- Offer Profile

-

Founded in 2000, TM Robotics has supplied industrial robots internationally for more than two decades. During this period, we’ve exclusively partnered as the premier distributor for Shibaura Machine in Japan, formerly known as Toshiba Machine. We’re proud to deliver the highest quality machinery to customers around the world — and to represent a company with such a unique history in Japan’s manufacturing past.

Shibaura Machine was first founded as Shibaura Machine Tool Co. in 1938, and was Japan's first large-scale machine tool manufacturing business. Shibaura Machine Tool Co. completed its first mass-produced tool at the newly-opened Tsurumi Plant in 1939. It afterwards went on to produce its first electric refrigerator, the cigarette rolling machine, textile machines and more.

In 1956, Shibaura Machine Tool Co. manufactured its first injection molding machine. The company soon-after merged and absorbed Shibaura Machine Tool, and the company name was changed to Toshiba Machine Co., Ltd in the early 1960s. Toshiba Machine opened its Sagami Plant in 1964, dedicated to the production of hydraulic machinery used for heavy construction machines.

SCARA ROBOT RANGE

-

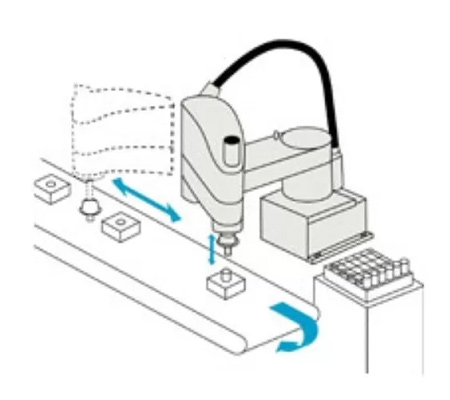

Developed in 1981, the SCARA robot has been around for a while; but, that doesn’t mean it is outdated — it has simply stood the test of time. Our range of SCARA robots is the widest on the market, and also the easiest to install and quickest to deliver a return on investment.

Standing for Selective Compliant Articulated Robot Arm, SCARA robots were designed to mimic the action of a human arm to automate assembly or loading and unloading tasks with speed and precision. The idea is to get all the benefit of a human employee at a higher speed and without fatigue. Adding one or more SCARA robots to the production line is one of the more affordable ways to increase production speed and deliver payback on your automation investment, something that is increasingly important to remain competitive in the Industry 4.0 landscape.

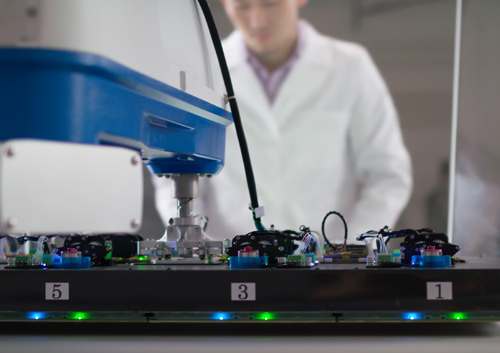

SCARA robots are ideal for industrial operations such as food processing, pharmaceutical or electronics manufacturing and automotive assembly applications where effective and fast pick and place functionality is essential. Components can be picked, placed, moved, packed and unpacked with ease by a robot that keeps its factory floor footprint to a minimum. We can even mount them on the ceiling.

SCARA industrial robots will automate for less

With dozens of bases models, each with dozens of options, we can put together the perfect robot for your needs. We’ve got small ones, fast ones and tough ones, so no matter what process you’re automating, we can help get it right.

For example, the THP range was designed to be low weight and have low inertia levels. The durable range offers a fast cycle time of 0.3 seconds, 120 cycles per minute as well as being able to operate continually for 24 hours. The THP550 has an arm length of 550mm and a maximum payload of 2kg, making it ideal for fast-paced functions in food processing and pharmaceutical manufacturing.

The THL low energy series is a good choice for businesses looking for a cost-effective automation solution. With a payload up to 10kg, the range includes the THL500, THL600 and THL700, which have arm lengths of 500mm, 600mm and 700mm respectively and all of the machines in this series offer a Z-axis rotation of 360°. The THL1200 is the largest machine in the range, offering a wider working envelope for a wider operational area.

SCARA THP Range: High speed SCARA robots

-

High speed SCARA robots

High performance SCARAs that are capable of working at maximum speeds with continuous operation. Designed with the use of a lightweight arm and the achievement of low inertia to realize the highly durable models that offer a fast cycle time of 0.3 second level, and the 120 cycles per minute in a continuous operation.

SCARA THP550

-

- Standard Cycle Time: 0.29s (with 1kg load)

- Max Payload: 2kg

- Arm Length: 550mm

Shibaura Machine has developed the THP550, a high-speed SCARA robot, which has been designed specially for high-speed handling applications in the food processing and pharmaceutical packaging fields.

The THP550 has an arm length of 550mm and a maximum payload of 2kg. The main features include a lighter body weight and low inertia of the second arm. The first arm is made from solid aluminium for higher rigidity, but the robot achieves extremely fast cycle times of 0.29 per seconds (1kg). The durability of the body structure has remarkable resistance under frequent acceleration and deceleration.

The THP550 is equipped with the especially developed controller, the TS3000E, which has built-in ethernet/USB ports as standard. This controller has the capability to share a vision system on multiple robots, so it makes conveyor and vision synchronization effortless and affordable. It also provides easy maintenance for programming data input/output.

Additionally, the built-in PLC function allows easy connection with HMI, touch screens and control of I/O equipment, regardless of the robot operation and program. Options such as IP65 and clean-room specifications are available for this model.

