N.M. Heilig

Videos

Loading the player ...

- Offer Profile

- ONE-STOP-SHOP FOR RECYCLING AND BULK MATERIAL HANDLING SYSTEMS

Bulk material handling, production, and recycling systems: we design, develop, deliver, install, and maintain a wide variety of machinery, from single units to complete turnkey installations. With our expertise and experience, we have been supplying many industries in the field of recycling and handling of dry bulk goods. This experience leads us to aim for higher goals every year, to keep developing, and to help our clients meet their stringent demands. NM Heilig is proud to offer installations with:- over 98% continuous operation, so hardly any downtime for maintenance

- 90%-99% of recovery and purity rates in plastic recycling thanks to optical sorting (NIR)

- over 6000 ton/hour capacities (depending on bulk handling conveyance, materials, and density)

- exact conveying capacity measurements up to +/- 0,5%

Product Portfolio

BULK MATERIAL HANDLING AND RECYCLING EQUIPMENT

MACHINERY FOR RECYCLING & BULK HANDLING SYSTEMS

NM Heilig offers a wide range of machinery for the recycling and bulk handling industries:- Conveyor systems

- Transloading equipment

- Mobile equipment

- Screens

- Storage solutions

- Air separator

- Mixers Crushers

- Washing systems

- Control rooms

AIR SEPARATOR

- In the recycling and bulk handling industry, implementing an air separator to the process sorts the materials and separates the lighter from the heavier fractions. Other names for this application are air classifier, wind sifter, and wind shifter. The advantage of (pre-)sorting through an air stream is that it does not require any water and guarantees a high separation efficiency up to 95-99%.

AIR SEPARATOR TO SEPARATE DIFFERENT FRACTIONS

Depending on your particular installation and the material stream to be sorted, the separation process by an air classifier can be customized by settings such as:- inclined position

- speed of the conveyor

- speed of the separation roller

- speed and compression of the air

- inclined angle of the air nozzle

NM Heilig often manufactures air separators in combination with complete (pre-)sorting installations, particularly for light, airy bulk items in bulk handling and recycling facilities for household waste, paper, cardboard, and plastics.

INDUSTRIAL MIXERS

- For a variety of materials, NM Heilig offers customized industrial mixers, also referred to as a conical mixer or Nauta mixer, with capacities from 6 liters up to 75.000 liters.

We are experienced in designing and manufacturing industrial mixing equipment for powders and pastes for the following industries:- Food industry

- Feed industry

- Pharmaceutical industry

- Chemical industry

Together with the industrial mixing solutions expertise of Heilig Mixing Technology B.V., we manufactures and supplies many designs.

CRUSHING EQUIPMENT

- Crushing equipment can be put to use to create a proper particle size. These machines can be designed and manufactured both stationary and mobile and as an individual unit or implemented in a recycling or bulk handling process.

CRUSHING EQUIPMENT FOR PERFECT PARTICLES

NM Heilig offers a wide variety of crushers, including:- jaw crusher

- clod crusher

- impact crusher

- hammer mill crusher

- roller crusher

- cone crusher

Applications of crushing equipment can be found in:- construction and demolition

- sand and gravel

- granite

- ore and coal

- aggregates and bottom ash

CONTROL ROOMS

- Today, mechanical sorting and separating have been developed into sophisticated techniques, that manual or visual inspection is no longer required. However, in some cases, clients prefer to incorporate control rooms or sorting cabins in the recycling process when:

- client requires a final inspection in product streams

- quality processed materials fluctuate strongly (e.g. contaminants)

- limited budget for investment in automation

CONTROL ROOMS OR INSPECTION CABINS

Recycling industries that include inspection zones include:- household waste or municipal waste

- construction and demolition waste

- bottom ash waste

- paper and cardboard

- plastic waste

WASHING SYSTEMS

- To wash various materials during the processes of the recycling and bulk handling industry, the Heilig Group can design, manufacture, and supply a wide variety of washing systems, for instance, washing drums, bucket wheels, hydrasander, hot washers, frictions washers.

Examples include:- For the plastic recycling industry a friction washer and the PET Hot washer.

- For the coal or ore washing process, NM Heilig has developed a washing drum to wash off the soil, rock, and other impurities. Separating magnetite and cleaning ore and coal improves the quality, making the end product more valuable and environment-friendly.

- For sand and gravel, a bucket wheel recovers, deslimes and dewaters sand, gravel and other mineral materials, as well as remove clays and silts. Sand recovered from dredging can be desalinated and classified.

