- Offer Profile

-

Garlock is a global manufacturer of high-performance sealing solutions with an emphasis on safety, longevity, and productivity. We work closely with our end-user customers, distribution partners, OEMs (original equipment manufacturers), industry associations, and government entities to understand their unique sealing challenges and respond with innovative solutions that keep people safe and the environment protected.

With a history dating back over 130 years, Garlock today maintains a global presence of manufacturing and distribution facilities that allow us to meet our customers’ needs with unprecedented responsiveness and ingenuity.

Leaders in Sealing Integrity

- Garlock's portfolio of innovative products deliver solutions that solve unique sealing challenges, improve plant productivity, reduce costs, and help our customers comply with increasingly stringent environmental regulations.

Browse below to view our time-tested products that serve a wide variety of markets, including Chemical Processing, Food and Beverage, Marine, Mining, Nuclear, Oil and Gas, Pharmaceutical, Power Generation, Primary Metals, Pulp and Paper, Water and Waste Water, and more. Bearing Protection

- KLOZURE® Bearing Isolator Labyrinth Seals for pumps, motors, and gearboxes.

KLOZURE® Bearing Isolators feature a unitized labyrinth design to prevent ingress of contaminants and egress of lubrication. KLOZURE® Bearing Isolators are most commonly found in pumps, motors, and gearboxes. Both split and solid styles are available. All KLOZURE® Bearing Isolators are proudly MADE IN THE USA!

Bearing Isolator Labyrinth Seals

- KLOZURE® Bearing Isolator Labyrinth Seals for pumps, motors, and gearboxes.

KLOZURE® Bearing Isolators feature a unitized labyrinth design to prevent ingress of contaminants and egress of lubrication. KLOZURE® Bearing Isolators are most commonly found in pumps, motors, and gearboxes. Both split and solid styles are available. All KLOZURE® Bearing Isolators are proudly MADE IN THE USA!

Oil Seals

-

Garlock® KLOZURE® Oil Seals Configured to Meet Industry Requirements

KLOZURE® Oil seals from Garlock® KLOZURE® are available in a wide variety of configurations to meet the requirements of major industries. MILL-RIGHT® materials are used on all elastomeric seals for superior bearing protection. KLOZURE® Oil Seals are available in more than 50 different styles in sizes from ¼" to over 90", solid or split, metal-cased or all-rubber. KLOZURE® Oil Seals have had a strong brand presence in the U.S. since the 1920s. Today they are also manufactured and branded in China and Germany. Technology has advanced over the years, and the oil seals are now available in MILL-RIGHT® elastomers which provide longer service life than their predecessors.

Compression Packing

-

Garlock Compression Packing will contribute to maintain a safe process, meet stringent fugitive emission limits and save resources, with proven reliability.

Our packing products will generate the greatest return on initial investment in terms of leakage control, service life, dependability, and cost-effectiveness. We also provide expertise with highly knowledgeable application engineering support.

Garlock compression packing is rigorously tested to ensure effective sealing in valves, pumps, agitators, and other rotary equipment. The development of the compression packing line reflects the evolution and innovation in the materials used in its production. Garlock develops and manufactures it's own technical yarn braided into packing, along with high performance proprietary coatings, that are essential in this age of sealing performance requirements.

Garlock's product line includes industry recognized Low Emission valve stem packing, leading-edge and award winning pump packing sets like dry-running DSA, and water saving HYDRA-JUST®. We pioneered the development of emission control valve stem packing in the early 1980s. Our innovation efforts have yielded a portfolio of low emission packing products to suit customer needs and meet EPA’s latest requirements.

Compression Packing by Material

-

- Graphite and Carbon Packing

- PTFE Packing

Compression Packing by Use

- Browse packing by use: Pump, Valve, Mixer, Soot Blower, Rotational, and Static Equipment.

Accessories

- Lantern Rings, Lubricant, and Tools for use with Compression Packing.