Product Features & Benefits- Highly durable models

- Long continuous operation at maximum speed

- Outstanding performance in high-precision processes

- No fatigue even from 24-hour, high-cycle operation

- Lightweight arm and the achievement of low inertia

- Fast cycle time of 0.3-second level, and 120 cycles per minute in 24-hour continuous operation

SCARA THP700

-

- Standard Cycle Time: 0.345s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 700mm

Shibaura Machine has developed the new high-speed SCARA robot, the THP700, which has been designed specially for high-speed handling applications in the food processing and pharmaceutical packaging fields.

The THP700 has an arm length of 700mm and a maximum payload of 10kg. The main new features include a lighter body weight and low inertia of the second arm. The first arm is made from solid aluminium for higher rigidity, but the robot achieves extremely fast cycle times of 0.345 per seconds (2kg). The durability of the body structure has remarkable resistance under frequent acceleration and deceleration.

Product Features & Benefits

The THP700 is equipped with the newly developed controller, the TS3000E, which has built-in Ethernet/USB ports as standard. The new controller has the capability to share a vision system on multiple robots, so it makes conveyor and vision synchronization effortless and affordable. It also provides easy maintenance for programming data input/output.

Additionally, the built-in PLC function allows easy connection with HMI, touch screens and control of I/O equipment, regardless of the robot operation and program. Options such as IP65 and clean-room specifications are available for this model.- Highly durable models

- Long continuous operation at maximum speed

- Outstanding performance in high-precision processes

- No fatigue even from 24-hour, high-cycle operation

- Lightweight arm and the achievement of low inertia

- Fast cycle time of 0.3-second level, and 120 cycles per minute in 24-hour continuous operation

SCARA TH Range

-

Strong payload capacities, rigid, high speed and flexible

The well-established TH series have an arm to meet every application requirement. The range extends from 180mm to 1200mm and cable of handling up to 20Kgs.

SCARA TH250A

-

- Controller: TS3000

- Standard Cycle Time: 0.41 s (with 1kg load)

- Max Payload: 3kg

- Arm Length: 250mm

The maximum speed of TH250A is 12% faster than the earlier TH250 model and the cycle time has been shortened with high rigid speed reducer.

The ball screw splines with clean room grade lubricant is ideal for use in clean rooms.

This size of model is used in hard disc manufacturing line, inspection process after machining and plastic parts handling and more.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA TH350A

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.41 s (with 1kg load)

- Max Payload: 3kg

- Arm Length: 350mm

Same maximum speed as model TH250A, TH350A is faster than that of the earlier TH350 models.

With the introduction of the highly rigid gears, the cycle time has been reduced with the improvement of acceleration has been improved.

The clean-room-grade lubricant for the ball screw spline makes them ideal for clean-room applications.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA TH450A

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.3 s (with 1kg load)

- Max Payload: 5kg

- Arm Length: 450mm

High speed and high precision SCARA robot with an arm length of 450m and capable of handling payloads up to 5 Kgs.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA TH550A

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.33 s (with 2kg load)

- Max Payload: 5kg

- Arm Length: 550mm

High speed and high precision SCARA robot with an arm length of 450m and capable of handling payloads up to 5 Kgs.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA TH650A

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.31 s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 650mm

The TH650A SCARA robot boasts highly rigid gears in each axis, enabling an increase in acceleration and life span with easy maintenance.

Both arms are made from aluminium casting and provides high rigidity, with an arm length of 650mm and a maximum payload capacity of 10kg.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA TH850A

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.39 s (with 2kg load)

- Max Payload: 20kg

- Arm Length: 850mm

The TH850A is a high-speed SCARA robot with an arm length of 850mm, and a maximum payload capacity of 20kg.

Ideal for various production lines and large material handling, the TH850A also supports options such as cleanroom design, IP65 and ceiling-mount type.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA TH1050A

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.39 s (with 2kg load)

- Max Payload: 20kg

- Arm Length: 1050mm

The TH1050A SCARA robot has an arm length of 1050mm, and a maximum payload capacity of 20kg.

The TH1050A is made with a labyrinth structure offering dust protection both inside and out, making it the perfect solution for all applications with a dust-free environment.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA TH1200A

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.39 s (with 2kg load)

- Max Payload: 20kg

- Arm Length: 1200mm

The largest of the TH-A series, the TH1200A has a compact body and an arm span of 1200mm, as well as a maximum payload capacity of 20kg.

The TH1200A is ideal for use in many high precision pick-and-place applications, such as line packaging and assembly work.

Product Features & Benefits- Heavy duty arm

- Rigid arm structure

- Highest payload in its class

- Up to 20kg payload

- Arm lengths from 180 to 1200mm

- Ideal for end of line packaging and assembly work

SCARA THL Range: Energy efficient SCARA robots

-

Cost effective and energy saving SCARA range

Shibaura Machine’s latest line of cost effective and lightweight SCARA Robots, the THL Series, is ideal for price-conscious end-users, and system integrators looking to incorporate automation. The THL Series consists of eight SCARA robot models from 300mm up to 1200mm arm lengths capable of handling payloads up to 10kgs.

To bolster the robot’s overall performance, the THL features an aluminium extrusion cross-section, custom designed and manufactured for Shibaura Machine robots. Providing no compromise in strength, the aluminium extrusion is 55 per cent lighter than cast aluminium and its values are calculated precisely to maintain strong mechanical capabilities of the robot arm.

SCARA THL300

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.48s (with 2kg load)

- Max Payload: 5kg

- Arm Length: 300mm

THL Series SCARA Robots include the THL300 and THL400 with arm lengths of 300mm and 400mm respectively.

Each THL offers a payload of 5kg. Cycle times (with 2kg load) are .48s for the THL300 and .47s for the THL400. All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360°.

Maximum speeds range from from 5.1m/s to 6.3m/s overall.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

SCARA THL400

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.48s (with 2kg load)

- Max Payload: 5kg

- Arm Length: 400mm

THL Series SCARA Robots include the THL300 and THL400 with arm lengths of 300mm and 400mm respectively.

