- Offer Profile

-

Cavitar Ltd is an expert in illumination lasers based on diode laser technology. Our laser lighting is used in many demanding high-speed imaging and machine vision applications. We offer versatile components, products and systems for end-users of R&D applications as well as for integrators of industrial monitoring systems.

CAVILUX illumination lasers have a higher power, brightness and efficiency than traditional light sources used in industrial process monitoring. Our lasers enable customers to see through heat and freeze fast motion. These unique features increase the accuracy of critical measurements in R&D applications. In industry our solutions enable improved real-time visual monitoring and ergonomics which leads to substantial cost savings in manufacturing. Fiber coupling enables compact solutions also in challenging industrial environments with limited space.

Laser illumination

-

CAVILUX laser illumination is the high-performance lighting technology for demanding high-speed imaging and machine vision applications in various industrial processes and in R&D. Industrial end users, machine vision integrators, R&D professionals and scientific community can utilize CAVILUX laser illumination technology either as a stand-alone product or as an integrated monitoring solution. These powerful products are easy to use and they are fully compatible with high-speed cameras as well as different kind of machine vision cameras (single or multiple).

CAVILUX products are based on Cavitar Ltd’s pulsed high-power diode laser illumination technology that can generate millions of pulses per second. The pulsed light power is typically several hundreds of watts, and the brightness can be millions of times greater than in LED or halogen light sources. The light output is essentially monochromatic while at the same time having very low degree of coherence. The possibility to couple the light into a fiber enables wide variety of unique optical solutions for illumination. Full light power can e.g. be launched to a desired shape with uniform intensity over a long distance or it can be used in very challenging industrial environments with limited space.

CAVILUX® HF

-

CAVILUX HF is a versatile and powerful high-performance pulsed diode laser light source. It is very suitable light source for high-speed cameras, and an excellent and versatile tool for scientific and industrial R&D work.

Typical application examples include welding, flow and spray studies, material testing, ballistics and explosions. CAVILUX HF is compatible with schlieren and shadowgraphy optical solutions.

The high maximum duty cycle (2 %) of CAVILUX HF enables it to operate at frame rates up to several hundreds of thousands of frames per second.

Benefits- High power and brightness (up to 500 W coupled to a 1.5 mm diameter fiber)

- Ability to generate pulses at high speed (e.g. 20.000 fps) or ultra-high-speed (e.g. 1 million fps)

- Pulse length from 50 ns to 200 µs possible

- Monochromatic and low-coherence light

- High flexibility through fiber optics and changeable illumination optics

Applications

- Welding

- Shockwaves

- Flows and sprays

- Ballistics and explosions

CAVILUX® Smart

-

CAVILUX Smart is a versatile and powerful pulsed diode laser light source. It is an ideal light source for high-speed and machine vision cameras in scientific and industrial R&D.

CAVILUX Smart can generate pulsed light power of hundreds of watts., The light output is essentially monochromatic with low degree of coherence, which is ideal for illumination purposes as there are no chromatic aberrations or speckle. CAVILUX Smart can generate arbitrary pulses or bursts of pulses with precisely adjustable duration for the length of each individual pulse and each delay between pulses.

Benefits

- High power and very short pulses down to 10 ns

- Ideal light source for schlieren and shadowgraphy applications

- Excellent for ultra-high-speed imaging with short pulses

- Versatility by varying pulse duration and repetition rate

- Monochromatic and low-coherence light

Applications

- Shockwaves

- Flows and sprays

- Schlieren imaging

- Welding

- Ballistics and explosions

- Materials testing

CAVILUX® HF UHS for Ultra-High-Speed Illumination

-

CAVILUX HF UHS is a powerful pulsed diode laser light source with very short pulses and very high repetition rates. It is an ideal light source for ultra-high-speed cameras up to 5 MHz.

CAVILUX HF UHS can generate pulsed light power of hundreds of watts at as short as 50 ns pulses. The light output is essentially monochromatic with low degree of coherence, which is ideal for illumination purposes as there are no chromatic aberrations or speckle.

