- Offer Profile

-

NEUMAIER INDUSTRY at a glance:

- Founded in 1990

- Owner and managing director: Mr Bernd Neumaier

- Around 90 members of staff

- Two business sectors: Sheet metal processing & System engineering

- 25 years experience in industrial sheet metal processing

- Development and production of mechatronic systems since 2000

- Systems partner of Linde Material Handling

- Company area of approx. 20,000 m² (further 20,000 m² next to the existing company site currently under development)

- Certified company

- Comprehensive sheet metal warehouse

- Own truck fleet

Sheet metal processing and contract manufacturing

-

Industrial sheet metal processing

At NEUMAIER sheet metal processing we manufacture high-quality sheet metal constructions, welded assemblies and mounting units  both in single piece production and in series. State-of-the-art production methods and machines as well as efficient coordinated operating procedures in connection with our long-standing and highly trained specialist staff enable us to provide high-quality sheet metal processing. A lean manufacturing structure and an extensive sheet metal storage area are the basis for flexible and fast sheet metal processing.

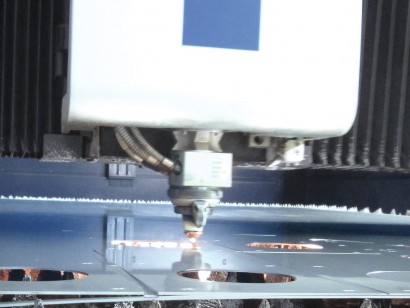

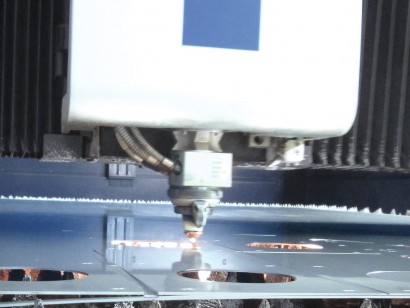

Laser cutting: CO2- and solid laser

-

We cut sheet metal with great precision and best quality using high-performance laser cutting machines made by Trumpf. A total of three laser cutting machines are available for this at our company: Two CO2 laser cutting machines with a laser capacity of 6 kW and a solid laser machine TruLaser 5040 fiber with a powerful 5 kW fibre laser.

The Trumpf laser cutting machines are particularly characterized by a high cutting quality in all sheet thicknesses. High cutting speeds can also be achieved with minimum non-productive times. High process safety is guaranteed in fully automatic operation. We can manufacture both single-item parts and serial parts with our laser cutting machines economically and with perfect quality.

Laser cutting performance data

Machines:

3 x Trumpf laser cutting machines

Technology:

5 kW solid laser and 6 kW CO2-laser

Working area:

max. 6,000 mm x 2,000 mm

Materials and sheet thicknesses:

Steel plate: up to 30 mm.

Stainless steel, wear-resistant steel, aluminium: up to 25 mm.

Copper and brass: up to 10 mm.

(other materials and sheet thicknesses on request)

Surface finishing: Clean surfaces

-

Various procedures and machines are available for the finishing of sheet metal surfaces at our company, guaranteeing a smooth and clean surface of the cut parts.

With a Weber multi function machine we can not only deburr, but also chamfer and descale the cut edges resp. polish the surfaces.

A sandblasting unit with airless blasting-continuous blasting procedure supplements our service capacity in the field of surface reworking.

Surface finishing performance data

- Machine: 1 x Weber Grinder

- Procedure: Grinding, deburring, chamfering, descaling

- Working area: 6,000 mm x 1,500 mm

- Material thickness: 1 mm to 100 mm

- Machine: 1 x Sandblasting unit

- Procedure: Airless blasting-Continuous blasting

- Working area: 1,500 mm x 15,000 mm

- Material thickness: 1 mm to 650 mm

The advantages of a good processing of the surfaces lies in a lower risk of injury during subsequent handling or further processing. A clean finishing of surfaces is especially important among other things in the case of cut parts that are varnished afterwards. By chamfering the edges for example, a corresponding structure of thicknesses of layers is possible, offering nearly the same service life as the varnish on the surface. If the cutting areas were descaled in addition, the perfect mechanical adhesion is also guaranteed there.