Each THL offers a payload of 5kg. Cycle times (with 2kg load) are .48s for the THL300 and .47s for the THL400. All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360°.

Maximum speeds range from from 5.1m/s to 6.3m/s overall.

Product Features & Benefits- Low Cost

- Light to Medium Duty

- Up to 10kg Payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

SCARA THL500

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.45s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 500mm

THL Series SCARA Robots include the THL500, THL600 and THL700 with arm lengths of 500mm, 600mm and 700mm respectively.

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .45s for the THL500 and THL600, and .50s for the THL700. All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º.

Maximum speeds range from 6.3m/s to 7.9m/s overall.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

- Ideal for end of line packaging and assembly work

SCARA THL600

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.45 s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 600mm

THL Series SCARA Robots include the THL500, THL600 and THL700 with arm lengths of 500mm, 600mm and 700mm respectively.

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .45s for the THL500 and THL600, and .50s for the THL700. All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º.

Maximum speeds range from 6.3m/s to 7.9m/s overall.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

- Ideal for end of line packaging and assembly work

SCARA THL700

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.50 s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 700mm

THL Series SCARA Robots include the THL500, THL600 and THL700 with arm lengths of 500mm, 600mm and 700mm respectively.

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .45s for the THL500 and THL600, and .50s for the THL700. All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º.

Maximum speeds range from 6.3m/s to 7.9m/s overall.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

- Ideal for end of line packaging and assembly work

SCARA THL800

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.47 s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 800mm

The largest THL SCARA Robots include the THL800, THL900 and THL1000 with arm lengths of 800mm, 900mm and 1000mm respectively.

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900, and .48s for the THL1000.

All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

- Ideal for end of line packaging and assembly work

SCARA THL900

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.48 s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 900mm

The largest THL SCARA Robots include the THL800, THL900 and THL1000 with arm lengths of 800mm, 900mm and 1000mm respectively.

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900, and .48s for the THL1000.

All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

- Ideal for end of line packaging and assembly work

SCARA THL1000

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.48 s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 1000mm

The largest THL SCARA Robots include the THL800, THL900 and THL1000 with arm lengths of 800mm, 900mm and 1000mm respectively.

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900, and .48s for the THL1000.

All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

- Ideal for end of line packaging and assembly work

SCARA THL1200

-

- Controller: TS3000 (E)

- Standard Cycle Time: 0.48 s (with 2kg load)

- Max Payload: 10kg

- Arm Length: 1200mm

The largest THL SCARA Robots include the THL800, THL900, THL1000 and now the THL1200 with arm lengths of 800mm, 900mm, 1000mm and 1200mm respectively.

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900; .48s for the THL1000 and .58s for the THL1200.

All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

Product Features & Benefits- Low cost

- Light to medium duty

- Up to 10kg payload

- Arm lengths from 300 to 1000mm

- Ideal for loading and unloading applications

- Ideal for end of line packaging and assembly work

SCARA THE Range: High load performance SCARA robots

-

High speed SCARA robots for synchronised control and tracking precision

The THE series of Shibaura Machine's range of SCARA industrial robots are designed for assembly and inspection applications in the electronics equipment and automobile components industries. This new product range includes the THE400 SCARA robot and the THE600, which is the latest model of the series. A cost-effective option suitable for users and system integrators, the THE series is the perfect tool for fast-cycle automation.

SCARA THE400

-

- Controller: TS5000 Controller

- Standard Cycle Time: 0.31s (with 2kg load)

- Max Payload: 5kg

- Arm Length: 400mm

The SCARA robot THE400 from Shibaura Machine lends itself to the assembly and inspection processes of electronic equipment and automobile components where precision is required.

Accurate movement trajectory with high speed operation and high load performance.

The THE400 offers a cycle time of 0.39 seconds (with 2kg load). Maximum load of 5kg.

SCARA THE600

-

- Controller: TS5000 Controller

- Standard Cycle Time: 0.31s (with 2kg load)

- Max Payload: 12kg

- Arm Length: 600mm

Designed for assembly and inspection applications in the electronics equipment and automobile components industries, the THE600 SCARA is a powerful automation tool.

Advancing from the specifications of the existing THE400 SCARA, the THE600 has been developed to meet growing demand for fast-cycle automation. The THE600 model includes improvements in synchronised control and tracking precision.

The THE600 is compact in design and offers improved high speed, with 60 per cent higher payload capacity than competing SCARA models in the same price range, making it the price-to-performance leader.

Affordable price, impressive performance.

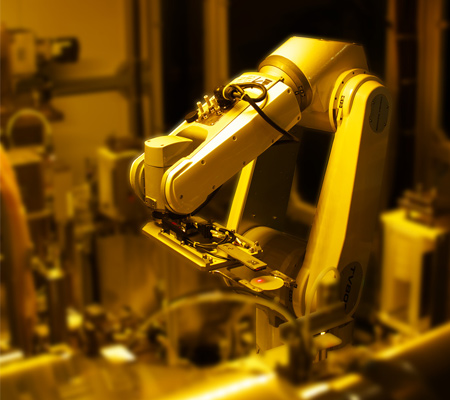

6-AXIS ROBOTS

-

Shibaura Machine 6-axis industrial robots

Compact in design yet offering high performance, 6-axis robots are the ideal solution for many manufacturing enviroments. They provide the optimal combination of flexibility, strength and reach. Able to move along six different axes, 6-axis industrial robots are suited for precision automation and can easily be reprogrammed to complete other tasks.

Vertically articulated 6-axis industrial robot range

TM Robotics offers industrial robot manufacturer Shibaura Machine’s TV, TVL and TVM range of 6-axis robots, which find uses in a host of handling applications across a wide variety of industries, including manufacturing for automotive components, plastics, medical, packaging and the pharmaceutical sector.