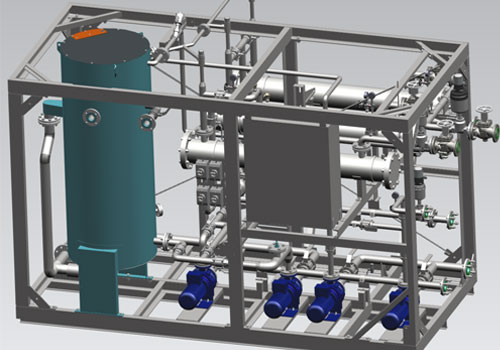

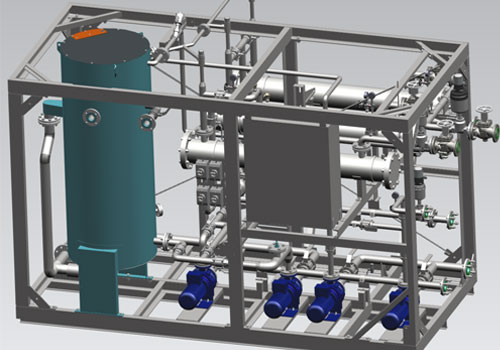

SKID CONSTRUCTION

- N.M. Heilig offers options to engineer and build assembled parts or full turnkey installations by skid construction. With prefabrication, we produce the skid, pumping, dosing and heat exchangers systems, screening and sorting systems, at our workshop.

On-site assembly will only consist of interconnecting piping and cabling. We have tailor-made solutions to match all requirements and sizing.

Skid construction provides the following advantages and guarantees you a smooth process:

REDUCE- Downtime

Everything is prefabricated within optimized conditions in our workshop - On-site assembly time

Our plug and play solutions only need interconnecting of piping and cabling

GUARANTEE- High-quality

We create the perfect conditions for assembly in our own workshop - Testing

Pre-testing and PED testing upfront

- Downtime

RECYCLING INSTALLATIONS

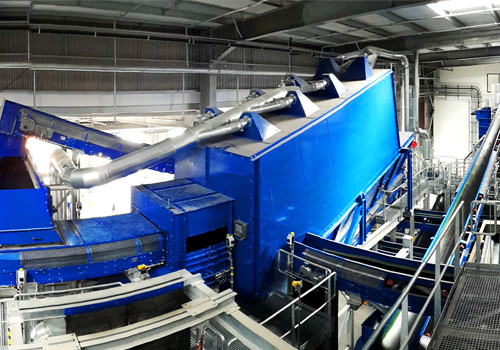

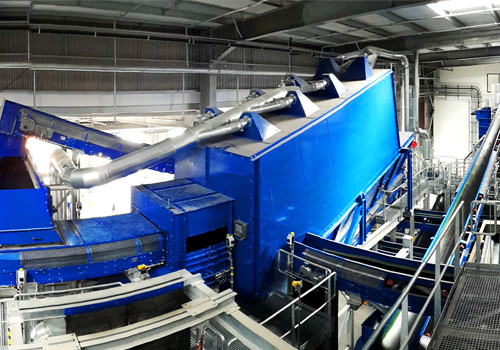

- Turning waste into energy and new products is what the recycling industry (MRF) is all about. Recycling goals have been set higher in the past decades and will surely increase in the years to come. As an engineer and manufacturer of recycling installations, NM Heilig has been developing different techniques to recover energy and valuable materials from various waste streams.

OPTIMAL WASTE MANAGEMENT THANKS TO BEST RECYCLING TECHNIQUES

For optimal recycling, a variety of techniques is used. The goals are to pre-sort, sort, separate, clean, and dry the materials from a waste stream during a continuous operation and with an absolute minimum in maintenance time. NM Heilig listens to her customers and according to their requirements, designs complete turnkey installations including among others:- screens

- conveyors

- dosing bunkers

- silos, hoppers

- crushers

- eddy current separators

- overbelt magnets

- optical sorting (NIR)

- classifiers

- and air separators

WASTE RECYCLING STREAMS

On the next pages you will find more information about the various techniques and industries NM Heilig operates in, including:- Municipal solid waste

- Construction and demolition waste

- Wood waste

- Bottom ash

- Paper and cardboard waste

- Plastic waste

- Single stream waste

MUNICIPAL SOLID WASTE

- The key to proper waste management of municipal solid waste, or household waste, is utilizing the best separation techniques. Material Recovery facilities (MRF) require the most effective installations to create valuable materials from the waste stream to achieve highest throughput, recovery, and purity rates.

Despite the pre-sorting and separation within the household, the real waste still consists of mixed materials including plastics, aluminum, wood, ferrous and non-ferrous substances, textiles, glass, organic material, and paper. These valuable materials can be converted into new products in order to prevent waste from being incinerated or dumped in landfills.

NM HEILIG SEPARATING AND SORTING EQUIPMENT

NM Heilig engineers and manufactures machinery with various separation techniques applicable to the solid waste recycling industries and material recovery facilities (MRFs). Besides recovering valuable materials, implementing our machines in your recycling process can also result in compost and RDF leaving a minimum amount of dump waste.