Edge bending: CNC bending with 4 press brake machines

-

Customer requirements in the field of bending can be perfectly implemented in our edge bending department with a total of 4 highly modern CNC Bystronic press brake machine. We can produce your sheet metal bending parts with a maximum pressing force of 800 tons and a bending length of max. 6,200 mm. All 4 bending units obtain a first class bending result and are equipped with maximum technical possibilities.

The Bystronic press brake machines are all equipped with the same control system and the same tools. This enables us to maintain an optimum machine performance and therefore flexible and rapid production of customer orders, both in the case of single-item components and series production. Our press brake machines are controlled by CNC-control system. This enables us to also simulate the planned bending process. Test bends are therefore not necessary. The first part is also a good part.

Bending performance data

- Machines: 4 x Bystronic press prake machine

- Pressing force: up to max. 800 tons

- Bending length: up to max. 6,200 mm

- Assembly height: up to max. 1,150 mm

- Sheet thickness: up to max. 25 mm

- Lifting height: up to max. 865 mm

The bending sheet metal is an important procedure in industrial sheet metal processing. For the sheet metal can only be formed into the desired shape using the bending procedure. To do so the sheet metal is pressed into the lower tool (die) by the upper tool (stamp). Many tool variations and dies are available for the various requirements on angle and radii. The sheet metal to be bent is placed on a stop, so that the bending process is carried out as efficiently as possible. The result is a perfect bend and optimum basis for the further processing of the sheet metal product.

Laser welding: Reduced costs & highest precision

-

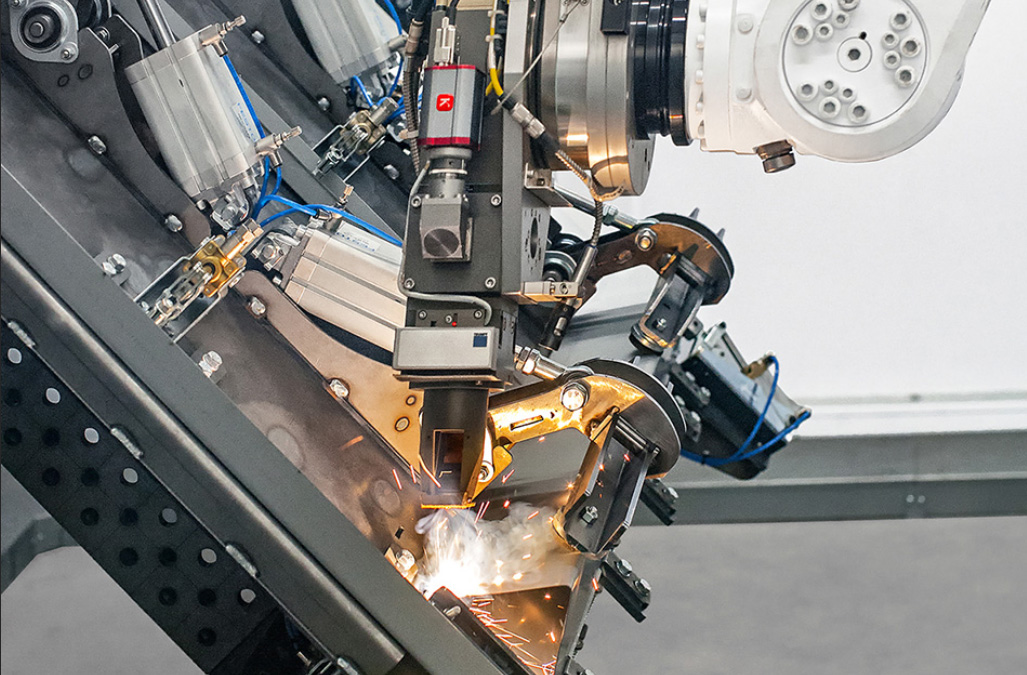

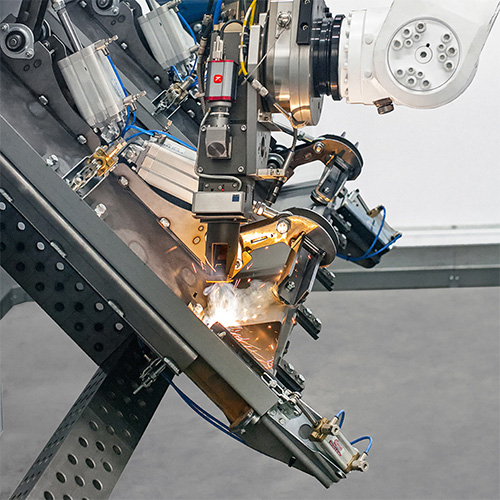

We offer our customers a new and high-performance welding technology with the TRUMPF TruLaser Robot 5020 that has considerable advantages over conventional welding procedures – in both quality and economic respects.