As a result, the company is one of a very few worldwide suppliers who can offer easy to use 6-axis, SCARA and Cartesian robots - with reaches from 600-1700mm and payloads up to 20kg - that are sourced from a single industrial robot manufacturer.

6-Axis TV Range: Handling robots

- Shibaura Machine have developed a range of 6-axis robots so as to offer our customers the additional flexibility required in certain applications. The technology is based upon the clean, quick and high performance level of the SCARA but with the full movement of a 6-axis robot.

6-AXIS TV800

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.4~0.5 sec

- Max Payload: 5kg

- Arm Length: 800mm

The TV800 has a total arm length of 800mm, a reach of 892mm and a composite maximum speed of 8.06 metres per second.

The robot has a maximum cycle time of 0.4 to 0.5 seconds, repeatability of ±0.02mm and a maximum payload of five kilograms.

The new six axis robot uses an absolute position detection system, with a robust AC motor at its heart.

Product Features & Benefits- 6-Axis vertically articulated arms

- Available in 800, and 1000mm arm lengths

- Up to 5kg payload

- Ideal for machine loading/unloading and assembly applications

6-AXIS TV1000

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.6 sec

- Max Payload: 5kg

- Arm Length: 1000mm

The TV1000 has a total arm length of 1000mm, a reach of 1090mm and a composite maximum speed of 9.61 metres per second.

The robot has a maximum cycle time of 0.6 seconds, repeatability of ±0.03mm and a maximum payload of five kilograms.

The new six axis robot uses an absolute position detection system, with a robust AC motor at its heart.

Product Features & Benefits- 6-Axis vertically articulated arms

- Available in 800, and 1000mm arm lengths

- Up to 5kg payload

- Ideal for machine loading/unloading and assembly applications

6-AXIS TV1000H

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.9 sec

- Max Payload: 10kg

- Arm Length: 1000mm

A pick-and-place robot.

TV1000H is based upon the clean, quick and high-performance level of the SCARA robot but with the full movement of an arm robot 6 axis. The Shibaura Machine verticle articulated robot provides high rigidity, high durability and is light-weight in design.

This 6 axis mechanical desktop robotic arm, can be used in a host of pick and place applications such as machine loading, unloading and assembly applications. Known for its unique design, the TV1000H has a total arm length of 1000mm and a reach of 1090mm contributing to a composite maximum speed of 9.61 meters per second.

Performing to a maximum cycle time of 0.9 seconds, and repeatability of ±0.03mm and a maximum payload of ten kilograms, this robot can offer our customers that additional flexibility required in certain applications.

The 6-axis robot uses an absolute position detection system, with a robust AC motor at its heart, and can also be combined with vision and conveyor tracking solutions for complex pick and place, fully automated quality control and inspection tasks.

Product Features & Benefits- 6-Axis vertically articulated arms

- Available in 800, and 1000mm arm lengths

- Up to 10kg payload

- Ideal for machine loading/unloading and assembly applications

6-Axis TVM Range: Shibaura Machine 6-axis robots

-

The cost-effective TVM model is a vertically articulated robot series aimed at a multitude of industries, including automotive components, plastics, medical, packaging, and pharmaceutical, due to its high productivity in transfer and assembly and lightweight, reliable design.

The TVM robot’s lightweight design is improved by the addition of an aluminium extrusion. This section of the robot is up to 55 per cent lighter than the usual cast aluminium. From a production perspective, reduced weight reduces the overall cost of production and components, further improving the costs associated with this machine.

6-AXIS TVM 900

-

- Controller: TSL3200 (E)

- Maximum Reach: 1124mm

- Max Payload: 20kg

- Arm Length: 900mm

The new cost-effective TVM model is a vertically articulated robot series aimed at a multitude of industries, including automotive components, plastics, medical, packaging, and pharmaceutical, due to its high productivity in transfer and assembly and lightweight, reliable design.

Shibaura Machine has initially released three models of the TVM – all with varying specifications:

- TVM900/TSL3200E; Reach 1124mm, Payload 20kg

- TVM1200/TSL3200E; Reach 1418mm, Payload 15kg

- TVM1500/TSL3200E; Reach 1715mm, Payload 10kg

Combined with Shibaura Machine’s robot vision recognition package, TSVision3D, the TVM also supports easy implementation of bin-picking automation.

With such convenience, no CAD data is necessary for model registration. Instead, the introduction of an automated system is supported with an easy calibration procedure.

Product Features & Benefits- 6-Axis vertically articulated arms

- Available in 900, and 1500mm arm lengths

- Up to 20kg payload

6-AXIS TVM 1200

-

- Controller: TSL3200 (E)

- Maximum Reach: 1418mm

- Max Payload: 15kg

- Arm Length: 1200mm

The new cost-effective TVM model is a vertically articulated robot series aimed at a multitude of industries, including automotive components, plastics, medical, packaging, and pharmaceutical, due to its high productivity in transfer and assembly and lightweight, reliable design.

Shibaura Machine has initially released three models of the TVM – all with varying specifications: - TVM900/TSL3200E; Reach 1124mm, Payload 20kg

- TVM1200/TSL3200E; Reach 1418mm, Payload 15kg

- TVM1500/TSL3200E; Reach 1715mm, Payload 10kg

Product Features & Benefits

Combined with Shibaura Machine’s robot vision recognition package, TSVision3D, the TVM also supports easy implementation of bin-picking automation.

With such convenience, no CAD data is necessary for model registration. Instead, the introduction of an automated system is supported with an easy calibration procedure.- 6-Axis vertically articulated arms

- Available in 900, and 1500mm arm lengths

- Up to 15kg payload

6-AXIS TVM 1500

-

- Controller: TSL3200 (E)

- Maximum Reach: 1715mm

- Max Payload: 10kg

- Arm Length: 1500mm

The new cost-effective TVM model is a vertically articulated robot series aimed at a multitude of industries, including automotive components, plastics, medical, packaging, and pharmaceutical, due to its high productivity in transfer and assembly and lightweight, reliable design.

