- Offer Profile

- For 90 years, GROB has been a leader in designing and building highly-innovative production and automation systems. The continuous development of in-house expertise, the quest for perfection and the high level of vertical integration in the plants all over the world create products and technologies of outstanding quality.

System Solutions

- All competencies under one roof

Profound know-how and use of the latest technologies make GROB a recognized expert in the system business. To precisely meet its customers' requirements, GROB produces complete system solutions in the form of top-quality customizable manufacturing lines. These lines consist primarily of modular machining centers and special-purpose machines that are interlinked with the latest automation solutions.From planning to engineering through to operationally ready delivery and commissioning, GROB offers all core competencies from a single source. This deep vertical integration allows dynamic and customer-specific adjustments to capacities and guarantees an outstanding degree of reliability.

G-modules – Machining centers

The flexible manufacturing system from GROB

GROB G-series offers customers in the automotive sector the perfect solution for productive and highly dynamic manufacturing: The G-modules are modular machining centers, and are therefore available in various sizes and as single- or two-spindle machine variants. The sophisticated concept used for the series was developed from decades of experience garnered by GROB in the system business. It is reflected in a broad range of applications, maximum flexibility and the highest possible productivity.

G300

- The G300 machining center is designed specifically for

use in flexible series production and offers customers from the automotive

sector the ideal solution for high-precision cutting.

As the smallest size among the various G-series stages, the G300 boasts impressive space-saving external dimensions and dynamic motion sequences – for fast, efficient and ultra-modern production.Technical data

- Working travels 600/770/750 in X-/Y'-/Z-axis (mm)

- Max. speeds 95/45/100 in X-/Y'-/Z-axis (m/min)

- Interference diameter 600 (mm)

The benefits at a glance

- Reduced machine width

- Maximum tool length

- Fast tool change

- Broad range of applications

- Modern machine design

- Expandable tool pockets in the tool magazine

- Intelligent power unit arrangement

- Highly effective loading concept

G500

- The modular standard of the G500 machining center

makes it the ideal solution for the flexible series production of automotive

components such as cylinder blocks and cylinder crankcases.

With fast chip-to-chip times, ideal chip fall and horizontal machining, the G500 machine variant guarantees productive cutting in line with customers' specific requirements.Technical data

- Working travels 800/950/970 in X-/Y'-/Z-axis (mm)

- Max. speeds 90/50/100 in X-/Y'-/Z-axis (m/min)

- Interference diameter 900 (mm)

The benefits at a glance

- Reduced machine width

- Maximum tool length

- Fast tool change

- Broad range of applications

- Modern machine design

- Expandable tool pockets in the tool magazine

- Intelligent power unit arrangement

- Highly effective loading concept

G700

- GROB offers customers from the automotive sector the G700 – an autonomous module with large work area for a modern and productive manufacturing line.

The G700 is designed for maximum machine and process flexibility. It is composed from one modular system to various equipment levels in line with the customer's specific requirements.Technical data

- Working travels 1,250/920/1,160 in X-/Y'-/Z-axis (mm)

- Max. speeds 60/50/60 in X-/Y'-/Z-axis (m/min)

- Interference diameter 1,350 (mm)

The benefits at a glance

- Reduced machine width

- Maximum tool length

- Fast tool change

- Broad range of applications

- Modern machine design

- Expandable tool pockets in the tool magazine

- Intelligent power unit arrangement

- Highly effective loading concept

G320

- With its G320, the G-series two-spindle machining

center, GROB offers a compact and modular machine variant for use in highly

flexible manufacturing lines in the automotive sector.

To increase efficiency in the production process, two motorized spindles arranged in parallel machine two parts at the same time. Having the pallet changer option, the compact G320 guarantees dynamic and economic manufacture without additional change-over times.Technical data

- Working travels 600/655/750 in X-/Y'-/Z-axis (mm)

- Max. speeds 90/75/100 in X-/Y'-/Z-axis (m/min)

- Interference diameter 2x695 (mm)

The benefits at a glance

- Reduced machine width

- Maximum tool length

- Fast tool change

- Broad range of applications

- Modern machine design

- Expandable tool pockets in the tool magazine

- Intelligent power unit arrangement

- Highly effective loading concept

G520

- GROB offers customers from the automotive sector its

G520 two-spindle machining center, an autonomous machine variant for

machining two parts in parallel.