Benefits

- High power and brightness (up to 500 W coupled to a 1.5 mm diameter fiber)

- Ability to generate pulses up to 5 million fps

- Minimum pulse length of 50 ns

- Monochromatic and low-coherence light

- High flexibility through fiber optics and changeable illumination optics

Applications

Check out how CAVILUX HF UHS can be used in your field of industry and how our customers have used it in the following applications:

- Schlieren imaging

- Materials testing (e.g. DIC, Hopkinson bar)

CAVILUX® OEM for Machine Vision Systems

-

CAVILUX lasers are ideal light sources for industrial machine vision solutions. They are immune to surrounding lighting conditions and ‘see’ through blinding brightness. The very short light pulses enable the accurate visualization of fast motion without motion blur. Therefore these lasers are excellent light sources for machine vision. The products are compact and robust, and fiber coupling brings further flexibility even in cramped spaces. CAVILUX OEM lasers are optimized versions for specific machine vision applications and they are typically derivatives of CAVILUX standard lasers containing the essential features needed by the application.

Benefits

- High power and brightness

- Immune to surrounding lighting conditions

- Short pulses

- Easy to integrate, plug and play operation

- Designed for 24/7 industrial use

- Robust for harsh environments

- Compact for challenging setups

- Long working distance solutions for safe distance from the process are possible

Applications

- Welding imaging

- Surface topography

- Flow process monitoring

- 3D measurements

Cavitar’s Welding Camera

-

The core of the welding process emits very bright light that “blinds” the eye as well as normal camera systems. Without special visualization techniques the proper visual monitoring of a welding process is impossible.

Cavitar’s Welding Camera enables the clear visualization of welding processes as if they were cold. It is a complete, compact ready-to-use visualization solution including camera, integrated laser illumination and optics. It is applicable for all major arc welding processes like GMAW (MIG, MAG) and TIG. The technology is also suitable for all major beam welding processes like CO2 laser, fiber laser, diode laser, Nd:YAG laser and electron beam applications.

Benefits

- Welders and operators can adjust the process based on the images in real-time

- Images can be used for image analysis and automation

- Images or videos can be stored for quality documentation

- Fast error detection reduces scrap

- System can be operated from a safe distance to the process

- Improved working ergonomics for the welder

- Reduced risk of inhaling unhealthy welding fumes

- Faster set-up time for welding processes

- High image quality

- Compact system for easy integration

- Plug and play operation

- Robust and suitable for 24/7 industrial use

- Eye-safe solutions are possible

Applications

- GMAW welding (MIG, MAG)

- TIG welding

- Hybrid welding (laser and arc welding)

- Laser welding (e.g. CO2, Nd:YAG, fiber and disc lasers)

- Electron beam

- Robot welding

- Semi-automated welding

- Linear welding

- Orbital welding

Applications

-

CAVILUX laser illumination has several unique features that enable completely new and improved measurement possibilities in various industrial and scientific applications. Our illumination laser technology is ideal for high-speed cameras of all speeds as well as for machine vision cameras.

With CAVILUX laser illumination it is possible to see through heat by eliminating thermal light from the object. It is therefore possible to see the process as if it were cold. This feature is especially important in welding industry and hot metal processing.

CAVILUX lasers also create very short pulses that can “freeze the motion” of very fast objects. This is of high importance when monitoring fast-moving industrial webs, flow processes at high magnification or in defense applications such as ballistics, explosions and shockwaves.

CAVILUX laser illumination enables the highest possible image quality in various applications. The compact, yet robust, design of our products enables the operation both in laboratory and production line environments. The possibility of fiber coupling also makes it possible to realize solutions in limited space.

Additive Manufacturing

-

Additive manufacturing is a process where additional material is added onto a metal surface to improve the surface quality or to create 3D structures. The most common welding methods such as beam and arc welding methods can be applied for additive manufacturing. Processing lasers are typically used in laser sintering processes where a powder bed is melted by a laser beam (SLM – Selective Laser Melting, DMLS – Direct Metal Laser Sintering). Same type of lasers can be used also for directed energy deposition where the filler material is added from the process head (DED). Cold Metal Transfer (CMT) is typically used for arc based deposition due to its lower heat input as compared to other Gas Metal Arc Welding (GMAW) methods.

