- Offer Profile

-

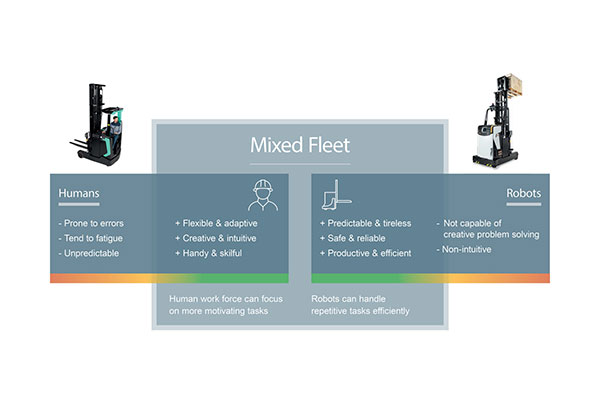

The Rocla AGV Solutions brand offers a full range of modular, industry-specific material handling solutions for a wide variety of purposes. It does this through the mixed-fleet approach: we design the best material handling solution for each logistics facility that combines automated vehicles with human expertise. All this is backed up by our proprietary FleetController software and asset-value retaining Life Cycle Services For customers, this means exceptionally short delivery times, easy implementation, and a lower total cost of ownership.

Rocla AGV Solutions is part of Mitsubishi Logisnext Europe’s AGV operations, based in Järvenpää, Finland. Rocla AGV Solutions operates globally with a highly skilled staff, drawing on over 40 years of experience. Since 1982 Rocla AGV solutions have delivered thousands of vehicles and projects internationally.

The Rocla AGV Solution for Warehouse Automation

-

Rocla automated guided vehicles (AGVs) allow your warehouse to automate its functions using solutions that can be adapted to the most common industrial settings.

Warehouse logistics: perfectly suited for automation with AGVs

Warehouse logistics operations face high demands, but are also challenged by the uneven return on investment if fully automated. Automating all processes may not be worth it, as the risk is over-automation and poor return on investment. Automated guided vehicles (AGVs) are perfectly suited to solving these challenges.

Automated Guided Vehicles

-

- Wide range of models for warehouses

- Proven record in warehouses

- Tangible cost and efficiency benefits

AGV Applications for Warehouses

-

- Cut IT costs through integration

- Increase efficiency through digitalization

- Reduce maintenance with remote diagnostics

FleetController Software

-

- User friendly

- Developed by us in-house

- Industry-leading product optimization

Life Cycle Services

-

- Retain asset value

- Smartly timed maintenance proposals

- Audits by us to map your specific needs

ROI Calculator

-

- Calculate return on investment

- See why not deploying AGVs could cost

- Discover tangible monetary benefit

Mixed Fleet

-

- Agile and flexible

- Allows you to cut costs and risks

- Compatible with existing operations

Automated Guided Vehicles

- Automated guided vehicles (AGVs) are a solution for a variety of industrial and logistics processes. Browse the list of AGVs here and learn more about the solution for your industry.

Automated Compact Truck ACT

-

The automated compact truck (ACT) is ideal for heavy-duty lifting in narrow spaces. With a strong hydraulic unit, ACT can lift heavy loads up to 6 meters in as narrow as 2.6-meter aisles. Thus, it is an excellent choice for higher warehouses, where it works as a companion for other high-lifting vehicles and manually operated forklifts. ACT operates easily between warehouse and production or inbound and outbound areas, and it fits easily in the existing warehouse environment with minimal rack modifications.

ACT is the winner of iF Design Award 2024 and Red Dot Design Award 2024.

Key Benefits of Automated Compact Truck ACT- Available as forkover and counterbalance

- Enables heavy lifting to 6 meters even as narrow as 2.6-meter aisles

- Easy integration; fits in existing warehouse logistics

- Responsive user interface

- Designed to meet ISO 3691-4 safety standard

- Designed to operate in the same environment with manual operations

Reach Truck ART

-

The Rocla Reach Truck ART (Automated Reach Truck) is a multipurpose solution that is especially suitable for large warehousing operations.

Rocla’s automated reach truck (ART) is designed to operate in an aisle width of 3 m. New and innovative software and sensor technology considerably increase load handling speed. The agile turning radius and lifting capability of 10 m fulfil the requirements of the most common warehouse environments.

Key Benefits of Reach Truck ART- Fast and reliable load handling

- Agile turning radius

- Lifting capacity of 10 m

- Can operate in aisles as narrow as 3 m

- Safe operations with advanced obstacle protection

- Precise load handling

Counterbalance AWT

-

The Counterbalance AGV is optimal in use of storage floor space or for push-back and drive-in racks in pallet transportation and warehousing applications.