The G520 meets all the requirements of a modern manufacturing line with maximum flexibility and productivity. With an integrated pallet changer, this version machines dissimilar parts without additional change-over times.Technical data

- Working travels 750/840/970 in X-/Y'-/Z-axis (mm)

- Max. speeds 90/75/100 in X-/Y'-/Z-axis (m/min)

- Interference diameter 2x798 (mm)

The benefits at a glance

- Reduced machine width

- Maximum tool length

- Fast tool change

- Broad range of applications

- Modern machine design

- Expandable tool pockets in the tool magazine

- Intelligent power unit arrangement

- Highly effective loading concept

Modular special-purpose machines

- Create your own individual machine

Autonomous and extremely flexible: GROB modular special-purpose machines are the logical further development of our transfer lines and are modularly constructed from standardized machining units. Thanks to their autonomous supply concept, they can be ideally combined with our G-modules to create hybrid manufacturing lines. Optimized precision guaranteed!Advantages

- Compact, modular structure

- Autonomous units with integrated power elements

- Can be combined with machining centers and automation solutions

- Maximum standardization for highly precise machining operations

- Optimized rigidity and dynamics

- Optimum chip transport for MQL machining and wet machining

- Energy-efficient

- Flexibly expandable

- Faster retool facility

- Optimum accessibility for operation and preventive maintenance

Machining units

Milling unit: For large milling diameters and special milling tasks

Broaching unit: For finish machining and bearing fitting with cast iron machining

Multi-spindle and tapping unit: For short cycle times, high productivity and maximum accuracy

Brushing unit: For oil ducts

Measuring unit: For high-precision measuring tasks

Custom spindle unit: For camshaft, crankshaft and balance shaft boreholes, and also for machining with support bearing and feed-out system Machining centers for frame structure and chassis parts

- The solution for your frame structure and chassis

parts

GROB presents its latest developments in the form of its G500F, G520F, G600F and G700F machines. These versions are designed specifically for single- or two-spindle machining of frame structure and chassis parts, as well as battery housings. The optimized chip transport facility and high machine dynamic make these space-saving machining centers the ideal solution for dry, MQL and wet machining of parts for the automotive industry. No matter whether stand-alone or linked to other machines: GROB machining centers offer a convincing and perfect basis for the automated production of your frame structure and chassis parts.

G500F

- With optimized chip fall, high dynamics and short chip-to-chip times, the G500F is the ideal solution for complete and highly precise 5-axis machining of frame structure parts and battery housings.

Use the space-saving machine variant for your dry, MQL or wet machining and integrate the G500F into your automated manufacturing line either as a stand-alone solution or linked to other machines.Technical data

- Working travels 1,550/875/785 in X-/Y'-/Z-axis (mm)

- Max. speeds 70/50/90 max. in X-/Y'-/Z-Achse (m/min)

- Interference diameter 1,070 (mm)

The benefits at a glance

- Best chip fall

- High dynamics

- High manufacturing flexibility

- High machining accuracy

- Customer-specific part loading

- As a stand-alone machine or linked in the system

- Suitable for MQL machining operations

- Short chip-to-chip times

G520F

- The GROB G520F machine concept guarantees customers in

the automotive industry flexible and precise 5-axis machining of frame

structure and chassis parts, as well as battery housings.

As a stand-alone system or machining center linked to other machines, the two-spindle G520F is able to cut two parts in parallel in the shortest time possible – high dynamics and ideal chip transport included.Technical data

- Working travels 750/840/785 in X-/Y'-/Z-axis (mm)

- Max. speeds 70/60/90 in X-/Y'-/Z-axis (m/min)

- Interference diameter 2x798 (mm)

The benefits at a glance

- Best chip fall

- High dynamics

- High manufacturing flexibility

- High machining accuracy

- Customer-specific part loading

- As a stand-alone machine or linked in the system

- Suitable for MQL machining operations

- Short chip-to-chip times

G600F

- With optimized chip transport and high machine

dynamics, the G600F machine variant achieves outstanding results for

machining frame structure and chassis parts and battery housings.