Similar to welding processes, in additive manufacturing there is a high energy impact on a small area and the processes emit large amount of thermal light. Therefore the core of the process is extremely bright, and thus also a major challenge for camera-based imaging systems of additive manufacturing processes.

Cavitar’s CAVILUX laser illumination enables clear visualization of additive manufacturing processes as if they are cold by eliminating the process brightness. This is mainly due to the high spectral brightness of the laser lighting in combination with efficient filtering of the thermal light. Our solutions can be applied principally in all arc and laser based additive manufacturing and metal 3D printing processes. The solutions range from high-speed imaging for research purposes to quality assurance in industrial production lines.

Imaging of Ballistics and Explosions

-

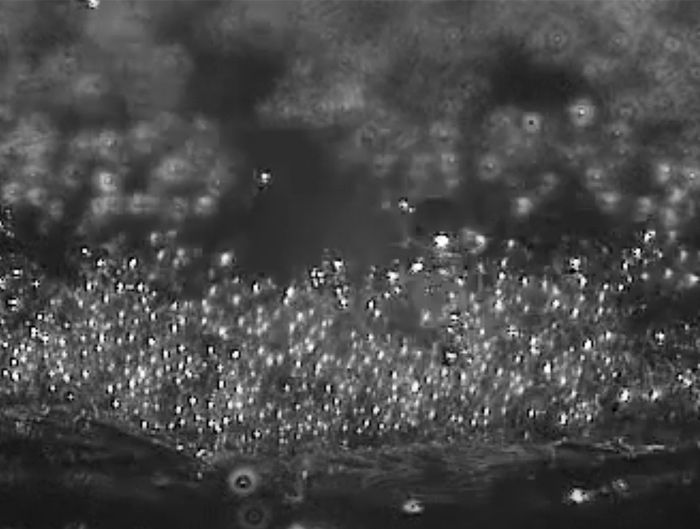

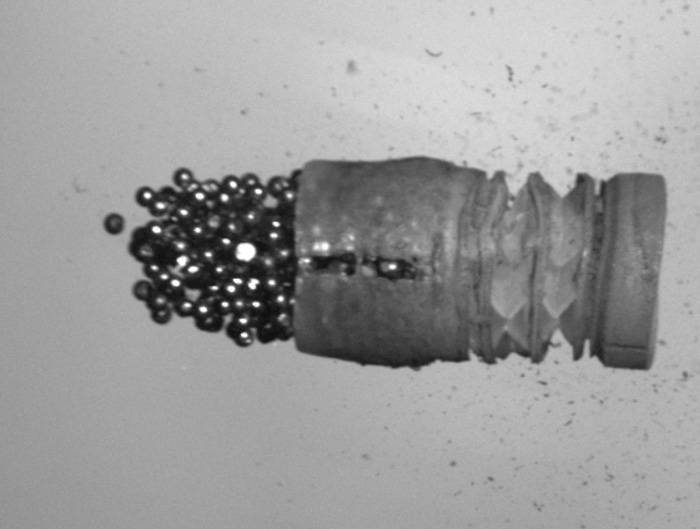

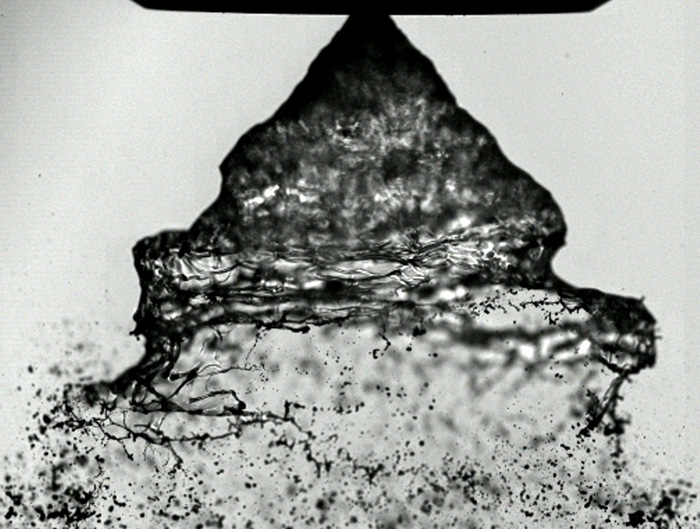

Ballistics and explosions typically have objects of interest that are very small and extremely fast. Motion blur becomes more severe as the object speed increases and if the camera shutter time is longer than the motion of the event itself. This effect is further challenged as the magnification of the image increases. The camera exposure time is often a limiting factor in the visualization of such processes. The other way of reducing motion blur is the use of very short light pulses. This requires high-power illumination during that short pulse duration.