INSTALLATIONS FOR MUNICIPAL SOLID WASTE PROCESSING INCLUDES UNITS SUCH AS:- Conveyor systems

- Screens

- Bunkers

- Hoppers

- Silos

NM Heilig always focusses on maintaining maximum uptime and minimizing unscheduled downtime. Involving our engineers at an early stage offers result driven solutions, whether this concerns single units or turnkey recycling installations, including electrical controls.

CONSTRUCTION AND DEMOLITION WASTE

- Construction and demolition waste consists of materials such as concrete, masonry, wood, glass, metals, and plastics. To sort the demolition waste stream from a dumpster, separate and process the various course materials requires robust units that endure the wear and tear. In designing our machines, we focus on high throughput, recovery and purity rates.

SORTING, CRUSHING, AND SEPARATION OF FERROUS METALS

NM Heilig offers both mobile and stationary machinery for the various process steps of sorting, crushing, and separation of ferrous metals from construction and demolition waste. Our robust designs withstand the influences of rough materials and offer continuous operation requiring minimal maintenance.

WOOD WASTE RECYCLING

- Although wood is composed of cellulose, an organic molecule, wood waste in itself is not organically recyclable. Waste from demolitions, discarded wooden pallets, and other treated wood for example, contains metal and non-metal contaminants.

WOOD WASTE RECYCLING MANAGEMENT = WASTE TO NEW RESOURCES

In the wood recycling industry multiple applications can be found, among which:- Untreated (clean) timber can be chipped, and if needed metal impurities can be separated, to generate raw materials for manufacturing building supplies, fire logs, mulch, compost, gardening substrate, and fuel for biomass.

- Treated wood that is painted or varnished can be shredded and treated in a few steps to be used as fuel for power plants.

Incorporating the recycling units of NM Heilig with a high throughput and recovery, you can contribute to reducing wood waste and produce renewable energy. Please contact us for more information on the machinery we engineer and manufacture and find out how we can be of service.

BOTTOM ASH

- Bottom ash is the residue from municipal solid waste incineration which is also called slag or incinerator bottom ash (IBA). In contrast to the past when slag was dumped, current technology enables bottom ash processing plants to recover valuable materials. But also transform the residue slag into useful materials. At NM Heilig, we have engineered machinery and installations to treat slags contributing to zero waste management.

APPLICATIONS OF IBA

As a result of incineration, waste facilities generate bottom ash (IBA). Thanks to the latest technology applied in NM Heilig machines, this IBA can be processed into an aggregate (IBAA). This material is suitable for earthworks, pavement construction, and the production of asphalt for roads and waterways. It can replace natural aggregates.

VALUABLE METALS CAN BE SEPARATED

Recovery of valuable metals is just as important for recycling companies to earn money from processing. The aluminum and heavy metals are highly valuable materials to recover from the slags. the metals are turned into raw material for high-quality re-use at melters.

The sorting and cleaning systems NM Heilig builds and supplies, are applied for separating:- metals (through magnets)

- non-metals (non-ferrous separator)

- various fractions (screens)

PAPER AND CARDBOARD

- Recycled paper and cardboard are products possessing unique recycling properties. NM Heilig has been engineering recycling installations for this industry with a high throughput and extreme high purity rates with minimal loss of quality during the process. Recycling this material offers both economic and environmental sustainability.

HIGH-QUALITY RECYCLING OF PAPER AND CARDBOARD

Producing recycled paper consumes 70% less energy than producing from natural resources. The advantages of aiming for zero waste include:- reduced waste dumps and/or landfills

- reduced exploitation of natural resources

- lower energy consumption

- lower water consumption

- lower CO2 emissions

The systems NM Heilig engineers and builds to separate impurities and process the used paper and cardboard can vary in configuration, from standard units to a customized installation applicable to your branch.

You can think of installations to separate old corrugated containers (OCC) from mixed recyclables, or to separate mixed fiber, containers, and fines by making use of the 2-D and 3-D characteristics of these materials.

PLASTIC WASTE

- The number of plastic recycling plants has increased and become more sophisticated over the years. This growth can be accredited to a higher people’s awareness and more plastic collection facilities worldwide.

MEETING THE HIGH DEMANDS FOR PLASTIC RECYCLING

Recycling plastic waste, however, is more complicated than paper due to the many variations of plastic materials and colours, the inability of consumer pre-sorting and the food trade’s demands with which recycled plastics need to comply (e.g. for soda bottle recycling). Finding out which combination of units offers the best plastic recycling installation requires a partner with expertise and experience.

THE EXPERIENCE OF NM HEILIG

NM Heilig has many references in the plastic and PET recycling industry with high recovery and purity rates (90%-99%). We can act as your partner in various fields:- research and analysis of process conditions

- engineering

- technical assistance

- manufacturing

- pre-assembling

- installation

- start-ups

- after-sales service

We build and supply customized or standard units up to complete turnkey customized pre-sorting systems and washing lines for plastic waste.

