- Offer Profile

-

FCC FibreCableConnect GmbH develops and manufactures fiber optic cables for laser beam delivery up to 1 kW laser power for industrial and medical applications, based on standarded connectors like SMA or D80. In addition, fiber bundles, probes for spectroscopy and optical fiber couplers as well as customer and application-specific special solutions.

Applications:

- Laser Technology

- Healthcare

- Science

- Defense

- Marine

- Process Control

- Electrical appliances

- Optical Metrology

- Pharmaceutical Industry

Fiber optic cables for laser beam delivery up to 1 kW

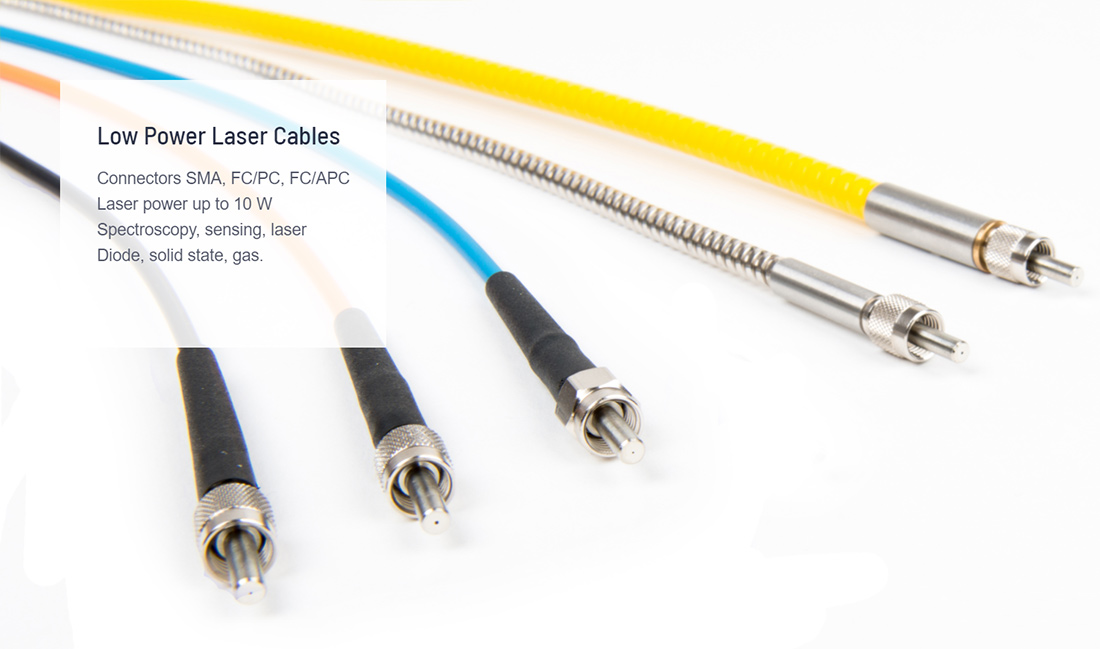

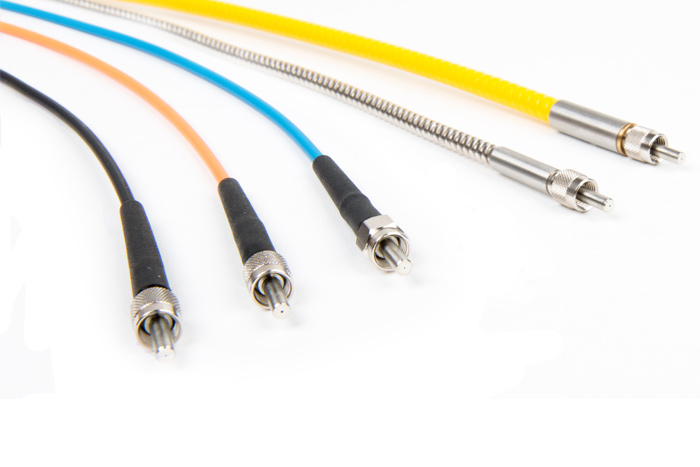

Laser Cable Low Power

- The low power fiber cables are used in various applications such. Spectroscopy, sensors, laser light transmission from milliwatt to 2-digit watt range. Several designs are offered according to the performance and application requirements. Starting with the selection of the right fiber over connectors up to the protective jacket.