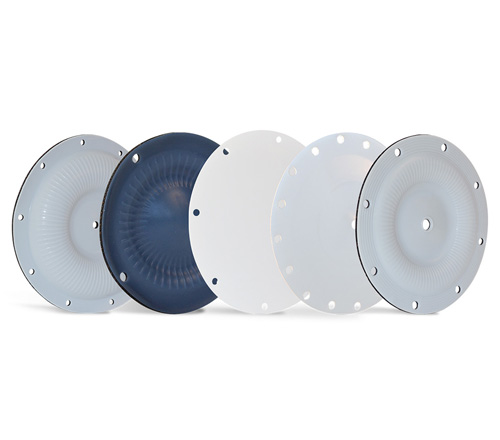

Diaphragms for Pumps and Valves

- Garlock manufactures the most durable and long-lasting pump and valve diaphragms available, reducing equipment downtime and increasing productivity. From pure PTFE to one-piece bolt-on PTFE bonded rubber diaphragms, if you have a difficult or critical application, Garlock has the diaphragm to meet your needs.

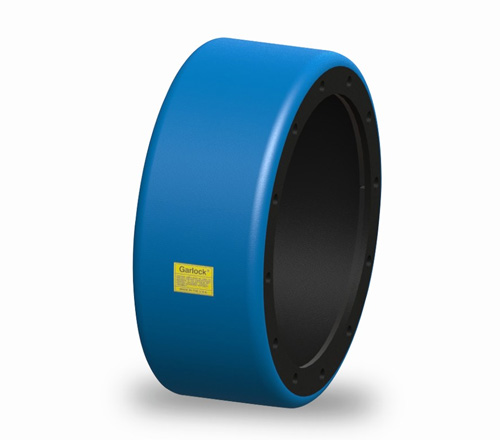

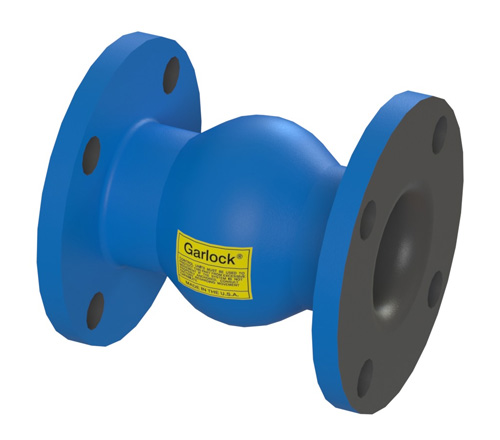

Expansion Joints

-

Garlock Expansion Joints offer superior performance, reliability, and service life, resulting in improved plant safety and increased mechanical integrity of equipment. As specifically engineered products that are inserted in a rigid piping system, Garlock Rubber Expansion Joints will:

- Absorb movement

- Improve thermal stability

- Relieve system strain due to thermal change, load stress, pumping surges, wear of settling

- Reduce mechanical noise

- Compensate for misalignment

- Eliminate electrolysis between dissimilar metals

All of our expansion joints carry safety ratings that exceed product specifications in areas such as pressure and movement. Non-metallic expansion joints and flexible couplings are ideally suited for a wide variety of industries.

