- Offer Profile

-

EGIS, a medium-sized Swiss company, has been specialising for 50 years in the production of high-precision linear guidance systems which are essentially used in the following fields:

- Machine tool construction

- Printing machines

- Measurement technology

- Automation

- Robotics

- Optics

- Productronics

- Medical technology

M AND V GUIDEWAYS

-

M and V guideways are combined with angled flat cage assemblies and are particularly suitable for high load carrying capacities, rigidity, minimal friction and a high level of accuracy. They are used as linear locating bearings. They are manufactured in standard lengths up to a maximum of 1,000 mm which allows for rapid delivery.

In order to respond to specific customer requirements, the guideways in this range can also be supplied in made-to-measure lengths, i.e. in any required length up to the maximum length specified in the dimension table.

The guidance systems can be set to be free of clearance or can be preloaded to enhance rigidity using pressure screws.

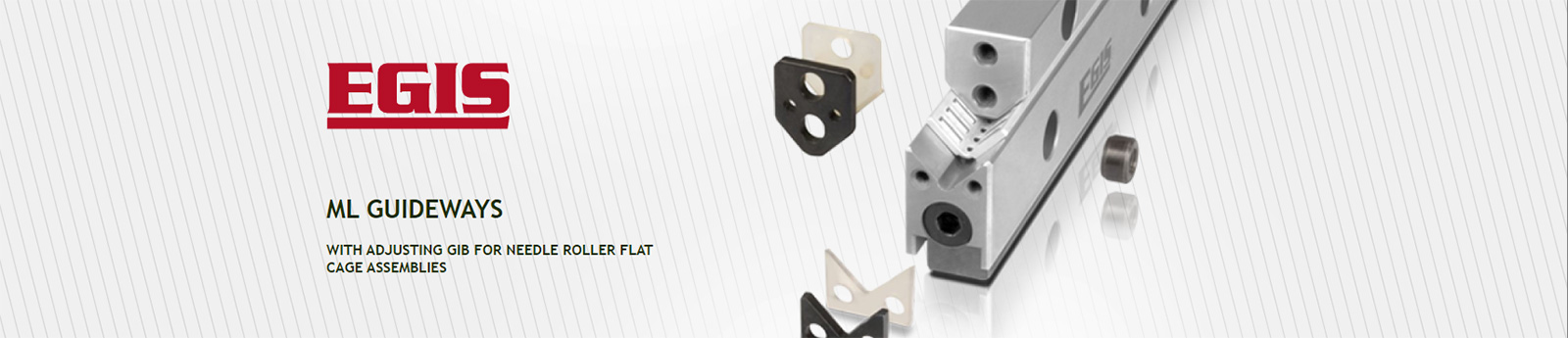

ML GUIDEWAYS

-

This series combines an M guideway with an adjusting gib which distributes the preload equally over the entire length of the guidance system.

The pitch of the gib surface is 1.5%. ML guideways fulfil optimum requirements in terms of rigidity and precision.

MVZ (M/V/ML) GUIDEWAYS

- In this series, the angled flat cage assembly is subjected to positive control by an integrated toothed wheel / toothed rack unit. This guarantees perfect movement for the flat cage assembly even under difficult operating conditions.