The Counterbalance AWT is perfect when your facility needs to use storage floor space optimally, or when your pallet transportation or warehouse calls for push-back and drive-in racks. It is a suitable automated guided vehicle in a wide range of applications, given its lifting height of up to 8,400 mm and permitted loads of up to 2,500 kg. It facilitates both two- and four-pallet transport. This vehicle is compatible with drive-in racks, as well as suitable for push-back racks. It is also an ideal solution for gravity-flow racks. Due to its structure, the Counterbalance AWT is optimal in applications where support legs, otherwise known as straddle options, cannot be used.

Key Benefits of Counterbalance AWT- Lifting height of up to 8,400 mm

- Loads of up to 2,500 kg

- Compatibility with drive-in racks

- Suitability for push-back racks

- An ideal solution for gravity-flow racks

- Ideal operation in applications wherein support legs (straddle options) cannot be used

Very Narrow Aisle AWT

-

The Very Narrow Aisle AWT is intended for pallet handling and storage applications in pallet racking with very narrow aisles (VNA).

The Very Narrow Aisle AWT is intended for pallet handling and storage applications in pallet racking with very narrow aisles (VNA). The vehicle is specially designed for good performance with high lifts.

This AGV is equipped with telescopic load handling forks as standard. A turret head for trilateral turning (90…0…+90 ) of load forks is available as an option for more versatile pallet handling.

Key Benefits of Very Narrow Aisle AWT- Suits very narrow aisles

- Good performance with high lifts

- Telescopic load handling forks as standard

- Versatile pallet handling

- Modular structure

- Suits high storage capacity facilities

Reel Fork AWT

-

For efficient and reliable reel handling, Mitsubishi Logisnext Europe offers the Reel Fork AWT as a solution to the paper, packaging, and printing industries, in addition to those performing tissue and plastic reel handling.

The Reel Fork AWT is an ideal solution for efficient and reliable reel handling in the paper industry. In addition, this Mitsubishi Logisnext Europe solution suits the packaging, and printing industries, as well as those performing tissue and plastic reel handling. The Reel Fork AWT is equipped with fixed or adjustable forks for delivery of efficient material handling as your applications require.

Key Benefits of Reel Fork AWT- Designed specifically for reel handling

- Ideal system for horizontal reel transport

- Variable reel diameters and widths

- Fixed or adjustable forks

- Loads of up to 8,000 kg

- Modular design

- Light-, medium-, or heavy-load solutions

- Special models for customer-specific loads

Roll Clamp AWT

-

For efficient and reliable roll handling, Mitsubihsi Logisnext Europe offers solutions to the paper, packaging, and printing industries, in addition to tissue and plastic roll handling.

The Roll Clamp AWT is an ideal solution for efficient and reliable roll handling in the paper industry. In addition, this Mitsubishi Logisnext Europe solution suits the packaging, and printing industries, as well as those performing tissue and plastic roll handling. The Roll Clamp AWT is equipped with rotating clamps that allow for flexible and reliable material handling as your applications require.

Key Benefits of Roll Clamp AWT- Lifting height of up to 7,250 mm

- Loads as great as 6,000 kg

- Variable roll diameters and widths

- Rotating clamp as an option

Conveyor AWT

-

The Rocla conveyor AGV is excellent for expanding the functionality of conveyor systems. It operates as an unfixed conveyor that is able to serve several fixed conveyors.

The Conveyor AWT which keep materials flowing. It serves as an unfixed conveyor that can pick up and deliver several conveyors. This keeps areas open for forklift and human traffic. Another factor is that conveyor system failure suspends all movement of material in the process. With the AGV system, the material keeps moving even if one vehicle is non-operational. The AGV system also leaves the floor space open for easy cleaning and maintenance.

Key Benefits of Conveyor AWT- Excellent for expanding the functionality of conveyor systems

- Operates as an unfixed conveyor

- Can serve several fixed conveyors

- Keeps operating area open for both human and forklift traffic

- Loads of up to 2 x 2,500 kg

- Transfer height of up to 950 mm

- Variable transfer height as an option

Bale Clamp AWT

-

This solution is ideal for automated transport and warehousing of pulp bales at pulp mills, distribution warehouses, and paper and board mills.

