- Offer Profile

- As a global technology and material group, we are constantly exploring unique and innovative ways to make a difference for businesses and people. Being a foundation company, SCHOTT has anchored a responsibility for scientific research, society and the environment deeply in its DNA. Represented in over 30 countries by 17,100 employees, we are a highly skilled partner for many high-tech industries: Healthcare, Home Appliances & Living, Consumer Electronics, Semiconductors & Datacom, Optics, Industry & Energy, Automotive, Astronomy & Aerospace. Whatever challenges the future might hold, we can’t wait to come up with innovative solutions and turn visions into reality.

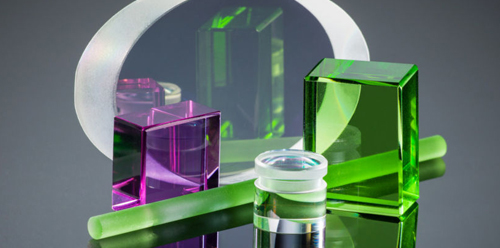

Optics

- SCHOTT's more than 140 years of experience in glass and optical technology enables us to play a key role in a number of global industries. This experience also means we offer a complete service to our customers, with fully realised optical solutions that understand your individual requirements and challenges.

Optical Glass

High Homogeneity Glass

-

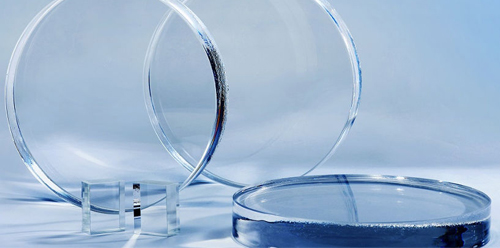

Extremely high homogeneity for large precision optics

The superior quality of an optical material is reflected in its homogeneity and an extremely narrow variation refractive index range throughout. Such glasses are well-suited to be used in high-power laser, wavefront sensitive metrology, satellite technology and astronomical applications.

"HT" & "HTultra" Glass

-

Optical glasses with ultra-high transmittance

SCHOTT’s HT and HTUltra range are very high-quality glass products that offer optimum transmittance – a property that lends it to a large number of optical applications including prisms for 3D digital cameras, high-end projection systems and binoculars.

i-Line Glass

-

i-Line glass - for applications requiring high uv-transmittance

In response to increased demand, a number of SCHOTT’s high homogeneity glasses are also available as i-Line glasses that combine extremely high refractive index homogeneity and high UV transmittance at 365 nm.

Low Tg Glass for Precision Molding

- Precision molding is a state-of-the-art technology for the volume production of complex or aspherical lenses for applications such as digital cameras, smartphones and microscopes. SCHOTT offers several low Tg (glass transition temperature) glasses for this purpose.

Optical Glass

- More than 120 optical glass types

Our unrivalled range of around 120 glass types is constantly evolving as new innovations and melting processes are introduced to optimize efficiency and cost-effectiveness. SCHOTT optical glasses are available in the form of raw glass, cut blanks and pressings, as well as finished components, and we work closely with customers to tailor our products to their needs.

Radiation Resistant Glass

- In space, medicine, the nuclear industry and a range of scientific sectors, optical glass may be exposed to high-energy radiation such as gamma, electron, proton and neutron radiation. This radiation changes the transmittance of optical glass, especially near the UV-visible edge of the spectrum.

Optical Components

Aspherical Lenses

-

ASPHERES FOR SUPERIOR IMAGE QUALITY

SCHOTT was a pioneer in the development of aspherical lenses and started manufacturing aspheres in 2001. Aspheres offer greater freedom in optical design and avoid spherical aberrations, while a smaller footprint results in lighter and more compact designs that can be customized to your needs.

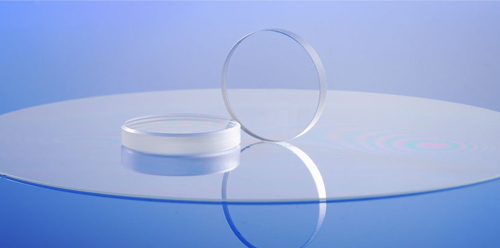

Spherical Lenses

-

LENSES AS SINGLETS, DOUBLETS, TRIPLETS IN DIFFERENT SHAPES

Many different industries rely on spherical lenses to collect, focus and diverge light, with applications including projection systems, cameras and microscopes. These depend on spherical lenses to expand light and enhance focus and imaging quality.