Shibaura Machine has initially released three models of the TVM – all with varying specifications: - TVM900/TSL3200E; Reach 1124mm, Payload 20kg

- TVM1200/TSL3200E; Reach 1418mm, Payload 15kg

- TVM1500/TSL3200E; Reach 1715mm, Payload 10kg

Product Features & Benefits

Combined with Shibaura Machine’s robot vision recognition package, TSVision3D, the TVM also supports easy implementation of bin-picking automation.

With such convenience, no CAD data is necessary for model registration. Instead, the introduction of an automated system is supported with an easy calibration procedure.- 6-axis vertically articulated arms

- Available in 900, and 1500mm arm lengths

- Up to 10kg payload

6-Axis TVL Range: Industrial robot brands

-

Industrial robot brands

This lightweight, compact vertically articulated 6-axis Robot offers high performance and productivity on all assembly and handling applications, yet because of its compact size, it also saves on space delivering all of the functionality that you would insist on from a 6-axis Robot, but with a fraction of the expected foot-print within your production line.The TVL industrial robot brands also include an aluminium extrusion cross-section. The design takes inspiration from the Shinkansen bullet train — reducing weight without compromising on strength or performance. This also achieves an impressive 70 per cent reduction in power requirements compared to other robot series

TM Robotics is one of a very few industrial robot manufacturers worldwide who can supply easy to use 6-axis. Click here to discover how TM Robotics became one of the leading robotic arm manufacturers.

TVL500

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.4 sec

- Max Payload: 3kg

- Arm Length: 500mm

The TVL500 Six-Axis Robot with a reach of 602mm and a payload of 3kg really packs a punch as it delivers a high speed, highly accurate, energy saving performance at a low cost.

This brand new light weight, compact vertically articulated Six-Axis Robot offers high performance and productivity on all assembly and pick-and-place applications, yet because of its compact size, it also saves on space delivering all of the functionality that you would insist on from a Six-Axis Robot, but with a fraction of the expected foot-print within your production line.

Product Features & Benefits- 6-Axis vertically articulated arms

- Available in 500 & 700mm arm lengths

- Up to 3kg payload

- Ideal for machine loading/unloading and assembly applications

TVL700

-

- Controller: TS3100 (E)

- Standard Cycle Time: 0.4 sec

- Max Payload: 4kg

- Arm Length: 700mm

The TVL700 Six-Axis Robot with a reach of 700mm and a payload of 4kg really packs a punch as it delivers a high speed, highly accurate, energy saving performance at a low cost.

This brand new light weight, compact vertically articulated Six-Axis Robot offers high performance and productivity on all assembly and pick-and-place applications, yet because of its compact size, it also saves on space delivering all of the functionality that you would insist on from a Six-Axis Robot, but with a fraction of the expected foot-print within your production line.

Product Features & Benefits- 6-Axis vertically articulated arms

- Available in 500 & 700mm arm lengths

- Up to 4kg payload

- Ideal for machine loading/unloading and assembly applications

Cartesian Robot Range

-

Cartesian robots

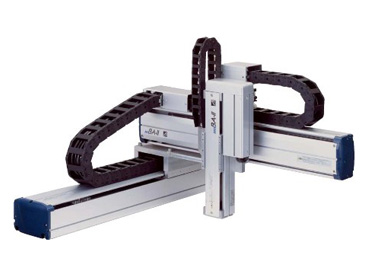

Shibaura Machine has manufactured Cartesian robots since 1986. The line-up of Cartesian robot models focuses on providing high reliability and ease of operation. Shibaura Machine’s BA-III Series of Cartesian robots are designed for simplicity. In fact, there is little-to-no programming required to operate robots from this range.

Our Cartesian robot offering is a true plug and play system. All the cables, connectors, junctions’ boxes, actuators, servo-motors, controllers are provided as a set and can be delivered assembled.

While this series reduces complexity, it also helps reduction in footprint and cost for engineering time as motors do not need to be calibrated to the actuator and the controller.

Linear robots

For easy understanding when considering a robot’s work envelope, the one-dimensional motion of these machines boasts high reliability. In fact, our Cartesian robots use between three and four sliding joints for fast and effective mechanical movement.

For this reason, these robots are suitable for several production lines, including parts assembly, conveying and transfer applications.

Want to find out which Cartesian robot is best for you? Our team are at hand to discuss how the right industrial robot can boost your facility’s productivity, without breaking the bank.

Controllers

-

- Master Controllers

- Slave Controllers

- Options

Cartesian BA3 Series

-

Cartesian robot actuators

Launched in 1986, the Cartesian robot COMPO ARM has developed a proven track record among many devoted customers because of its features of high reliability and ease of operation. For this reason, today, it is used as an integral part in many different types of production lines.

The BA-III series carries on the features of the previous BA-II series while also providing enhanced functions for even greater ease of operation. Models are available from single-axis to Cartesian axes (2 to 4 axes) and in a wide range of variations for also meeting the future needs of customers.

Cartesian BAC actuators

-

- CARTESIAN BAC5D / 7D SLIDER

- CARTESIAN BAC5D / 7D TABLE

- CARTESIAN BAC3D / 4D ROD

Options

Cleanroom Rated Robots

A Cleanroom environment keeps the level environmental pollutants such as dust, aerosol particles, chemical vapors, and airborne microbes to a low level and are typical in electronic manufacturing, medical production environments, and some aerospace applications.

In terms of industrial robots, the cleanroom rating is defined as protecting to the environment from contamination by the robot, and in reverse, cleanroom rated robots are protected from the environment.

Typically, the lower the ISO number or lower the class number, the cleaner the rating..

