PPH Antha-Pol

- Offer Profile

- FULL-SERVICE PARTNER IN MACHINERY HANDLING BULK MATERIALS AND WASTE

Antha-Pol is specialized in machinery for bulk material handling and recycling industries. However, we are proud to supply valued clients from other industries as well. For instance, material recovery facilities, waste disposal companies, recycling installations, dry bulk terminals, production industries, and the shipyard industry.

Our engineers design customized units with the aim to fit your installations perfectly. That means we consider your production requirements and wishes when consulting you. Our technical staff produces the machines, and our service team takes care of delivery and installation. Consider us your full-service partner, from design to installation.

Product Portfolio

RECYCLING AND BULK HANDLING MACHINES

- Many industries handle bulk. Recycling of waste materials and handling of dry bulk materials are examples of processes where managing bulk goods is common. Aside from growing markets in the recycling industry to reduce waste and landfills, also other industries such as production facilities, dry bulk terminals, food, and feed industries require quick and accurate controls of their materials.

At Antha-Pol, we have the know-how and experience to design and manufacture machines, equipment, and steel structures for that purpose. Think of conveying, sorting, storing, separating, and unloading. We know that every industry comes with their own requirements. An ideal solution often derives from good advice and small adjustments to standard units render a higher throughput and purities in your particular production process. We aim to help our clients attain their goals by supplying machines that fit their installation perfectly. CUSTOM-MADE CONVEYORS

Units and Systems

The perfect conveyance method of your bulk handling or recycling materials is one that meets your specific requirements. Standard units require making sacrifices. Therefore, when designing an ideal custom-made conveyor solutions for our customers, we consider factors such as locations, dimensions, speeds, controls, inclinations, building materials, and material specifications. With the details provided by our clients, we can calculate the best balance for a perfect production in combination with the highest throughput.

VIBRATING CONVEYORS

- For a constant flow and high throughput

While rendering a high throughput, a vibrating conveyor provides a constant and dosed flow of materials. At Antha-Pol, we are experienced in designing and manufacturing customized vibrating equipment for transporting various bulk materials such as granulates and powders as well as materials from recycling streams.

When designing a vibrating conveyor, also referred to as a vibratory feeder or vibration conveyor, we gladly offer our expertise to make it suitable for your installation. This may be an existing or a newly, to be designed production line. According to your requirements for a specific design, we can include configurational options such as:- extracting materials from various types of bunkers and silos

- customized controls for precise dosing and paused feeding

- speed controls

- horizontal, inclined or grizzly design

- different design and finishing materials (metal alloys, coatings, mesh sizes, etc.)

CHAIN CONVEYOR

- For heavy-duty industries

Chain conveyors differ from conventional conveying systems in their method of power and transmission. This enables the transportation of heavy materials that are unsuitable for a belt conveyor or roller conveyor. We design a durable construction with sturdy materials that can withstand high-impacts and provides a long-lasting operation.

Chain conveyor systems find their application in industries such as reclining and bulk handling. We can customize your installation with options such as inclination and you choice of durable materials such as (stainless) steel and/or rubber.

APRON CONVEYORS

- For high impact materials or bulk

The apron conveyor is a type of conveying system with overlapping plates commonly used in bulk handling industries that process materials from waste streams and sand and gravel, ores, soils, fertilizers, etc. It can carry both large and/or heavy items and is also very suitable for bulk.

We can design a wide variety of models and shapes and include various materials to suit your requirements. Thinks of features such as inclined design. Or the application of durable materials to resist heat, abrasion and wear and tear. We construct an installation that can withstand the impact over a long period of time making it one of the most cost-effection solutions you can find.

BELT CONVEYORS

- Tailored to your requirements

The belt conveyor is a conveyor system to carry materials from one place to another. We distinguish belt systems for items (material handling) or bulk materials, such as sand and gravel, ores, soils, fertilizers, etc.

Reach out to us at an early stage of the configuration design of your installation. This way, we can assist you to make the best choices for a customized belt conveyor. Among others, we consider the required capacity, drives and power, inclination and connection to other conveyors or machines.

One of the most commonly used conveyor systems can be customized to a fast, efficient and cost-effective method of material transportation. Besides standard requirements such as dimension, power and controles, we can include the following options in your design:- durable, low-maintenance design

- covered system (dust control)

- expandable or telescopic parts

- mobile or stationary

- swiveling on wheels, rails or tracks

- sampling station

- weighing station

- discharge systems to discharge materials along the side of the conveyor

SCREENS

Units and Systems

What applies to our conveyors and conveying systems, naturally also applies to our screens. The ideal screening method of your bulk handling or recycling materials is one that fits your specific demands. Experience shows that choosing a customized unit offers better results than settling for a standard machine.

Our engineers are experienced in calculating with factors such as locations, dimensions, connections to (pending) installations, inclinations, sieve types, and mesh sizes. Of course, also material specifications, for instance, the (free) flow of material streams are considered.

SCREENING DRUM

- For a continuous operation

A screening drum is one of the machines Antha-Pol supplies that separates, sorts, and sieves by utilizing screens. The trommel screen or rotary drum, other words for a screening drum, renders high efficiency with low energy consumption.

When designing a screening drum that suits your requirements, we consider the following variables:- length

- diameter

- inclination

- drum

- shape

- mesh

- size

Bank on our expertise to offer you the best-customized screening machine with a rotary drum. A natural fit with your (pending) process installation will bring you the advantages of continuous operation with high throughput and excellent purities.

VIBRATING SCREEN

- For precise sorting, sieving, and shifting

With a vibrating screen as part of your installation, separating, sieving, and sorting of a wide range of materials can be done efficiently and precisely. At Antha-Pol, we are experienced in designing and manufacturing vibrating screen equipment for recycling and bulk handling industries.

