KWB

Videos

Loading the player ...

- Offer Profile

- KWB offers individual

solutions for heating with wood. Whether it is a refurbishment, a new

building, a farm or a business, we have the pellet heating, the wood chip

boiler or the log boiler that fits you.

KWB stands for power (Kraft) and heat (Wärme) from biomass and is synonymous with cutting-edge biomass heating systems from Austria. The brand from Styria in Austria was created by following a clear vision:

Product Portfolio

PELLET HEATING SYSTEMS

- Comfortable and automatic heating with pellets

KWB pellet heating systems are modern and efficient central heating systems that mainly run on climate-neutral wood-pellets. The work fully automatically. KWB heating systems come with different varieties of filling chambers.

Advantages of a pellet-heating system

Pellet heating systems are just as user-friendly as central heating systems fired with oil or gas. However, they cause the lowest fuel costs as well as the lowest carbon emissions when it comes to central heatings.

Heating comfortably with pellets

Heating with KWB is quintessentially comfortable: At a capacity range of 135 kW KWB pellet heating systems come with a wheeled ashes container. Up to 15 kW there is almost no cleaning effort as the ashes container only has be emptied every two years.

At a high capacity range we separately offer large ahes container in order to be able to guarantee an easy operation.

Thanks to the dual control system consisting of a dial and a touchscreen display the heating can intuitively be operated. Combined with the KWB Comfort Online platform it can also be controlled remotely.

Cheaper than oil and gas

As pellets are made of a renewable commodity and as the pellet market works independantly from the political international situation heating with pellets is significantly cheaper than heating by oil or burning gas. All KWB wood-fired heatings are government-funded.

Ecofriendly pellets

Pellets mainly consist of sawdust which means that no tree has to be cut to the ground for producing them. As wood regrows our customers are virtually heating in a climate-neutral way.

Modern wood-pellet heating systems are extremely clean. They meat meet even the most stringent restrictions in Germany and Austria.

KWB EASYFIRE

- Pellet heating system 2,4 – 35 kW

Thanks to CleanEfficiency Technology, the KWB Easyfire wood pellet heating system is a milestone on the path towards an emission-free heating technology. The KWB Easyfire pellet heating system also sets a new benchmark for easy heating.

Heat simply and cleanly- With a footprint of just 0.82 m²

- convenient movable ash container

- fits in any boiler room

- emissions within the regulated guidelines

KWB EASYFIRE 1

- Pellet heating system 10/15/20 kW

The Austrian quality product is a proven solution for single- and multi-family homes and is available with hopper or as KWB Easyfire 1 Plus with automatic fuel filling.

Heating with KWB quality- 40,000-times proven combustion system

- Easy filling from a storage container with 200 l volume

- Extra-charge item: Ash compaction and automatic heat exchanger cleaning

KWB MULTIFIRE

- Pellet and wood chip heating system 20 - 120 kW

The large power range of 20 to 120 kW combined with highest fuel flexibility makes it

possible to deploy the new KWB Multifire wood chip or pellet heating system in a

larger single family home, in commercial facilities and including smaller district heating

networks.

Robust all-rounder for economical heating- Crawler-burner with high-alloy and self-cleaning cast rotary grate elements

- CFD-optimised nozzle geometry and arrangement

- High efficiency turbulators

- Automatic ash removal

KWB PELLETFIRE PLUS

- Pellet heating system 45 – 135 kW

The large power range of 45 to 135 kW combined with highest fuel flexibility makes it

possible to deploy the KWB Pelletfire Plus pellet heating system in larger single family

homes, commercial facilities including smaller district heating networks.

The robust pellet boiler for economical heating- Clean combustion: Crawler burner