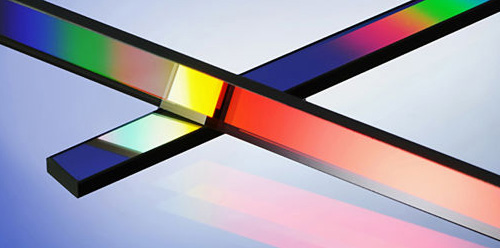

Prisms

-

PRISMS AS PERFECT CUSTOM COMPONENTS

Flat polished surfaces of prisms are used for the refraction, reflection or dispersion of light, and are positioned inside optical systems. SCHOTT is expanding the potential of prisms by using non-standard materials to improve and expand the range of technical specifications and applications.YOUR ADVANTAGES

- SCHOTT offers prisms at various processing stages: milled, polished, coated, cemented or assembled.

- The most appropriate processing method (CNC or pressing) is selected depending on the quantity, size and type of glass.

- Extensive expertise in cementing.

- Flexible production process – from a single piece to serial production.

- All prisms can be coated to specific custom designs to serve your chosen application.

Protective Windows for LiDAR

- WINDOWS & SUBSTRATE OF THE HIGHEST PRECISION

Protective glass windows from SCHOTT ensure high imaging quality and enable reliable 3D scanning of the surroundings.

CHARACTERISTICS

SCHOTT glass windows provide reliable protection to the LiDAR system’s sensitive electronics and optics. At the same time our materials are compliant with automotive regulations. The applied AR coatings enhance transmission, withstand harsh environments and the reflection color can be easily customized.

Optical Filters

Optical components

-

THERE IS A SOLUTION TO EVERY FILTER REQUIREMENT

In the rapidly developing field of optical components, SCHOTT is leading further expansion. Our quality and innovation enable the growth of key technologies such as laser machining, laser treatment in medicine, automotive technology, digital projection and the Internet of Things (IoT).SCHOTT can leverage its prominent presence in numerous industries to develop customized solutions for a broad range of applications, including lithography, astronomy, opto-electronics, digital projection, augmented reality, life sciences, the automotive and aviation sectors. A portfolio of more than 120 optical glasses offers limitless potential.

NIR Cutoff Filters / Blue Filter Glass

-

A PRODUCT FAMILY WITH TWO GROUPS THAT HAVE EXTRAORDINARY PROPERTIES

Near-infrared radiation (NIR) cutoff filters ensure that we perceive the world in the right colors, and SCHOTT’s premium-quality filters and blue glass components offer exceptional vision and high NIR absorption. As experts in this rapidly developing area, SCHOTT manufactures both high humidity resistance glasses and glasses with steep NIR cutoff.

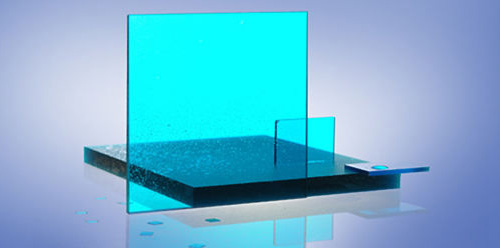

Optical Filter Glass

-

ONE OF THE WORLD’S BROADEST PORTFOLIOS

For more than 135 years, SCHOTT Optical Filter Glass has been known for its high quality, purity and outstanding properties. Offering selective absorption in certain wavelength ranges, our broad portfolio and experience in the field means we can find a bespoke spectral solution for your exact requirements.

UV Bandpass Filters

-

SPECIAL UV FILTER GLASSES FOR TANNING BEDS

Our UV bandpass filters for the analysis of fluids and gases deliver long-term reliable performance for a broad range of spectroscopic applications. These rugged assembled filters provide high blocking outside the narrow bandpass to ensure a high signal-to-noise ratio.YOUR ADVANTAGES

- Narrow bandpass with FWHM 6-15 nm.

- Passband transmission of 15-30% within λ 200-350 nm.

- Tight center wavelength tolerances down to +/- 0.5 %.

- High blocking of typical OD > 4 within a blocking range of λ 200-600 nm.

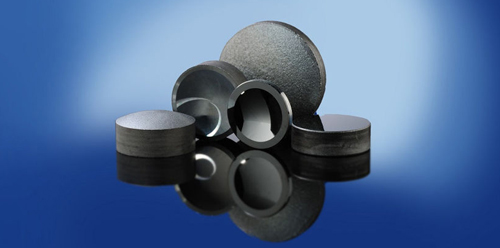

IR-Materials

Infrared Chalcogenide Glasses

-

RELIABLE SOLUTIONS FOR THE INFRARED INDUSTRY

When common infrared (IR) materials have reached their limits, infrared chalcogenide glass (IRG) supports demanding applications in terms of cost, performance and processing power. These glasses encompass the common infrared transmission bands 3-5 μm and 8-12 μm, but are able to transmit as low as 0.7 μm.YOUR ADVANTAGES

- Low dn/dt and dispersion, with high color correction

- Low Tg so moldable for high volume production.

