- Offer Profile

-

The CHIRON Group is a strong unit. Covers the entire spectrum in the area of expertise for milling and mill-turning. Enables precise, productive and flexible machining in all user industries with comprehensive offerings. And: The CHIRON Group is an agile unit. Identifies potential at an early stage, takes advantage of it consistently and shapes its own future and the future of its customers with innovative products and services.

Why are we sought throughout the world as specialists for vertical milling and mill-turning machining centers, and for our turnkey and automation competence? Because on a daily basis, about 1,900 employees tackle complex demands and develop future-proof solutions with real team spirit.

Milling / Mill-turn

-

Milling centers from the CHIRON Group convince in all industries and leave nothing to be desired in terms of efficiency, precision and dynamics. The key advantage of the highly productive systems, ranging from small to large, for micro-machining up to the production of structural components for automotive and aerospace, is their modularity. Whether it's one, two or even four spindles, in combination as a one-place or two-place machine, for machining aluminum, brass or titanium, right through to high-tensile steels or for maximum-precision machining of free-form surfaces: the CHIRON Group has the right series for all your tasks and workpiece dimensions – in exactly the right machine configuration. All milling centers compress your manufacturing process into the smallest possible space. Standardized interfaces enable an easy integration of intelligent automation solutions.

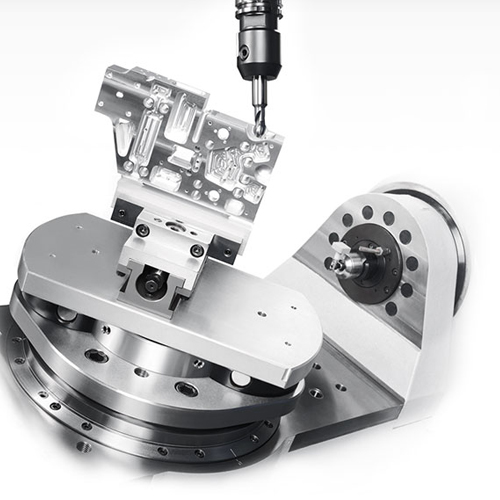

Mill-turning centers from the CHIRON Group perform challenging milling, turning, and drilling operations in an optimum machining process, as well as 5-axis simultaneous machining. By utilizing the main spindle and counter spindle, you can machine sides 1 to 5 in OP10 and sides 2 to 6 in OP20. To do this, the degrees of freedom are expanded using swivel head technology or by storing the rotary spindles in the fourth axis. Material can be fed via bar loader at any time. Handling systems smartly integrated in the machine take care of feeding chuck parts and discharging finished parts to a defined storage place. Reduced throughput times, increased productivity, and maximum precision right from the very first workpiece: Your demand, which the engineering of the CHIRON Group transfers into the best application-specific process.

Micro5

-

Medical technology, watch housing and plates, watch movements, jewelry and components for precision mechanics and micro-mechanics: For any situation in which small, high-value parts require dynamic and high-precision machining, the Micro5 is leading a small revolution. The machining center with five axes is extremely compact and can be set up very quickly almost anywhere: in the production hall or right at the workstation.

The »5« in the name Micro5 stands for the ideal 5:1 ratio of machine size to workpiece and for maximum efficiency: Energy consumption is 50 times lower compared to conventional systems, and a high-performance spindle enables very short machining times. Combined with the Feed5 handling system for automated loading and unloading, the result is a practical and environmentally friendly complete solution for processing delicate workpieces at high speed.

Highlights:

- High-precision 5-axis machining

- Ultra-compact machine

- Machining cube max. side length 50 mm

- High-static rigidity and repeat accuracy

- Outstanding thermal stability

- High-speed cutting

- Low energy consumption < 500 W

- Precious metal recovery

- Magazine with 60 tools in the working area

- Palletizing with up to 6 pallets in the working area

- Easy access for service and maintenance

- Excellent view of the production process

- Easily automated with Feed5

08 Series

-

Minimum tolerances of a few µm and top surface quality: You can meet these requirements with the versatile machining centers of the 08 Series. All models stand for high performance in a compact form. They are quick to set up, easy to operate, very stable, highly dynamic, and low-maintenance. Their modular design makes it possible to configure each basic machine to an individual solution that is perfectly tailored to your manufacturing needs.