Mitsubishi Logisnext Europe has successfully helped a number of customers in recent years in the paper, print, packaging, and tissue industry solve logistics challenges through better material flow. Here, vehicles such as the Bale Clamp AWT have been key. Our intention is to standardize, digitalize and automate material handling, using the most rational option in each case. The goal is more reliable production and storage processes and the replacement of conventional material handling equipment. Rocla’s modern solutions offer a wide range of reliable and efficient applications in the paper industry, such as newsprint day storage and the commercial printing industry.

Key Benefits of Bale Clamp AWT- Transfer from a bale-wrapping line or truck unloading to pulp storage

- Operation of pulp storage

- Transport to de-wiring stations

- Preparation of truck loading

- Lifting height of up to 7,250 mm

- Loads of up to 6,000 kg

Straddle AWT

-

The Straddle AWT is a simple but very capable AGV. Suitable for handling pallets and customer-specific loads in the distribution and manufacturing sector and in all industries that handle pallets and have related transportation needs.

Straddle AWT is suitable for handling pallets and customer-specific loads in the distribution and manufacturing sector and in all industries that handle pallets and have related transportation needs. Also, it is capable of load-on-load operation and deep stacking of pallets with stable loads.

Straddle AWT’s high lifting capacity and support structure are well suited for both conveyor handling and high lifting. It works well in different applications and has an appealing price/performance balance.

Key Benefits of Straddle AWT- Lifting height of up to 8,600 mm

- Loads of up to 2,500 kg

- Pick-up from conveyors

- Ideal for Manufacturing, Tyre and Food & Beverage industry

Optimal Automation – Defined by Your Processes

- Optimal automation means solutions that are built to optimally serve your specific intralogistics processes. The fluency of your operations defines the level of automation rather than the other way. Our priority is to ensure that your business is running in the most optimal and efficient way, today and tomorrow.

Find the perfect balance between automation and manual operations

- Our solution combines the best of AGVs and manual lift trucks, their abilities and technical features to create a perfect mix for your fleet. As a comprehensive solution provider, we offer a wide range of material handling solutions and services from AGVs and manually operated forklifts to racking, AGV system software and intralogistics consultation. We ensure that each solution is designed for your specific needs.

Build a dream team

- Like in any sports team, every player has their own strength and position. So do the AGVs and the manual forklifts. To build a winning team, you need a perfect combination of different skills, optimal for their place and role. Mixed fleet means team play; AGVs work with repetitive, tiresome and burdensome tasks, and humans tackle the jobs requiring precision and creative decision-making. Fluent operations and seamless collaboration with manual lift trucks and other people-driven operations make your logistics fluent and allow you to adjust to variations in capacity demands.

Mastering the material flow control

- In our solution, the same process can be handled by AGV or manual operator, which increases flexibility significantly. We help you to pinpoint the processes where automation creates the most value. Agility to allocate tasks to both automated and manual operators, depending on the process, schedule and prioritisation, creates the optimal utility rate. Our system software optimises the material flow and maximises efficiency, creating a comprehensive intralogistics solution where everything works smoothly and reliably, accelerating your business.

AGV Applications

-

Rocla automated guided vehicles (AGVs) can be used to automate a variety of material storage and manufacturing processes. Whether you need to reach extremely high or work on the floor level, we’ll provide you with the most suitable solution

Automated guided vehicles to make your internal logistics processes safe and reliable

Automation might be the key if you are searching for a way to lean your processes and optimise your operations. AGVs are an ideal solution for cutting costs and ensuring the reliability of operations in a wide range of logistical settings. Follow the links on this page to learn more about how AGVs can be applied to make your facility more efficient.

Pallet Racking

- Pallet racking is the most common racking method for unit loads and makes individual pallets easily accessible. This storage method has a low capital cost and is flexible as the pallet racks can be adjusted and supplemented with ease, and the racking can be fitted with bearers for cables, half-pallets and more. With automation, you can turn your shelf racking even more efficient. Whether your rack is low or reaches a height of up to 10 meters, your aisle wide or as narrow as three meters, and your traffic one-way or two-way, we will help you find the perfect solution for your needs.

Reach Truck ART

-

The Rocla Reach Truck ART (Automated Reach Truck) is a multipurpose solution that is especially suitable for large warehousing operations.

Rocla’s automated reach truck (ART) is designed to operate in an aisle width of 3 m. New and innovative software and sensor technology considerably increase load handling speed. The agile turning radius and lifting capability of 10 m fulfil the requirements of the most common warehouse environments.

Key Benefits of Reach Truck ART- Fast and reliable load handling

- Agile turning radius

- Lifting capacity of 10 m

- Can operate in aisles as narrow as 3 m

- Safe operations with advanced obstacle protection

- Precise load handling

Counterbalance AWT

-

The Counterbalance AGV is optimal in use of storage floor space or for push-back and drive-in racks in pallet transportation and warehousing applications.