Laser Cable Low Power SMA-Standard

-

- Applfications: Laser, Sensors Spectroscopy

- Wave Length: UV-VIS-NIR

- Protective Tubing: Metal, PVC (Aramid-Strain Relief ), Silicone

Technical Data:

- Connector Type: FSMA-905

- Ferrule Diameter: 3,174 +/-0,004

- Ferrule Length: 9,80 mm +/- 0,1

- Ferrule Material: Arcap

- Connector Length: 15 mm

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 105/125, 200/220, 200/240, 400/440, 600/720, 800/880, 1000/1100

- Bending Radius Short Term: 100 x Claddingdurchmesser

- Bending Radius Long Term: 300 x Claddingdurchmesser

- Protective Tubing: FRNC, Metall/Silikon, Metall/PU, Biegeradiusbegrenzung

Laser Cable Low Power FC/PC – FC/APC

-

Execution with ZrO2 ferrules for single and multimode fibers up to 128μm cladding diameter and metal ferrules for fibers with a cladding diameter from 128μm. APC version with bevel cut of 8 °.

Technical Specification:

- Connector Type FC/PC, FC-APC, wide key

- Ferrule diameter 2,5

- Ferrule Material Metal, ZrO2

- Connector length 15 mm

- Fiber Length 0,2 - 30,0 m

- Core/Cladding 105/125, 200/220, 200/240, 400/440, 600/660, 800/880, 1000/1100

- Bending Radius short term 100 x Cladding Diameter

- Bending Radius long term 300 x Cladding Diameter

- Protective Tubing FRNC, Metal/Silicon, Metal/PU, Bending Radius limited

Laser Cable High Power SMA

- HP-SMA connectors are available in different versions, depending on the power transferred. This depends on many factors. Above all, the core diameter of the fiber, the beam profile of the laser and, in addition, the spot size of the focused laser beam and its centric alignment with the fiber core. Ideally, the spot diameter should make up about 80% of the fiber core. For powers up to 100 watts, no heat sink is usually required, provided that the cladding modes are not stripped off. Otherwise, it is advisable to use a correspondingly sized heat sink at 10 watts, assuming that 1% of the power in the cladding (cladding) is performed.

Laser Cable High Power SMA-FK up to 50 W

-

- Ferrule for freestanding fibers

- Power CW 10 – 50 watts

- Length of the connector body 15 mm

- Thermal efficiency: low

- Fiber core diameter 100 – 1000 μm

- Fiber cable length max. 50m

Technical Specifications:

- Connector Type: FSMA, Ferrule for free standing fiber

- Ferrule Diameter: 3,174 +/-0,004

- Ferrule Length: 9,80 mm +/- 0,1

- Ferrule Material: Arcap

- Connector Length: 15 mm

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 100/660, 200/280, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Bending Radius short term: 100 x Claddingdurchmesser

- Bending Radius long term: 300 x Claddingdurchmesser

- Protective Tubing: FRNC, Metall, limited bending radius

Laser Cable High Power SMA-FM – up to 50 W

-

- Ferrule for freestanding fibers

- Material: Arcap

- Power CW 10 – 50 watts

- Length of the connector body 25 mm

- Thermal efficiency: high

- Fiber core diameter 100 – 1000 μm

- Fiber cable length max. 50m

Technical Specifications:

- Connector Type: FSMA, Ferrule for free standing fiber

- Ferrule Diameter: 3,174 +/-0,004

- Ferrule Length: 9,80 mm +/- 0,1

- Ferrulen Material: Arcap

- Connector Length: 25 mm

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 100/660, 200/280, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Bending Radius short term: 100 x Cladding Diameter