08 Series machining centers are available with a single or double spindle, for 5-axis simultaneous machining, with workpiece changing during machine operation for large quantities, and as a mill-turning machine for multi-functional machining from the bar. In addition, the precision+ designation includes all machine types with linear direct drive as further variants for the special requirements of medical and precision technology.

Highlights:

- Reliably strong performance

- Compact machine layout

- Vertical moving column principle

- Steel/mineral-cast machine bed

- High rigidity and thermal stability

- Motor spindles with water cooling

- Dynamic direct drives and precision guides with precision+

- Fully enclosed working area, stainless steel covers

- Ideal chip flow

- Ergonomic operating and loading concept

- Easy access to all units for servicing

- Easily expandable with tailor-made automation

12 Series

-

So you want quality and precision quickly, at low cost per unit? These standards are combined in the machining centers of the 12 Series, which are ranked among the best in their class in terms of speed, compact design, and versatility. All models can be perfectly tailored to your requirements with high-tech modules: spindles and spindle systems, tool changers, table variants, and additional automation.

Using the proven traveling column design of the FZ 12 S five axis, you can manufacture workpieces with high surface quality in one clamping position. Both the single spindle variant and the DZ 12 S five axis carry out 5-axis simultaneous operations; the double spindle variant allows a high output at optimum unit costs. FZ/DZ 12 W are equipped with a workpiece changer for convenient loading and unloading during machine operation.

Highlights:

- Reliably strong performance

- Compact machine layout

- Vertical traveling column

- Mineral-cast machine bed

- High rigidity and thermal stability

- Motor spindles with water cooling

- Robust rotary axes

- Fully enclosed working area, stainless steel covers

- Ideal chip flow

- Ergonomic operating and loading concept

- Easy access to all units

- Easily expandable with tailor-made automation

15 Series

-

The 15 Series machining centers are among the best in their class in terms of speed, compact design and reliability. They have huge reserves for highly productive milling and, thanks to their modular construction, for example with several spindle and table variants, can be configured to create your ideal individual solution. Choose them for consistently fast machining and high availability at reduced unit costs.

For machining complex workpieces with many tools, the single and double spindle machines can be equipped with a chain type tool changer. Alternatively, the basket tool changer is currently the fastest tool change system on the market, ideal for machining reamed bores with high precision. The FZ/DZ 15 W with workpiece changer for loading and unloading during machine operation are the specialists for large quantities.

Highlights:

- Fast, productive machining

- Reliable performance

- Compact machine layout

- Vertical traveling column

- Mineral casting machine bed

- High rigidity and thermal stability

- Dynamic direct drives and precision guides

- High running, positioning, and long-term precision

- Robust rotary axes

- Fully enclosed working area, stainless steel covers

- Ideal chip flow directly into the chip feeder

- Ergonomic operating and loading concept

- Easy access to all units for servicing

16 Series

-

Challenging materials, closer tolerances, and specifications for process reliability: The 16 Series has a machine platform with a mobile gantry design that is specifically tailored to your present and future requirements. Single and double spindles effectively combine dynamics, precision, and excellent surface quality when machining complex workpieces. Plus, the modular concept allows individual configuration to suit your needs.

The FZ 16 S five axis is designed to meet particular requirements for accuracy in 5-axis machining and for demanding machining applications, e.g. in aerospace for machining components from a solid block. The DZ 16 W with workpiece changer is the first choice for machining a large number of workpieces in very short cycle times; they are even more productive and more autonomous with the Variocell UNO automation unit.

Highlights:

- Outstanding machining quality and precision

- For larger workpieces up to 700 mm and 360 kg

- Machine platform with a mobile gantry design

- High rigidity - static and dynamic

- Excellent thermal stability

- Actively cooled drive components

- Highly productive motor spindles

- Round axes with direct torque drive

- Ideal chip flow

- Up to 162 tools

- Loading and unloading during machine operation

- Intuitive TouchLine operating system

- Easy access to all units

18 Series

-

Compact, powerful, fast: The 18 Series single and double spindle machining centers offer the ideal conditions for highly productive machining and precise results. Whether it's for flexible single-part production or for small and medium-sized Series production, tried-and-tested modules can be individually configured to suit your production needs in the Automobile, Aerospace or Mechanical Engineering industries.