The Counterbalance AWT is perfect when your facility needs to use storage floor space optimally, or when your pallet transportation or warehouse calls for push-back and drive-in racks. It is a suitable automated guided vehicle in a wide range of applications, given its lifting height of up to 8,400 mm and permitted loads of up to 2,500 kg. It facilitates both two- and four-pallet transport. This vehicle is compatible with drive-in racks, as well as suitable for push-back racks. It is also an ideal solution for gravity-flow racks. Due to its structure, the Counterbalance AWT is optimal in applications where support legs, otherwise known as straddle options, cannot be used.

Key Benefits of Counterbalance AWT- Lifting height of up to 8,400 mm

- Loads of up to 2,500 kg

- Compatibility with drive-in racks

- Suitability for push-back racks

- An ideal solution for gravity-flow racks

- Ideal operation in applications wherein support legs (straddle options) cannot be used

Automated Compact Truck ACT

-

The automated compact truck (ACT) is ideal for heavy-duty lifting in narrow spaces. With a strong hydraulic unit, ACT can lift heavy loads up to 6 meters in as narrow as 2.6-meter aisles. Thus, it is an excellent choice for higher warehouses, where it works as a companion for other high-lifting vehicles and manually operated forklifts. ACT operates easily between warehouse and production or inbound and outbound areas, and it fits easily in the existing warehouse environment with minimal rack modifications.

ACT is the winner of iF Design Award 2024 and Red Dot Design Award 2024.

Key Benefits of Automated Compact Truck ACT- Available as forkover and counterbalance

- Enables heavy lifting to 6 meters even as narrow as 2.6-meter aisles

- Easy integration; fits in existing warehouse logistics

- Responsive user interface

- Designed to meet ISO 3691-4 safety standard

- Designed to operate in the same environment with manual operations

Pallet VNA Racking

-

Very narrow aisle pallet racking is a good storage option when square meters are at a premium. We help you to find the most suitable solutions for this storage option.

Very narrow aisle pallet racking is cost-effective when square meters are expensive or limited. These AGVs are designed to operate on significantly narrow aisles not much wider than the vehicle itself. Also, this AGV can handle loads to either side, making it efficient for tight aisles.

Very Narrow Aisle AWT

-

The Very Narrow Aisle AWT is intended for pallet handling and storage applications in pallet racking with very narrow aisles (VNA).

The Very Narrow Aisle AWT is intended for pallet handling and storage applications in pallet racking with very narrow aisles (VNA). The vehicle is specially designed for good performance with high lifts.

This AGV is equipped with telescopic load handling forks as standard. A turret head for trilateral turning (90…0…+90 ) of load forks is available as an option for more versatile pallet handling.

Key Benefits of Very Narrow Aisle AWT- Suits very narrow aisles

- Good performance with high lifts

- Telescopic load handling forks as standard

- Versatile pallet handling

- Modular structure

- Suits high storage capacity facilities

Mobile Racking

-

Mobile racking combines the advantages of conventional racking, yet the use of space is exceptionally efficient as the available area has been carefully utilised. With this solution, the pallets are always accessible, even though they are arranged more closely together than in conventional shelving.

In mobile racking, the racking rests on motor-driven trolleys and is transported using floor-installed rails. A dense storage unit with a moving aisle can be formed from a series of racks. Mobile racking affords very high space usage, but by contrast, it offers low handling capacity.

Rocla AGVs work well together with mobile shelves, creating an efficient and space-saving solution for the customer, which, together with our experienced experts, makes an efficient and functional solution.

Counterbalance AWT

-

The Counterbalance AGV is optimal in use of storage floor space or for push-back and drive-in racks in pallet transportation and warehousing applications.

The Counterbalance AWT is perfect when your facility needs to use storage floor space optimally, or when your pallet transportation or warehouse calls for push-back and drive-in racks. It is a suitable automated guided vehicle in a wide range of applications, given its lifting height of up to 8,400 mm and permitted loads of up to 2,500 kg. It facilitates both two- and four-pallet transport. This vehicle is compatible with drive-in racks, as well as suitable for push-back racks. It is also an ideal solution for gravity-flow racks. Due to its structure, the Counterbalance AWT is optimal in applications where support legs, otherwise known as straddle options, cannot be used.