SINGLE STREAM RECYCLING

- The perceived value whether pre-sorting materials benefits the recycling process is questioned throughout the world. On the one hand, people feel more environmentally engaged by sorting their household waste. On the other hand, not everyone comprehends the value of recycling.

ADVANCED TECHNOLOGY FOR SINGLE STREAM RECYCLING

At NM Heilig, we have developed the techniques to sort and separate mixed waste, or otherwise referred to as commingled waste. We offer tailor-made sorting, separating, and cleaning machines utilizing the advanced technologies such as infrared sensors to handle single waste streams.

NON-FERROUS-METALS

- EXPERTISE IN NON FERROUS METALS RECYCLING

For the treatment of IBA (incinerator bottom ash) from waste-to-energy plants, NM Heilig is your partner to separate the non-ferrous metal mix into an aluminum fraction, a heavy metal fraction, and a residue waste stream. We offer our expertise in non ferrous metals recycling and provide turnkey pre-sorting installations in combination with the specialized knowledge of our sister company Recco Non Ferro Metals.

RECOVERY OF VALUABLE MATERIALS, HEAVY METALS AND PRECIOUS METALS

Example factions include:- aluminum, brass, copper, gold, and silver which are meticulously recorded and charged

- glass, plastics, metals, and wood to be recycled

- sand, stone, concrete to be recycled in aggregates

BULK HANDLING SYSTEMS

BULK HANDLING SYSTEMS FOR MINERALS AND MINED MATERIALS

Bulk handling comprises more than transshipment alone. With main ports such as Rotterdam and Amsterdam, NM Heilig is a company based in the center of the European hub for material handling of various crops, minerals, and mined materials.

Not surprisingly, we have been developing and manufacturing bulk handling installations for many decades and have become a leader in the field of:- Coal Ores and additives Sand and gravel Granite Minerals Sand from sea and earth moving Fertilizers Sugar Cacao

TRANSSHIPMENT, STORAGE AND TREATMENT OF BULK

For the transportation, transshipment, storage, and treatment of bulk goods, NM Heilig builds and supplies both single units and turnkey bulk handling installations. Depending on the particular properties and the bulk density of the materials, bulk handling systems can process up to 6,000 tons per hour.

More than often, the systems require tailored engineering which may include: conveyors, screens and sieves, crushers, washing drums, mixers, desalination, classification, and fractions.

We implement strong and durable components only and aim for supreme bulk installations with a high throughput, efficient transshipment, and distinct treatment of bulk materials.

SAND AND GRAVEL INDUSTRIAL EQUIPMENT

- Sand and gravel are mined from quarries, open-pit-mines or dredged from waters such as rivers, lakes, and seas. To transform the rough minerals into fit for use types of gravel, aggregate, sand, and for concrete construction, various production processes are required, including:

- screening

- crushing

- washing

- desalinating

- sorting

- fractioning

Depending on our client’s requirements, NM Heilig designs, builds, and installs purpose-made industrial equipment. This includes both the processing and classification of sand and gravel as well as the transshipment to sea ships, barges, railway cars, and trucks and storage at terminals.

For the transportation, transshipment, storage, and treatment of bulk goods, NM Heilig builds and supplies both single units and turnkey bulk handling installations. Depending on the particular properties and the bulk density of the materials, bulk handling systems can process up to 6,000 tons per hour.

More than often, the systems require tailored engineering which may include: conveyors, screens and sieves, crushers, washing drums, mixers, desalination, classification, and fractions.

We implement strong and durable components only and aim for supreme bulk installations with a high throughput, efficient transshipment, and distinct treatment of bulk materials.

COAL HANDLING INSTALLATIONS

- COAL BULK HANDLING PROCESSES AFTER COAL MINING

Despite the growth of renewable and sustainable sources of energy, coal is still a resource we depend on to fulfill both our demands for energy and steel production. As a result, the coal mining industry (CHPP) is indispensable for bulk handling of:- coal

- coking coal

- pet coke

- metallurgical coke

- anthracite

These industries, however, can optimize coal handling by implementing efficient installations to increase handling speed and quality of the coals and, subsequently, reduce downtime during production process.

COAL HANDLING INSTALLATIONS

For all of the coal handling processes as mentioned below, NM Heilig offers a wide range of products. As a company located in the center of the European coal transportation, we have gained extensive knowledge and experience in manufacturing both mobile machines and stationary designs for turnkey installations.

COAL CRUSHING

The coal crushing process is suitable to create the appropriate particle size for the different applications. With machines like impact crushers, hammer mills, single roller crushers, and double rollers coal products for a variety of industries can be produced.

COAL DRYING

After the washing process, the coal is dried while conducted through a coal drying installation based on a fluid bed drying technique. After drying, the coal is screened into various fractions to be stored in different silos and other storage solutions.

