- Offer Profile

-

MASTERS OF LASER MARKING

Our turnkey laser marking solutions for traceability and product markings are easy to use and optimized for industrial production processes. Our solutions can also replace traditional marking methods, such as inkjets, with extremely short payback time.

LASER MARKING SYSTEMS FOR PERMANENT, HIGH-QUALITY MARKINGS

- Laser marking offers the possibility to create high-quality product markings on virtually any material in any shape. Cajo Technologies provides laser marking systems for all industrial marking needs on various plastics, polymers, steel, aluminum, chrome, brass, copper, and other alloys. Markings can be made on virtually any product shape or form. We are confident we can find the traceability or brand marking solution for any production process. Additionally, Cajo’s lasers are able to perform at high speeds and even on metals that are still at high temperatures. The marking solution can be delivered as a stand-alone system, as a system integrated into a manufacturer’s production line, or as a capability added to other industrial fabrication equipment. Cajo lasers are a user-friendly and cost-effective alternative for your marking needs.

CAJO TAILOR - INTEGRABLE MARKING SYSTEMS

- Cajo Tailor is a laser marking system that can be integrated to a production line or to a device. It can replace efficiently traditional marking systems, such as ink jets. The solution allows for a precise, homogeneous and durable marking that is not dependent on the environmental conditions or surface structure. Cajo Tailor is a long-lasting and maintenance-free solution.

CAJO TAILOR™

-

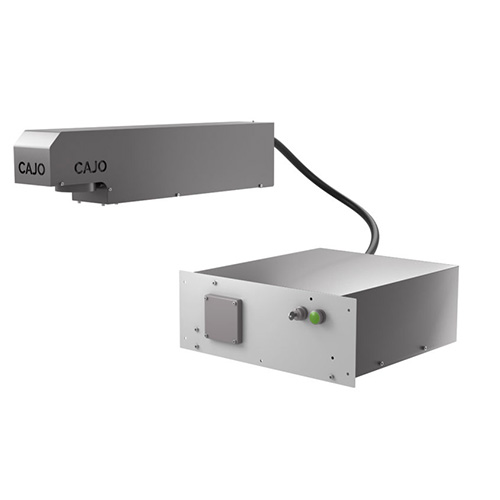

Cajo Tailor Fiber™ and Cajo Tailor Advanced™ are laser systems that can be integrated to a production line or to a device. The systems enable high-speed on-the-fly marking, without stopping the production line and they have been designed to replace the traditional marking methods, such as ink jets. Cajo Tailor systems allow for a precise, homogeneous and durable marking that is not dependent on the environmental conditions or surface structure.

The systems are suitable for permanent marking of products and semi-products made of, for example, metals, plastics or coated plastics and metals. With Cajo Tailor Advanced™ you are also able to mark for example soft polymers, light reflecting metals (copper, brass) and all materials which can be marked with Cajo Tailor Fiber™. The Cajo Tailor Advanced™ system allows making of nonabrasive as well as engraving marking.

Pre-defined marking library for selected materials is built into the system. The user interface allows flexible customization of marking content, for example, logos, serial numbers, barcodes, QR codes, data matrices and other product information. Cajo Tailor systems are long-lasting solutions with low maintenance.

- Laser type: Pulsed fiber laser

- Wawelength: 1060–1080 nm

- Laser power: Tailor Fiber (20/50/100 W), Tailor Advanced (20 W)

- Beam guiding: High-speed optical galvanometers

- Marking speed (max): 500 characters/s or 7 m/s,

can be upgraded up to 1000 characters/s or 14 m/s - Marking field options: 175 x 175 / 220 x 220 mm