- Absorb movement

Ducting and Low Pressure Expansion Joints

Piping Expansion Joints

Accessories for Expansion Joints

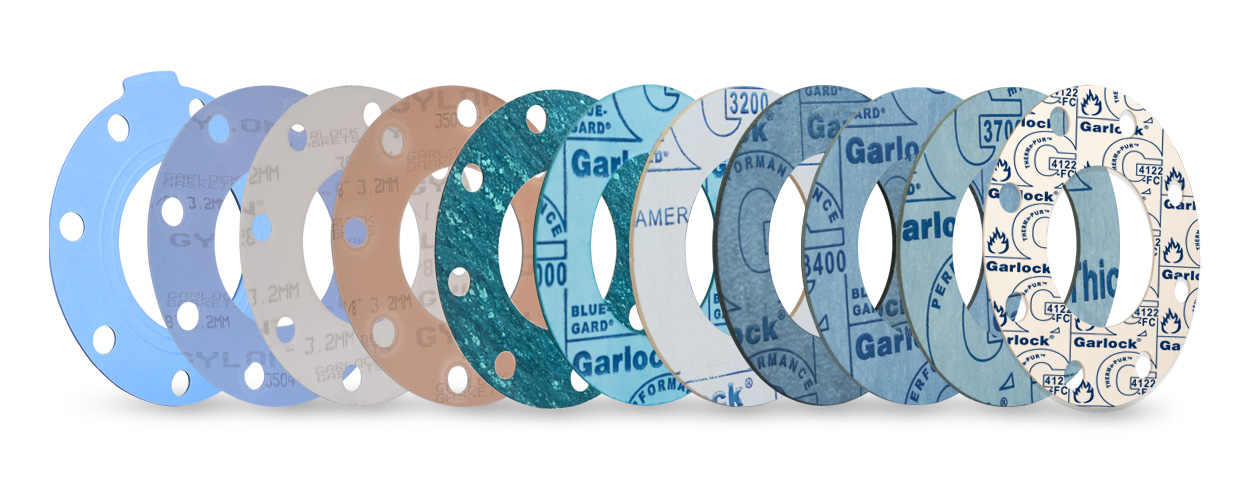

Gaskets

- Garlock Gaskets and Gasket Sheet Material have remained the gold standard of sealing for over 125 years with good reason: Our products are made using unique, proprietary materials developed through years of experience to offer unrivaled sealability, reducing service calls and increasing uptime, even under the most extreme conditions.

Garlock gaskets are offered in a wide range of materials and configurations, including GYLON® Restructured PTFE, Compressed Fiber, GRAPH-LOCK® Flexible Graphite, THERMa-PUR® Extreme Temperature, High-Performance Premium Rubber, Metallic Gaskets, Non-Metallic Cut Gaskets, and the new TUFF-RAIL® Tank Car Manway Gaskets.

Gasket Sheet Material

-

Developed over years as an industry leader, the Garlock gasket sheet material portfolio includes a wide array of options to ensure a sealing solution for even the most demanding applications. Whether it’s less than ideal flanges, pressure and temperature extremes, or aggressive media, Garlock has an answer for your greatest challenges.

GYLON®, known industry wide as the material of choice for severe chemical services, is offered as a traditional flat sheet as well as with the new EPIX® profiled surface option, which is ideal for misaligned, worn, or pitted flanges.

Garlock’s Compressed Fiber Gasket Sheet Material uses a time-tested proprietary manufacturing process, and covers everything from general service to extreme applications.

Garlock’s Premium Rubber family of products are manufactured using high-quality homogeneous rubber compounds, unlike commercial or utility rubber products, which are made with low-quality blends, prone to media incompatibility and gasket failure.

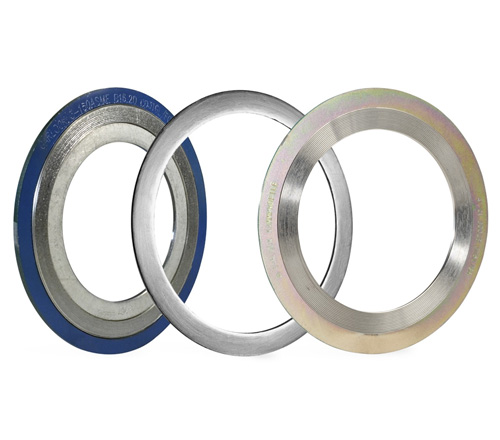

Metallic

-

Metal gaskets are designed to withstand extreme temperatures, pressures and chemical exposure. Available in standard and custom configurations, these rugged metal gaskets are made of a wide range of materials to accommodate all types of process applications.

Looking for a product to procure for your construction project? If you are looking for a specific product for a construction project, working on a piping system engineering spec, or need additional help of any kind, our Engineering and Construction team is available for assistance no matter where you are located

Non-Metallic

-

Garlock Non-Metallic Gaskets utilize the wide breadth of our award-winning gasket sheet material portfolio and are engineered to seal a wide array of service conditions including aggressive chemicals and extreme temperatures, making Garlock gaskets the gold standard for over 130 years.

Our Standard Pipe Flange Gaskets are engineered to meet the demands of aggressive medias and extreme temperatures. Whether your need is fire safe, cryogenic, food contact approved, or worn flanges that won't hold a seal, there is a Garlock gasket for your application.