Key Benefits of Counterbalance AWT- Lifting height of up to 8,400 mm

- Loads of up to 2,500 kg

- Compatibility with drive-in racks

- Suitability for push-back racks

- An ideal solution for gravity-flow racks

- Ideal operation in applications wherein support legs (straddle options) cannot be used

Reach Truck ART

-

The Rocla Reach Truck ART (Automated Reach Truck) is a multipurpose solution that is especially suitable for large warehousing operations.

Rocla’s automated reach truck (ART) is designed to operate in an aisle width of 3 m. New and innovative software and sensor technology considerably increase load handling speed. The agile turning radius and lifting capability of 10 m fulfil the requirements of the most common warehouse environments.

Key Benefits of Reach Truck ART- Fast and reliable load handling

- Agile turning radius

- Lifting capacity of 10 m

- Can operate in aisles as narrow as 3 m

- Safe operations with advanced obstacle protection

- Precise load handling

Block Storage

-

Block storage is a storage method for pallets and products of uniform size. It is space-efficient and does not require significant investments.

High storage density and high space create good starting points for efficient storage: When the goods are packed together tightly, and all the articles on the pallets form an even surface, the vertical stacking of the pallets is viable. A high volume increases the solution’s effectiveness, so Block storage is ideal for applications with large quantities of the same article.

With long-time experience, we know the possibilities and limitations of block storage, and we want to help you achieve the best benefits from it for your organisation. Please reach out to us to hear more.

Bale Clamp AWT

-

This solution is ideal for automated transport and warehousing of pulp bales at pulp mills, distribution warehouses, and paper and board mills.

Mitsubishi Logisnext Europe has successfully helped a number of customers in recent years in the paper, print, packaging, and tissue industry solve logistics challenges through better material flow. Here, vehicles such as the Bale Clamp AWT have been key. Our intention is to standardize, digitalize and automate material handling, using the most rational option in each case. The goal is more reliable production and storage processes and the replacement of conventional material handling equipment. Rocla’s modern solutions offer a wide range of reliable and efficient applications in the paper industry, such as newsprint day storage and the commercial printing industry.

Key Benefits of Bale Clamp AWT- Transfer from a bale-wrapping line or truck unloading to pulp storage

- Operation of pulp storage

- Transport to de-wiring stations

- Preparation of truck loading

- Lifting height of up to 7,250 mm

- Loads of up to 6,000 kg

Reach Truck ART

-

The Rocla Reach Truck ART (Automated Reach Truck) is a multipurpose solution that is especially suitable for large warehousing operations.

Rocla’s automated reach truck (ART) is designed to operate in an aisle width of 3 m. New and innovative software and sensor technology considerably increase load handling speed. The agile turning radius and lifting capability of 10 m fulfil the requirements of the most common warehouse environments.

Key Benefits of Reach Truck ART- Fast and reliable load handling

- Agile turning radius

- Lifting capacity of 10 m

- Can operate in aisles as narrow as 3 m

- Safe operations with advanced obstacle protection

- Precise load handling

Counterbalance AWT

-

The Counterbalance AGV is optimal in use of storage floor space or for push-back and drive-in racks in pallet transportation and warehousing applications.

The Counterbalance AWT is perfect when your facility needs to use storage floor space optimally, or when your pallet transportation or warehouse calls for push-back and drive-in racks. It is a suitable automated guided vehicle in a wide range of applications, given its lifting height of up to 8,400 mm and permitted loads of up to 2,500 kg. It facilitates both two- and four-pallet transport. This vehicle is compatible with drive-in racks, as well as suitable for push-back racks. It is also an ideal solution for gravity-flow racks. Due to its structure, the Counterbalance AWT is optimal in applications where support legs, otherwise known as straddle options, cannot be used.

Key Benefits of Counterbalance AWT- Lifting height of up to 8,400 mm

- Loads of up to 2,500 kg

- Compatibility with drive-in racks

- Suitability for push-back racks

- An ideal solution for gravity-flow racks

- Ideal operation in applications wherein support legs (straddle options) cannot be used

Pallet Gravity Flow Racking

-

Pallet gravity flow racking offers compact storage for high-frequency goods in settings with a number of different articles.

Gravity flow racking is used in many places in manufacturing industry and it suits well, for example, as work-in-progress storage. It enables the first in, first out (FIFO) principle.

In this method, the racking is sloped and equipped with rollers. The goods move forward from intake to retrieval thanks to the force of gravity. The goods can roll on undriven conveyors with braking rollers, driven rollers, or wheeled load carriers.

Reach Truck ART

-

The Rocla Reach Truck ART (Automated Reach Truck) is a multipurpose solution that is especially suitable for large warehousing operations.

