- Offer Profile

- Customers worldwide trust the

exceptional reliability of our

Products "Made in Germany"

Our quality standards have been shaped byover 80 years of experience in pump manufacturing and engine and plant engineering.

High durability, solid and innovative construction and quality control are the outstanding traits of our pumps. All components of the pumps are manufactured in Germany. Third party components are manufactured by major German firms.

HIGH PERFORMANCE PUMPS

- Solutions for nearly all liquids

With our diverse standard and high performance pumps we are able to

serve all your needs and response to any challenge.

Our rotative displacement pumps are robust, self-priming and have running

dry capability:- Pressures up to 120 bar

- Flowrates from 1,5 l/h to 300m3/h

- Viscosity up to 1.400.000 mPas

- Temperature up to 450°C

- Efficiency up to 92%

- Suction lift up to 8m

- Solids up to 90%

GEAR PUMPS

- With our diverse standard and high performance gear pump range we are able to serve all your needs and respond to any challenge. Our gear pumps are robust, self-priming and are designed for your specific application.

On demand, we can provide external gear pumps which API, ATEX, GOST-R, TR CU and TA Luft compliantZeilfelder gear pumps are specially designed for*:

- complex and difficult challenges

- pressure up to 120 bar

- suction lift up to 8 m

- flow rates from 1,5 l/h to 260m3/h.

- viscosity up to 150.000 mPas

- temperature from -60°C to 450°C

- dosing (repeat accuracy > 99 %)

- explosive und toxic substances

- liquids containing solids (up to 90%)

- liquids containing shear sensitive materialsa (for exemple fruits)

- polymerizing or coagulating liquids

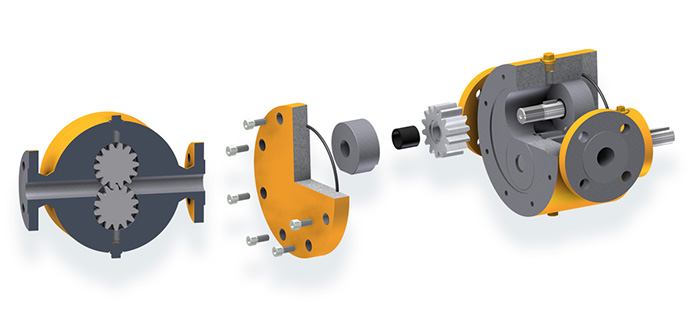

GEAR PUMPS: ZK BLUE Series

-

For high end applications, high process efficiency and quality

The ZK BLUE Series representes the low volume high precision part of our gear pump range. The ZK Blue Series are mainly milled from any type of steal, but can as well be maode out of Titan and Ceramics.

On demand, we can provide external gear pumps which are API, ATEX,TR-CU 10, TR-CU 12 and TA Luft compliant.

- Pressure: standard 25 bar (optional up to 120 bar)

- Viscosity: up to 150.000 mPas

- Flow rates: 0,4 up to 300 l/min (0,025 to 18 m³/h)

- Speed: up to 3000 rpm

- Suction lift: up to 6 m

- Temperature: -60 to 450°C

- Materials: all available materials

- Seals: lip seals, packing, single or double mechanical seals, magnetic coupling

GEAR PUMPS: PQ Green Series

-

For standard applications

With our diverse standard and high performance gear pump range we are able to serve all your needs and respond to any challenge. Our gear pumps are robust, self-priming and are designed for your specific application.