Garlock's STRESS SAVER® Pipe Flange Gaskets are ideal for lightweight piping and non-metallic flange applications where low bolt load and chemical resistance are issues.

Look to our In-Line Strainer Gaskets for an effective and inexpensive way to protect valuable downstream equipment such as metering devices from dangerous debris in the pipeline.

Lubrikup® Prolene Boiler Manhole and Handhole Gaskets are constructed of proprietary rubber compounds to ensure optimal performance and a long-lasting seal.

Sanitary PTFE Gaskets

- GYLON BIO-LINE® PTFE material provides exceptional sealing performance for all pharmaceutical and food processing applications and processes. Its restructured PTFE composition provides safe, durable and consistent sealing performance in a range of challenging environments, including exposure to acids, caustics, sensitive media, low and high temperatures and pressures.

By remaining flexible, tight and flush with the pipe bore, even under high loads, GYLON BIO-LINE® gaskets further eliminate the potential for process material contamination caused by traditional elastomeric seals.

Tank Car Manway Gaskets

- Designed to fit the most common manways and constructed from industry proven Gylon® material, TUFF-RAIL® manway gaskets provide a reliable, reusable gasket that offers superior performance over other PTFE materials.

Hydraulic Components

- Garlock hydraulic components include heavy-duty packing and seals to meet the demanding requirements of todays reciprocating equipment. Key hydraulic component products include CHEVRON® V-ring packing and GARTHANE® urethane seals.

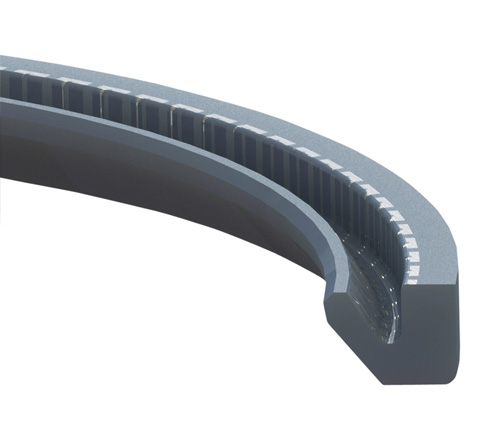

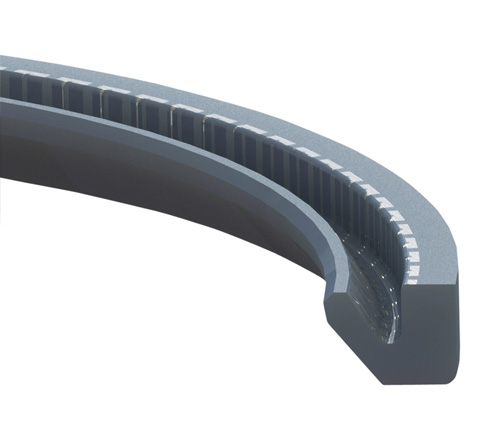

CHEVRON V-Ring Packing

-

In 1928, Garlock Palmyra developed its CHEVRON® packing, the first automatic hydraulic packing using standard duck and rubber tubing, which it continues to manufacture. Garlock CHEVRON® packing is the original automatic hydraulic and pneumatic design for sealing rods, pistons, and plungers. This hydraulic packing was subsequently expanded from its original use in steam engines to applications in the off-road equipment, power generation, and automotive industries. Since then the global growth of CHEVRON® hydraulic packing has continued in the oil and gas and nuclear industries.

The distinctive and exclusive hinge-like action of each CHEVRON® ring permits immediate reaction even to minor pressure changes. Each individual lip of a CHEVRON® packing set independently reacts to pressure, and automatically effects a seal. The multiple lip configuration automatically distributes pressure and an effective seal along the shaft. The proprietary design of Garlock CHEVRON® packing also permits an automatic reaction to pressure shock and overloads. Once Garlock CHEVRON® packing has been selected and installed, it will seal effectively and automatically. CHEVRON® is now available in Deep V-ring design.

Engineered Packing

- Custom V-Ring sets designed for your application.