COAL GRADING

A classification process installation, mostly implemented at transshipment locations or coal preparation plants, is used to grade the coal delivered from a variety of locations throughout the world. Depending on the properties of incoming coal and the required output fraction, a customized screening plant processes the bulk coal with a throughput varying from 100 to 300 tons an hour. Both dry screening and wet screening installations are used.

COAL TRANSPORTATION

A significant part of coal bulk handling consists of transportation and transshipment. Our home country the Netherlands is the center of European coal distribution thanks to our sea ports, rivers, and railway connections. The strategic location and dimension of Rotterdam harbor allow bulk carriers up to 365,000 dwt to enter the seaport 24/7.

COAL WASHING

Coal washing is a suitable process to reduce both the ash content of coal products and the impurities. Depending on the requirements in particle size and quality, machines such as jigs, wash drums, cyclones, and water-only cyclones can be implemented.

GRANITE INDUSTRIAL HANDLING EQUIPMENT

- Similar to sand and gravel, granite is mined from quarries or open-pit-mines in both crushed stone form and dimension stone. The rough material requires several processes to convert the mineral into usable granite, gravel, and aggregates for further production.

NM Heilig designs plant systems to process the granite. For transshipment, we offer everything from loading and unloading systems to terminal logistic systems. For processing, we offer sorting, conveying, crushing, and storage systems.

MINERALS PROCESSING SYSTEMS

- Efficient processing of minerals, rock minerals, and ore requires a well-thought plant design that minimizes cumbersome utility of bulldozers, lorries, and shovels and also increases handling and storage capacity.

Processing installations include handling, for example, mineral sands, ores, concentrates, magnesite and ferroalloys. But also sand, gravel, and salt.

NM HEILIG DESIGNS AND MANUFACTURES SPECIALIZED SYSTEMS INCLUDING:- mobile telescopic stacker conveyors

- silo systems (storage)

- colossal ship loading and unloading equipment

- truck and railcar loading systems

- crushing and screening systems

- mixing equipment

CONVEYOR SYSTEMS

- Conveyor systems come in many shapes and sizes. At NM Heilig we have been applying conveyor technologies for almost 4 decades and to many industries. We know that client’s requirements differ and the most practical solution is a tailor-made one, whether part of a complete installation or single units and parts.

CONVEYOR SYSTEMS FOR RECYCLING AND BULK HANDLING INSTALLATIONS

Together with our sister company Bezner, also part of the Heilig group, we can extend our range of customized conveying systems.

BELT CONVEYORS

- FOR WASTE MANAGEMENT AND BULK MATERIAL HANDLING

Belt conveyors are included in nearly every solution we design for our customers in the waste recycling and bulk handling industry. This unit offers a desirable method for continuous and inexpensive conveyance.

We are experienced in engineering belt conveyors for both waste management and bulk material handling.

A BELT CONVEYOR MOVES YOUR MATERIALS

Customized options are available to enhance the employability of belt conveyors. Example choices include:- variation in length (from a few meters up to a few kilometers)

- flexible in the application (in various parts of the installation)

- open or covered

- expandable

- telescopic

- mobile or stationary

- tripper systems to discharge material alongside the conveyor

- swiveling on wheels or rails

- belt weighing systems

- material flow control

- motion control

- belt misalignment switches

- pull cord switches

- limitation switches

- cross belt sampler

- dust control units

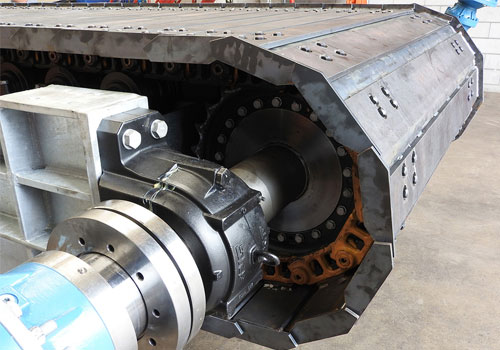

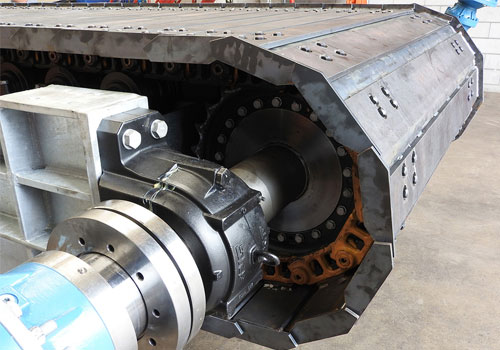

CHAIN CONVEYOR FOR HEAVIER MATERIALS

- For conveying heavier materials, a chain conveyor is a suitable solution offering power and traction. Opposite to conventional conveyor technologies, the motor of the chain conveyor is connected by chains to sprockets preventing the conveyor from slipping due to the heavy load.