With a fast basket tool changer, rigid table, and large working area, the FZ 18 S is suitable for universal use. For flexible machining of rims in sizes of 16 to 24 inches, a special wheel variant is also available. You can manufacture large quantities productively with the FZ/DZ 18 W machining centers with automated tool and workpiece changers.

Highlights:

- Reliably strong performance in long-term operation

- Compact machine layout

- Flexible wheel device

- Vertical traveling column

- Mineral casting machine bed

- High rigidity and thermal stability

- Dynamic direct drives and precision guides

- High running, positioning, and long-term precision

- Robust rotary axes

- Fully enclosed working area, stainless steel covers

- Ideal chip flow directly into the chip feeder

- Ergonomic operating and loading concept

- Easy access to all units for servicing

19 Series

-

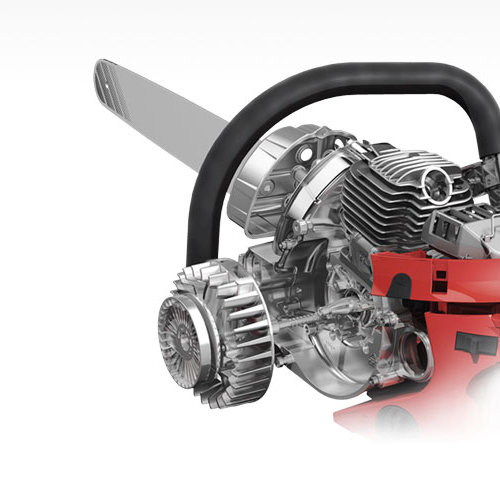

Manufacture complex components for tools or machinery, for power transmission or aircraft landing gear, for off-highway or energy applications? In series on a single-spindle machining center? Absolutely. With the FZ 19 S five axis in mobile gantry design. The model of the new 19 Series is universally applicable for a wide range of parts and stands for everything that characterizes the series: Power, precision and dynamics. And, above all: high productivity.

CHIRON Group motor spindles, various rotary table packages and magazines for up to 196 tools enable application-specific configuration and thereby optimum customer benefit. With constantly reduced downtimes, high performance and surface quality. These advantages are shared by the FZ 19 S mill turn which can also be used for turning large and heavy workpieces up to 0.8 t and 800 mm in diameter.

Highlights:

- Precise, flexible and high performance machining

- Mobile gantry design for high static and dynamic rigidity

- Best thermal stability thanks to actively cooled drive components

- Gantry round axes with direct torque drive

- Many tools in the machining center for extensive processing operations

- Easy access to the working area for set-up, automation and crane loading

- Tool change during machine operation for maximum output

- Intuitive operation via TouchLine

22 Series

-

The 22 Series convincingly addresses the current requirements on precision, dynamics and high technical availability in the complete machining of large-volume components such as electric motor and transmission housings, oil sumps and chassis components. The foundation for this is a machine platform with a mobile gantry design. This significantly increases rigidity for even more precise machining results.

Using the DZ 22 W five axis with workpiece changer and a spindle distance of 600 mm, two different main spindles can be operated, depending on the task at hand: the high-speed spindle for workpieces made from aluminum or aluminum alloys, and the high-torque spindle for hard-to-machine materials and large tools. The series also includes configurations for direct loading and a HSK-A100 interface.

Highlights:

- Double spindle machining of large components in short cycle times

- Rigid machine bed with a mobile gantry construction for high precision

- Active cooling of all components

- Compact, flexible machine layout

- Many tools for versatile machining

- Tool change during machine operation for maximum output

- Process is easily visible thanks to the separation of operating and loading sides

- Workpiece changer for loading and unloading during machine operation

- Intuitive operation via TouchLine

- Easy automation via robots or gantry

25 Series

-

The 25 Series has been explicitly designed for the machining of complex, large-volume workpieces. With a spindle distance of 800 mm, the DZ 25 S five axis is ideal for direct loading. The DZ 25 P five axis with pallet changer for double spindle machining of aluminum components for industries like automotive and aerospace has significantly reduced cycle times, excellent parts quality, and high flexibility.