The 1,550 mm interference range diameter, long travel paths and a swivel head with a range of 180 degrees make the G600F the ideal solution for complete 5-sided machining in your automated manufacturing facility.Technical data

- Working travels 1.500/1.265(+320)/1.100 in X-/Y'-/Z-axis (mm)

- Max. speeds 95/60/50 in X-/Y'-/Z-axis (m/min)

- Interference diameter 1,550 (mm)

The benefits at a glance

- Best chip fall

- High dynamics

- High manufacturing flexibility

- High machining accuracy

- Customer-specific part loading

- As a stand-alone machine or linked in the system

- Suitable for MQL machining operations

- Compact external dimensions

G700F

- Thanks to its extra large working area, the G700F is

ideal for large structural components and allows machining of parts up to a

size of 1,500 x 900 mm.

Furthermore, a narrow bridge ensures the best possible accessibility to the underside of the part for optimal 6-sided machining.Technical data

- Working travel 1,450/990/1,030 in X-/Y'-/Z-axis (mm)

- Speeds 60/75/100 max. in X-/Y'-/Z-axis (m/min)

- Interference diameter 1,500 (mm)

Benefits at a glance

- Best chip fall

- High dynamics

- High manufacturing flexibility

- High machining accuracy

- Customer-specific part loading options to choose from

- Can be used as a stand-alone machine or linked to other machines

Universal machining centers

- The unique GROB machine concept

GROB universal machining centers offer you almost limitless possibilities for the milling and mill-turn machining of parts from the most diverse materials. Thanks to their compact design, high productivity and maximum stability, these machining centers guarantee effective manufacture and adapt, through extensive configuration options, ideally to suit individual requirements.GROB universal machining centers are perfectly suited to the 5-sided machining of parts with chamber holes and chamfers, as well as form and flow profiles. Their unique machine concept makes them ideally equipped for state-of-the-art automation technology.

Milling centers

- Universal machining centers for optimized milling

results

GROB machining centers offer you almost limitless possibilities for machining parts from the most diverse materials and adapt to your requirements down to the finest detail. The compact design, large swivel range and horizontal spindle position are just some of the outstanding machine features that make GROB the ideal partner for your manufacturing facility. The new access-series rounds out the product range of GROB universal machining centers, offering ideal entry versions to the company's unique technology.

G350

- The G350 5-axis universal machining center offers all

customers in the machining sector almost limitless possibilities for milling

parts made of the most diverse materials.

Our universal machining center is designed to meet the multiple requirements of various sectors and offers a convincing range of applications.Technical data

- Working travels 600/855/750 in X-/Y'-/Z-axis (mm)

- Max. speeds 70/45/90 in X-/Y'-/Z-axis (m/min)

- Interference diameter 720 (mm)

The benefits at a glance

- High productivity

- Optimized availability

- High visibility

- Flexible applications

- Maintainable

- Compact design

- Optimized access

- Round-the-clock service

G550

- The G550 machining center guarantees the best milling

technology and extremely stable and precise cutting of practically all

materials.

Benefit from the process reliability, efficiency and durability of our unique machine concept and trust in the GROB G550 for a dependable manufacturing facility.Technical data

- Working travels 800/1,020/970 in X-/Y'-/Z-axis (mm)

- Max. speeds 65/50/80 in X-/Y'-/Z-axis (m/min)

- Interference diameter 900 (mm)

The benefits at a glance

- High productivity

- Optimized availability

- High visibility

- Flexible applications

- Maintainable

- Compact design

- Optimized access

- Round-the-clock service

G750

- The G750 5-axis universal machining center offers

customers in industrial manufacturing top notch results when it comes to

milling large parts.

The G750 machining center is suitable for practically every material and boasts convincing flexibility in various sectors.Technical data

- Working travels 1,000/1,100/1,170 in X-/Y'-/Z-axis (mm)

- Max. speeds 60/50/75 in X-/Y'-/Z-axis (m/min)

- Interference diameter 1,280 (mm)

The benefits at a glance

- High productivity

- Optimized availability

- High visibility

- Flexible applications

- Maintainable

- Compact design

- Optimized access

- Round-the-clock service

G1050

- The innovative concept of the G1050 machining center

offers customers from diverse sectors the ideal pallet dimensions for large

parts.