- Bending Radius long term: 300 x Cladding Diameter

- Protective Tubing: FRNC, Metall, Bending Radius limited

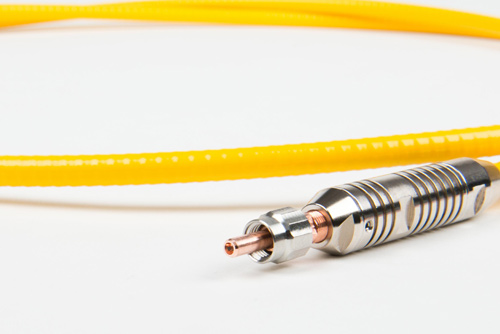

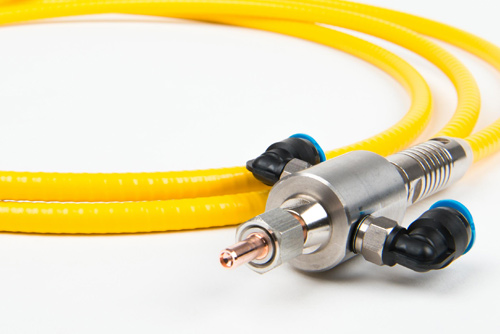

Laser Cable High Power SMA-FM Copper – up to 100 W

-

- Ferrule for freestanding fibers

- Power CW up to 100 watt

- Material: copper

- Length of the connector body 25 mm

- Thermal efficiency: very high

- Fiber core diameter 100 – 1000 μm

- Fiber cable length max. 50m

Technical Specifications:- Connector Type: FSMA, Ferrule for free standing fiber

- Ferrule Diameter: 3,174 +/-0,004

- Ferrule Length: 9,80 mm +/- 0,1

- Ferrulen Material: Copper

- Connector Length: 25 mm

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 100/660, 200/280, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Bending Radius short term: 100 x Cladding Diameter

- Bending Radius long term: 300 x Cladding Diameter

- Protective Tubing: FRNC, Metall, Bending Radius limited

Laser Cable High Power SMA Passive Cooling – up to 500 W

-

- Ferrule for freestanding fibers

- Power CW up to 500 watts

- Material: copper

- Length of the connector body 55 mm

- Passive cooling

- Thermal efficiency: excellent

- End cap and mode stripping optional

- Fiber core diameter 100 – 1000 μm

- Fiber cable length max. 50m

Technical Specification:

- Connector Type: HP-SMA, Ferrule for free standing fiber

- Ferrule Diameter: 3,174 +/-0,004

- Ferrule Length: 9,80 mm +/- 0,1

- Ferrulen Material: Copper

- Connector Length: 70 mm incl. Heat Sink Adapter

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 100/660, 200/280, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Bending Radius short term: 100 x Cladding Diameter

- Bending Radius long term: 300 x Cladding Diameter

- Protective Tubing: Metal, Bending Radius limited

Laser Cable High Power SMA-Active Cooling – up to 500 W

-

- Ferrule for freestanding fibers

- Power CW up to 500 watts

- Material: copper

- Length of the connector body 90 mm

- Active cooling

- Thermal efficiency: excellent

- End cap and mode stripping optional

- Fiber core diameter 100 – 1000 μm

- Fiber cable length max. 50m

Technical Specifications:

- Connector Type: HP-SMA, Ferrule for free standing fiber

- Ferrule Diameter: 3,174 +/-0,004

- Ferrule Length: 9,80 mm +/- 0,1

- Ferrulen Material: Copper

- Connector Length: 75 mm incl. Heat Sink Adapter

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 100/660, 200/280, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Bending Radius short term: 100 x Cladding Diameter

- Bending Radius long term: 300 x Cladding Diameter

- Protective Tubing: Metal, Bending Radius limited

Laser Cable High Power D80

- The High Power D80 connector is available in different versions with passive or active cooling. In principle, only free-standing fibers and ferrules of good heat-conducting copper alloys are used. The heat sink is dimensioned depending on the power. The complete structure is torsion- and stress-free mounted, but mechanically extremely stable. The Ferrullenbereich is guaranteed glue-free.

