.

Rails for the carts are available for transporting EU and US pallets and the carts have attachment holes for adding other customized equipment. A two year warranty is offered, when this top module is bought and used together with the ROEQ S-Cart300 series.

All ROEQ top modules come with the ROEQ Assist software tool which is fully compatible with MiR software. It reduces the integration time needed, assisting the setup of the system, and creating the right footprints for the robot to facilitate safe navigation. The tool builds standard missions to get you up and running faster.

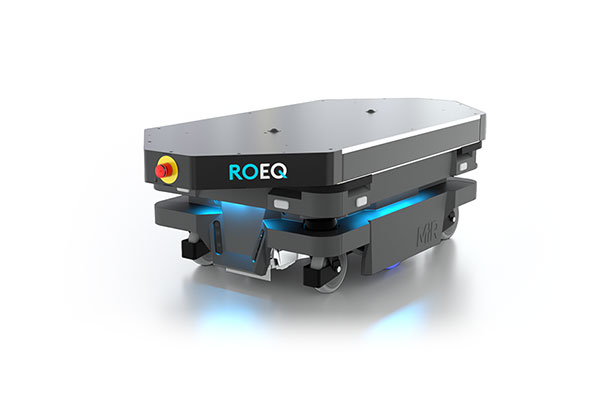

ROEQ - TML200

-

Simplify your logistics by seamlessly lift and transport

The ROEQ Top Module Lifter TML200 for the MiR250 is a flexible top module that can lift, transport and drop off pallets, crates and racks, as well as shelf carts. A versatile solution for transporting different types of loads with only small adjustments.

For equipment and accessories designed to work with the TML200, see TML200 Forks, PR250 Pallet Rack, S-Cart300L and IO kit TML200.

Nord Modules - Dock Target

-

The Dock Target from Nord Modules works with Nord Modules Pallet Mover and allows for docking of the AMR and safe loading/unloading of pallets to and from an existing conveyor line.

The Dock Target is installed at the end of a conveyor line and is adjustable in height.

The Dock Target communicates wirelessly with the Pallet Mover to ensure safe loading or unloading of pallets between the conveyor and the Pallet Mover

Interroll - LCP AMR top module

- Interroll offers a unique plug and play solution for your internal material handling requirements in combination with the MiR AMR. The LCP AMR Top Module is tailored for transporting light goods (up to 50 kg) and is part of a scalable and modular platform which also includes LCP stationary docking stations in different dimensions. Combined with the InfraRed communication handshake system between AMR, Top Module and docking stations you will get a flexible and full solution that is easy to integrate.

Nord Modules - PM1000, Pallet Mover

-

The Pallet Mover enables the Mobile Robots to pick up and deliver pallets – transporting them to e.g. production lines or packing stations, thereby enhancing internal logistics.

The Pallet Movers integrated technology enables communication to external roller conveyors by wireless signals. A Nord Modules dock target can be installed on an existing conveyor line allowing the PM1000 to successfully dock and receive or deliver a pallet.

This fully automated premium solution allows heavy payload transportation of up to 1180 kg to optimize logistics and production.

Noed Modules - PM800

-

The Pallet Mover enables the Mobile Robots to pick up and deliver pallets – transporting them to e.g. production lines or packing stations, thereby enhancing internal logistics.

The Pallet Movers integrated technology enables communication to external roller conveyors by wireless signals. A Nord Modules dock target can be installed on an existing conveyor line allowing the PM800 to successfully dock and receive or deliver a pallet.

This fully automated premium solution allows heavy payload transportation of up to 1200 kg to optimize logistics and production.

Hyperion - Pallet Handling Conveyer

-

Hyperion’s conveyors integrate as plug-and-play additions with the MiR500, MiR600, MiR1000, and MiR1350 robot.

Simply connect the included cables to the robot auxiliary ports and fasten the conveyor to the robot.

Once installed, users can operate the conveyor running the provided sample mission to index a pallet in or out, or by utilizing the manual buttons to test or troubleshoot.

Projk DC Connect

-

- Top module for shelf missions like no other

- Wireless power transfer from the MiR, through the top module to a specifically designed trolley.

- Trolley accessories available such as conveyors, roller tables and static shelf units, keeping the MiR free for a multitude of tasks, having only the DC>

- Robust, industrial and simple design, plug and play operation!

- Proven concept completed over 6 months ago (April 19) with continued development using our in house innovation team.

This application is compatible with: MiR100, MiR200

item - Base Frame

-

Base Frame Construction Kit - ideal for building your own racks

- Dimension 860 mm x 570 mm

- All dimensions are adaptable.

Noll - PCB Magazine Feeder

-

The integrated conveyors enable a fully automated loading and unloading process at the machines. The entire system is suitable for use in ESD areas. The minimum transfer height, measured from the floor, is 450 mm. Other heights are available on request.

With the help of the automated PCB transport, employees who were responsible for in-house transport can now pursue more value-adding activities.

Nord Modules - Pallet Lift US

- Optimize your internal logistics by automating the internal transportation of pallets with the Nord Modules US Pallet Lift Top Module. Nord Modules US Pallet Lift autonomously picks up and delivers pallets in the Pallet Rack. Stable handling and transport of pallets up to 40x48”. It enables the MiR AMRs to lift pallets autonomously from the Pallet Rack and lowers the pallet for stable transportation of payloads up to 1250 kg.