Thanks to the various versions with 4- or 5-axes, the machine can be optimally matched to specific customer requirements and offers a convincing range of applications.Technical data

- Working travels (5-axis version) 1,600/1,700/1,540/300 in X'-/Y-/Z-/W-axis (mm)

- Max. speeds (5-axis version) 60/60/50/35 in X'-/Y-/Z-/W-axis (m/min)

- Interference diameter 1,600 (mm)

The benefits at a glance

- High productivity

- Optimized availability

- High visibility

- Flexible applications

- Maintainable

- Compact design

- Optimized access

- Round-the-clock service

Mill-turn machining centers

- Universal machining centers for perfectly precise

mill-turn operations

Thanks to extensive configuration options, the G350T, G550T and G750T universal mill-turn machining centers can be ideally matched to your requirements. GROB machining centers achieve complete machining of the part by milling and turning in a single clamping, thereby saving time, space and investment costs in your production facility.

G350T

- The compact G350T mill-turn machining center enables

machining of smaller parts from practically any material in just one setup.

Benefit from the process reliability and durability of the GROB machine concept and see for yourself the diverse range of applications our innovative G350T machining center covers.Technical data

- Working travels 600/855/750 in X-/Y'-/Z-axis (mm)

- Max. speeds 70/45/90 in X-/Y'-/Z-axis (m/min)

- Interference diameter 620 (mm)

The benefits at a glance

- High productivity

- Optimized availability

- High visibility

- Flexible applications

- Maintainable

- Compact design

- Optimized access

- Round-the-clock service

G550T

- The G550T mill-turn machining center offers the

machining sector almost limitless possibilities for machining parts made of

the most diverse materials.

High productivity, maximum stability and excellent maintainability set GROB universal machining centers apart, making them the ideal solution for your automated manufacturing facility.Technical data

- Working travels 800/1,020/970 in X-/Y'-/Z-axis (mm)

- Max. speeds 65/50/80 in X-/Y'-/Z-axis (m/min)

- Interference diameter 900 (mm)

The benefits at a glance

- High productivity

- Optimized availability

- High visibility

- Flexible applications

- Maintainable

- Compact design

- Optimized access

- Round-the-clock service

G750T

- The G750T mill-turn machining center is designed to

machine large parts from the most diverse materials with incredible

stability and precision down to the very last detail.

See for yourself the high productivity and outstanding quality of GROB mill-turn machines and employ the G750T to get the best out of your manufacturing facility.Technical data

Working travels 1,000/1,100/1,170 in X-/Y'-/Z-axis (mm)

Max. speeds 60/50/75 in X-/Y'-/Z-axis (m/min)

Interference diameter 1,280 (mm)The benefits at a glance

- High productivity

- Optimized availability

- High visibility

- Flexible applications

- Maintainable

- Compact design

- Optimized access

- Round-the-clock service

Electromobility

- Successfully into the future with GROB

Drawing on decades of experience in the production of high-efficiency manufacturing lines and assembly systems, GROB meets the best possible criteria for the development and production of innovative electromobility concepts.In acquiring DMG meccanica, the Italian specialist for winding and insertion systems for stator production, GROB further expanded its expertise and became a well-prepared partner for the series production of hybrid and electric drives in the automotive industry. Benefit from our leading edge in electromobility: Rely on the experience and technical know-how of GROB for your manufacturing line and assembly system.

Electric motors and E-machines

- Customized GROB turn-key solutions

Years of research into innovative technologies for the reliable series production of E-machines and electric motors, combined with decades of experience in the system business enable GROB to quickly realize top quality turn-key solutions. GROB supports you from the outset with the design of your products, from the planning phase through to the implementation of assembly systems. As a result, you ideally meet your particular requirements for electromobility and guarantee economic production with the highest yield quantities.GROB range of services

- Stator assembly

- Rotor assembly

- Mechatronics

- Final assembly

- Motor and gearbox housing production (machining)