CAVILUX illumination lasers offer very short and high-power pulses that can significantly reduce the amount of motion blur. Both of these features – short pulses and high power – are contributing to sharp and good image quality. In addition to the motion blur, the thermal radiation effects of explosions create further challenges. The brightness of the explosion can be greatly suppressed with CAVILUX illumination lasers. This is due to the narrow bandwidth of the laser emission which enables the use of narrow band optical filters that only transmit the laser emission band and block essentially all radiation outside the pass band.

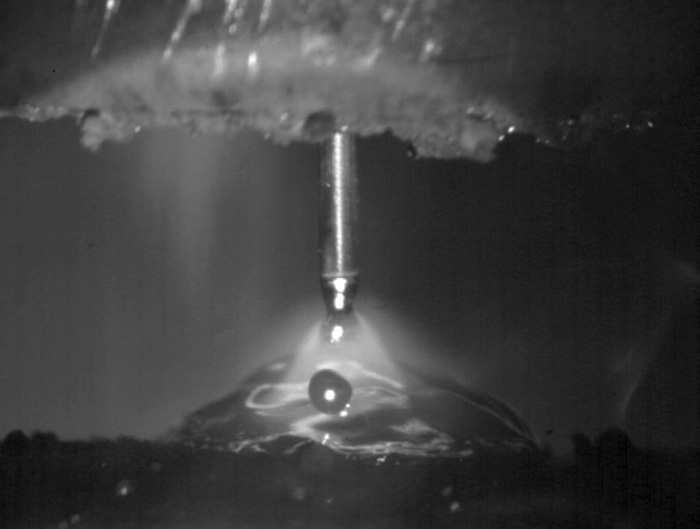

Flow and Spray Imaging

-

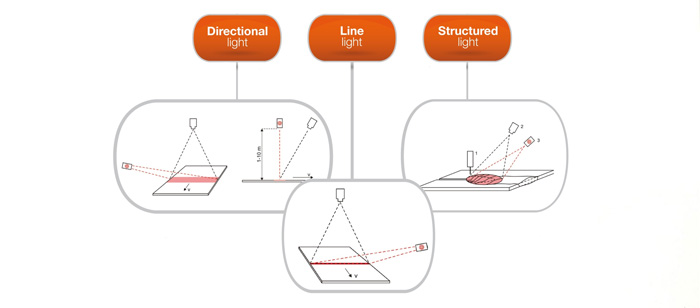

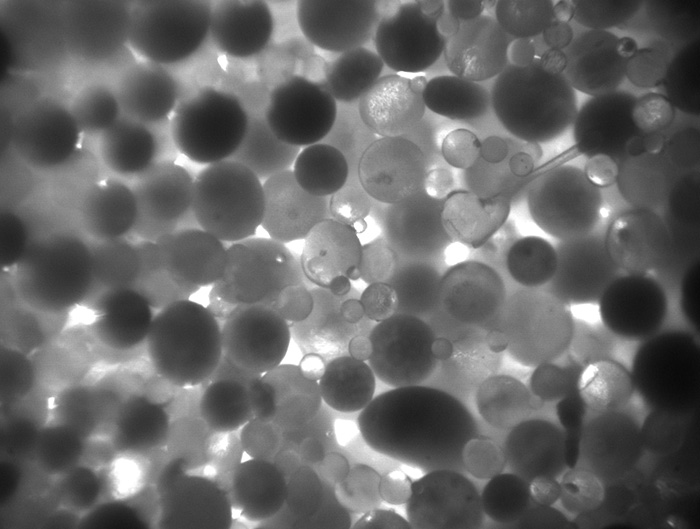

Different kinds of flows and sprays are performing essential functions in numerous of applications in industrial processes, medical applications and even inside consumer products like inkjet printers. Flow and spray imaging can be applied in order to study and monitor liquid and gaseous flow parameters or process objects like droplets, bubbles and different kind of particles. When imaging flows and sprays the objects of interest are typically very small and fast, or they can even be embedded in dense and opaque liquids.