A central advantage of the 25 Series is it is operated and loaded on separate sides, which allows optimum access to the working area and a clear view of the process. Greater precision is ensured by the spindles, which can be moved independently of each other in the X and Z direction. The machining centers can also be configured to suit your needs and expanded to be a fully automated complete solution for increased utilization.

Highlights:

- Double spindle, productive machining of large components

- Outstanding precision due to rigid machine bed with a gantry construction

- High dynamics through rapid acceleration and rapid traverse speeds

- Spindles can be moved independently on the X and Z axes

- Process is easily visible, thanks to the separation of operating and loading sides

- Many tools for versatile machining

- Tool change during machine operation

- Independent tool change for each spindle for short chip-to-chip times

- Compact, flexible machine layout

- Loading and unloading during machine operation with pallet changer (DZ 25 P)

- Intuitive operation via TouchLine

- Easy automation via robots or gantry

28 Series

-

Complex hybrid drives, lightweight constructions for chassis and structural components, battery trays, more efficient internal combustion engines: The 28 Series is the convincing response to the changes in the manufacturing processes and your more stringent requirements for machining technology. With a spindle distance of 1,200 mm, the double spindles are ideal for 5-axis machining of challenging, large-scale workpieces: productive, dynamic, and precise.

The compact, flexible machine layout, spindles that can be moved independently on the X and Y axes, simple automation, optimum access to the working area, and operation and loading on separate sides are all further benefits for your day-to-day production process. There's also the layout of the machining center such as the DZ 28 S five axis for direct loading or the DZ 28 P five axis with pallet changer for high quantities and short cycle times.

Highlights:

- Double spindle, productive machining of large components

- Outstanding precision due to rigid machine bed with a gantry construction

- High dynamics through rapid acceleration and fast rapid traverse speeds

- Spindles can be moved independently on the X and Z axes

- Process is easily visible thanks to the separation of operating and loading sides

- Many tools for versatile machining

- Tool change during machine operation

- Independent tool change for each spindle for short chip-to-chip times

- Compact, flexible machine layout

- Loading and unloading during machine operation with pallet changer (DZ 28 P)

- Intuitive operation via TouchLine

- Easy automation via robots or gantry

MILL Series

-

From small parts to large workpieces, the machining centers of the MILL Series provide you with ideal conditions for productive machining at low unit cost, with precise results. All models are characterized by a strong milling performance and X-axis traveling distances of up to 8,000 mm, from the MILL 800 five axis for 5-axis simultaneous and complete machining, to the MILL 8000 for long bed production of workpieces up to 8 m in length.

Large and variable working areas for larger workpieces or multiple clamping positions, high dynamics and powerful drives, quick set-up and easy operation: These are further highlights for the flexible production of individual parts, as well as in the production of small- and medium-sized series. Every MILL machining center can be configured according to the application. From the MILL 2000 onwards, the working area can be divided for parallel machining, as well as loading and unloading.

Highlights:

- Vertical traveling column

- Large traveling distances with compact external machine dimensions

- Swivel head for more flexibility in machining

- Dynamic direct drives and precision guides

- Robust machine bed with coolant and chip removal

- High rigidity and thermal stability

- speed+ variant for even faster machining

- Large working area for structural components

- Automatic tool change with the pickup method

- Ergonomic operating and loading concept

- Loading and unloading during machine operation

- Can be expanded to four or five axes

- Easy access to all modules

715 Series

-

5-axis complete machining, milling-turning operations in any sequence on six sides, workpiece dimensions up to a diameter of 300 mm and a length of 1,000 mm: The 715 Series brings together all of these options into one machine platform. Clear advantages over production spread across several machines: Higher precision, shorter throughput times, more flexibility, minimized set-up times for small batch sizes, and reduced logistics costs.

The Series is available in two versions with different expansion levels: MT for Mill Turn, MP for Multi Profile. The optional second machining unit can be used for guide bushes, steady rests, rotating centers, vices, or other turning tools. Integrated workpiece handling provides significantly increased productivity and reduced costs in each machine, with additional unmanned shifts.