- Pressure: up to 20 bar

- Viscosity: up to 150.000 mPas

- Flow rates: 10 to 4.120 l/min (0,1 to 250 m³/h)

- Speed: up to 1.780 rpm

- Suction lift: up to 4 m

- Temperature: -20 to 250°C

- Materials: all available materials

- Seals: lip seals, packing, single or double mechanical seals, magnetic coupling

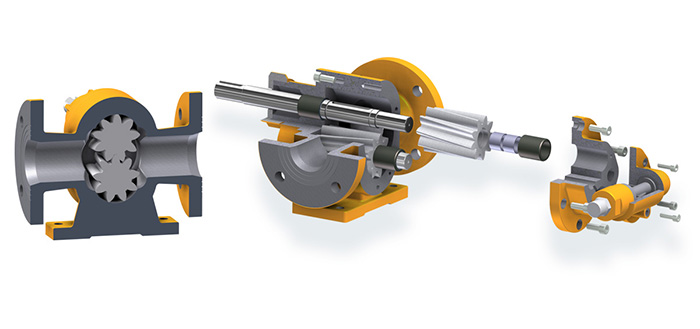

GEAR PUMPS: ZH/ZV BLUE Series

-

For high end applications, high process efficiency and quality

The ZH/ZV BLUE Series represent our heavy duty, high flow and high quality gear pump range. The casing is made out of casting steel materials.

On demand, we can provide external gear pumps which are API, ATEX,TR-CU 10, TR-CU 12 and TA Luft compliant

- Pressure: standard 25 bar (optional up to 120 bar)

- Viscosity: up to 150.000 mPas

- Flow rates: 1 up to 4.350 l/min (0,03 to 260 m³/h)

- Speed: up to 3000 rpm

- Suction lift: up to 6 m

- Temperature: -60 to 450°C

- Materials: all available materials

- Seals: lip seals, packing, single or double mechanical seals, magnetic coupling

INTERNAL GEAR PUMPS: ZI Green Series

-

Internal Gear Pump - the Economical Solution

With our economical internal gear pumps we offer interesting solutions for standard pressure applications.

- Pressure: up to 14 bar

- Efficiency: up to 90%

- Viscosity: 1 to 55.000 mPas (higher value upon request)

- Flow rates: 10 up to 4.120 l/min (0,1 to 250 m³/h)

- Suction lift: up to 4 m

- Temperature: -40 to 300°C

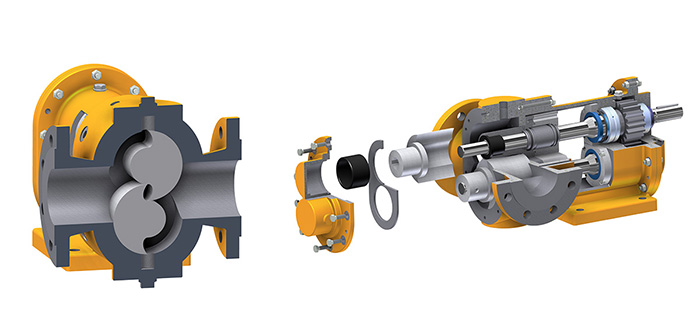

ROTARY LOBE PUMPS

- With our diverse standard and high performance pumps

we are able to serve all your needs and response to any challenge.

Our rotative displacement pumps are robust, self-priming and have running dry capability.

On demand, we provide as well pumps which are API, ATEX and TA Luft compliantZeilfelder rotary lobe pumps are specially designed for*:

- complex and difficult challenges

- liquids containing up to 90% of solids

- liquids containing shear sensitive materials (for example fruits)

- polymerizing or coagulating liquids

- liquids containing cristals or fibers

- dosing (repeat accuracy > 99 %)

- pressure up to 64 bar

- suction heights up to 8 m

- flow rates from 0.03 to 28.500 l/min.

- viscosity from 0.3 to 1.4 mPas

- temperature from -60°C to 450°C

- explosive und toxic substance

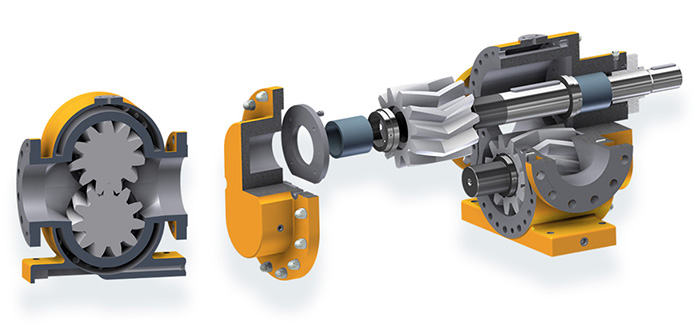

ROTARY LOBE PUMPS: KE & KD BLUE Series

-

For high end applications, high process efficiency and quality

Our rotary lobe pumps are self-priming, dry-run capable and reversible pumps designed for highly viscous liquids containing solid particles. Two non-contacting rotary lobes work together to transfer the liquid, while the shafts are driven by timing gears outside the process liquid.

