- Offer Profile

-

Smart design for optimum production flow

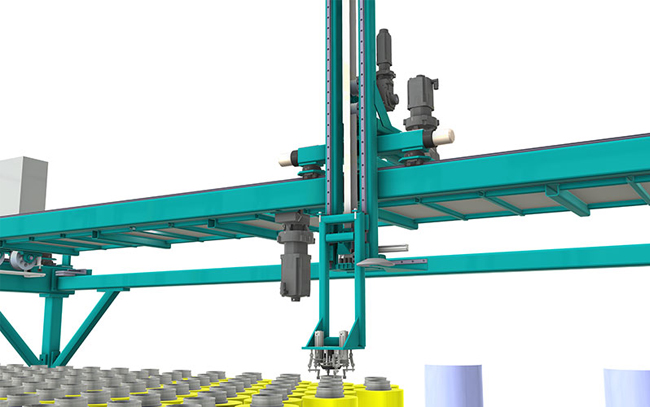

Gantry robots are typically mounted over the working area and ideal for precise picking and placement of heavy payloads or part loading and unloading.

Our design includes sophisticated interpolating motion systems that enables almost limitless options for any combination of high speeds, long strokes, heavy payloads, and high positioning accuracy.

Special requirements for harsh environments or low noise are easily incorporated.

GANTRY ROBOTS

Powerful – Flexibility and minimal maintenance

A gantry robot is among the most effective for high-speed product handling on the market – while also offering utmost precision and repeatability. With their streamlined design, gantry robots achieve greater dynamic performance, shorter cycle times and higher throughput. It also enables a wide range of different payload capacities, configurations, and special variants, ensuring that we always can optimize a solution for your application, no matter how challenging the handling task. Thanks to the advanced and robust design, our gantry robots have extremely long maintenance intervals – with more manufacturing uptime, high availability, and maximum energy efficiency.- Payload from 30 – 800 kg (higher on demand)

- Tailormade to customer specifications

- Speed X axis 2,5 m/s

- Speed Y (3 axis) 2,5 m/s

- Speed Z axis 1,5 m/s

- Repeatability +/- 1 mm

- Individual gripper design

ROBOT GANTRY – Smart design for optimum production flow

-

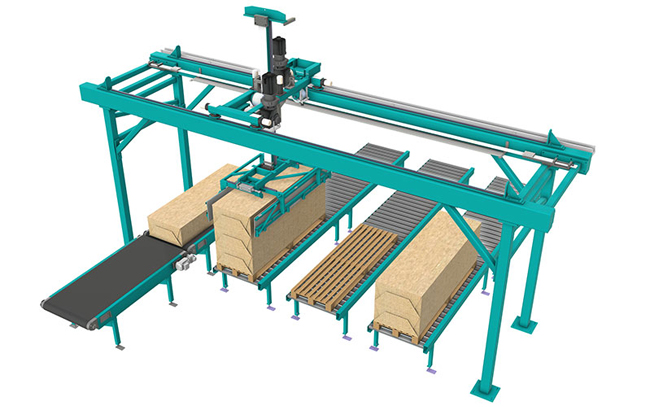

A gantry robot can handle items weighing up to hundreds of kilos, at high speed, perfect accuracy, and repeatability. A gantry can be delivered with up to 3 motion axis, and for maximum capacity in tandem design.

The robot can be supplied with a special designed gripper or with a standard flange for installation of your own gripper. The Gantry robot can be delivered as a standalone unit or as an integral part of a complete material handling system.

The gantry robot handling unit has a compact footprint by using a modular frame design enabling 1 to +20 locations. The smooth robot handling of your products eliminates the risk of damages and flexibility for stacking/handling various size products.

When customer demand is rising, the product handling often becomes a bottleneck. Gantry robots can take your production capacity and flexibility to the next level.

?Gantry benefits

- Increase speed of material handling/ palletizing improves productivity

- Can handle heavy-weight items and transfer them at lifting height

- Can handle variations in products and proliferation

- Improve quality and consistency

- Increase safety by reduced operator handling and eliminate the use of overhead crane and forklifts

- System reduces risk for employees’ subject to repeatable movement

- No external lubrication required. All lubrication in gears and track conveyor are food grade.

- Easy to measure the return of investment

- Allows for 24 hour operation with minimum staff and 365 days per year due to the robust/reliable design

GANTRY 2 AXIS

-

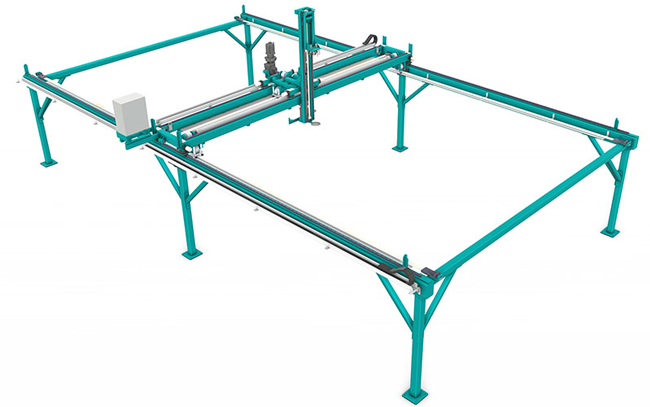

A two axis gantry robot is typical used where high capacity/speed of the picking and placing system.