U-Seals / Cups

- Browse U-Seals / Cups by size and height.

Industrial Hose

Industrial Discharge Hose

- Abrasion resistant extreme temperature industrial discharge hoses featuring ABRA-LINE® and ABRA-SHIELD® liners.

Industrial Suction Hose

- Abrasion resistant extreme temperature industrial suction hoses featuring ABRA-LINE® and ABRA-SHIELD® liners.

Joint Sealant Tape

ePTFE Joint Sealant Tape

- Thickness (inch): 0.059 - 1.200

Thickness (mm): 5.08 - 30.48

Width (inch): 0.500 - 0.625

Width (mm):12.70 - 15.88

Length (feet):15.0 - 150.0

Length (Meters):4.68 - 46.8

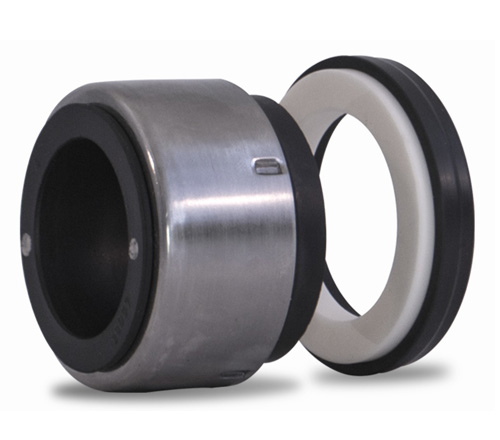

Mechanical Seals

-

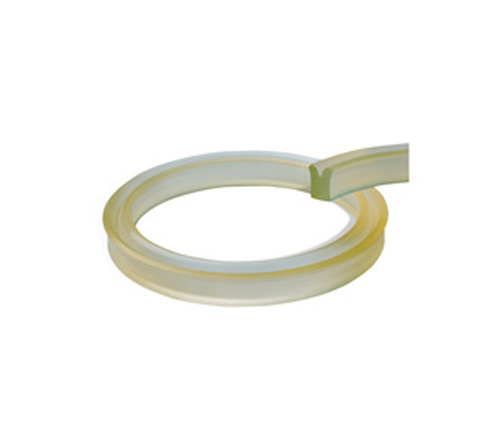

KLOZURE® mechanical seals for pumps, agitators mixers and other rotating shaft applications are available in both lip and face seal designs in four primary styles and a wide range of sizes. Key products include P/S®-II lip seal, Syntron RP shaft seal, PK component seal, and the GMP series of single and double cartridge mechanical seals.

We manufacture mechanical seals for numerous applications in the chemical, pulp and paper, mining, and power generation industries.

Cartridge Seals

- All-in-one seals that provide simple sealing solutions and ease of installation.

Component Seals

- Separate rotaries and stationaries for inside and outside mount applications.

Oil Production Seals

- LubriKup® molded cups and packing are specifically designed for the oil production industry.

Downhole Sucker Rod Pump Seals

- Für Anwendungen mit Saugstangenpumpen im Bohrloch. Garlock LubriKup® Dichtungsprodukte umfassen Flanschringe, geteilte Ringe und druckbetätigte Ringe.

Polished Rod Stuffing Box Packing

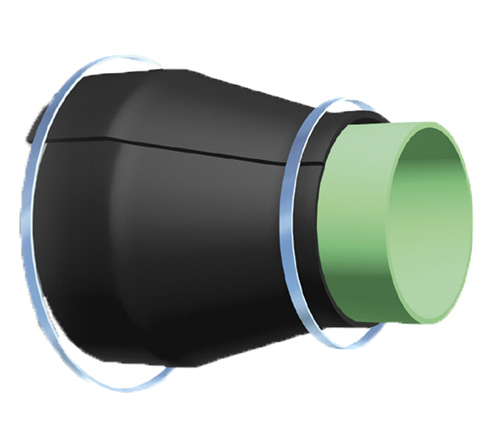

Pipe Casing Spacers and End Seals

Casing End Seals

- A safe, clean, and cost-effective solution to prevent foreign material from entering the opening between the carrier and the casing.