Rocla’s automated reach truck (ART) is designed to operate in an aisle width of 3 m. New and innovative software and sensor technology considerably increase load handling speed. The agile turning radius and lifting capability of 10 m fulfil the requirements of the most common warehouse environments.

Key Benefits of Reach Truck ART- Fast and reliable load handling

- Agile turning radius

- Lifting capacity of 10 m

- Can operate in aisles as narrow as 3 m

- Safe operations with advanced obstacle protection

- Precise load handling

Counterbalance AWT

-

The Counterbalance AGV is optimal in use of storage floor space or for push-back and drive-in racks in pallet transportation and warehousing applications.

The Counterbalance AWT is perfect when your facility needs to use storage floor space optimally, or when your pallet transportation or warehouse calls for push-back and drive-in racks. It is a suitable automated guided vehicle in a wide range of applications, given its lifting height of up to 8,400 mm and permitted loads of up to 2,500 kg. It facilitates both two- and four-pallet transport. This vehicle is compatible with drive-in racks, as well as suitable for push-back racks. It is also an ideal solution for gravity-flow racks. Due to its structure, the Counterbalance AWT is optimal in applications where support legs, otherwise known as straddle options, cannot be used.

Key Benefits of Counterbalance AWT- Lifting height of up to 8,400 mm

- Loads of up to 2,500 kg

- Compatibility with drive-in racks

- Suitability for push-back racks

- An ideal solution for gravity-flow racks

- Ideal operation in applications wherein support legs (straddle options) cannot be used

Conveyor Pick-up/Drop-off

-

Conveyors are often used to move goods between processes and to and from warehouses. Interfacing with conveyors is common for Mitsubishi Logisnext Europe’s AGVs.

Conveyors are a convenient method of moving goods from production to warehouse or from warehouse to production or shipment. AGVs operate with conveyors the same way as manual forklifts do. AGVs and conveyors interact safely by using I/O signals to negotiate when an AGV is allowed to enter a conveyor.

Reach Truck ART

-

The Rocla Reach Truck ART (Automated Reach Truck) is a multipurpose solution that is especially suitable for large warehousing operations.

Rocla’s automated reach truck (ART) is designed to operate in an aisle width of 3 m. New and innovative software and sensor technology considerably increase load handling speed. The agile turning radius and lifting capability of 10 m fulfil the requirements of the most common warehouse environments.

Key Benefits of Reach Truck ART- Fast and reliable load handling

- Agile turning radius

- Lifting capacity of 10 m

- Can operate in aisles as narrow as 3 m

- Safe operations with advanced obstacle protection

- Precise load handling

Counterbalance AWT

-

The Counterbalance AGV is optimal in use of storage floor space or for push-back and drive-in racks in pallet transportation and warehousing applications.

The Counterbalance AWT is perfect when your facility needs to use storage floor space optimally, or when your pallet transportation or warehouse calls for push-back and drive-in racks. It is a suitable automated guided vehicle in a wide range of applications, given its lifting height of up to 8,400 mm and permitted loads of up to 2,500 kg. It facilitates both two- and four-pallet transport. This vehicle is compatible with drive-in racks, as well as suitable for push-back racks. It is also an ideal solution for gravity-flow racks. Due to its structure, the Counterbalance AWT is optimal in applications where support legs, otherwise known as straddle options, cannot be used.

Key Benefits of Counterbalance AWT- Lifting height of up to 8,400 mm

- Loads of up to 2,500 kg

- Compatibility with drive-in racks

- Suitability for push-back racks

- An ideal solution for gravity-flow racks

- Ideal operation in applications wherein support legs (straddle options) cannot be used

Conveyer AWT

-

The Rocla conveyor AGV is excellent for expanding the functionality of conveyor systems. It operates as an unfixed conveyor that is able to serve several fixed conveyors.

- Excellent for expanding the functionality of conveyor systems

- Operates as an unfixed conveyor

- Can serve several fixed conveyors

- Keeps operating area open for both human and forklift traffic

- Loads of up to 2 x 2,500 kg

- Transfer height of up to 950 mm

- Variable transfer height as an option

Automated Compact Truck ACT

-

The automated compact truck (ACT) is ideal for heavy-duty lifting in narrow spaces. With a strong hydraulic unit, ACT can lift heavy loads up to 6 meters in as narrow as 2.6-meter aisles. Thus, it is an excellent choice for higher warehouses, where it works as a companion for other high-lifting vehicles and manually operated forklifts. ACT operates easily between warehouse and production or inbound and outbound areas, and it fits easily in the existing warehouse environment with minimal rack modifications.