Laser Cable High Power D80 Passive Cooling – up tp 500 W

-

Laser cables High Power D80 Passive cooling – up to 500 W are mainly used in the area of material processing such as laser cutting or laser welding. The passive heat sink as well as 4mm copper ferrule allow a high thermal efficiency due to a very good heat dissipation. Optionally available with end caps and mode stripping. The complete structure is torsion- and stress-free mounted, but mechanically extremely stable.

Technical Specifications:

- Connector Type: D80, Ferrule for free standing fiber

- Ferrule Diameter: 4,000 -0,004

- Ferrule Length: 10,00 mm - 0,1

- Ferrulen Material: Copper

- Connector Length: 70 mm incl. Heat Sink Adapter

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 100/660, 200/280, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Bending Radius short term: 100 x Cladding Diameter

- Bending Radius long term: 300 x Cladding Diameter

- Protective Tubing: Metal, Bending Radius limited

Laser Cable High Power D80 Active Cooling – up to 1 KW

-

Laser cables High Power D80 Active cooling – up to 1 KW are used as well as passively cooled high power connectors in the field of material processing: laser welding, laser cutting. Due to the active cooling of the connector body, however, an even higher optical power condition is possible by very efficient heat dissipation. Optional versions with mode stripping and end cap are available. The complete structure is torsion- and stress-free mounted, but mechanically extremely stable.

Technical Specifications:

- Connector Type: D80, Ferrule for free standing fiber

- Ferrule Diameter: 4,000 -0,004

- Ferrule Length: 10,00 mm - 0,10

- Ferrulen Material: Copper

- Connector Length: 90 mm incl. Heat Sink Adapter

- Fiber Length: 0,2 - 30,0 m

- Core/Cladding: 100/660, 200/280, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Bending Radius short term: 100 x Cladding Diameter

- Bending Radius long term: 300 x Cladding Diameter

- Protective Tubing: Metal, Bending Radius limited

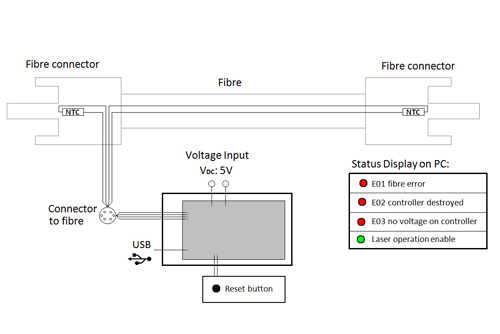

Laser Cable High Power D80 Fiber Monitoring

-

Laser cables High Power D80 fiber breakage monitoring are used in particularly critical applications, where a defect in the fiber can have particularly serious consequences. Apart from the fiber break, the plug temperature is also detected. The system shuts off automatically in the event of a defect, thus preventing uncontrolled leakage of the laser beam. Optionally, fiber breakage monitoring is also available for HP-SMA connectors.

Technical Specifications:

- Operating Voltage: 5 V DC

- Load Bearing Capacity: 10 W

- Operating Temperature: 10 °C bis 30 °C

- Shutdown Temperature: +60 °C

- Tolerance of the Shutdown Temperature: +/- 2 °C

- Lifetime of the Relay: 100000 Switching cycles

- Switching Time of the relay: <7 ms

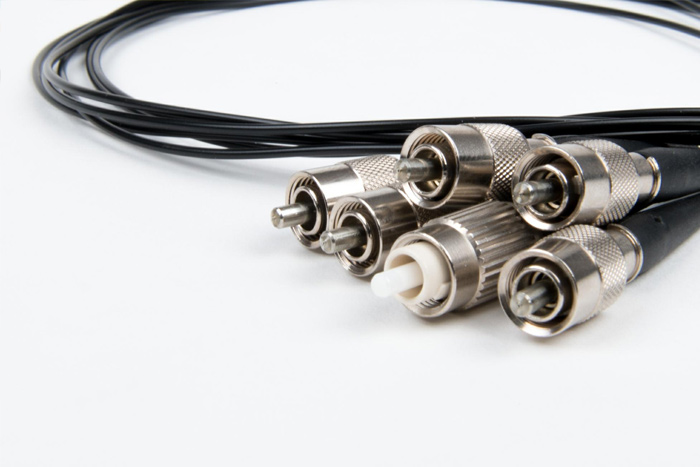

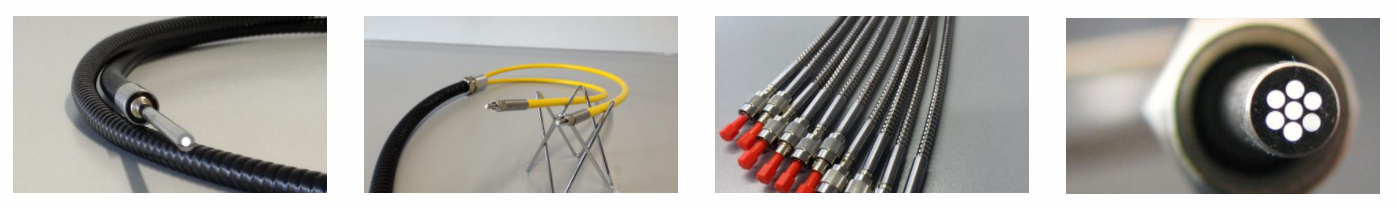

Optical Fiber Bundle

- In spectroscopy, optical Fiber bundles are part of a modern spectrometer’s equipment. They establish the connection between the spectrometer, the sources of illumination light for measurement and evaluation technology. In spectroscopy, special fibers coated with polyimide are used for fiber bundles. This polyimide layer is only a few microns thick and must not be stripped off during production of a fiber bundle, because it increases the distance between the fibers within the bundle only slightly. At the same time it stabilizes the fiber. Apart from the SMA connectors FC/PC connectors are also used. Inside the plugs, several fibers are bonded to form a fiber bundle, sometimes highly temperature-resistant, with special fiber arrangements as a gap or matrix to suit the receiver.

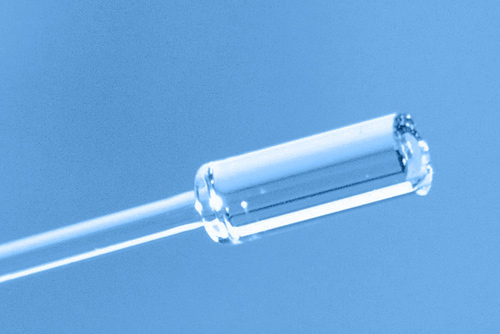

End Cap for Multimode Fibers

-

When coupling of the laser beam, it is focused into the fiber core, while a high power density occurs on the front surface. Although the anti-reflective (AR) coating of this surface reduces the Fresnel loss, it does not tolerate high power density even despite a large core diameter. A fiber end face without AR coating allows greater performance, but simultaneously leads more heat into the connector on the output side. This must be considered in terms of heat management.

For small fiber core Diameters with high power density dominate fiber connectors with a cylindrical end cap made of quartz glass currently. This end cap is larger than the fiber core and is spliced to the optical fiber. In doing so, the laser beam is focused onto the fiber core via the end surface of the quartz cap, where, at the same laser power, the power density is significantly lower. When, for instance, coupling 500 W of laser power in a 200 micron fiber, a 3 mm long quartz cap changes the energy density at the surface by the factor of 30. This allows the use of AR coating also in the kilowatt range. The method requires robust and low-loss splicing that guarantees a high damage threshold at the border between the end cap and the fiber.