CAJO TAILOR CO2™

-

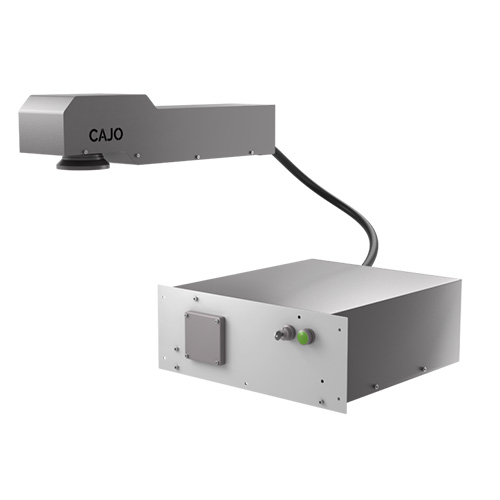

Cajo Tailor CO2™ is a laser system that can be integrated to a production line or to a device. It has been designed to replace the traditional marking systems, such as ink jets. The system allows for a precise, homogeneous and durable marking that is not dependent on the environmental conditions or surface structure.

The system is suitable for permanent marking of plastic, glass, stone, wood, leather and other organic materials.

Pre-defined marking library for selected materials is built into the system. The user interface allows flexible customization of marking content, for example, logos, serial numbers, barcodes, QR codes, data matrices and other product information. Cajo Tailor CO2™ is a service friendly and long lasting solution.

- Laser type: CO2 laser

- Wawelength: 10 600 nm

- Laser power: 30 W

- Beam guiding: High-speed optical galvanometers

- Marking speed (max): 500 characters/s or 7 m/s

- Marking field options: 175 x 175 mm

CAJO TAILOR GREEN™

-

Cajo Tailor Green™ is a laser system that can be integrated to a production line or to a device. It has been designed to replace the traditional marking systems, such as ink jets. The system allows for a precise, homogeneous and durable marking that is not dependent on the environmental conditions or surface structure.

The system is suitable for permanent marking of metals, coated metals, soft materials like polymers, and sensitive parts including electronic components. It is optimal for creating all the traceability and identification markings, including micro-scale barcodes, data matrix and QR codes.

Pre-defined marking library for selected materials is built into the system. The user interface allows flexible customization of marking content, for example, logos, serial numbers and other product information. Tailor Green™ is a service friendly and long lasting solution.

- Laser type: Pulsed fiber laser

- Wawelength: 532 nm

- Laser power: 20 W

- Beam guiding: High-speed optical galvanometers

- Marking speed (max): 500 characters/s or 7 m/s

- Marking field: 150 x 150 mm

CAJO TAILOR DEEP ENGRAVER™

-

Cajo Tailor Deep Engraver™ is a laser system that can be integrated to a production line or to a device. The system is designed for deep engraving of metals. The deep engraved markings enable readability also on metals with flake formation and rust, which makes Cajo Tailor Deep Engraver an optimal marking solution for all the applications in the first stages of metal processing chain (marking of plates, rolls, coils etc.)

Pre-defined marking library for selected materials is built into the system. The user interface allows flexible customization of marking content, for example, serial numbers, bar codes, QR codes, data matrices and other product information. Cajo Tailor Deep Engraver™ is a long-lasting solution with low maintenance.

- Laser type: Pulsed fiber laser

- Wavelength: 1060–1080 nm

- Beam guiding: High-speed optical galvanometers

- Marking speed (max): 350 characters/s

- Marking field: 175 x 175 mm

CAJO VEGA™ - STAND-ALONE MARKING SYSTEMS

-

STAND-ALONE MARKING SYSTEMS FOR VERSATILE MARKING OF SEMI-FINISHED AND FINISHED PRODUCTS

Our stand-alone marking systems can be used as separate working stations, or they can be integrated as a part of a production line with lots of configurations available, for example conveyor belt and automatic side doors. With our stand-alone systems, you can mark and create patterns flexibly on different semi-finished and finished products.