Highlights:

- Unit comprising base machine and workpiece automation

- Large working area for workpieces up to dia. 300 mm x 1,000 mm

- Short throughput times through six-sided complete machining

- Full turning function thanks to rotary spindles and clampable milling spindle with 20,000 rpm

- Direct drive torque swivel head, optimized for 5-axis simultaneous machining

- Main spindle and counter spindle with identical, powerful performances

- Automation with bar stock up to dia. 65 mm or chuck parts up to dia. 200 mm

- Easy set-up of lower machining unit, also for mapping out other clamping positions

- Integrated tool store for up to 128 tools

- Loading and unloading during machine operation

831 Series

-

Do you need complete machining of complex, precise workpieces with a diameter up to 400 mm, single or double spindle, 5-axis from chuck parts, whether it is a prototype, pilot series, or volume production? The right solution is the mill-turn centers of the 831 Series for full capacity in milling and turning with high dynamics and precision, in one machine.

Milling, turning, and drilling operations can be combined into any sequence to create the optimum machining process. This is a great benefit, when geometric form and positional tolerances of a subsequent machining step have to be realized with high precision in relation to a given reference. High surface area productivity and fast set-up and changeover are further plus points.

Highlights:

- Precise 5-axis complete machining from chuck parts

- Made for large workpieces and multiple clamping

- High process reliability

- Individual process sequence design

- High surface area productivity with MT 831 TWIN

- Reduced costs per unit

- Full turning spindles in the C-axis

- Full milling and turning capacity in HSK-A63

- Torque technology in the A-axis

- Manual or automated workpiece handling

baseline Series

-

Do you want more orders than machine capacity? How about swift, cost-effective entry into the world of high-quality manufacturing with the CHIRON Group? Then the baseline Series is perfect for you. Whether it's for contract manufacturing, for applications in the automotive industry, toolmaking, or mechanical engineering, the pre-configured machining centers demonstrate their strengths in all industries: short delivery times, attractive price and proven top-quality technology.

Thanks to their standardized structure, the machines are available quickly and provide everything you need for productive, precise machining. Currently, the Series comprises the following models: FZ 15 S five axis baseline and FZ 15 W baseline with basket or chain-type tool changer and MILL 800 five axis baseline.

Highlights:

- Available at short notice, durable and low-maintenance

- Vertical moving column principle

- Thermally stable

- Maximum precision in positioning and simultaneous operation

- Dynamic direct drives

- Ergonomic operating and loading concept

- Easy access to all units for servicing

- DataLine can be integrated for machine and process diagnostics

Automation

-

Automation improves efficiency and achieves a higher output with lower costs. The second advantage is simplification – with system competence from the CHIRON Group. Together, the machining center and automation solution becomes a highly productive complete system, a perfect match for your fleet of machines and your manufacturing environment.

This system expertise plus the experience gained from many challenging projects, makes the difference: It simplifies the whole process at the machine and in the surrounding environment, reduces demands on personnel, decreases working time, and enables largely autonomous manufacturing – unmanned, into a third shift and on weekends.

Feed5

-

The future of micro-machining is productive, sustainable, and automated – with the combination of the Micro5 machining center and Feed5 handling system for loading and unloading. The compact, 6-axle robot feeds workpieces automatically and, most significantly, enables greater autonomy while producing higher quantities.

Using a Feed5, up to two Micro5 machines can be automated. The handling system and machining center are also elements of the SmartFactory, like the Pilot5 coordinate measuring module and machining modules such as laser markers, 3D printers and cleaning units.

Highlights:

- Handling system for up to two Micro5

- Workpiece and pallet changer

- High autonomy, thanks to storage for up to 10 pallets

- Blow off of equipment and workpiece

Variocell UNO

-

Designed for series production, the compact unit, comprising a workpiece store and changing mechanism, enables the manufacture of a large number of workpieces in very short cycle times and with a high degree of autonomy – unmanned, able to continue into a third shift and at weekends. Especially on machines with a workpiece changer, the unit offers significant added value with respect to the productive process of loading and unloading blanks and finished parts during machine operation.