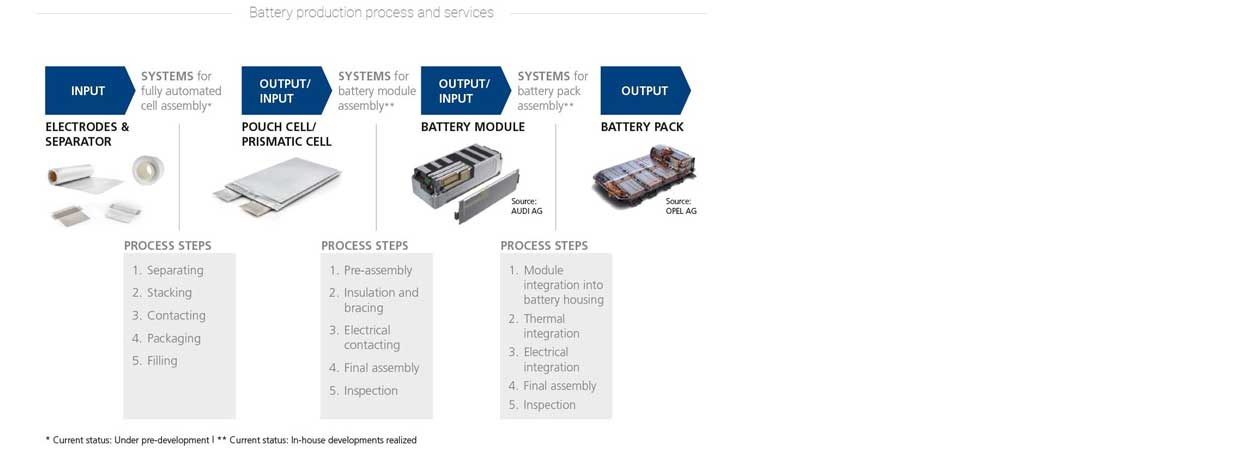

GROB develops and produces machines and systems for the large-scale manufacture of electric motors. At our sites in Mindelheim and Turin, we are working on the various winding technologies for round and rectangular wires – depending on drive and motor size. The product range spans from stand-alone, semi-automatic machines through to fully automated turn-key projects for our customers from the automotive industry. Batteries

- System concepts for battery systems

The efficient production of battery cells and the reliable assembly of battery modules and packs are becoming increasingly important due to the technological transition in vehicle powertrains. GROB is researching new processes, materials and technologies to establish their usability in the automotive industry and offering process-safe, high-quality systems for the manufacture and assembly of energy storage systems. The focus is always on what our customers need – so degrees of automation, cycle times and yield quantities are guaranteed to match their requirements!GROB range of services

- Cell assembly

- Module assembly

- Pack assembly

- Housing production (machining)

To the future of electromobility with GROB. Draw on our decades of experience in assembly line and system construction and benefit from GROB's know-how for your electromobility projects. It is our pleasure to advise you!

Fuel cells

- Automated solutions for fuel cells

Fuel cell assembly is a promising technology within electromobility, and a key area of focus for GROB research and development. For the assembly of components in the vehicle fuel cell drive, GROB offers innovative and automated manufacturing and assembly lines that guarantee a high degree of flexibility, precision and reliability. From the first idea to the conceptual design through to series-capable production, our customers benefit from the individual implementation of their systems, and receive comprehensive advice from a single source in the process.

GROB range of services- Stack assembly

Research and development at the highest level. Based on excellent know-how and high quality and reliability, GROB offers you all the services involved in the conceptual design and manufacture of your energy storage systems.

Automation

- For a perfect production process

The GROB system machines, universal machining centers and assembly lines are among the best in the world – our matching automation solutions make them even more efficient. To maintain the highest quality standard, all components are produced in-house and are optimally matched to our customers' specific needs. GROB's semi-automated to fully automated technology guarantees optimized part handling and efficient production. Pallet Solutions

Pallet changer system

Improve the productivity of your GROB machine by setup during part machining. A rotating pallet changer exchanges the pallets between setup station and work area of the machine and clamps the pallets on the rotary table and the setup station. A high degree of process reliability is guaranteed by an integrated seating check system and by flushing the zero point clamping system during the pallet change sequence.

The benefits to you:- Retooling or loading and unloading of the parts to the machine setup station during the machining operation

- Pallet changer system compactly integrated into the machine

- Optimized access to the rotatable and lockable setup station

- Fast exchange of pallets between work area and setup station

- Seating check system for the pallets already located in the pallet changer system

- Wide-opening setup station doors with crane loading capability

Rotary pallet storage system (PSS-R)

The GROB rotary pallet storage system expands the G-module to a flexible production cell to offer optimum entry to automated, highly efficient production.