Casing Spacers

- Browse options featuring positive insulation, high abrasion resistance, low coefficients of friction, extreme temperature resistance and more.

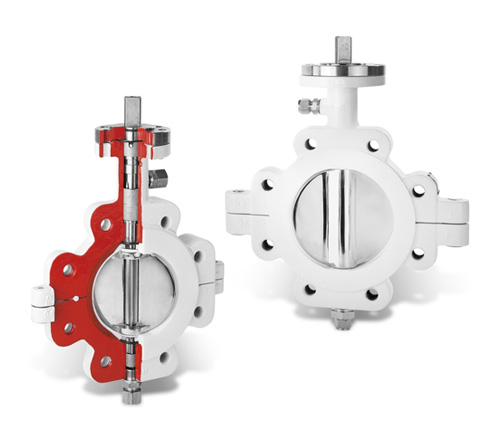

Valves

-

Butterfly valves are renowned throughout the chemical, petrochemical, Garlock process, and many other industrial sectors for their quality, performance and reliability in demanding conditions. Garlock valves set the standard in TA-Luft compliance, plus the valves are certified with SIL 3 according to EN 61508.

GAR-SEAL® butterfly valves are used where corrosive, abrasive, and toxic media need to be reliably controlled.

MOBILE-SEAL® butterfly valves are used on road tanker vehicles, railway cars, silos, and other transportation and storage containers.

SAFETY-SEAL® butterfly valves are used where electrostatic charges must be avoided.

STERILE-SEAL® butterfly valves are used for sterile processes.

Valve Accessories

-

Handles, Gear Operators, and Air Actuators for Garlock Butterfly Valves

Garlock offers a full range of butterfly valve accessories, including standard handles, special locking handles, gear operators, air actuators, limit switches, and electro-pneumatic positioners.

Handles

- Both our standard Handle assembly and special Locking Handle assembly are available.

- Standard Handles available from 2 in / 50.8 mm to 8 in / 203 mm

- Locking Handles available from 2 in / 50.8 mm to 4 in / 101 mm

Gear Operators

- Gear operators available on all sizes, 2in / 50.8mm to 24in / 610mm

Air Actuators

- Actuators of customers preferred brand can be provided upon request.

GAR-SEAL® Butterfly Valves

- GAR-SEAL® Butterfly Valve for Control, Throttling and Shut-off Duties

GAR-SEAL® valves are used extensively where corrosive, abrasive, and toxic media need to be reliably controlled. They are typically used for accurate control, throttling, and shut-off duties in a wide range of industries, including chemical, petrochemical, chlorine, paper, electro-plating, and more. GAR-SEAL® butterfly valves offer reduced maintenance requirements and increased operational reliability.

MOBILE-SEAL® Butterfly Valves

-

Butterfly Valves for road tanker vehicles, railway cars, silos, and other transportation and storage containers.

MOBILE-SEAL® valves are used on road tanker vehicles, railway cars, silos, and other transportation and storage containers where high chemical resistance, reliability, and special safety requirements are essential. MOBILE-SEAL® is EN 14432 approved.

SAFETY-SEAL® Butterfly Valves

- Butterfly Valve for Avoiding Electrostatic Charges

SAFETY-SEAL® valves are used in applications where corrosive, abrasive, and toxic media need to be handled and electrostatic charges must be avoided at the same time.

STERILE-SEAL® Butterfly Valves

- Valves for Sterile Processes

These valves are used in applications where sterile processes need to be maintained in the pharmaceutical and food industries without unnecessary and costly overhauls and replacement. The special characteristic of this valve is its external sterilization capability. The design is such that the critical "dead" areas of the valve, as well as the disc, body liner, and seals, can be sterilized with steam without coming in contact with the process medium.

Wall Penetration Products

Penetration Sleeves and Disks

- Hole-forming products including sleeves, wall collar products, and hole forming disks.

Wall Penetration Seals

- Secure, long-lasting, pressure-tight seals for water, gas, and sewer pipes of any size passing through walls, ceilings and floors.