Specifications:- Applications such as semi-conductor & pharmaceuticals

- TH-CR series extends to clean room class 10

- Operating speeds of Axis 2 and 3 are restricted to 80 percent

Ceiling mounted robots

Ceiling mount capabilities make the Shibaura Machine range of SCARA robots much more versatile. They save space in the robot cell, allowing valuable manufacturing real estate to be put to other uses.

This function has always been available as an option on the entire range of SCARAs (except TH180, TH250A & THL300).

However, since 2008 Shibaura Machine has gradually introduced catalogue versions on many of its models, which saves engineering time for the end user and the integrator.

Specifications:- Can be suspended from the top of the work area

- Makes the best possible use of the available area

Robot ingress protection IP65

-

Industrial robots benefit hugely from the versatility offered by IP65 ingress protection, which allows them to be become part of the manufacturing process in food and pharmaceutical applications, rather than being limited to end of line packaging.

Many of the SCARA robots in Shibaura Machine’s range are produced in ‘off the shelf’ IP65 versions. Those that aren’t can take advantage of the company’s IP65 ‘hoods’, which provide similar advantages and can be retrofitted to existing robots.

Specifications:

- Applications such as semi-conductor & pharmaceuticals

- In case of Z-axis 400mm, the height of the robot tool flange is located 10mm lower than the standard type and Z-axis stoke becomes 390mm

SCARA robot z-axis

-

SCARA robot z-axis

Product Overview

Every application is unique and occasionally the need arises to position the robot some distance from the product it is handling. On these occasions, the capability to extend the z-axis stroke of a SCARA robot can be invaluable, allowing the user to opt for this cost effective technology in place of more expensive, but larger, 6-axis machines.That this can be achieved without significantly reducing the payload, repeatability or speed of the machines simply demonstrates the versatility of the Shibaura Machine SCARA range.

Applicable Models: TH450A, TH550A, TH650A, TH850A, TH1050A

Specifications:

- TH450/TH550 Z-axis stroke can be extended up to 300mm

- TH650/TH850/TH1050 Z-axis stroke can be extended up to 400mm

- Larger margin for upward or downward movement

- Vital in long workplaces

Industrial robot jackets and bellows

- Ideal when using the robot in a hostile environment, to

protect from splashing or abrasive material, a jacket and bellows

combination can be a more cost effective option than full IP65 ingress

protection.

However, this option would only normally be recommended for applications where there is no chance of contaminating the manufactured product but where the robot itself needs to be protected.

The hood alone is normally used in dry but dirty environments to protect the ball screw, while the bellows are ideal for wet, dirty environments.Specifications:

- Applicable to all SCARA models

- Ideal when using the robot in a hostile environment.

- Protects from liquid splashing and abrasive materials.

- In the case of the Z-Axis 400mm, the height of the robot tool flange is 10mmlower than the standard model, so the z-axis stroke becomes 390mm.

Conveyor robots

- Conveyor and vision synchronisation is simple with

Shibaura Machine's range of industrial robots. As a result, the end user can

cut costs by ‘sharing' a single camera between all of the robots on a

conveyor.

Furthermore, the resultant, perfectly synchronized, automation reduces the incidence of damage to the conveyed items.

The net effect is greater efficiency and productivity, combined with savings in vision technology in asingle easy to implement package.

Specifications:

- The robot traces the conveyor’s movement

- Allows continuous handling of workpieces

- Allows supply of workpieces to a moving pallet

- Rotational synchronisation available

Logistics

Automated box opening robots

-

The Intelligent Box Opening Device (IBOD) is an inline, pass-through box opener for automating manual box cutting operations. The IBOD has built-in intelligence, measuring the size of every incoming case to automatically find the programmed cut lines. Boxes can be fed in pre-set size order or in mixed order without the need to run batches of the same size.

The IBOD is fully programmable and comes in two variations, depending on your box opening needs. The IBOD ONE is capable of cutting the top cases at rates up to 450 cartons per hour, and the IBOD DUO is capable of opening up to 750 cartons per hour.

The IBOD is available in three main cutting configurations: box top, front pick window, and tape seal cuts. It is completely automatic, self-feeding, and self-aligning. The IBOD uses photo optic and linear displacement measurements to derive the dimensions of each box as it is automatically captured and positioned for cutting.

A programmable motion device transforms the prescribed cut pattern to each box size. Blade stops and a box snugger are used together to give the cutting robot a squared and stationary target. The IBOD robot then uses software-controlled automation to cut boxes according to precise specifications defined by the customer.

The IBOD features heavy welded steel frame construction with main frame components fabricated from 100mm welded steel tube with heavy gauge steel panels and guarding. The front side panel and access door is 18mm thick acrylic for rigidity and safety.

Why automate box opening?

Manual box opening can be slow and labour intensive, while working with knives can result in minor accidents, cuts and lacerations for workers. Automating your box opening process with the IBOD improves productivity, eliminates injuries, and minimizes the damaged product associated with manual box opening.

The IBOD is the only patented automated box opener on the market!

Title

-

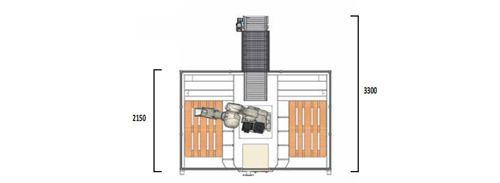

Economical fully automated packing machine

ORFER BoxCellPlus opens the cardboard, folds the flaps, fills out the cardboard boxes and seals the bottom with tape. Due to a modular structure and an adjustable control system it is easy to connect to an automated packing system. The high speed of Shibaura Machine SCARA robots has made the development of the packing cell possible.

The robot can handle all products weighing less than 10 kilograms due to its excellent handling capabilities. Shibaura Machine has been proven very reliable, durable, and maintenance-free, due to its simple structure.