Features:- Versions with up to 15 pallet storage positions at one to three levels

- Easily accessible setup station arranged next to the machine control panel

- Fast pallet change when using two pallets thanks to an innovative pallet changing device

- Visualization and organization of production orders with flexible production control software

- State-of-the-art production control software with 19-inch touchscreen panel

The benefits to you:- Complete solution from a single source in a standardized design

- Economic production with increased machine capacity utilization

- Capability to produce in unmanned/lightly-manned shifts

- Optimized view into the work area and towards the pallet storage positions

- Parallel loading and unloading of the pallets during the machining operation

- High storage capacity with small footprint

- Pallet storage solution for small initial investment Simple retrofit on existing machines

Linear pallet storage system (PSS-L)

The linear pallet storage system is a development from GROB that complements the product range with a highly automated, flexible manufacturing line for a wide variety of part machining.

Features:- Up to five machines can be connected to one system

- Expandable modular system consisting of at least one basic module

- System flexibly expandable by up to four expansion modules and additional setup stations

- Easily accessible setup station with crane loading capability

- Visualization and organization of production orders with a flexible production control software

- For machines with and without pallet changer

- Highly dynamic loading unit with optimized control system for reduced pallet change time

- Flexibly configurable according to your requirements

- Complete solution form a single source in a standardized design and an interface which is optimally matched to the machine

- Cost-effective production through increased machine utilization

- Permits a longer and unmanned production period

- Allows optimum access to work area of the machine during automation, e.g. for manual loading or setup work

- High storage capacity with small footprint

- Pallet storage solution with low investment

Top loading

Agile loading gantry

- The agile loading gantry is set apart by the extremely high acceleration rates and velocities achieved, and is suitable for loading medium-weight parts. This system offers other benefits in its ability to adapt simply to new part types. Thanks to its compact design, it can also be used in production halls with low hall height. The minimum number of components guarantees the highest availability.

Cartesian linear gantry

- The Cartesian linear gantry is designed for the fully automated direct loading of a G-module from above and is available in three different versions. It has one vertical axis per carriage and is therefore also suitable for extremely heavy parts. The Cartesian linear system travels in the horizontal and vertical plane at the same time, thereby also achieving more efficiency.

Cartesian linear gantry with telescope

- The Cartesian linear gantry with telescope is one of GROB's most recent top loading developments and is especially suitable for use in production halls with a low ceiling height.

Front loading

Automatic sliding changer

- The automatic sliding changer is normally equipped with a loading portal. Loading with agile loading gantry and automatic sliding changer is the GROB standard for automated, decoupled loading processes that guarantee minimum non-productive times during the machining process

Swiveling changer

- The swiveling changer decouples the part transport process from the machine loading process, which can be done either manually or via a portal. It is suitable for both partially and fully automated loading. A swiveling changer is able to load two machines, positioned opposite one another to save space, in succession.

Software

- Transparency and connectivity in your production

process

Our modular GROB-NET4Industry web applications allow you to network and digitalize your production processes across all plants to make your manufacturing facility even more efficient.From planning to engineering to maintenance, GROB-NET4Industry combines relevant modules for increasing productivity and offers you the all-round package for modern production in the Industry 4.0 era.

GROB4Line – The machine in sight via smartphone

- GROB4Line allows a GROB machine to be connected to the

Internet. Consequently, it can be monitored and controlled via a smartphone.

Combined with the notification function which sends messages (e.g. machine

shutdown, alarm messages or job fi nished) to defined smartphones, the

machine operator concerned can respond immediately and minimize unnecessary

downtimes

GROB4Line functionalities

- Mobile, dynamic display of machine data

- Information about status, alarm messages, tool and NC program at a glance

- E-mail notification for machine shutdown

- Definition of alarm messages for proactive e-mail notification

- Mobile monitoring of unmanned and lightly-manned machine operation

- Historical timeline diagram

Your package

Simple and intuitive remote access to your machines- Smartphone app for iOS (from Version 8) and Android (from Version 5)

- Intuitive administration in the GROB4Portal

- Rule configurator for customizations

- View via smartphone or computer

The benefits to you

- Improved manpower utilization

- On-call service/shift support

- Less downtime

- All information received, no matter what the locations

GROB4Analyze – Feedback from the machine for CIP

- GROB4Analyze determines the machine data with performance

indicators and visually prepares these data to maximum effect. The module

identifies non-productive phases, allowing the reasons behind weaknesses to

be swiftly determined and rectified. GROB4Analyze, then, is a helpful tool

for your Continuous Improvement Process (CIP).