- CFD-optimised nozzle geometry and arrangement

- High efficiency combustion

- Automatic ash removal

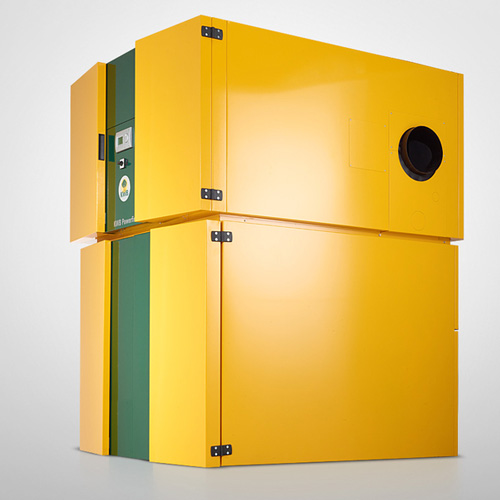

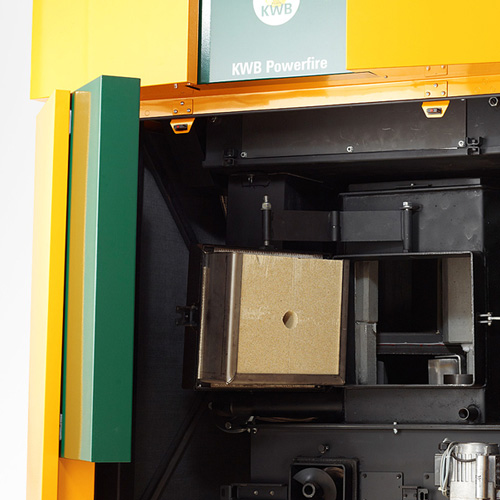

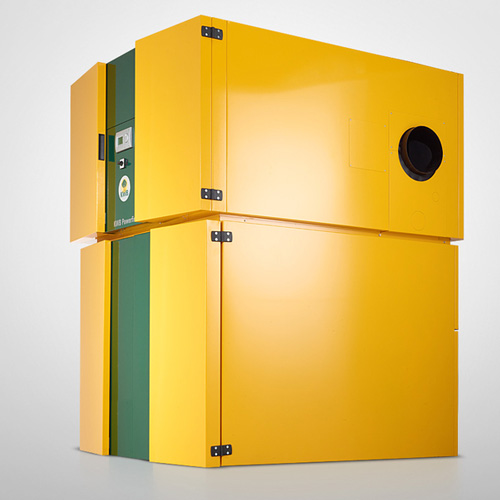

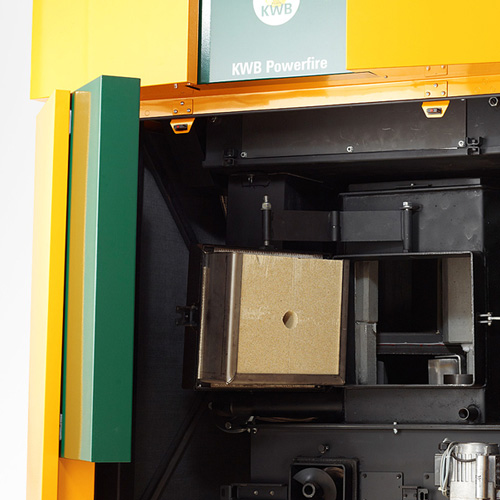

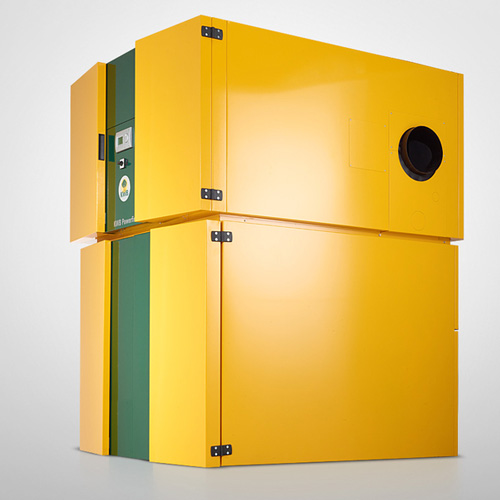

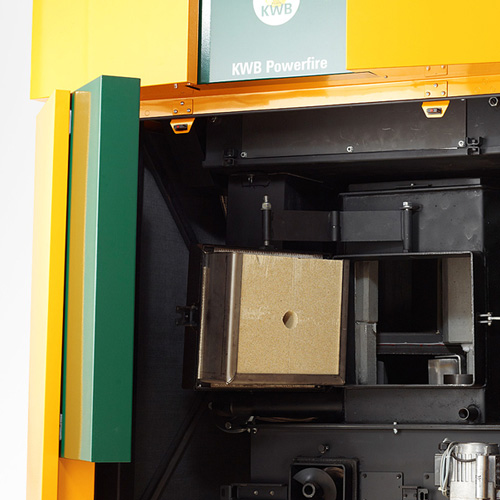

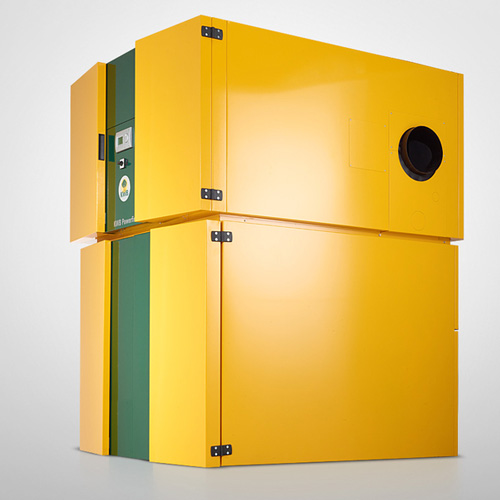

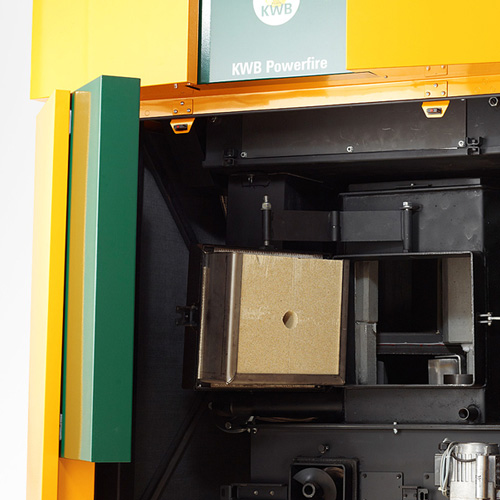

KWB POWERFIRE

- Pellet and wood chip heating system 150 - 300 kW

Our power package is one of the most compact heating systems in the 150 to 300 kW power range. The KWB Powerfire can be fired with wood chips or pellets and is perfectly suited for supplying regional district heating networks and larger buildings and systems (contracting).

Quiet power package for reliable heating- Compact rotary-grate combustion system

- Cyclone combustion chamber for minimum emissions

- Convenient 240-litre ash container

- Extendible substructure

- Full 10-year guarantee

WOOD CHIP BOILERS

- Heating with woodchips: Inexpensive and flexible

Your benefits

Wood chip fired heating systems are truly economic solutions as wood chip is a regional product. Therefore, it is inexpensive. Still, fluctuating fuel qulities are a challenge for a wood chip fired boiler.

Just to make sure

Reliability is a central quality attribute when it comes to our wood chip fired boilers. That is why our KWB wood chip fired boilers do not only consist of robust components but also:- The main burner parts are casted and consist of self-cleaning components. The concept stems from large biomass combined heat and power stations.

- We offer some comprehensive service- and maintenance packages.

We offer different kinds of storage room systems that fit the individual requirements of a wood-chip fired heating. Everything will be planned individually. We also support you when it comes to the different possibilities for grants in order to help you reduce the investment costs.

KWB MULTIFIRE

- Pellet and wood chip heating system 20 - 120 kW

The large power range of 20 to 120 kW combined with highest fuel flexibility makes it

possible to deploy the new KWB Multifire wood chip or pellet heating system in a