Heavy loads, found in both recycling and bulk handling industries, require large conveyors with a rubber belt to absorb the forces of the impact. Mostly, NM Heilig designs chain conveyors for moving heavier materials over a shorter distance with an incline.

We manufacture our chain belt conveyors with durable and high-quality materials only to provide our customers with the advantages of a long-term maintenance-free production process. The chain conveyors manufactured by NM Heilig are applied in industries such as:- Mining and bulk handling of minerals

- Waste management and recycling industry

- Wood processing

- Glass industry

- Paper and cardboard industry

- Plastics industry

APRON FEEDERS

- An apron feeder, or plate conveyor renders one of the most superior conveying technologies for sharp-edged or high-density materials that have a significant impact when landing from height on the conveyor surface. This includes cuts, impacts, punctures, and any other wear and tear. Example materials involve minerals from quarries and other heavy industries such as coal handling, fall pipe vessels and side stone installations for example with granite, construction and demolition recycling or scrap.

Other names for a plate conveyor you might come across are hinged steel belt, metal belt conveyor, and slat conveyor, but the principle of conveying on steel plates remain the same.

APRON FEEDER FOR HEAVY DUTY

NM Heilig designs, builds, and installs many applications for both horizontal and diagonal transport and both stationary and mobile units with (optional) features including:- durable steel or stainless steel for heavy duty applications

- continuous operations with low-maintenance

- low-speed applications

- variable speed applications (feeding during the process)

- ‘walking floor’ applications in bunkers

VIBRATING CONVEYOR

- To maintain a constant flow in any recycling or bulk handling process, implementing a vibrating conveyor is applied. A vibrating conveyor or vibratory feeder, which are other names for the same principle, allows:

- extracting bulk materials from silos, for feeding crushers or conveyors

- continuous flow of material streams

- precise dosing or bulk conveyance

- pauzes feeding almost immediately when machine is switched off

- adjustable speeds of the pneumatic or electronic control

NM Heilig designs, manufactures and supplies vibrating chutes with optional multiple drives, anti-wear lining, and dust-proof housing for industries such as:- sand and gravel

- bottom ash

- plastic recycling

- household waste or municipal solid waste

- wood waste

- coal

ELEVATOR CONVEYOR FOR VERTICAL TRANSPORTATION

- An elevator conveyor as we call it at NM Heilig is a vertical conveying unit within a bulk handling system or recycling system. The numerous applications for vertical transportation systems can be found in conveying materials in an efficient way to great heights, for instance silos or plants with multiple stories.

Example industries:- sand and gravel

- fertilizers

- recycling industry

- metallurgical industry

- feed industry (rice, oats, soybean, and maize)

Synonyms for an elevator conveyor are, for instance, vertical conveyor, lift conveyor, and bucket elevator.

Depending on the properties of the conveyed streams, the engineers of NM Heilig apply durable materials and select an appropriate configuration. Designing an elevator conveyor that needs to withstand the wear and tear of abrasive materials in heavier industries requires a different approach than when lightweight materials need to be conveyed through a covered system for dust-control. Also the speed and throughput capacity are significant factors in the design.

TRANSLOADING EQUIPMENT

- Bulk materials have a specific need for transloading to ensure an efficient and cost-effective method of transportation. Transloading equipments needs to be manufactured with high-quality materials that resist wear and tear and are robust.

TRANSLOADING EQUIPMENT FOR TRANSSHIPMENT OF BULK MATERIALS

For every part of the transloading conveyance system, NM Heilig designs and builds customized machinery. For instance, belt conveyors and stackers to transport materials to the stockyards or storage fields. To convey materials from the storage fields to inland vessels, trucks, or train cars we offer long conveyor systems, ship loaders, truck loaders, and rail car loaders. NM Heilig offers both stationary and mobile transloading equipment.

STACKER CONVEYOR

- The transloading of dry bulk goods to stockyards requires an efficient stockpile conveyor: the stacker conveyor. This large machine piles materials, such as minerals, sand and gravel, coal and other ores in designated areas of your stockyard.

The goal of a stacker is to pile materials in an even manner. Depending on our customer’s requirements, we can build a customized stacker according to any combination of the 4-way motion-principle:- horizontally by transporting the complete stockpile conveyor over a rail

- horizontally with optional telescopic boom vertically by lifting and lowering the boom stacker (luffing) rotationally by revolving the stacker crane around its axis (slewing)

At NM Heilig, we design and manufacture stackers according to your specific requirements, which means that we aim to supply a machine that is fit for cone or chevron stacking offering the highest capacity possible. Also, we customize the control system for a semi or fully automated installation.

TRUCKLOADER

- A truck loader is an indispensable method of transport for further processing of bulk materials in bulk goods preparation plants, industrial plants and material recovery facilities (MRF) in the recycling industry.