- Lower density than established infrared materials e.g. Germanium.

- Lower price than established infrared materials.

- Conventional processing, meaning no constrains for grinding, polishing and diamond turning.

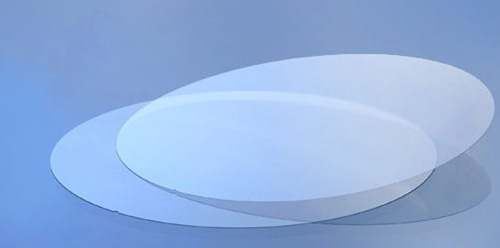

Sapphire for Advanced Imaging

-

FOR ADVANCED IMAGING, SENSING AND SECURITY

Sapphire is one of the hardest, most durable and scratch-resistant materials, and offers a broad transmission range from UV to mid infrared wavelengths. It is suitable for use in extreme environmental conditions and can withstand major fluctuations in temperature.YOUR ADVANTAGES

- Extreme hardness and high mechanical strength.

- High transmission from UV to IR.

- Various shapes from round to square available, and up to 300 mm in diameter.

- SCHOTT uses advanced equipment and state-of-the-art metrology for manufacturing and quality control.

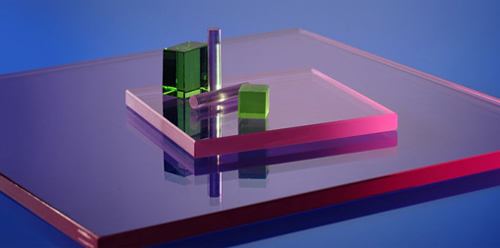

Laser Materials & Components

Laser Glass Materials

-

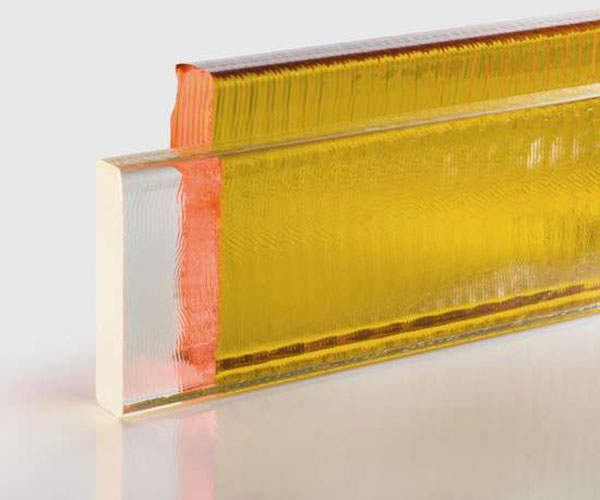

Thanks to its unique technical properties, glass is an ideal host material for the rare-earth ions that give optically pumped lasers their power. SCHOTT harnesses those qualities in a range of active laser glass products and components that can be tailored to a variety of optical and industrial needs.

SCHOTT is constantly developing new glass products and offering new options to customers. We have developed platinum-particle-free melting, allowing for customization options including high-fluence laser glass, laser slabs and rods with outstanding quality and homogeneity. In addition, a range of coatings and finishes helps us meet all customer requirements.

Laser Components

- Lasers are of critical importance to a number of industrial, scientific, medical, and defense applications. SCHOTT offers a range of passive laser components, such as aspherical lenses, polarizers, beamsplitters, mirrors, prisms, windows and flow tubes, as well as coatings for all wavelengths with a high laser-induced damage threshold.

Special Flat Glass & Wafer

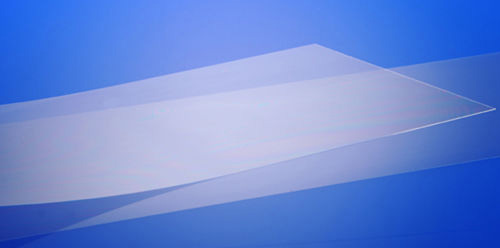

AF 32® eco Thin Glass

-

ENVIRONMENTALLY-FRIENDLY GLASS WITH HIGH TRANSMITTANCE

With a unique range of properties, as well as semiconductor process compatibility, AF 32® eco offers a flexible option for designers. This alkali-free glass is produced using SCHOTT’s unique down-draw process, which results in a broad thickness range, excellent transmittance and a superior surface quality.SCHOTT AF 32® eco has a low coefficient of thermal expansion similar to a silicon wafer, making it ideally suited to wafer-level packaging in the semiconductor industry. With high thermal stability, high optical quality, excellent dielectric properties, and very low roughnesses, it fits a broad range of applications.