larger single family home, in commercial facilities and including smaller district heating

networks.

Robust all-rounder for economical heating- Crawler-burner with high-alloy and self-cleaning cast rotary grate elements

- CFD-optimised nozzle geometry and arrangement

- High efficiency turbulators

- Automatic ash removal

KWB POWERFIRE

- Pellet and wood chip heating system 150 - 300 kW

Our power package is one of the most compact heating systems in the 150 to 300 kW power range. The KWB Powerfire can be fired with wood chips or pellets and is perfectly suited for supplying regional district heating networks and larger buildings and systems (contracting).

Quiet power package for reliable heating- Compact rotary-grate combustion system

- Cyclone combustion chamber for minimum emissions

- Convenient 240-litre ash container

- Extendible substructure

- Full 10-year guarantee

WOOD-FIRED BOILERS LOGS & PELLET BOILERS

- Enjoy full indipendence

The advantages of a firewood heating

Our log wood fired boilers and combination boilers guarantee for independence. Wood is a local fuel. The delivery channels are short. On top of that you will get the highest state funding for a combination boiler. If you decide to combine the boiler with a solar array you can get up to 10.000 euros and more from the state.

KWB log wood fired boilers: particularly comfortable

Our carburetors for log wood are totally easy to operate. The KWB Classicfire has a 180 litre filling chamber, the largest of its class, that ensures long refill intervals. On top of that the boiler indicates on the control display how much firewood you should refill.

No compromises: The pellet module

You want to heat fully automatically for example when you are on vacation so as to be able return to a cosy and warm home? If yes, you will be interested in the optional pellet modul. Thanks to our ComfortOnline system you can start the heating remotely.

The pellet burner stems from our KWB Easyfire pellet heating which has been tested a ten tousand times. Thanks to the efficient comustion you only have to empty the moveable ashes container after the heating has consumed six tons of pellets.