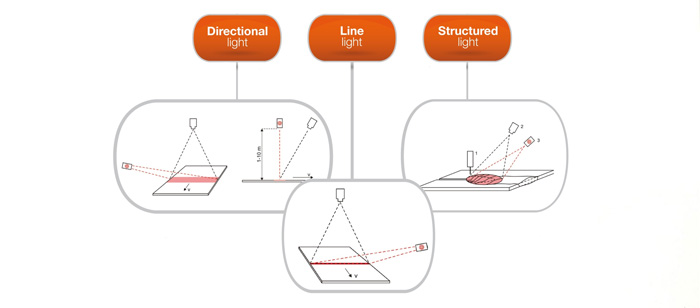

Motion blur becomes more severe as the speed of the object increases. The effect is further increased if the magnification of the image increases like in microscopic applications. The camera exposure time can be a limiting factor when choosing cameras to visualize such processes, but the other way of reducing the blur and “freezing the motion” are very short light pulses. Optical solutions for the illumination play also an essential role in picking up desired information from the flow such as velocity or mixing of different phases.

CAVILUX laser lighting offers very short pulses to monitor and visualize a wide range of applications in research and industry. These systems are also used in online monitoring systems where the growth of particles is measured to allow control of the processes. Wide variety of optical solutions for the light sources is available.

Flow Process Monitoring

-

Different kinds of flows and sprays are performing essential functions in numerous of applications in industrial processes, medical applications and even inside consumer products like inkjet printers. Flow and spray imaging can be applied in order to study and monitor liquid and gaseous flow parameters or process objects like droplets, bubbles and different kind of particles. When imaging flows and sprays the objects of interest are typically very small and fast, or they can even be embedded in dense and opaque liquids.

Motion blur becomes more severe as the speed of the object increases. The effect is further increased if the magnification of the image increases like in microscopic applications. The camera exposure time can be a limiting factor when choosing cameras to visualize such processes, but the other way of reducing the blur and “freezing the motion” are very short light pulses. Optical solutions for the illumination play also an essential role in picking up desired information from the flow such as velocity or mixing of different phases.

CAVILUX laser lighting offers very short pulses to monitor and visualize a wide range of applications in research and industry. These systems are also used in online monitoring systems where the growth of particles is measured to allow control of the processes. Wide variety of optical solutions for the light sources is available.

High-Speed Imaging

- High-speed imaging is a common technique for troubleshooting and for obtaining a better understanding of the object or process under study. When combined with a compatible high-speed camera, CAVILUX laser illumination dramatically enhances the image quality and operating speed of the imaging system. CAVILUX lasers are versatile and powerful pulsed diode laser light sources that are very suitable for scientific and industrial R&D applications.

Machine Vision

-

Wide range of imaging sensors are used in industrial manufacturing in order to achieve high-quality products and efficient manufacturing processes. Camera-based sensors often have many advantages over other types of sensors because they produce 2D-information or even 3D-information by nature. In order to achieve desired information from the process, the choice of illumination is critical. While LED is the most common light source for many machine vision systems, they cannot solve several specific requirements.

CAVILUX laser illumination addresses the challenges that typical light sources like LEDs or halogen lamps cannot solve. These lasers are designed for easy integration into machine vision systems and their capability of eliminating motion blur and seeing through thermal radiation opens up new possibilities for machine vision systems.

Shockwave Imaging

-

In ultra-high-speed applications, such as shockwave imaging, motion blur is typically one of the key factors that reduce the information content of the images. If the camera exposure time is not short enough, or if the output power and brightness of the illumination are not high enough, motion blur cannot be avoided. CAVILUX laser illumination overcomes both of these problems by providing short light pulses of high power and brightness up to repetition rates in the MHz range.