Water Infiltration Sealing Systems

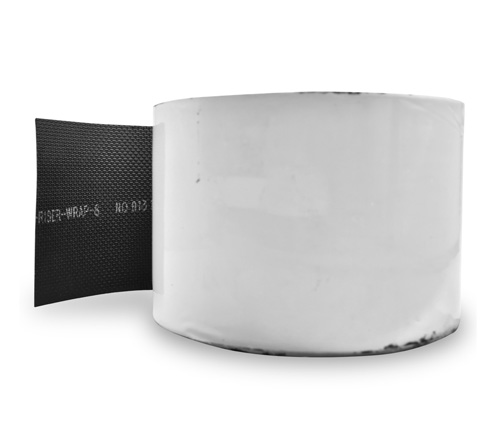

Boa-Tape Extra Grip Water Infiltration Taping Seal System

- No primer and no torchjust peel, tape, roll, and go!

Boa-Tape is a pressure sensitive taping system designed to seal joints against ground water infiltration, encapsulate manholes or vaults and protect pipelines. The 50 mil. elastomeric mastic in combination with 15 mil. of woven polypropylene makes this tape extra-extra sticky.

Riser-Wrap® Water Infiltration Sealing System

-

Riser-Wrap® is a two-layer protective pipe wrap consisting of an adhesive liquid covered by a heat shrink sleeve.

The Riser-Wrap® seal is a two-layer system designed for corrosion and sealing protection on pipelines and encapsulating manholes to seal joints against ground water infiltration. The first layer is a viscoelastic adhesive liquid sealant covered by a heat shrink sleeve. The sleeve is a thick-walled (2.5mm), cross-linked, high density polyethylene membrane.

Garlock Brands

-

pco.edge family - the most versatile sCMOS camera portfolio on the market

The pco.edge family of sCMOS cameras features an excellent combination of high resolution, high quantum efficiency, high frame rates and high dynamic range. All of the cameras are available with different cooling grades and different interfaces.

BLUE-GARD®

- BLUE-GARDs best-in-class sealing performance saves you material, time, and labor.

With decades of tried and tested sealing performance across a wide range of applications, BLUE-GARDs unique blend of aramid fibers, fillers, and elastomeric binders enhance torque retention and drastically lower emission levels. Garlocks BLUE-GARD technology utilizes a proprietary releasing agent to ensure ease of gasket removal. BLUE-GARD offers costs savings by reducing waste, maintenance time, fluid loss, and energy consumption. Explore our BLUE-GARD portfolio for solutions to your unique sealing challenges.

GYLON®

-

GYLON gives you a tight seal for reduced leakage and more uptime, even in the most challenging chemical and corrosive environments.

Manufactured using a Garlock proprietary process, GYLONs unique physical properties reduce creep, cold flow, and improve performance reliability. GYLON offers superior leak-prevention, leading to increased uptime, reduced maintenance, and substantial cost-savings. While GYLON is most often associated with Garlocks gasket products, it is also used as a high-performance material in compression packing, pump diaphragms, expansion joints and dynamic seals.

KLOZURE®

- KLOZURE Bearing Isolators and Oil Seals provide ultimate performance and protection when uptime and reliability are critical concerns.

Garlock's KLOZURE brand of dynamic seals are designed, manufactured, and tested to ensure long life, safety, and value. KLOZURE seals are available in a wide variety of configurations to meet the challenging requirements of major industries around the world.

With decades of experience solving demanding rotating equipment sealing challenges, you can depend on KLOZURE to provide solutions that are specifically engineered to be durable and cost effective.

Whether your challenge involves the cost of maintenance, harsh operating conditions or high levels of dependability, you can count on Garlock to back our KLOZURE solutions with world class engineering, top quality materials, industry leading application support, and global distribution networks.

LINK-SEAL®

- Get a permanent hydrostatic seal thats perfect every time with LINK-SEAL, the original modular sealing system.

Create a permanent seal for any cylindrical object passing through walls, floors, and ceilings. Designed to resist aging, LINK-SEAL wall penetrating seals provide lasting protection against the entry of water, soil, and backfill material.