The energy is introduced without contact and positioned very precisely on the component by the laser beam. Because of this only low thermal stress and an extremely limited heat affected zone result. Lean seam geometries and a smooth surface are the result. As a result, reworking is also reduced or even completely omitted. High process speeds ensure short processing times. In addition, the automatic rotation changer makes a simultaneous loading and unloading of the machine possible during the welding process.

Laser welding performance data

- Machine: TruLaser Robot 5020

- Working area: 2,000 mm x 950 mm x 1,000 mm (larger dimensions on request)

- Load: approx. 750 kg

- Laser power: 6 kW

- Sheets: Sheet steel, stainless steel, aluminium, copper and brass

- Loading/Unloading: Rotation changer for simultaneous loading and unloading

Advantages of laser welding

- Welding of complicated seam geometries

- Pinpoint, precise energy introduction of low distortion welding

- Minimum thermal material impact

- No or only light reworking

- High automation and welding speed

- Quality monitoring and documentation of process data

- High process safety due to fully automatic CNC-control

- Thermal conduction welding for optically perfect welding seams

- Deep welding for highest stability

The TRUMPF laser welding machine is the optimum addition to our previous welding machines. A welding robot made by Cloos is also in use as well as manual welding stations. In this way we can react flexibly and rapidly to the requirements and needs of our customers.

Cloos welding robot: Automated welding

-

The CNC-controlled Cloos robot welding machine offers maximum flexibility in automated welding. Thanks to two rotating/swivel work-piece positioners arranged side by side, the machine can be loaded and unloaded simultaneously. By uniting the two work-piece positioners, structural components with a length of up to 7 m can be welded.

A high seam volume can be generated by using a tandem welding torch. A high welding speed is also possible by using the tandem welding torch.

An on-line follow-up of the welding seam is possible with a laser sensor attached to the welding torch. This guarantees a clean torch guidance at the work-piece and so ensures high seam quality. Furthermore, the welding torch can be positioned very precisely on the work-piece by the laser sensor.

Cloos welding robot performance data

- Machine: CLOOS QIROX C

- Welding head: One and two wire welding head

- Procedure: MIG-MAG

- Working area:

Two stations: 3,200 x 1,600 x 1,600 mm.

One station: 7,000 x 1,600 x 1,600 mm

(larger dimensions on request) - Load: max. 4,000 kg

- High process safety and automation by CNC-control and laser sensor

- Optimum seam course by on-line follow-up

- Simultaneous loading and unloading

- High welding speeds

- Economical welding also of big components

- High quality of welding seams

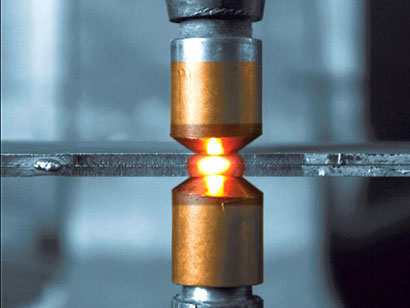

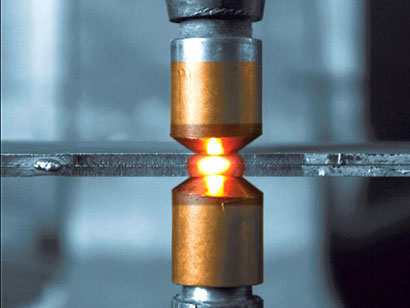

Spot welding: joining with utmost precision

-

In the field of spot welding we have two DALEX machines in operation at our facilities: a spot welding machine of type PMS and a spot welding gun of the 3328-6 series.