- Clear visibility of shockwaves

- More detailed images as compared to other light sources

- Applicability up to 10 MHz with ultra-high-speed (UHS) version

- E.g. medical applications, combustion in pressure chambers, materials testing

- Recommended products: CAVILUX HF or CAVILUX Smart

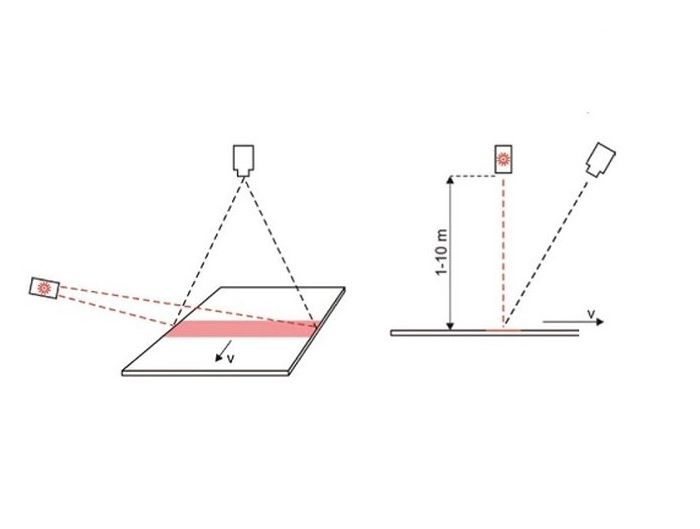

Surface Topography

-

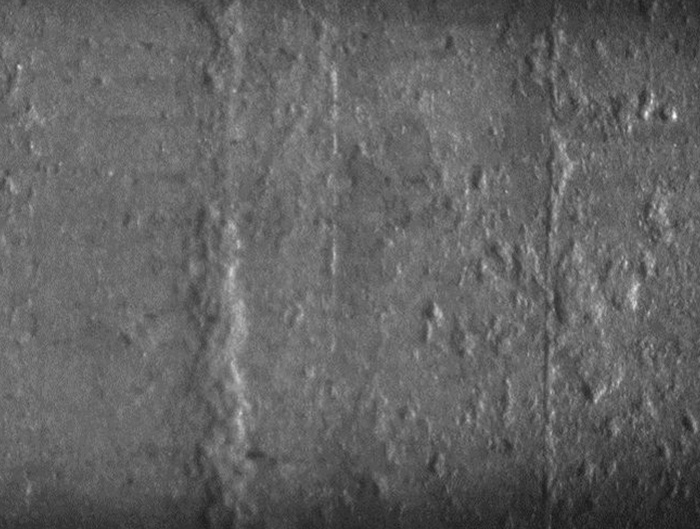

Monitoring the surface topography of webs (e.g. paper) or metals (e.g. slab) is vital in many manufacturing applications in order to detect errors and to ensure appropriate quality control. Early detection of flaws in the surface can help to fix problems right away during the process, and hence reduce the amount of scrap that would otherwise appear. Real-time monitoring can thus be a valuable asset in paper, metal and process industries.

Traditionally, vision based monitoring meets special challenges whenever processes are running at high speed or they contain hot objects. Due to the high speed of many industrial webs, like in paper manufacturing, motion blur is seriously limiting the detection of small flaws. On the other hand, processes with hot objects, such as in hot metal rolling in foundries, can hide valuable information behind the glow of the material.

CAVILUX lasers can generate short pulses of high power and high spectral brightness which typically eliminates all problems related to motion blur or disturbing thermal light from the hot object. As a result, fast and/or hot webs can be monitored reliably, enabling fast error detection and reduced amount of scrap.

Welding Imaging

-

In welding applications typically metallic pieces and components are joined together by melting the material in the connection area. In some applications, especially with thick materials, filler material is added to the joint. The heat is typically induced by electricity like in induction welding, spot welding and arc welding, or by electromagnetic radiation as in laser and electron beam welding. Due to the high energy impact on a small area, the processes emit large amount of thermal light. Therefore the core of the welding process is extremely bright, and thus also a major challenge for camera-based welding imaging systems.

Cavitar’s laser illumination enables clear visualization of welding processes as if they were essentially cold by eliminating welding brightness. This is mainly due to the high spectral brightness of the laser lighting in combination with efficient filtering of the thermal light. Our solutions can be applied principally in all arc and laser welding processes. The solutions range from high-speed imaging of welding for research purposes to quality assurance of welding processes in industrial production lines.