The 2 axis moves along 2 different axis: the X-axis (lengthwise movement) and the Z-axis (up and down movement).

GANTRY 2 AXIS

-

Significantly increases efficiency

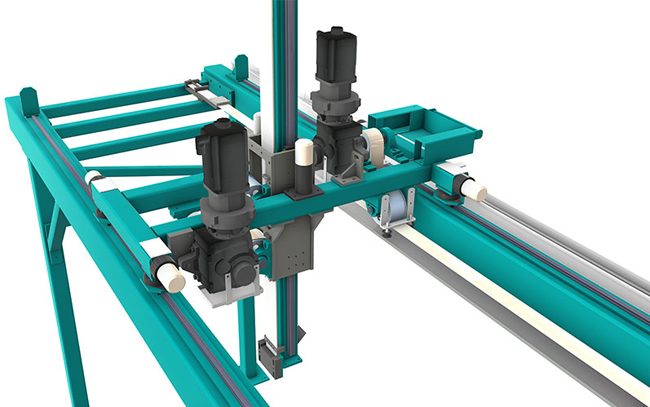

Our design uses two horizontal linear guides in the x-axis supported on a robust steel frame, where the gantry carriage moves smoothly in between on the linear guides.

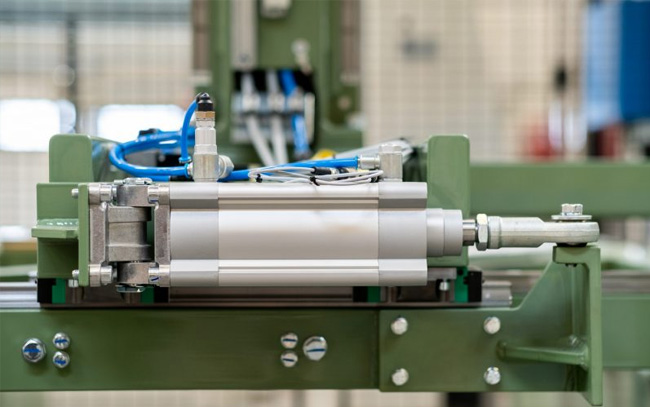

The vertical stroke for the gripper is done by the gantry carriage and the vertical “slider” is also using guides.

Because of the double beams in the X-axis, the gripper working payloads are resolved as forces on the X axes.

This significantly increases the system’s stiffness and allows long stroke lengths and high speeds.

Specifications

- Payload from 30 – 800 kg (higher on demand)

- Tailormade to customer specifications

- Speed X axis 2,5 m/s

- Speed Z axis 1,5 m/s

- Repeatability +/- 1 mm

- Gripper design +/- 1 mm

A two axis gantry robot is typical used where high capacity/speed of the picking and placing system.

The 2 axis moves along 2 different axis: the X-axis (lengthwise movement) and the Z-axis (up and down movement).

Our design uses two horizontal linear guides in the x-axis supported on a robust steel frame, where the gantry carriage moves smoothly in between on the linear guides.

The vertical stroke for the gripper is done by the gantry carriage and the vertical “slider” is also using guides.

Because of the double beams in the X-axis, the gripper working payloads are resolved as forces on the X axes.

This significantly increases the system’s stiffness and allows long stroke lengths and high speeds.

GANTRY 3 AXIS

-

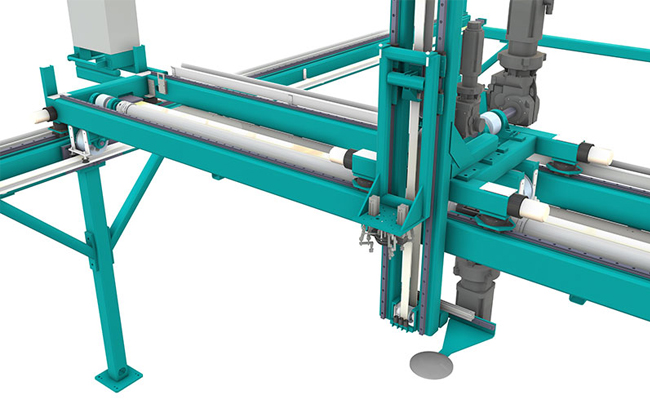

A three axis gantry robot is typically used where there is a variation in the product type handled by size, type, color etc. and a larger number of loading stations are required.

The three axis moves along 3 different axis: the X-axis (lengthwise movement), the Y-axis (across movement) and the Z-axis (up and down movement).

The robot has a pickup position and several loading positions.

GANTRY 3 AXIS

-

Our design use two horizontal linear guides in the x-axis supported on a robust steel frame, where the gantry carriage moves smoothly in between the linear guides.

The “slider” moves across the gantry carriage also in guides.

The vertical stroke for the gripper is done by the gantry carriage.