Ideally combined with a buffer storage tank

Log wood fired heatings will be combined with buffer storage tanks. In that way they work even more efficiently. KWB offers premium storage technology. In that way your heating is prepared for for supplements: The thermal solar array. The collectors of our solar array stem from the global leader greenone TEC.

KWB POWERFIRE

- Our combi-boiler: Flexible and safe heating

- 40,000 times proved underfeed burner from KWB Easyfire

- convenient and clean ash removal with a movable ash container

- automatical switch between log wood and pellets

KWB CLASSICFIRE

- Log-wood heating system 18/38 kW

The KWB Classicfire log-wood heating system combines traditional wood heating with

modern convenience. The capacity range of 18/38 kW makes the KWB Classicfire the

ideal heating system for one- and two-family houses as well as agricultural companies.

The KWB log-wood gasifier comes standard with a pellet flange, making it easy to upgrade to a combination boiler at a later point in time.

Classic and convenient heating- More comfort: The 185 l filling chamber, the largest of its class, guarantees long refilling intervals: 185 l for logs of 50 cm lengthwise and 33 cm widthwise

- Possibility to upgrade to a combination boiler without major expenditures

- Quick heat thanks to the quick charge valve

- Added value: automatic ignition, automatic heat exchanger cleaning or ash

container provide even more comfort

SYSTEM ACCESSORIES

- Your complete energy system from a single sourceK

WB is not only a specialist when it comes to heating with renewable energy but also has a profound know-how when it comes to individual storage room solutions, efficient storage systems and intelligent control technology.

Storage technology

- The right storage ensures that your heating becomes an

energy central: The storage takes the warmth from the heat generator and

distributes it based on demand.

There are boilers, buffer storages and stratified tanks. Hot water storages contain heated raw water. Buffer storages provide heat for raw water and heating. Stratified tanks are special buffer tanks that store warm water in different layers depending on its temperature which is highly efficient. KWB storages are also avialable combined with a solar contactregister so that a solar-thermal plant can be incorporated.

With pellet heatings, heat pumps and woodchip boilers we recommend installing a buffer storage. If you heat with solarthermics and/or wood firewood it is necessary to install a buffer storage.

Advantages of a KWB storage room system?- Reliability

KWB offers particularly low maintenance storage room systems. - Comfort

Fuel storage: Long refilling intervals as the available space gets optimally used. - Efficiency

The sorage room concept protects the pellets, minimizes the dust and maximizes the efficiency of your wood fired heating.

- Reliability

Storage room technique and fuel transportation system

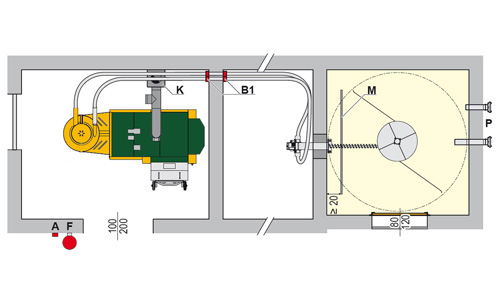

- Planning example of a KWB PelletfirePlus pellet heating

system including a pellet stirrer and a suction conveyance.

Since KWB has developed automatic wood fired heating systems our engineers concentrate on save, comfortable and low-maintenance storage room solutions.

The patented KWB Pellet Stirrer Plus is one of our unique features: A ground low fuel transport system that allows for optimal space utilisation including a heavy-duty gear.

Our goal is to find the right storage room solution for your individual structural requirements. The fuel gets transported via KWB seduction conveyance (pellets only), a screw or a stirrer. Upon request we also plan your special solution (e.g.: drop shaft, push floor).

Advantages of a KWB storage room system?- Reliability

KWB offers particularly low maintenance storage room systems. - Comfort

Fuel storage: Long refilling intervals as the available space gets optimally used. - Efficiency

The sorage room concept protects the pellets, minimizes the dust and maximizes the efficiency of your wood fired heating.

- Reliability

Intelligent control technology

- KWB offers intelligent control technology. The dual

control system is really easy to handle thanks to the proven dial and

touchscreen display. With the KWB Classicfire heating its practical fill

level sensor will always display how much log wood you need to add to

efficiently operate your system.

The Comfort Online platform lets you monitor and control the heating system via smartphone, tablet or laptop/PC from anywhere in the world. It is not necessary to install an app or software. If anything changes concerning the status of your heating you will immediately get informed via sms or mail. Another plus: The visualisation oft he heating is complementary for KWB customers.