Our 24-hour economy requires short delivery times and trucks to be on the road. So, loading and unloading should take the least possible time and calls for efficiency. NM Heilig designs, manufactures, and installs, a wide range of truck loaders all over the world. Optional features such as a bunker for buffer storage, automatic switches, a movable Y-shape discharge hopper for multi-loading or dust prevention are only a few examples.

Bulk handling and recycling industries include:- sand and gravel

- minerals

- municipal solid waste recycling

- construction and demolition

- bottom ash recycling

- wood waste

- plastic and PET recycling

RAIL CAR LOADER

- FOR DRY BULK GOODS AND WASTE STREAMS

A rail car loader is a system used for loading and unloading train cars with dry bulk materials. Transportation of bulk goods by vessel and train is a cost-efficient way, and many countries have a connection to waterways and railways. NM Heilig has extensive experience in designing railcar loading installations for the bulk handling industry all over the world. Of course, our services also extend to the production, installation, and maintenance of rail car loaders.

Loading hopper cars or coal flood loaders, which are other names for rail car loaders, are often used during transshipment in ports and dry bulk preparation plants. Example industries include:- coal and ore mining

- sand and gravel

- minerals

- recycling industry

The rail cars are measuredly fed from conveyor systems that stop feeding once the necessary filling level in the compartment has been reached. Following, the rail car compartments are loaded one after the other offering continuous loading or a temporary buffer storage. In the case locations of loading at your plant needs to be flexible, we advise mobile hoppers and mobile loaders.

SHIP LOADERS FOR HIGH CAPACITY

- Transshipment of dry bulk loads but also storage and loading to ships is best carried out with a ship loaders, or otherwise referred to as dry bulk loader: a stacker boom belt conveyor with a loading bellow underneath. Both the boom construction and the lower loading device are extendable during operation. The system can drive alongside the quay on a rail.

STATIONARY SHIP LOADER FOR HIGH CAPACITY

NM Heilig is experienced in engineering stationary loaders as well as mobile ship loaders for transshipment of all dry bulk materials to bulk carriers and inland vessels.

MOBILE EQUIPMENT

- Besides transloading equipment for bulk materials, NM Heilig also designs and manufactures mobile equipment. Another efficient and cost-effective method of transportation, but in a construction that offers flexible employability on many terrains thanks to the options of, for instance, telestack, swiveling chassis,or tracks on the machines.

MOBILE HOPPER

- A semi-mobile or mobile hopper, or mobile bunker, is a flexible material handling solution. When utilized as a temporary storage system, a mobile loader is often required. Also, a mobile hopper can be put to use as a measuredly feeding system, in which case a conveyor system (belt conveyor or vibrating conveyor) is included.

MOBILE HOPPER AS TEMPORARY STORAGE OR FEEDING SYSTEM

NM Heilig can design a variety of dosing hoppers provided with optional discharge conveyor and/or vibrating chute, wheel set or tracked system, depending on the required capacity, product properties, and particle sizes. Also, the choice for a fully mobile or semi-mobile feed hopper depends on the conveying process and work site.

NM Heilig mobile hopper feeder conveyor offers:- continuous material handling operation and less loading movements by shovels

- high throughput for a wide variety of materials

- flexible application thanks to the mobility

MOBILE LOADER

- A mobile loader can be put to use as a ship loader, truck loader or railcar loader and to load other conveyor systems, for instance during storage and handling of bulk materials. The applications are numerous and subsequently so are the NM Heilig designs with parts such as conveyors, link conveyors, tracked mounted conveyors, telescopic conveyor, and portable conveyors.

MOBILE LOADER FOR VERSATILITY

The versatile applications for mobile loaders include:- loading barges, inland vessels, and cargo carriers

- loading lorries and trucks

- storage and transshipment of bulk materials

The advantages of a mobile loader comprise:- flexible employability on many terrains (optional swiveling chassis or tracks)

- application to various materials (telescopic system and optional feeder bunker)

- no costly fixed construction

MOBILE SCREENING EQUIPMENT

- For (pre-)sorting and classifying bulk materials and waste streams on different terrains that are not always easily accessible, a mobile screener is the ideal screening equipment. A chassis with tracks or wheelset allow the unwieldy machine to be transported from one place to the other.

MOBILE SCREENING EQUIPMENT FOR (PRE-)SORTING ON DIFFERENT TERRAINS

NM Heilig designs mobile screeners with a choice of:- screening decks depending on particle size requirements

- single or multiple decks in the case of multiple fraction-screening

- chassis with tracks or wheel set

- screening panels: steel, polyurethane, PUR (washing), wire mesh, grizzly screens, and disc screens

Needless to say, that we manufacture our mobile screeners with user-friendly controls and robust, high-quality materials only for continuous operations and low-maintenance. Our designs are applied to sort, size, and classify e.g. coal, coking coal, ores, construction waste, aggregates, minerals, and bottom ash.