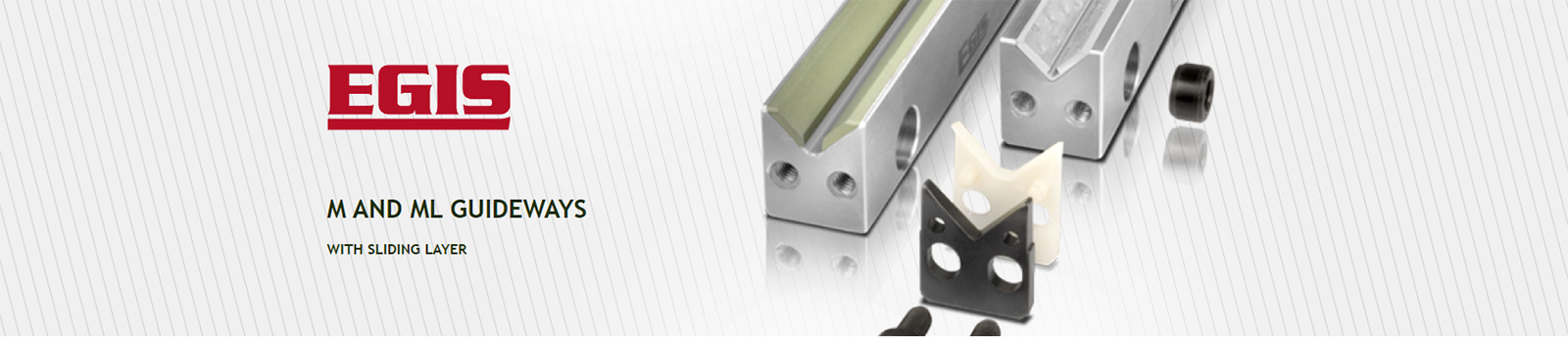

M AND ML GUIDEWAYS WITH SLIDING LAYER

- The guideways in this series consist of an unhardened guideway with a layer fixed by adhesive. They are combined with V guideways and possess the same mounting dimensions as the M/ML and V guideways with flat cage assemblies. They are used in particular when an increased level of friction is required to provide damping or when static or pulsating loads are involved.

S AND J GUIDEWAYS

- These guideways are used in combination with needle roller flat cage assemblies as linear non-locating bearings. They are supplied in two versions, one of which possesses a flat structure and is therefore space-saving whilst the other has the same dimensions as the corresponding M and V guideways.

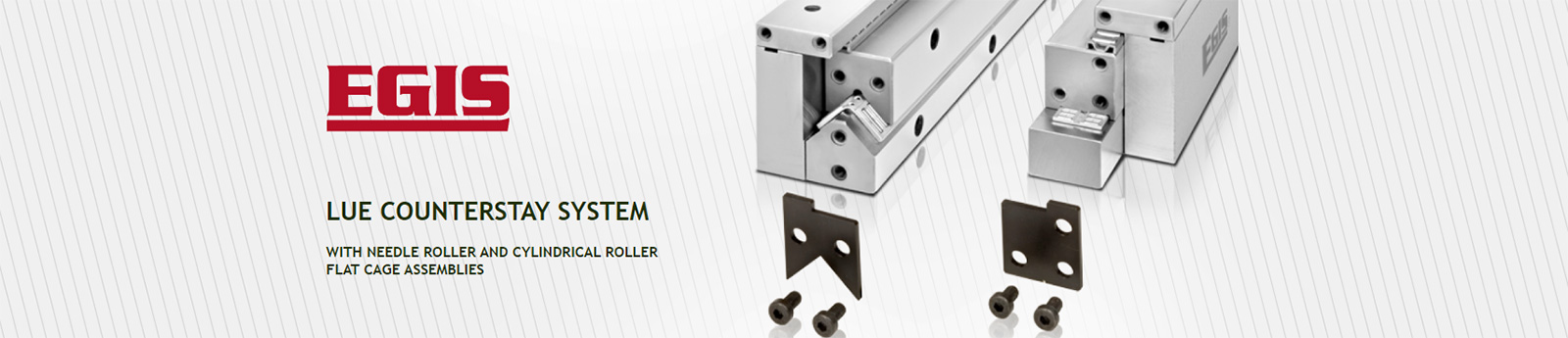

LUE COUNTERSTAY SYSTEM

-

These units consist of a locating guidance system, a non-locating guidance system and an L counterstay which preloads the two guidance systems. This arrangement prevents the system from becoming distorted by thermal expansion.

The LUE counterstay system is particularly suited to high -precision applications. This system provides the highest level of accuracy of all linear guidance systems with roll -ing elements.

FLAT CAGE ASSEMBLIES

- Flat cage assemblies consist of a basic cage made from plastic or metal and a large number of precisely guided rolling elements. Needle rollers provide a minimal con -struction height and optimum load carrying capacity and rigidity whilst cylindrical rollers are less demanding with regard to the connecting structure and have a slightly less rigidity. Balls create the lowest level of friction of all rolling bearings. Flat cage assemblies are designed for use with precision guideways but can also be used directly with customer-specific elements with appropriate raceways.

SPECIAL DESIGNS

-

- Guideways for cross roller and ball flat cage assemblies

- Guideways for hydrostatic guidance systems

- Guideways for air bearings

- Guideways with specific shapes and dimensions

- Linear recirculating roller bearings (RUSW and U-100)

Product Technology