ACT is the winner of iF Design Award 2024 and Red Dot Design Award 2024.

Key Benefits of Automated Compact Truck ACT- Available as forkover and counterbalance

- Enables heavy lifting to 6 meters even as narrow as 2.6-meter aisles

- Easy integration; fits in existing warehouse logistics

- Responsive user interface

- Designed to meet ISO 3691-4 safety standard

- Designed to operate in the same environment with manual operations

FleetController – Next generation software for AGVs

-

Combining efficiency with ease of use, FleetController is a system software solution for Automated Guided Vehicles (AGVs). It connects with your WMS (Warehouse Management System), and keeps the fleet running by automatically optimising the orders and routes of your material flow. With Dashboard, the graphic user interface, you can monitor, manage and maintain your AGV fleet.

Flexible platform, easy integrationFleetController offers one platform that connects all components needed to run and manage efficient AGV operations. It integrates with the warehouse management system and manages the intra-logistic transports.

As a fully automated system, it will run on its own. A set of optimisation algorithms ensure that you get the maximum capacity out of your fleet. Through continuous optimisation, the orders and routes are being computed for fluent, efficient traffic flow at all times.

Warehouse Management System

-

Use your facility’s own warehouse management system, acquire one from Mitsubishi Logisnext Europe, or use a third-party one, subject to agreement. Its central purpose is to know where the goods are and where they are heading. The Logisnext FleetController software works seamlessly with it to manage the automated guided vehicle (AGV) fleet.

If your logistics facility already has a Warehouse Management System (WMS) that tells you where your goods are and where they are travelling, you can integrate it with FleetController software from Mitsubishi Logisnext Europe. Depending on the specifications of your WMS, various degrees of integration work may be needed to ensure complete compatibility with FleetController. That is a process we’ll be happy to guide you through so you can continue to use your WMS to both have an overview of goods movements and to communicate with your fleet of automated guided vehicles (AGVs).

User Interface

-

FleetController comes with a Dashboard, a novel browser-based tool for monitoring, optimizing, and managing automated guided vehicle (AGV) operations. Ideally, the AGV fleet manages itself. However, should the need arise, the Dashboard is only one browser-window away.

Dashboard offers a window into the operations of the AGV system at any time, combining the monitoring data into a unified and intuitive user interface. Dashboard is designed for factory and warehouse operators who manage the AGV system and need information about the automated intra logistics process at a glance. Dashboard delivers real-time data of the fleet operations. It is meant for users requiring visual insight into vehicle locations and movement. This browser-based tool can be accessed on any standard workstation. Dashboard displays both transport and fleet operational history, as an optional feature. With logged data, operators can easily monitor fleet movements, tasks and KPIs, such as the number of transports completed. The system also automatically flags incidents of interest for later inspection.

Integration

-

With the FleetController architecture, integration is agile and straightforward. This means savings of time and money in system implementation and modernization. We operate using a REST interface between the Warehouse Management System and FleetController – a well-known, established way to connect two systems.

FleetController is explicitly designed for our AGVs. Many tasks that have traditionally been managed in the Warehouse Management System or by third party controllers can be managed in FleetController. This allows light integration with the warehouse management, saving system implementation and maintenance costs.

FleetController comes with a REST Application Programming Interface. The standard interface is much easier to use than proprietary technologies. This means lighter integration with the Warehouse Management System, as less work is needed.

Optimization

-

Logisnext Solutions software is the key to optimal automation. Combining efficiency with ease of use, FleetController Suite is a software solution for Automated Guided Vehicles (AGVs). It connects with your WMS (Warehouse Management System) and keeps the fleet running by automatically optimising the routes and orders for maximum fleet capacity. This facilitates high-throughput material flow.

A large logistics facility may have dozens of AGVs operating simultaneously. While AGVs operate autonomously, something further is needed to ensure that the entire facility operates logically and with the best exploitation of all resources. This is where the FleetController’s optimisation comes in.

FleetController Suite comes with proprietary optimisation logic that scales automatically to material flow demands. Designed and developed in-house, its algorithms are based on decades of experience in automation.

Life Cycle Services

- As a customer, it is essential that you get the best value out of our solution, achieve a rapid return on investment, and keep the entire solution reliable and available for as long as possible. With our Life Cycle Services, you can enjoy continuous productivity without unnecessary interruptions. Leave the worrying for us, and we’ll let you focus on your core business instead!