GROB4Analyze functionalities- Visualization of 12 machine states

- Dynamic display in various diagram formats

- Drilldown function in the timeline diagram

- NC, tool, override, alarm and potentiometer data*

- Machine/shift comparison for evaluation

- Report and evaluation export*

Your package

A simple and fl exible solution for machine data logging (MDL)- Simple access via the GROB4Portal

- Direct connection to the machine control system

- Data and report export module*

- Long-term storage of data for evaluation (option)

The benefits to you- Data provisioning for an effective CIP

- Determination of savings and optimization potentials

- Optimal use of available capacities

- Support for cause identification Identification of unproductive phases

- Creation of reports for production managers*

GROB4Simulate – Complex processes and parts simply simulated

- GROB4Simulate produces an entirely virtual image of the

machine, including tool, clamping system, part and NC program. This allows a

previously collision-tested and verified NC program to be transferred to the

machine.

GROB4Simulate functionalities- Simulation of the actual NC code 3D machine simulation in real time Collision monitoring Component matching Real-time visualization of coordinate systems and tool reference points Checks outside the axis values Interactive and automatic clearance of residual material

Your package

Powerful simulation system based on state-of-the-art technology- Machine and NC code simulation in real time Precise emulation of all monitoring functionalities Integrated 3D machine model Single block and batch mode

The benefits to you- Remote server cloud simulation – upload simulation files in the GROB4Portal and GROB-NET4Industry will look after the rest Analysis and comparison of the digital model with the machined component Highlights areas with machining allowance and contour violations, as well as ± tolerance Simulation of multi-channel mill-turn machining centers, as well as synchronized or continuous 5-axis programs

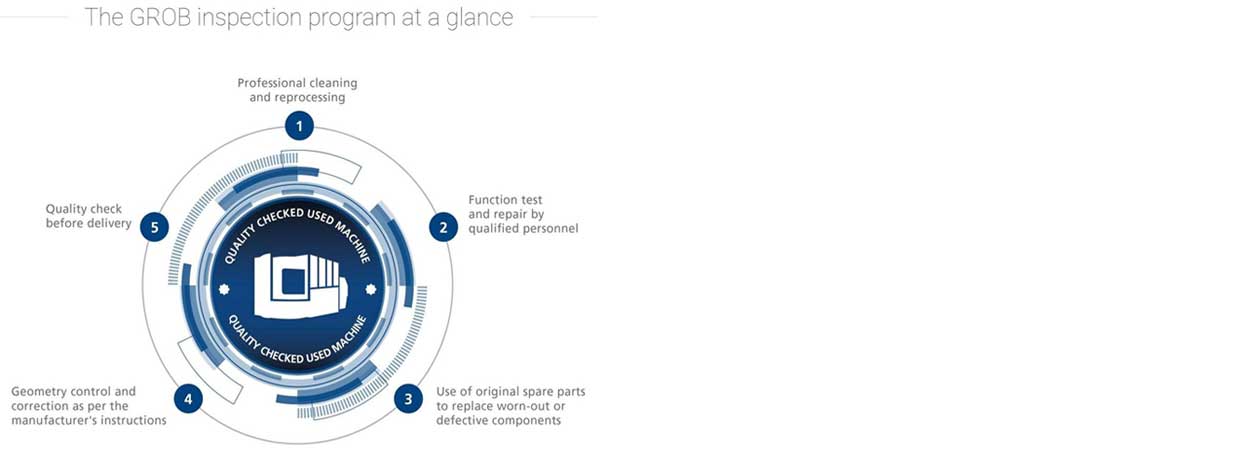

Quality-checked used machines

Discover GROB quality-checked used machines

The benefits to you

Quality that lasts: Thanks to excellent engineering and long-term spare parts availability, the GROB G350, G550 and G750 machining centers can be used for an above-average period of time. In our quality-checked used machines center, we put used machines from GROB through their paces and make them fit again for use by a new customer.- Certified quality

- Comprehensive function test before delivery

- Possibility to view all available machines in our quality-checked used machines center at the Mindelheim site

- Only original spare parts are used

- Immediately available in our quality-checked used machines center

- Tested precision and reliability