Due to the module’s shelf lift design, it can be used for various other lifting applications as well.

Nord Modules - Pallet Lift EU

-

Optimize your internal logistics by automating the internal transportation of pallets with the Nord Modules EU Pallet Lift Top Module. Nord Modules EU Pallet Lift autonomously picks up and delivers pallets in the Pallet Rack.

Stable handling and transport of EU size pallets. It enables the MiR AMRs to lift pallets autonomously from the Pallet Rack and lowers the pallet for stable transportation of payloads up to 1250 kg.

Nord Modules - SC200-480

- The NORD Shelf Cart merges with our Quick Mover installed on the mobile robot, to receive or deliver objects placed on the Shelf Cart anywhere in the production site. The NORD Shelf Cart can be mounted with any individual application or solution the customer might wish for. Due to the design of the Shelf Cart, the AMR can recognize when it is under the cart to transport it around.

ROEQ - TMS - C3000 Ext

-

Developed as part of a full ROEQ cart solution to collect, transport and deliver pallets, skids, boxes etc. in free space. The ROEQ TMS-C300 top module works together with the ROEQ S-Cart300 series on the MiR250 for payloads up to 300 kg.

The extended top module has been designed with safety in focus, with easy access to the emergency stop even when carrying pallets and other loads up to 120 cm.

Rails for the carts are available for transporting EU and US pallets and the carts have attachment holes for adding other customized equipment. A two year warranty is offered, when this top module is bought and used together with the ROEQ S-Cart300 series.

All ROEQ top modules come with the ROEQ Assist software tool which is fully compatible with MiR software. It reduces the integration time needed, assisting the setup of the system, and creating the right footprints for the robot to facilitate safe navigation. The tool builds standard missions to get you up and running faster.

MiR Software

-

If you see MiR AMR’s as just a means of moving goods from A to B, chances are you haven’t yet discovered the full capability of MiR’s software. MiR’s software, consists of on-robot software and MiR Fleet – centralized fleet control software and MiR Insights that shares data you can use to optimize your AMR utilization.

Seize the potential of your AMRs

The MiR software is next generation software that helps you get maximum throughput of your AMRs. It enables your MiR robots to operate efficiently - individually and in large fleets.

The navigation of AMRs is better than ever with MiR Software: the robots can reroute smoothly, switch maps fast, and interact easily thanks to an enhanced user-interface and planner that optimize driving patterns and avoid bottlenecks.

When you want to optimize the usage of your MiR robots, MiR Insights help you visualize and analyze your fleet.

- Increased robot performance

- Enhanced cybersecurity

- User-friendly UI

- Open REST interface

- Analyze and Visualize

Centralized Control of Robots

- Optimizing robot traffic with efficient fleet management

MiR Fleet offers centralized control of robots from a single station, throughout all your facility, thanks to an intuitive web-based interface. Programming and overseeing a diverse MiR robot fleet, equipped with various top modules, MiR Hooks, or accessories, becomes straightforward. Once programmed, the system autonomously prioritizes tasks and selects the most suitable robot based on position and availability.

Robot Software

- Transforming efficiency and user control with MiR SW for your AMRs

When you invest in a MiR robot, it comes with the latest software pre-installed, free of charge.

This next-generation software enhances performance, allowing MiR robots to complete missions faster through an improved planner that swiftly recalculates routes when meeting obstacles.

Moreover, the latest version of MiR’s robot SW has improved cybersecurity according to IEC 62443 standards. It incorporates enhanced cybersecurity measures, including software code signing, extended robot authentication, and robot operating system updates.

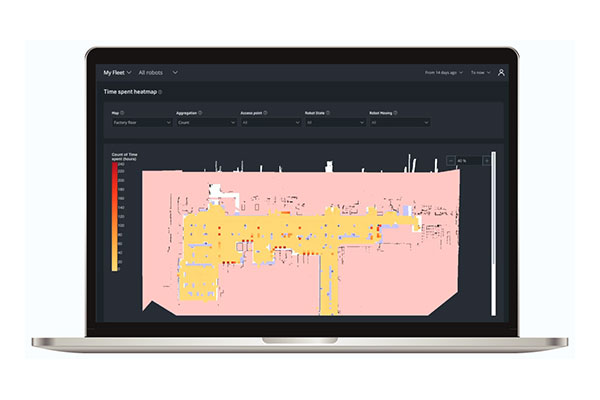

Visualize. Analyze. Optimize.

-

MiR Insights is a cloud-based software that empowers customers to make data-driven decisions, allowing them to optimize their MiR robot fleet's performance and minimize downtime.

These insights can be leveraged to identify patterns in robot behavior, optimize mission flow, and reduce inefficiencies, ultimately resulting in increased productivity and improved ROI.

Monitor fleet and robot data over long periods of time with Data Dashboards-

Track your sites’ KPIs such as distance driven, completed missions, and robot utilization rate.

-

Identify when specific events occurred, such as abrupt WiFI signal changes or unexpected workflow interruptions to self-troubleshoot and maximize the uptime of your MiR robots.

-

Correlate data across multiple robots to analyze areas where you can improve the performance of your fleet and increase the overall productivity.

-