With additional equipment, the VariocellUno is the ideal solution for your production scenario. It is ideal for use with multiple grippers, stations for turning, cleaning, brushing, press-fitting, measuring, cleaning, labeling and other components for flexible tasks right through to six-sided machining. Additionally, the asymmetrical design enables optimum access to both the working area and the loading and unloading area of the machine.

Highlights:

- For 08, 12, 15, 16, 533 Series and retrofittable to existing machines

- Compact unit with a small footprint

- High degree of utilization for increased profitability

- Replacement of blanks and finished-parts during machine operation

- Robot can be used for additional tasks

- Large storage capacity, storage medium according to requirements

- Integrated measuring part discharge of, for example, SPC parts

- Simple set-up and commissioning

- Easy to operate and program

- Best access to the working area for cleaning and maintenance tasks

- Machining center and automation from a single source

Variocell MOVE

-

Higher machine uptime, increased efficiency, reduced unit costs, less strain on operators: With the Variocell MOVE, you can achieve these benefits wherever they are currently needed. The compact robotic cell with inclined pallet system for intelligent workpiece handling can be flexibly combined with changing milling and mill-turning centers from the CHIRON Group into a highly productive unit.

Depending on the application, additional stations can be integrated, e.g. for turning the workpieces. Laser scanners create graded protective areas around the Variocell MOVE. When operators approach, the speed is reduced (level 1) or the system is shut down (level 2).

Highlights:

- Handling system for the 12, 15, 16, 18, MILL and baseline Series

- High degree of utilization for increased profitability

- Compact unit with a small footprint

- Flexible and easy set-up

- Intuitive operating and programming

- High operating safety thanks to laser-scanned protective zones

- Smart workpiece handling and fast pallet exchange

- Robot reach up to 2,000 mm

- Handling capacity up to 15 kg

- Loading capacity per drawer max. 300 kg

- Drawer size 1,100 x 570 mm

- Workpieces up to 250 mm height/diameter

- Optional gripper unit for prismatic workpieces

- Robot FANUC M-20iD/35

- Machining center and automation from a single source

Variocell PALLET

-

Variocell PALLET is your handling system for dynamics and flexibility when machining small batch sizes or complex workpieces, and manufacturing individual parts with long machining times. The rotary indexing table takes up to ten paletts of blanks; the system feeds blanks consecutively into the machining center, then removes the machined workpieces and pallet together after the machining process is complete.

The automation unit grants one-spindle machining centers from the CHIRON Group several advantages: significantly higher productivity. Another advantage: One pallet can be machined while the operator loads another. In addition, the motorized mobile transfer trolley ensures excellent accessibility at all times, even in confined spaces.

Highlights:

- Handling system for the five-axis machines from the 12, 15, 16, 18 and MILL Series

- Small batch sizes, complex workpieces, individual parts with long machining times

- High degree of utilization for increased profitability

- Replacement of blanks and finished parts pallets during machine operation

- Medium and large storage capacity according to pallet size

- Simple set-up and commissioning

- Easy to operate and program

- The working area is accessible for cleaning and maintenance tasks

- Loading and unloading can also be performed manually, where necessary

- Machining center and automation from a single source

Variocell SYSTEM

-

Load one or more machining centers of the CHIRON Group with workpieces and devices? Completing additional tasks with maximum autonomy and productivity? You have our support using expertise in automation and productivity for demanding projects! With a Variocell SYSTEM automation solution for your individual needs.

Handling systems, gantry or articulated arm loaders, workpiece storage for blanks and finished parts, double grippers, pallet stores, feeding or discharging equipment, peripheral units for cleaning, identification, testing or measuring: These are just a few examples of the many modules specialists use to create your Variocell SYSTEM and your highly automated manufacturing process.

Highlights:

- For all series from CHIRON and STAMA

- Numerous customer-specific automation projects

- Maximum flexibility in design

- Custom-fit handling and clamping concept

- Robot can be used for additional tasks

- Integration of peripheral units

- Easy to operate and program

- Machining center and automation from a single source

Turnkey: Smart solutions from planning to series production

-

As a user, you can expect a manufacturing solution that is as individual as it is smart: a solution that is perfectly suited to your industry and translates your specific requirements – piece number per manufacturing unit, price per component – into an efficiency-optimized, turnkey machining process for your workpiece. A turnkey solution from the Application branch of the CHIRON Group is supplemented, where necessary, by the expertise of the Medical & Precision Technology Center.