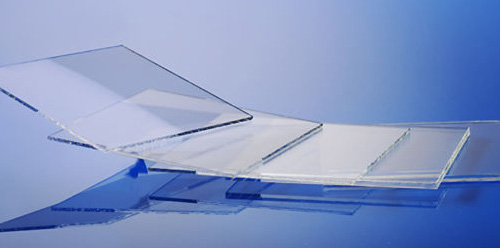

B 270® i Ultra-White Glass

-

HIGHLY TRANSPARENT GLASS

SCHOTT B 270® offers outstanding optical performance in a wide range of thicknesses. Suitable for a broad range of applications, customers across a wide variety of industries have relied on this highly transparent, super-white modified soda-lime glass for decades thanks to its high quality.The crown glass B 270® is designed to deliver consistent transmittance of light across a range of wavelengths, from ultraviolet to near-infrared. SCHOTT uses a selection of high-purity raw materials for the manufacture of this modified soda-lime glass to avoid any discoloration, which gives the glass a beautifully pure ‘super white’ look and exceptional clarity.

BOROFLOAT® 33 Borosilicate Glass

-

FLAT HIGH-QUALITY, MULTI-FUNCTIONAL FLOAT GLASS

Tough, light and versatile, BOROFLOAT® is coveted by technology companies and scientific institutes for its superb technical capabilities. Excellent transparency and thermal and chemical resistance make it ideal for use in automotive applications, digital projection, inspection windows and much more.

Introduced by SCHOTT in 1993, BOROFLOAT® is the worldÂs first floated borosilicate glass, and its pioneering spirit continues to perform across a wide variety of roles. From optics for space telescopes, cinema projectors and unmanned aerial vehicles to glass for measuring instruments, medical devices and oven doors, this cutting-edge material unfailingly delivers.

SCHOTT AS 87 eco

-

THE WORLD'S FIRST MASS VOLUME AVAILABLE, HIGH STRENGHt, ULTRA-THIN GLASS WITH NO NEED FOR SLIMMING

As the world’s first high-strength ultra-thin glass with no need for slimming, SCHOTT AS 87 eco is ideal for the protection of sensors and screens. Available in mass volume, this unique glass also offers high impact and scratch resistance, as well as high light transmission for pin-sharp detail.

D 263® LA eco Thin Glass

-

UNIQUE IN THE MARKET

As a low-alpha (LA) radiation sheet glass, this thin borosilicate glass is highly suitable for packaging radiation-sensitive devices such as CCD or high-end CMOS image sensors. SCHOTT’s unique down-draw method provides a fire-polished surface with high luminous transmittance.

D 263® M Cover Glass

-

COLORLESS BOROSILICATE GLASS FOR FLAWLESS MICROSCOPY

This advanced borosilicate glass is designed for optimum performance as cover glass for high resolution microscopes. Its outstanding geometrical properties and high optical performance means it can be relied upon to deliver accurate imaging in light and fluorescence microscopy applications.

D 263® bio Substrate Glass

-

This colorless borosilicate glass is produced by SCHOTT’s unique down-draw method, resulting in a flat, fire-polished surface, homogenous mechanical properties, low autofluorescence and high chemical resistance. This makes it a market leader in the biotech sector.

D 263® bio achieves very low intrinsic autofluorescence across the UV to NIR spectrum, while consistently tight refractive index tolerances help to ensure accurate diagnostic results in the biotech field. Strong chemical stability also makes it a reliable and long-lasting product for use in diagnostics.

D 263® T eco Thin Glass

-

This thin borosilicate glass is the gold standard in camera imaging thanks to its high optical precision. Manufactured with eco-friendly refining agents, D 263® T eco has high chemical resistance and a fire-polished surface, and is available in a variety of thicknesses from 1.1 mm down to 0.03 mm to enable miniaturization.

D 263® T eco offers a wide thickness range allied to extremely high thickness tolerances, low TTV (total thickness variation) making it a versatile product for adaptation to future product miniaturization.