The vertical “slider” is also using guides. Because of the double beams in the X-axis, the gripper working payloads are resolved as forces on the X axes.

This significantly increases the system’s stiffness and allows long stroke lengths and high speeds.

Specifications

- Payload from 30 – 800 kg (higher on demand)

- Tailormade to customer specifications

- Speed X axis 2,5 m/s

- Speed Y (3 axis) 2,5 m/s

- Speed Z axis 1,5 m/s

- Repeatability +/- 1 mm

- Individual gripper design

GANTRY ROBOT 3 AXIS

A three axis gantry robot is typically used where there is a variation in the product type handled by size, type, color etc. and a larger number of loading stations are required.

The three axis moves along 3 different axis: the X-axis (lengthwise movement), the Y-axis (across movement) and the Z-axis (up and down movement).

The robot has a pickup position and several loading positions.OUR GANTRY ROBOT DESIGN

Our design use two horizontal linear guides in the x-axis supported on a robust steel frame, where the gantry carriage moves smoothly in between the linear guides.

The “slider” moves across the gantry carriage also in guides.

The vertical stroke for the gripper is done by the gantry carriage.

The vertical “slider” is also using guides. Because of the double beams in the X-axis, the gripper working payloads are resolved as forces on the X axes.

This significantly increases the system’s stiffness and allows long stroke lengths and high speeds.

GANTRY DOUBLE HEAD

-

A 2-axis design with double heads consists of two gantry robots that share a common frame on the “X” axis.

The two robots are in constant communication with each other to prevent collision.

GANTRY DOUBLE HEAD

-

The robot has two pickup positions and a number of loading positions.

With two gantry carriages, a very large loading area can be covered. If one of the heads is parked for service, the other head can use both pickup positions as well as all loading positions.

The double head configuration will double the capacity of the gantry robot.

Specifications

- Payload from 30 – 800 kg (higher on demand)

- Tailormade to customer specifications

- Speed X axis 2,5 m/s

- Speed Z axis 1,5 m/s

- Repeatability +/- 1 mm

- Individual gripper design

APPLICATIONS

-

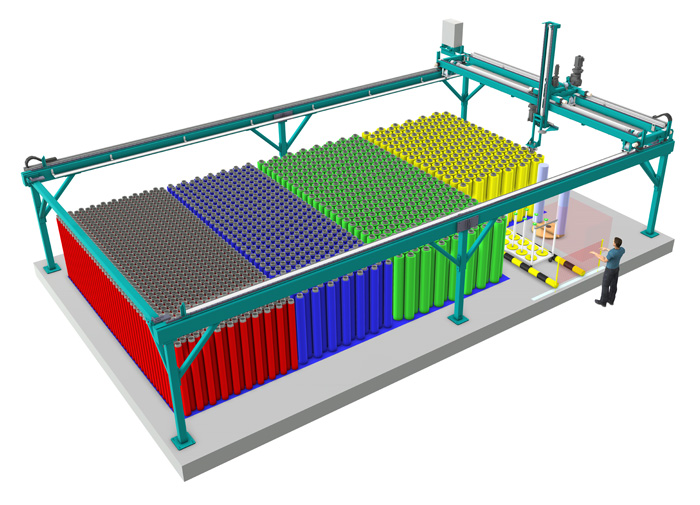

Application story – automatic sleeve handling and storage system

Handling of sleeves for flexographic printing machinesCH System has just designed, and factory tested a complete new automatic sleeve handling and storage system.

As the variation is quite large in the flexible packaging and lidding materials for food, pharmaceutical and tobacco applications, many different sleeves are used in the production.

Today are sleeves often manual handled, stored across the production facilities with no real marking and logistic registering.

The manual handling of sleeves in the past caused several repetitive work movements for the operator’s and each sleeve represent a large investment both in cost and manhours, so an automatic storage and handling system was the solution for the future.

The new automatic system can store up to 1500 individual sleeves, each with a unique number and floating storage location.

The sleeves are stored vertically and vary in length, diameter and weight. The heart of the new system is a 3-axis gantry robot located above the physical sleeve storage area of more than 100 m2.

Utmost care is the key word for ensuring safe storage of the sleeves, which goes hand in hand with our gantry robot design with precision, repeatability and smooth handling.

The robot gripper is specially designed for the application both lifting on the upper part of the sleeve and supporting at the bottom of the sleeve.

Managing the project

Beside the gantry robot the project also included trolleys and a “washing machine” for the sleeves. The complete project with mechanical & electrical engineering and software programming is handled in-house at CH System. The whole system is factory tested in our workshop before site installation and handover.

Robot gantry simulation

Real time computer simulation – computer model of a psysical system

- We always offer to do a full real time simulation of the proposed solution. Our simulations are based on our knowledge and experience of the specific product(s), dimensions, quantities, and number of variations. We produce our simulations by the use of the advanced simulation tool “Visual Components.” After a simulation has been made, it is possible to “gear” the real-time with a factor, which makes it possible for the project team to view the long term development of stock sizes, define bottle necks in equipment and up- or down-stream the gantry robot(s).