Technical Specifications:

- Connector Type: D80, HP-SMA

- End Cap-Diameter: 1,5 mm

- End Cap-Length:

- 3,8 mm - for fiber core 100µm und 200µm

- 2,5 mm - for fiber core > 400µm - End Cap-Material: Fused Silica

- AR-Coating optional:

- Only by L 3,8mm

- AR<0.7% in range of 750nm and 1070nm, also AR <30% (Transmission >70%) at 670nm +-15nm - Coating absorption: <15ppm@1064nm

- Fiber Type circular: 100/660, 200/500, 400/480, 600/720, 800/880, 1000/1100

- Fiber Type non circular: 100x100, 200x200, 400x400

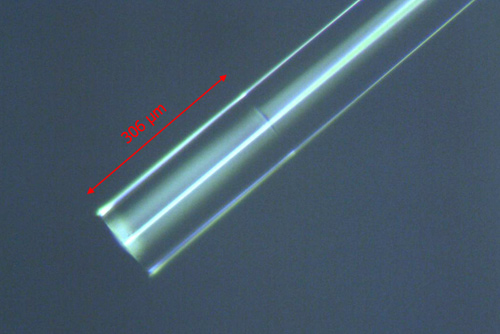

End Cap for Singlemode Fibers

-

During coupling into a singlemode fiber, the laser beam is focused into the fiber core, resulting a high power density on the facet. This is higher the smaller the fiber core and larger the laser power. To reduce the power density, an end cap will be spliced on the fiber facet. The laser beam is focused on the fiber core over the end face of this end cap, where at the same laser power, the power density is significantly lower.

The length of the end cap is adjusted exactly to the fiber core. For singlemode fibers this starts at 100 μm. The diameter of the end cap is adjusted to the cladding diameter of the fiber. The singlemode fibers with spliced end cap are terminated with standard connectors (SMA, FC …) but also with application-specific ferrules.

Technical Specifications:

- Connector Type: SMA, FC/PC, FC/APC, Special Ferrule

- End Cap-Diameter: The same like Cladding Diameter

- End Cap-Length: from 100 µm

- End Cap-Material: Fused Silica

- Fiber Type: Singlemode, Polarisation Maintaining PM Fiber

Mode Stripping

-

To obtain a good transfer performance, the beam must be optimally coupled into the fiber.

This requires that the focus on the fiber core generally should not to be more than 85% to 90% of the fiber core diameter. At the same time its divergence angle must be less than numerical aperture of the fiber. This is especially important for diode lasers that have a rectangular beam profile. If the laser beam couples not in the core only, but also in the cladding, the modes are also guided in the cladding. In order to remove them from the cladding, the specially developed for this purpose mode stripping is used. This mode stripper is installed in the connector body and removes the cladding modes over a certain length. The required length is defined according to the coupling properties (spot size and NA-difference). The mode stripper ensures that the beam profile looks perfect at the fiber output. The removed cladding modes are converted into the heat in the connector body. If, in this case, the connector is not sufficiently cooled, the fiber might burn off in the connector.For this reason, different requirements may be imposed on the length of the mode stripper. This is why FCC has developed its own software to determine the mode stripper length.

Fiber Monitoring

-

To monitor the temperature of the fiber, the connectivity and the fiber break, a double-wound copper wire is used. Over connectivity of the fiber connector the circuit is closed. The principle is based on applying voltage at temperature-dependent resistors, which is proportional to the respective resistance. If the voltage falls below the lower or the upper limit, a relay switches, interrupting power transfer to the laser. In monitoring the fiber, the upper limit voltage serves to protect against fiber breakage, while the lower limit voltage bridges the contacts for connectivity. In monitoring the fiber connector temperature, only the lower limit voltage is used to prevent the fiber connector from overheating.

Technical Specifications:

- Operating Voltage: 5 V DC

- Load Bearing Capacity: 10 W

- Operating Temperature: 10 °C bis 30 °C

- Shutdown Temperature: +60 °C

- Tolerance of the Shutdown Temperature: +/- 2 °C

- Lifetime of the Relay: 100000 Schaltzyklen

- Switching Time of the relay: <7 ms