Depending on your specific requirements, a customized vibratory screen separator will render ideal throughput and purities. For that purpose, we can deliver machines compliant with your production process with the following options:- linear or circular vibratory screens

- single or multiple decks

- variety of power sources

- variety of screens (star, disk, finger (grizzly), and dewatering)

- horizontal or inclined design

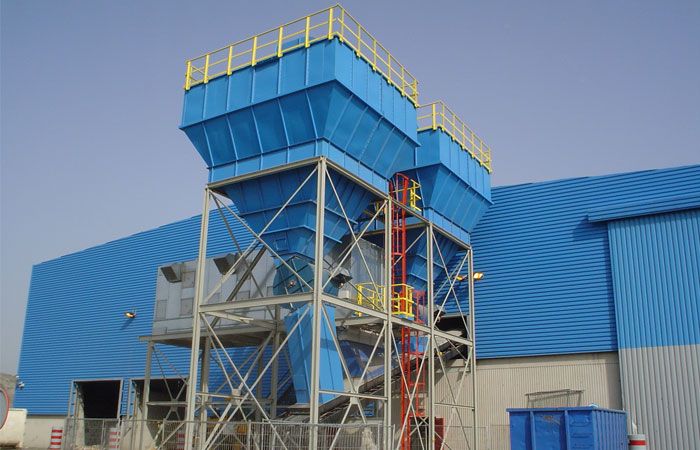

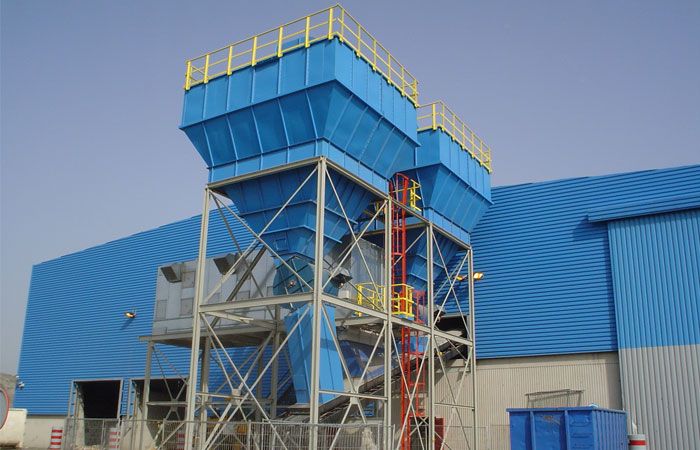

STORAGE SYSTEMS

Bunkers, Silos, and Hoppers

Each bulk handling or recycling process requires specific storage systems. Depending on your needs, you have a variety of units and systems to choose from. If you require square storage containers or large spaces, you could opt for a bunker or hopper rendering maximum storage space of the dimensions.

Round storage containers such as silos are perfect for bulk flakes, pellets, granulates and powders that need to remain free-flowing. For transloading materials to another conveying system or feeding production processes, a rectangular bunker may be the favorable solution.

HOPPER FOR BULK GOODS

- For easy storage, loading, and unloading

Aside from bunkers and silos, a hopper is another method to store bulk materials. With their specific square or rectangular shape, hoppers render more storage capacity than round storage containers.

As a single unit, Antha-Pol designs and manufactures hoppers with both open or closed top for easy loading. A bottom outlet allows measured dosing into ships, trucks or rail cars. Connecting a conveyor system to the hopper design offers a storage system within your production process.

SILO

- With complete discharge keeping bulk commodities free-flowing

A silo is a perfect method to (temporarily) store bulk commodities such as granulates, grains or powders. To keep the materials free-flowing during the discharge, we adjust our silo designs to prevent bridging, segregating and ratholing. Our bunker silos also ensure a complete discharge.

At Antha-Pol we carry out design, production, delivery, and installation of storage silos with the aim for fit you installation perfectly. We consider many factors, including:- dimensions of the intended location

- material properties

- fluidization

- level measurements

- partitioning walls

- steel structures for safety

- isolation

- ATEX-models

STATIONARY OR MOBILE BUNKER

- With or without conveyor

Keeping materials in a bunker for a shorter or longer period of time is a regular requirement in any bulk handling or recycling industry. At Antha-Pol we deliver bunkers in many shapes and sizes, for various functions and with many finishings. We distinguish:

Storage bunkers:- Single unit stationary storage bunkers

- Mobile storage bunkers

Bunker conveyors (also called dosing conveyor and storage conveyor):- System storage bunkers with belt conveyor or chain conveyor for speed and interval controls

- System storage bunkers with vibrating conveyor for a controlled and continuous flow of materials

Each of the bunkers mentioned above can be provided with one or more of the following options:- For abrasive or course materials, we can clad the inner surface of your bunker. Think of polyurethane plates or spray and Hardox plates.

- You have a choice of various steel alloys for the construction.

- Including a vibrator or impactor (pneumatic, hydraulic, or electric) will keep the bulk materials free-flowing.

STEEL STRUCTURES

For conveyance, storage, and screening installations

-

Connecting various bulk handling and recycling machines and systems can provide a huge benefit for staff and production efficiency. Antha-Pol is experienced in accompanying clients with the design of production installations. For that purpose, we can supply customized platforms such as:

- support constructions

- connecting bridges

- platforms

- storage floors

- walkways

We can add stairs, handrails, loading openings, and tilt-able railings. At your choice, we can manufacture from steel as well as stainless steel. Including a steel frame or construction makes your machines safely and easily accessible during operation as well as inspection and maintenance.