CAJO VEGA™

-

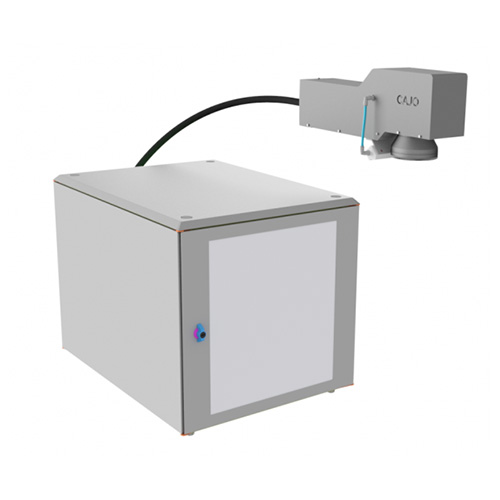

Cajo Vega™ marking system has been specifically developed for flexible and high class marking of semi-final and final products. With lots of configurations available, for example conveyor belt and automatic side doors, it can be integrated as a part of the production line, or used as a separate working station.The system is capable of permanently marking stainless steel, aluminum, and other metals and plastics.

Pre-defined marking library for selected materials is built into the system.The external control stand with easy-to-use user interface allows flexible customization of marking content, for example, logos, serial numbers, barcodes, QR codes, data matrices and other product information. Cajo Vega™ is a long-lasting solution with low maintenance.

CAJO VEGA FOR CABLES™

-

Cajo Vega for Cables™ is a completely automatized marking solution for continuous cable and wire marking. The system enables high-speed on-the-fly marking while delivering optimum marking result. With different adjusting options, like straighteners and cable rollers, it can be integrated as a part of the production line or used as a separate working station. The system is capable of permanently marking almost all cable materials.

Pre-defined marking library for selected materials is built into the system. The external control stand with easy-to-use user interface allows flexible customization of marking content, for example, logos, serial numbers, barcodes, QR codes, data matrices and other product information. Cajo Vega for Cables™ is the most economical solution for continuous marking of cables and wires. It is a long-lasting solution with low maintenance.

CAJO VEGA FOR WIRE HARNESS™

-

Cajo Vega for Wire harness™ is a turn-key solution for high class marking of wire harnesses. It includes a dedicated jig for marking thin and ultra-thin wires. The system can be integrated as a part of the production line or used as a separate working station. Cajo Vega for Wire harness™ is capable of permanently marking almost all wire harness materials.

The easy-to-use user interface has been specially designed for marking of wire harnesses and it allows flexible customization of marking content. Pre-defined marking library for selected materials is built into the system. Cajo Vega for Wire harness™ is a long-lasting solution with low maintenance.

CAJO HERCULES MULTIMARK™

-

Cajo Hercules Multimark™ is a turn-key solution for high-class marking of semi-finished and finished products with varying marking content. The marking head moves in X, Y and Z axes and the system enables marking multiple parts of one large item or several smaller items at one run. Cajo Hercules Multimark™ can be integrated as a part of the production line or used as a separate working station. It is capable of permanently marking stainless steel, aluminum, and other metals and plastics.

Pre-defined marking library for selected materials is built into the system. The external control stand with easy-to-use user interface allows flexible customization of marking content, for example, logos, serial numbers, barcodes, QR codes, data matrices and other product information. Cajo Hercules Multimark™ is a long-lasting solution with low maintenance.

DEDICATED MARKING SOLUTIONS

-

We have created in cooperation with our clients and partners several dedicated solutions for different business areas. Our marking library includes the parameters for marking over 4000 different material and color combinations, and we develop new ones continuously.

Ask our technical experts – the masters of laser marking – if there already is a ready-made dedicated solution for your marking needs!

Dedicated solutions – designed for your business!

Laser marking solutions for cable and wire markings

-

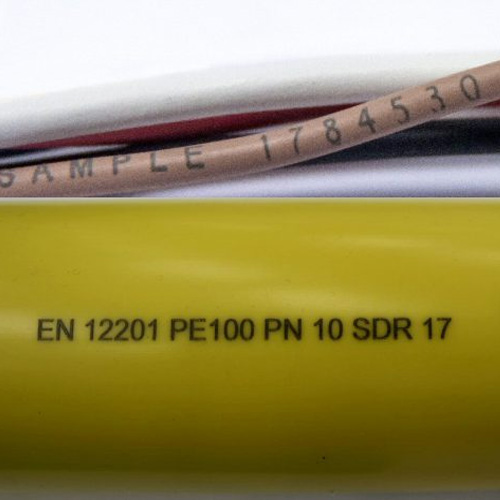

Cajo’s laser marking solutions have been developed to replace traditional methods like inkjets, with extremely short payback time. Compared to inkjet marking equipment, Cajo’s maintenance-free marking solutions don’t require additives or pigments, and the markings are exceptionally durable. The technology is also very ecological.