ORFER BoxCellPlus benefits:

- Fast installation and implementation

- Easy to use and cost effective

- Compact size

- Fast changes between different box sizes

- Large doors, easy access inside

- Strong frame structure

- Good visibility inside the machine

- High-quality components

Palletising robots

-

Cost Effective Palletising Solution

Plug and play palletising solution for multiple palletising applications, which will give a production capacity of eight to ten products per minute.

Benefits:- Short delivery time

- From 30 to 60 days upon availability including functional test before shipment

- Fast installation and startup

- Installation startup and training: 1 day

- Easy and flexible to use

- Simple and user friendly interface

- Compact dimension

- Easy to relocate

- Efficient and safe

- Double pallet position for a higher production efficiency

- Energy saving

- The latest generation of 6-axis robots is designed to reduce up to 40% of the electricity consumed

- Short payback time

- Short delivery time

Solutions

Automated soldering systems

Head for flame soldering

-

Do you require the maximum energy possible on the smallest possible space? Our flame soldering head is the perfect solution from our portfolio. A nozzle diameter of 0.5 to 1.2 mm offers you micro flame soldering in a new dimension. Different nozzles and a flame temperature of 2850°C create a highly flexible power package which is optimally adjusted to your needs.

Area of Application

Micro flame soldering is primarily used in areas where hard soldering is required (for example in the jewellery industry). This procedure can also be used for applications unrelated to soldering, such as flame polishing.

Head for high-frequency soldering

-

A new format of high-frequency soldering. Our high-frequency soldering head provides induction heating in the smallest format possible. Its maximum heating power of 2000 W guarantees reliable soldering connections to metallic components.

Area of Application

High-frequency soldering is used to heat metallic components with a high mass. Due to its very high temperature input to surfaces that can be adjusted in size flexibly, this procedure is able to provide the best possible process times.

Head for laser soldering

-

With the laser soldering head, we offer the perfect solution for generating a high degree of energy within a short period of time. Equipped with a 100-W laser and an integrated pyrometer as well as a camera, it enables perfect soldering without much room.

Area of Application

Soldering requiring a high degree of precision without much space is the supreme discipline of laser soldering. The high degree of energy density and a good transmission to the material are advantageous especially for heat-sensitive electronic components, such as flex prints, since the temperature effect on other components is minimised.

Head for robotics soldering

-

Our robotic soldering head combines the newest soldering technologies within one system. Intelligent feeder technology coupled with a powerful soldering head and a high degree of flexibility ensures reliable and repeatable processing regarding contact soldering.

Area of Application

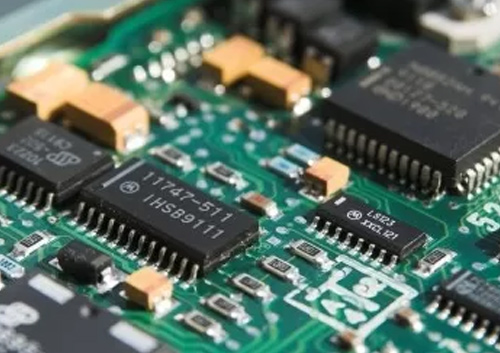

Robotic soldering is a comprehensive solution in soldering technology. There are virtually no limits for processing the most demanding soldering tasks. Highly recommendable and suitable for pin soldering on circuit boards for the electronics industry.

Automated soldering machines

Desktop soldering robot

-

Auto Soldering robot

Looking for a new way to automate soldering?

The SolderSmart® Soldering Robot is the ideal solution. Operated via a controller, this quick soldering robot is used for fully automated and reliable processing of single or multi-point soldering spots. Typical application areas include through-hole technology (THT) components soldering on assembled boards, soldering stranded wires to boards and soldering of connectors.

This desktop soldering robotprovides abrand-new way of managing soldering tasks — even the most complex of applications.

SolderSmart® meets the highest technical standards and the soldering process monitored and documented for traceability. Axes control can be achieved via a PC or server, with an easy to use Windows interface. Moreover, all relevant data such as heating duration, temperature variations and wire length is saved to the PC hard drive or server.

For optimal heat transfer, an optional electrically driven soldering iron can also be programmed to set travel and pressure parameters for specified soldering points.

Due to its modular design, the auto soldering robot may be used as an independent soldering station or as an integral part of a production line.

Thermode Soldering

-

Function:

Automatic thermode soldering (hot bar soldering). The soldering machine monitors the temperature at the thermode, which controls the soldering process. A linear transport system for automatic cable feeding can be attached.

Consisting of:

- Generator

- Wire feeder

- Soldering head with temperature monitoring

- Panel PC control

- Tool holder

- Base frame

- Protection device

- Linear axle

Comment:

The parts are fed to the thermode in a tool holder and then brazed with a high degree of process safety. Feeding and inserting the cables and the height of the soldering seam is monitored by sensors.

Iron soldering

-

Automated soldering of single pins on various printed circuits. Setup includes a cleaning system for the soldering tip thus increasing the life span of it and extending operational use.

Setup includes:

- SCARA robot

- Soldering head

- Cleaning unit

- Operating panel

- Base

- Protective enclosure

High-frequency Soldering

-

Automatic, high-frequency soldering of battery cables. The soldering machine has a temperature control, which governs the soldering process. A linear transport system can be added for automatic cable feeding.

Setup includes:

- HF generator

- Wire feed

- Pyrometer

- Water cooler

- Tool holder

- Base frame

- Guard

- Robot control with operating terminal

Flame soldering

-

The flame soldering machine solders brass pins to pre-punched brass badges. The badges are automatically fed from a magazine onto a rotary indexing table and processed over 8 stations. The soldering process is consistently monitored with sensors. The hydrogen used for flame welding is generated directly in the machine.

Setup includes:

- Machine frame with guard

- Rotary indexing table with 8 stations

- Vertical lifting unit

- 2 gantry axes

- SCARA robot with soldering paste dosing

- Hydrogen generator

- SCARA robot with flame soldering head

- Punch unit

- Wire dispenser

- Conveyor belt

- PLC control with swivelling operating terminal

Laser soldering

-

Automatic soldering of pins on different implementation of boards. The laser soldering can be used for the most different materials. The soldering robots disposes of a laser which solder connections carries out in the shortest time.