STORAGE SOLUTIONS

- For bulk handling and recycling industries, many processes require a temporary storage solution, a buffer storage for feeding a production system or transloading. NM Heilig designs and supplies customized storage systems such as:

- Hoppers

- Bunkers

- Silos

BUNKER

- For (temporary) storage and measured conveyance of dry bulk goods, NM Heilig designs, builds and delivers bunkers in a wide variety of styles and types.

A BUNKER FOR STORAGE AND CONVEYANCE OF DRY BULK GOODS

When used as a feeding unit for an installation or system, the bunker is often supplied with:- a belt conveyor, chain conveyor, or plate conveyor when during the process many start-stops are required

- a vibrating conveyor when a continuous adjustable flow is required.

Depending on the materials to be handled, the bunker can be constructed from carbon steel or stainless steel, in various material grades. Additionally, the inner surface can be cladded with wear resistant materials like options polyurethane plates (concrete, sand, and gravel) or sprayed and Hardox (for heavy duty applications such as coal, ores an aggregates). Optional pneumatic, hydraulic, or electric vibrators offer an optimum flow of your bulk materials.

At NM Heilig we use the name bunker, but in the industry also the terms bunker conveyor, dosing conveyor, and storage conveyor are used for the same principle.

BULK SILO

- A CUSTOMIZED SILO FOR STORAGE AND MEASURED DOSING OF BULK MATERIALS

For temporary storage and measured dosing of bulk dry goods, NM Heilig designs a silo that meets your needs. We manufacture the silos, or otherwise referred to as bunker bins, from carbon steel or stainless steel grades and ATEX models transportable by road or water.

Mostly, NM Heilig installs a silo as part of a complete turnkey installation, complete with elevator for industries:- plastic recycling

- wood pellets

- minerals

- crops (e.g. sugar)

- aggregates

Significant factors to consider in the silo design are the flowing properties of the materials. In order to ensure a complete discharge of the bulk materials, our silos can be designed to prevent flow, bridging, product segregation, and ratholing.

HOPPER

- A stationary hopper is a reliable material handling system for dry bulk goods that serves two purposes. For one, it can be put to use as a temporary storage system for transloading to trucks, dump trucks or rail cars. Second, it can be utilized as a measuredly feeding system together with a conveyor system such as a belt conveyor or a vibrating conveyor.

HOPPER FOR MEASURED DOSING AND STORAGE

At NM Heilig we use the name hopper, but in the industry also the terms feed hopper, hopper conveyor, hopper feeder conveyor, and bulk reception feeder are used for the same principle.

According to your specifications regarding particle size and material properties, NM Heilig designs, builds, and supplies hopper systems and mobile systems provided with optional:- discharge conveyor

- vibrating conveyor

- wear plates

- construction in carbon or various stainless steel grades

SCREENING EQUIPMENT

- Screening equipment comes in many shapes and sizes and provides a variety of sorting solutions. At NM Heilig we have been applying screening technologies for over 4 decades ánd to many industries. We know that client’s requirements differ and the most practical solution for your recycling or bulk handling process is a tailor-made one.

SCREENING EQUIPMENT FOR RECYCLING AND BULK HANDLING SORTING

Please find below examples of screens we offer: drums screens, mobile screens, and flat screens for dry bulk materials. Together with our sister company Bezner, also part of the Heilig group, we can provide our extended expertise in customized screening systems for the recycling industry.

VIBRATING SCREEN

- LINEAR AND CIRCULAR

Screening is a method to separate and sort recycling materials and bulk goods. NM Heilig designs and manufactures customized vibrating screens or vibrating sorters. We supply both linear vibratory screen and circular vibrating screens equipped with single or multiple decks, for instance:- single and multi-layered screens

- unbalance motors to set the screening box in circular or linear motion

- finger or grizzly screens

- star screens disk screens

- dewatering screens

Circular vibrating screens offer value for money thanks to their great performance and straightforward construction. Inclining the linear vibratory screen, or also referred to as a horizontal screen, may improve the throughput of the materials and the purity rates.

SCREENING DRUM

- FOR SORTING AND CLASSIFYING

A screening drum (also called trommel screen or rotary drum) can be applied to (pre-)sorting, classifying, and size splitting various types of waste or bulk materials into one or more fractions. According to your specifications and application, NM Heilig designs a screening drum, or trommel screen, that can vary in length and diameter, but also in the shape and mesh of the drum holes.

The advantages of a screening drum applied in the recycling or bulk handling process include:- the incline and rotary motion allow throughput without mechanical load

- free flowing stream without build-up of materials an equal material distribution onto screening surface

- drum technology allows high throughput drum shell minimizes noise and dust

NM Heilig has gained an extensive experience in developing screening drums for different types of bulk materials and waste streams. We always aim for the best solution, applying a variety of screens or combinations and variations in lengths and diameters.