During resistance spot welding, or also called spot welding, the parts to be joined are pressed together using two electrodes positioned opposite each other. An electric current is introduced into the parts to be joined by the electrodes. Based on the heat resulting from this (Joule effect) and the force with which the parts are pressed together by the electrodes, a permanent welded joint is produced. With the spot welding machine PMS 12-6 we can also join welding nuts from M3 to M12 using resistance projection welding.

Spot welding performance data

- Maschines: DALEX spot welding machine PMS 12-6

DALEX spot welding gun 3328-6 D - Procedure:

Resistance welding

Resistance projection welding - Working area:

Spot welding machine: up to approx. 750 mm overhang

Spot welding gun: up to approx. 600 mm overhang - Sheets:

Steel sheet, brass, aluminium, copper

- Maschines: DALEX spot welding machine PMS 12-6

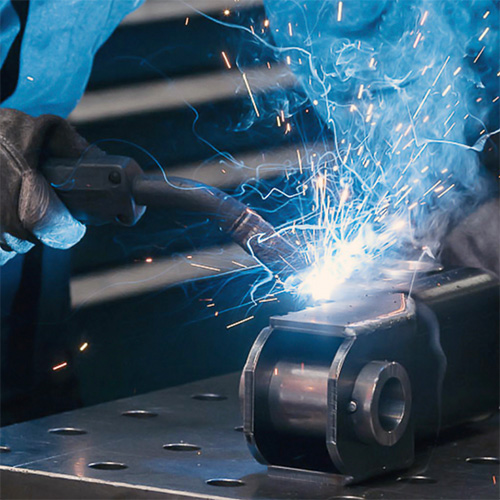

Welding: MIG-MAG-TIG

-

As well as automated welding with the laser welding machine TruLaser Robot 5020 and the Cloos welding robot (MIG-MAG), we also work with manual welding workstations. The MIG-MAG-TIG welding procedure is used in this case.

We can fulfil your welding specifications very well – both with internal manual welding workstations and with reliable external welding specialist companies, who all fulfil the corresponding requirements and guidelines in the field of welding – from simple welding components to very complex welding structural components.

Welding performance data

- Procedures: MIG-MAG-TIG

- Working area:

3,000 mm x 3,000 mm x 10,000 mm

(larger dimensions on request) - Weight of indiv.piece:

max. 5,000 kg (higher weights on request) - Finishing:

Flame straightening

Low stress annealing/Stress relief annealing

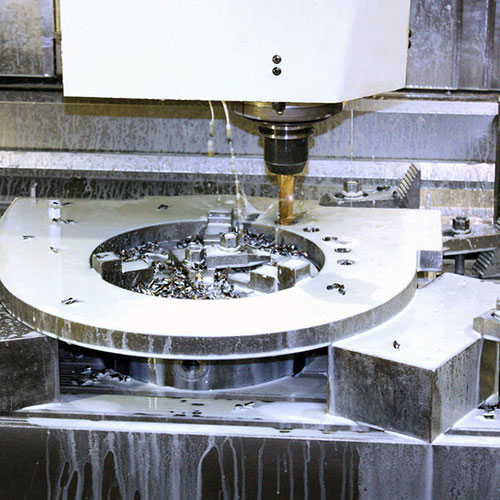

Mechanical machining

-

We carry out the mechanical machining of sheet parts and welding structural components either in our own factory or we pass these on to our selected and reliable partners and suppliers here in the vicinity.

The organization and transaction with the supplier is carried out by us completely. We select the most suited supplier for your requirements, clarify the technical requirements, look after the logistic transaction and execute an immediate quality check. You receive the finished machined parts from us.

The variety of machining in the mechanical machining at Neumaier Industry is almost unlimited and ranges from drilling, sinking, turning to milling work, straightening and the fixation of manufacturer's labels.