Life Cycle Services to maintain your assets’ value

-

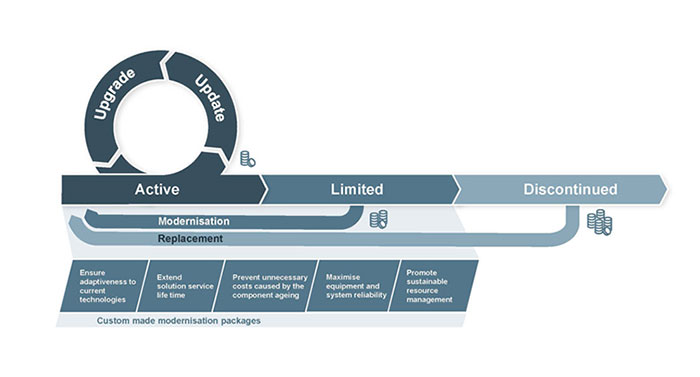

Life Cycle Services ensure that the solutions you are using can adapt to the necessities of current technologies, help you prevent unnecessary costs caused by the ageing of the components, and maximise the equipment and system reliability. The solution support management system consists of three phases: Active, Limited, and, if the solution has come to the end of its lifespan, Discontinued.

In the Active phase, the solution benefits from MLE’s Full Support, including maintenance and repair, spare parts and system know-how. The solution service lifetime is extended by periodic or condition-based software updates/upgrades and hardware updates, and AGVs run using the latest technology with maximum reliability.

In the Limited phase, MLE can support the solutions, including maintenance and repair, spare parts and system know-how if the resources, including components, are available. Additionally, during the Limited phase, increasing maintenance costs caused by ageing technology can be avoided by custom-made modernisation packages, including hardware and software upgrades.

After the solution reaches the Discontinued phase, the availability of services cannot be guaranteed. However, MLE can provide technical expertise on the best replacement according to the customer and industry needs.

For your industry

-

Mitsubishi Loginext Europe has a proud history of deploying automated guided vehicles (AGVs) in a range of industries, including paper, tyre and foodstuffs, to name a few. In addition, our AGV solutions suit many different logistical environments and processes.

Automation solutions for a variety of industries and processesThe Rocla AGV solutions from Mitsubishi Logisnext Europe can be applied in a wide range of industries and logistical facilities and processes. This means there is bound to be an AGV solution for your needs. We have vast experience in supplying AGV solutions to all of these in recent decades. Learn more on the pages in this section.

Warehousing and Logistics

- AGV Benefits for Warehouse Logistics Companies

- Reduce the number of errors in the warehouse or fulfilment centre

- Ensure just-in-time material flow

- Cut labour costs through automation

- Eliminate transport and product damage

- Know the total cost of ownership in advance

- Implement AGV solutions without stopping daily operations

- Maximize uptime with our diagnostics and support

Paper

- AGV Benefits for Paper and Board Companies

- Increase your machines’ up time by delivering rolls accurately and punctually

- Avoid damaged goods and equipment and reduce waste thanks to the AGVs’ smooth handling

- Advanced safety for personnel reducing accidents at the warehouse

- Pick the solution that suits precisely your roll/pallet/bale type and size

- Stay flexible when production and product handling requirements change

- Know the total cost of ownership in advance

- Implement AGV solutions without stopping production

Tyre

- AGV Benefits for Tyre Companies

- Cut labour costs through mixed fleet operations

- Easy integration between Rocla FleetController and your Manufacturing Execution Systems

- Greater material control through real-time transport monitoring

- Know the total cost of ownership in advance

- Implement AGV solutions without stopping production

- Maximize uptime with our diagnostics and support

Manufacturing Logistics

- AGV Benefits for Manufacturing Companies

- Achieve a clearly defined, planned process

- Reach a state of constant material flow

- Create the perfect conditions for just-in-time deliveries

- Stay flexible when production and product handling requirements change

- Know the total cost of ownership in advance

- Implement AGV solutions without stopping production

Packaging

- AGV Benefits for Packaging Companies

- Achieve high warehouse capacity

- Secure just-in-time supplies

- Benefit from AGVs purpose-built both as AGVs and for your setting

- Pick specialised customer orders without multiple handling

- Stay flexible when production and product handling requirements change

- Know the total cost of ownership in advance

- Implement AGV solutions without stopping production

Food and Beverage

- AGV Benefits for Food and Beverage Companies

- Achieve automated warehouse management

- Secure virtually 100% traceability

- Combine mobile racking with AGVs to save space

- Reduce damage to vehicles, stock and site

- Stay flexible when production and product handling requirements change

- Know the total cost of ownership in advance

- Implement AGV solutions without stopping production or modifying the warehouse