The engineers and technicians bring their expert knowledge to each stage and provide you with a complete, production-ready package designed for optimal interaction: with a machining center from the CHIRON Group, with tools, clamping devices and automation. If requested, with integration of upstream and downstream process steps and always with tailored services throughout the entire life cycle.

Complete turnkey competence:- Comprehensive process design

- Engineering and project management

- Validation of statistical process capability

- Assurance of target productivity

- Customized automation

- Production monitoring in the startup phase

- Training sessions for optimal use of the solution

- Tailored services

Digital solutions: SmartLine, SmartServices

-

The digitalization of production is increasingly focusing on more efficiency, greater availability, and increased productivity. Digital solutions from the CHIRON Group exploit this potential across all industries. And create real, lasting added value – in the machining centers, in production, and in the company.

SmartLine represents a modular software portfolio from a single source, designed for perfect interaction with CHIRON Group machining centers. The SmartServices are also modular in design: Digital services from the CHIRON Group Service, available from any location, for increased productivity.

Services

-

PERFORMANCE MEETS PRECISION: This is the promise that the CHIRON Group makes when they deliver every machining center as well as Automation solutions and Refurbishments. An integral part of this commitment is the highly efficient CHIRON Group Service with over 500 service professionals in 26 countries. With »classic« on-site services and reliable partners, they will support you throughout the entire lifecycle of your machine.

LifetimeSolutions: The right services at the right timeToday, professional CHIRON Group Service is more – it is looking ahead, planning ahead, and thinking ahead. This is exactly what the LifetimeSolutions will ensure: A targeted response throughout the entire lifecycle of the machine. Using a completely customized package with the ideal support and digital SmartServices to suit the machine, the production environment, and the respective requirements. And clear added value: Greater productivity, maximum machine availability, and therefore, optimized overall equipment effectiveness.

Performance up, cost down – in every phaseStart-up, production and modernization: With LifetimeSolutions you will receive comprehensive, targeted support in every phase. The service specialists ensure that the start-up phase is short, and a high machine availability is achieved as soon as possible. Then, it is a matter of securing this high level, identifying, and exploiting additional potential. In phase three, your machining center undergoes targeted modernization and is ready for a second life with new tasks.

Industries

Automotive

- Whether it's components for vehicles with conventional drive systems, hybrid models or electric vehicles: Everybody wants dynamic, precise machining in quick cycles at reduced unit costs. With the right, future-proof manufacturing technology for the entire range of parts.

Medical Technology

- Increasingly sophisticated workpieces, increasing quantities, higher risk categories, and more stringent traceability requirements: There is no other industry with such high and complex demands. It is, therefore, all the more important to have a partner that makes every effort to take your requirements and turn them into a reliable solution: high-precision machining centers, turnkey expertise and experience from numerous projects.

Aerospace

- Perfection, maximum safety, quality, and durability as the benchmark. An industry facing profound structural change and pressure to increase costs. To operate with confidence in this difficult field, you need production concepts for the future. Manufacturing solutions from the CHIRON Group further streamline operating procedures for maximum efficiency.

Precision Technology

- Creative pieces of jewelry with intricate details, watch plates with minimum tolerances for fits and geometries, components for high-precision scales or parts for precision mechanics: Your idea deserves to be brought to life with expertise. That is achieved using a machining center or mill-turn center from the CHIRON Group. For micrometer-precise long-term precision and perfect surfaces.

Tool Manufacturing

- Prototypes, single-piece production of special tools, large-scale production of standard tools. Expect a quick changeover, complete machining: The CHIRON Group offers flexible process solutions for the machining of tools and format parts, enabling you to turn your innovative edge into outstanding quality.

Mechanical Engineering

- Mechanical engineering is one of the most comprehensive technical disciplines and is continuing to develop rapidly. It is, therefore, even more important for you to have a partner that evolves and develops just as quickly, and in the CHIRON Group, you have just that. Your partner will mirror your innovative spirit and expertise and provide you with fitting, future-proof machining technology.