Mechanical machining performance data

- Straightening

- Deburring

- Sawing

- Drilling

- Sinking

- Tapping

- Turning

- Milling

- Chamfering

- Grinding

- Fixing manufacturer's label

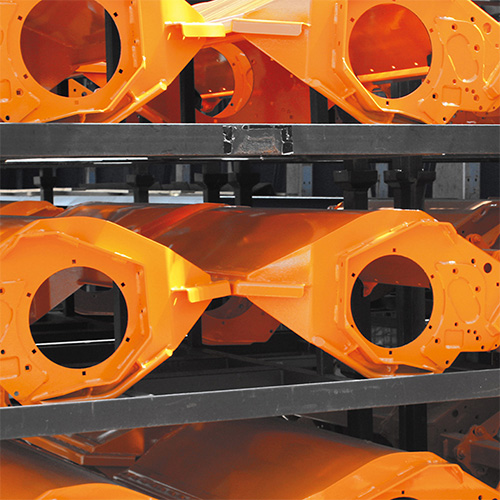

Surface refinement

-

For the surface refinement of gas-cutting parts or structural components we resort to our competent and reliable suppliers and partners here in our neighbourhood. By doing so, we are in a position to carry out every imaginable surface finishing according to your technical requirements. The possibilities here are nearly unlimited and range from phosphatising to powder coating to galvanizing and anodizing.

The organization and transaction with the supplier is carried out by us completely. We select the most suited supplier for your requirements, clarify the technical requirements, look after the logistic transaction and execute an immediate quality check. You receive the finished machined parts from us.

Surface refinement performance data

- Phosphatising

- CED electrophoretic painting

- Powder coating

- Wet painting

- Chromizing

- Anodizing

- Electrogalvanizing

- Hot galvanizing

Sheet metal processing

-

We manufacture both single parts and serial parts in the sheet metal processing department - from simple sheet metal cuts to complex and ready-to-mount assembly components – according to our customers' requirement profile. With over 30 years experience in industrial sheet metal processing we are experts in this field.

Our range of services in industrial sheet metal processing is very comprehensive. State-of-the-art production procedures and machines combined with our highly trained and experienced specialist staff enable us to carry out high quality sheet metal processing. A lean production structure and an extensive sheet metal stock are the basis for flexible and rapid sheet metal processing.

Assembly and Quality Assurance

Assembly

-

As a system supplier we offer our clients an all-round carefree package. In accordance with our customer requirements we produce and install complex subassemblies and mounted components from prototypes to line production.

Our in-house sheet metal production is the base for it all. Here all parts and subassemblies will be prepared – cutting, edging, welding and painting. The assembly department will fit the client subassemblies together. As part of this process all mechanical components as well as pneumatic, hydraulic or electrical parts will be connected and installed. We are also happy to source outside supplied parts for our customers.

Assembly performance data

- Assembly of mounted components and subassemblies

- Mechatronic systems including mechanics, pneumatics, hydraulics and electronics

- Testing procedure, technical inspection and quality control

- Dispatch and delivery

Our services also include the packaging and dispatch handling in accordance with customer requirements. Delivery will either be handled by our own fleet or through a trusted transport company.

We have many years of experience and know-how within fitting of mechatronic components. Our system engineering department develops, constructs and installs our own mechatronic systems and constructions. For example, the rotating driver’s workstations for forklift trucks or the load train Factory Train from Linde. We can tap into resource and knowledge with years of experience in mechatronic systems when installing customer specific subassemblies.

Quality assurance/inspection

-

Perfect quality and therefore high customer satisfaction is top priority at Neumaier Industry. Our own quality assurance department has every conventional test equipment devices at its disposal. The sheet metal parts and structural components pass through our quality control by spot check analysis. A 100% inspection of the parts can be carried out at the customer's request. Incoming merchandise inspections are also carried out after external production work. Machining or material faults can be identified early on in this way and remedied without delay. You receive your components from us according to your quality requirements.

Quality assurance performance data

- FARO Prime 6-axis measurement arm

- Initial sample inspection report (ISIR) according to QS 9000 / VDA volume 2 or TS 16949

- Inspection equipment to measure paint adhesion, layer thickness, roughness, degree of gloss or even permeability

- Investigations of machine, process and inspection equipment aptitude, statistical process monitoring, spot check analyses, Production Part Approval Process (PPAP)

All operating processes at our company are planned, regulated and controlled via an ERP system. Standardized operating procedures guarantee a lean production with best possible results.

Neumaier Industry is a certified company. Besides the quality management system, which we operate in accordance with ISO 9001, we also comply with DIN EN 1090 with delivery class of EXC3 and international norm DIN EN ISO 3834-2. In addition to that we own the transfer authority from TÜV SÜD with the material registering mark AD-2000.