Consisting of:

- Laser soldering system

- Robot

- Wire feed DVS 1490

- Teach panel PC

- Pyrometer

- Basic rack

Advantages:

- Controlling the temperature of the solder joint

- No contamination by the soldering tool

- Soldering of components of different materials

- Short soldering times , better temperature and shock resistance

- Contactless machining …..no tool wear

- Use of high-melting solder pastes

Case Studies

Saving space, saving costs

- Fold it, seal it, tape it, box it, pick it, place it — automate it. No, these aren’t Daft Punk lyrics, but the separate processes that Finland-based Orfer Oy needed to automate to speed up its packaging operations. However, automating these processes without expanding on factory floor space was no easy feat. For a new design of a fully automated packing machine targeted to the food and packaging industries, Orfer needed a robot that offered fast and accurate handling and that could easily integrate with a vision system to track and pick parts from a moving conveyor.

Grasping static electricity for revolutionary robotics

- Demonstrating static electricity by using a charged balloon to levitate your hair is a classic science experiment. But, imagine if you could harness the same static cling to handle a material as fragile as an egg, as flimsy as soft fabric — or to assemble the uppers of Nike trainers at 20 times the pace of a human worker. Hatched in the heart of Silicon Valley, in Sunnyvale, California, robotics start-up Grabit is harnessing static electricity, machine learning and automation from Shibaura Machine partner, TM Robotics, to do just that.

Automate for accident reduction

- Could Britain afford to lose 31.2 million working days? According to The Labour Force Survey, this figure illustrates the volume of unplanned worker absence due to non-fatal workplace injuries. In fact, the number of non-fatal workplace injuries in the UK reached 609,000 in 2017 — with cuts and lacerations among the most common causes. Industry leader in apparel distribution, Ralawise believes automation could be the solution.

A philosophy of automation

- In an industrial context, the word automation is often, inaccurately, used to mean only industrial robotics. In fact, it refers to everything from inverter driven conveyor systems to advanced manufacturing software. But it also has a meaning outside the world of industrial engineering.

Cartesian robot in use at glue gun testing plant

- TM Robotics, the European sales partner of Shibaura Machine, is involved in a project to develop a gluing system that will eliminate ‘lag’ in glue dispensing applications. Lag is the term used when a droplet of glue is accidentally deposited in the corner of an object when the dispensing robot changes direction. The project is being run from an R&D lab in Kettering by Metix, the supplier of two-component resin systems and AMT, one of TM Robotics’ system integrators. The project uses a Cartesian linear actuator provided by TM Robotics.

The robot worth its weight in gold

- Ten-tola gold bars – they’re small, they’re incredibly pure, they’re the backbone of trading and investment with the Middle and Far East and Shibaura Machine robots make them. The gold bars made by Johnson Matthey plc, one of the world’s leading specialists in precious metals and advanced materials technology, are cast at the company’s first fully automated gold bar production line at Royston, Hertfordshire. The line, uses advanced Shibaura SCARA robotics systems, available from TM Robotics (Europe) Limited and installed by Evershed Robotics Limited.

Robots bring major savings to plastics company

- More and more companies are turning to robotics to reduce operating costs. One such company is cable management specialist, C&C Marshall Ltd. The company has installed two TM Robotics’ SR-554 HSP SCARA robots at one of its UK plastics molding plants. The installation was prompted by the need to reduce the man-hours spent on the shop floor and increase production.

SCARA robot improves electronics assembly

- Shibaura Machine’s TH350 SCARA robot was the logical choice when a manufacturer of miniature circuit breakers (MCBs) needed to replace an existing pneumatic pick and place machine. After changes to the manufacturing process, the existing equipment was not able to perform the required task in the necessary cycle time. With the help of system integrator Automation & Robotics Ireland, the TH350 was installed and now easily meets its targets.

TM SCARA fastens on to the market

- TM Robotics and systems integrator Evershed Robotics havedemonstrated the speed and accuracy that can be gained by using robotics in the metal fabrication process.

The three companies have developed a system that machines lockable fasteners for car panels. It comprises four twin drill heads arranged on either side of a TM SR-504-HSP SCARA robot. Evershed Robotics designed the system so that one to four drills can be employed in a series, according to throughput requirements. At full output, the machine is capable of producing a finished fastener every four seconds.

Good things come in automated packages

- The earliest printed circuit boards, patented by Austrian inventor Paul Eisler in 1943, were assembled by hand. The tedious method involved manually cutting, trimming and soldering numerous wires. The process was slow and prone to error and unfortunately, it hasn’t evolved much since. Focusing on the manual side of processes, such as extra assembly, MIG-O-MAT approached Elmotec and TM Robotics to develop an automated soldering solution.

Robotic automation saves time and money in shrimp plant

- TM Robotics and Danish integrator BILA have installed two Shibaura Machine SR-854HSP SCARAs on a new shrimp processing line in Northern Denmark. The SCARAs save space, reduce operating costs and represent a flexible solution that could be re-deployed elsewhere in the plant if required. Previously, the process was completed manually.

Three types of flavoured shrimp are produced in separate 100g plastic containers. As the different containers travel down their respective lines, they are transferred by one of the Shibaura Machine SCARA robots onto a single line.

SCARA robot makes big impact for steel manufacturer

- The force exerted if 170.45 handguns were fired simultaneously at a single spot is applied to test the strength of pipes made by South Korean steel company POSCO Steel. TM Robotics teamed up with impact testing specialist Imatek Limited to deliver a robot system to handle the task safely. Nigel Smith, managing director of TM Robotics, explains how the steel giant can now offer its customers total confidence in the quality of its pipe steel.