LINK-SEALs hydrostatic sealing system of rubber applies secure, consistent pressure around pipes, ensuring error-proof installation in 75% less time than hand fitting flashings, mastics, or casing boots. With no caulk or grout required, your seal is ready for immediate protection without the need for dry time.s

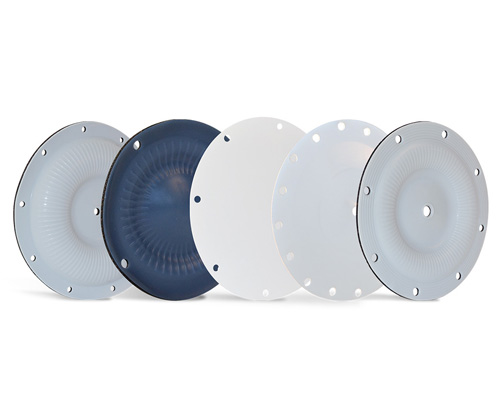

ONE-UP®

-

With superior cycle-life, ONE-UP Pump Diaphragms are the first choice for demanding industrial and sanitary applications.

ONE-UPs unique one-piece PTFE diaphragms are easy to install and guaranteed for superior cycle-life, even in aggressive critical service applications. Resistant to chemicals, abrasives, high temperature and pressure, ONE-UP pump diaphragms are engineered for a long life, reducing downtime maintenance and operating costs.

PS-SEAL®

- PS-SEAL PTFE Rotating Shaft Seals give you best-in-class sealing performance for a wide range of high-speed and extreme pressure conditions.

Where others fail, PS-SEALs reliably seal rotating shafts at high circumferential speeds, high pressures, and extreme temperatures. PS-SEAL's excellent chemical resistance makes it well suited for food and pharma applications, including those where FDA approval is required.

Available in a wide variety of standard or custom styles and materials, the PS-SEAL utilizes high-performance GYLON® modified PTFE to maintain contact between the seal and shaft. The result is a seal that can withstand pressures up to 50 times that of standard lip seals, surface speeds up to 45 m/s, and temperatures up to 500º F (260ºC), in both dry and abrasive environments.

The portfolio of Garlock PS-SEALs includes standard, non-standard, and special customized seals.

THERMA-PUR

- Corrosion-resistant THERMa-PUR is the only gasket material designed to withstand high pressure and temperatures up to 1,832°F / 1,000°C.

Trusted for use in rocket boosters, THERMa-PUR takes on conditions that graphite cannot. This high-performance gasket material maintains an effective seal during pressure and temperature fluctuations, with excellent torque retention for lower leakage rates and less maintenance time.

THERMa-PURs is hydrophobic and resists water absorption and oxidation, keeping metallic gaskets in shape for a longer-lasting seal. When its time for removal, THERMa-PUR prevents gaskets from sticking to flanges, making removal easy and fast.

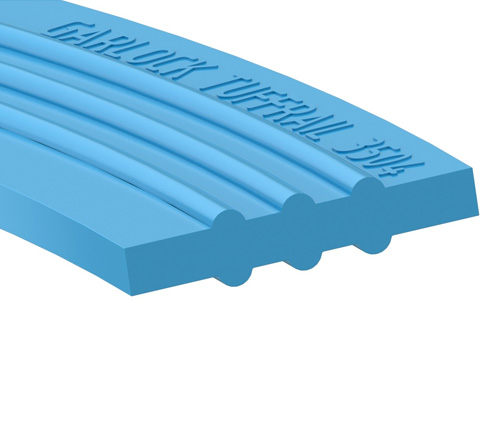

TUFF-RAIL®

-

Featuring raised sealing ribs and an unlimited shelf life, Garlocks TUFF-RAIL Manway Gaskets are ideal for heavy vibration and thermal cycling.

TUFF-RAIL Manway Gaskets create a tight seal, even in less-than-ideal bolting conditions and after multiple cycles.

Leveraging our industry-proven GYLON® material, TUFF-RAIL manway lid gaskets incorporate raised sealing features that protect against creep and cold flow. TUFF-RAIL gaskets prevent leaks, ensuring compliance with stringent environmental regulations.

Reusable, crush-resistant and engineered to a single size, TUFF-RAIL gaskets fit the most common manways (AAR-1, UTC-1, TRN-1), simplifying gasket selection and inventory requirements.