Compared to traditional laser marking technologies, Cajo’s lasers can produce markings remarkably faster and to a wider range of materials. We have tested and verified a material library of over 600 different types of cables and wires.

Turnkey solution to mark cables and wires

-

Cajo Vega for Cables™

Cajo Vega for Cables™ is a completely automatized marking solution for continuous cable and wire marking. The system enables high-speed on-the-fly marking while delivering optimum marking result. With different adjusting options, like straighteners and cable rollers, it can be integrated as a part of the production line or used as a separate working station. The system is capable of permanently marking almost all cable materials.

Pre-defined marking library for selected materials is built into the system. The external control stand with easy-to-use user interface allows flexible customization of marking content, for example, logos, serial numbers, barcodes, QR codes, data matrices and other product information. Cajo Vega for Cables™ is the most economical solution for continuous marking of cables and wires. It is a long-lasting solution with low maintenance.

Dedicated solution for wire harness industry

-

Cajo Vega for Wire harness™

Cajo Vega for Wire harness™ is a turn-key solution for high class marking of wire harnesses. It includes a dedicated jig for marking thin and ultra-thin wires. The system can be integrated as a part of the production line or used as a separate working station. Cajo Vega for Wire harness™ is capable of permanently marking almost all wire harness materials.

The easy-to-use user interface has been specially designed for marking of wire harnesses and it allows flexible customization of marking content. Pre-defined marking library for selected materials is built into the system. Cajo Vega for Wire harness™ is a long-lasting solution with low maintenance.

Fully Automated Solution to Mark Cables and Tubes On-the-Fly

-

Cajo Hercules for Extrusion™

Cajo Hercules for Extrusion™ is a completely automatized on-the-fly marking solution for continuous metal and plastic extrusion processes. It includes 1-3 laser units, which enables markings simultaneously from different angles.

Cajo marking lasers keep pace with the production speed while delivering optimum marking result. The system is capable of permanently marking different metals and plastics, like PE and PVC. Autofocus adjusts marking head position and follows the object´s movement in real-time.

Pre-defined marking library for selected materials is built into the system. Variable marking content can be entered via TCP/IP communication or HMI panel. Cajo Hercules for Extrusion™ is the most economical solution for continuous marking in extrusion processes. It is a long-lasting solution with very low maintenance.

Traceability markings for metal

-

In the metal industry, traceability is a critical factor. In problem cases, the product’s origins and production parameters have to be traceable in detail and location specific.

Hot mill manufacturers are required to accurately identify sheets, blocks, slabs, rolls or coils of hot metal both for mill record-keeping purposes and for their end customers. They are also required to mark these products with certain identification markings. These markings provide an “identity” for the product, thus enabling the manufacturer and the end-user to look up the manufacturing origin and history of the product in a database. Requirements by different standards place ever stricter requirements for product individualization, authenticity verification and traceability.

In metal production, e.g. in smelting plants, the temperature of the production environment is high. Traditional printed label materials will melt under these conditions because coatings and adhesives burn at high temperatures. Labels may also fail when they are exposed to oils and chemicals during hot metal processing or scraping and scuffing during transport. Because of these demanding circumstances, laser marking methods are practically the only reliable method for marking metal parts and products.

Cajo´s unique laser technology enables the identification to be created on-site and even on the fly, according to production line speed, and to be automatically and permanently marked to the hot mill products. Maintenance-free laser marking equipment decrease production outages, and hence, increase the profitability of the production facility. Laser marking method is a high-speed marking method, where markings can include 2D codes, text and/or numbers.