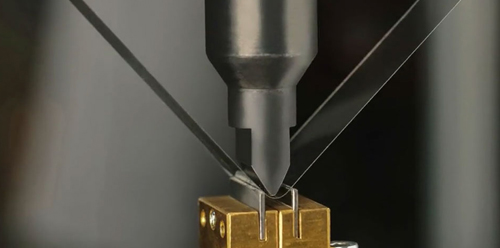

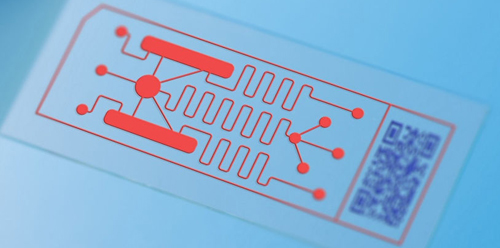

FOTURAN® II

-

SCHOTT FOTURAN® II is a photo-structurable glass produced in a continuous melting process to achieve outstanding homogeneity. After UV exposure and temperature processes, fine and uniform structures can be formed, which can be used in areas that require the characteristics of both glass-ceramics and fine structures.

FOTURAN® II is a photo-structurable glass, with areas crystallized by UV exposure and heat treatment able to be etched to produce exceptionally fine structuring with a high aspect ratio – in customized 3D forms if required. After a second exposure and tempering process, FOTURAN® II can also be transformed into an opaque glass-ceramic.

MEMpax®

-

MEMpax® is an extremely thin, smooth borosilicate glass with real versatility. While it shares similar chemical and physical characteristics to SCHOTTÂs world-renowned BOROFLOAT®, it opens up many new areas of potential application thanks to its lower thickness and fire-polished surface.

SCHOTT MEMpax® extends the world’s renowned BOROFLOAT® borosilicate glass thickness portfolio in extremely low thicknesses, from 0.07-0.55 mm. It also benefits from a pristine, fire-polished surface, removing the need for grinding and polishing, and can be used anywhere that extremely thin borosilicate glasses are required, such as MEMS and biotechnology applications.

ZERODUR®

ZERODUR®

-

ZERODUR® glass-ceramic has been one of SCHOTT's most unique and extraordinary products for over 50 years. With an extremely low thermal expansion, it's essential for a large number of demanding high-tech applications requiring exceptional precision.

The extremely low thermal expansion of ZERODUR® is homogenous throughout the entire bulk volume, which makes it ideal for a large range of applications involving precise positioning or imaging under changing temperature conditions.

ZERODUR® K20

-

ZERODUR® K20 is a low-thermal-expansion version of ZERODUR®, optimized to withstand higher application temperatures.

ZERODUR® K20 also offers strong IR transmittance and homogenous high reflectivity properties. The non-porous material also has good polishing abilities, excellent vacuum properties, and can be delivered as small, high-precision optical components.

Applications

Astronomy & Space

-

REACHING FOR THE STAR

To make aviation projects, astronomy and space missions possible, we partner with the industry to create innovative materials that overcome challenges and realize visions. For over a century, SCHOTT has provided cutting-edge solutions including glass-ceramics, specialty glass and glass-to-metal sealings.Due to their extraordinary properties, such as radiation resistance, thermal stability and mechanical stability, our products are ideally suited to realize projects even in the harshest environments and under the toughest conditions. Our materials portfolio has many applications on the ground, in the air, and in space. Production and volume of our products is highly scalable  a cost-efficient solution to industrialize certain standard components for the commercial aviation and space industries.

Industrial Equipement

-

THE TAMING OF THE LASE

Industrial and energy systems must be reliable and safe, as well as economical and long-lasting, with continuous improvements to stay ahead. SCHOTT's range of glass materials and components help by solving reliability challenges, developing more cost-efficient systems, and enabling powerful innovations.

Health

-

MEDICINE STEP-BY-STEP

The healthcare industry depends heavily on advancing technology, and while SCHOTT already plays a major role across this field, we continually work with experts to break new ground, developing innovations to enhance treatments, equipment and techniques.

Consumer Optics

-

WITH AN EYE ON FOCUS

In a competitive market, SCHOTT believes that constant innovation is vital. So we continue to work hard to develop new products and customizable solutions for customers who are demanding high performance and reliability to pass onto the consumer, as well as style-conscious esthetics.

Automotive

-

A SMALL STEPPER, A GIANT LEAP

SCHOTT has been a driving force in the automotive industry since the first vehicles were produced, delivering billions of cost-effective components with superior quality and stability. Whether setting new standards in packaging, lighting or safety, our versatile range delivers an outstanding experience.

Safety & Defense

-

RELIABLE SECURE

The stakes don’t get any higher than in global security and defense. That’s why these industries rely on SCHOTT to deliver innovative and reliable glass materials and components of supreme quality, with close working relationships helping to provide uncompromising levels of effectiveness and dependability.