Because of the very large internal cavities, rotary lobe pumps are able to handle extremely viscous liquids and large abrasive particles.

On demand, we can provide rotary lobe pumps which API, ATEX, TR-CU 10, TR-CU 12 and TA Luft compliant.

- Pressure: up to 40 bar

- Viscosity: up to 3.400.000 mPas

- Flow rates: 1 up to 5.000 l/min (0,06 to 300 m³/h)

- RPM: up to 3000 rpm

- Suction lift: up to 8 m

- Particle size: max 80 mm

- Temperature: -60 to 450°C

- Materials: all available materials

- Seals: lip seals, packing, single or double mechanical seals

ROTARY LOBE PUMPS: KS & KDS BLUE Series

-

Hardened design for heavy duty applications

Our KS & KDS Blue Series are specialy designed for heavy duty applications and liquides with highly abrasive particles.

On demand, we can provide rotary lobe pumps which API, ATEX, TR-CU 10, TR-CU 12 and TA Luft compliant.

- Pressure: up to 70 bar

- Viscosity: up to 3.400.000 mPas

- Flow rates: 2 up to 2.474 l/min (0,12 to 148 m³/h)

- Particle size: max 50 mm

- Suction lift: up to 4 m

- Temperature: -60 to 450°C

- Materials: all available materials

- Seals: lip seals, packing, single or double mechanical seals

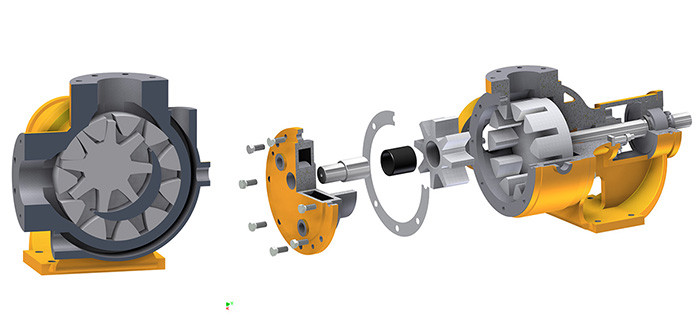

MULTI-WING LOBE PUMPS: KM BLUE Series

-

For high end applications, high prozess efficiency and quality

Our Multi-Win Lobe Pumps are a combination of gear and rotary lobe pumps designed for highly viscous liquids containing small solid particles. Two noncontacting lobes, consisting of multiple wings, work together to transfer the liquid, while the shafts are driven by timing gears outside the process liquid.

Because of the large number of lobes, multi-wing pumps are self-priming, dry-run capable and reversible pumps capable of handling extremely viscous liquids and small abrasive particles.

On demand, we can provide multi-wing lobe pumps which API, ATEX, TR-CU 10, TR-CU 12 and TA Luft compliant.

- Pressure: up to 70 bar

- Viscosity: up to 3.400.000 mPas

- Flow rates: 2 to 3.875 l/min (0,15 to 233 m³/h)

- RPM: up to 750 rpm

- Particle size: max 50 mm Efficiancy: 75 to 92%

- Suction lift: up to 6 m

- Temperature: -20 to 250°C

- Materials: all available materials

- Seals: lip seals, packing, single or double mechanical seals

INDUSTRIES

-

We offer Solutions for all industries in all requested certifications.

On demand, we provide as well pumps which are API, ATEX and TA Luft compliant

Our products porfolio offer rotary lob pumps for most applications. We offer explosion proof and seal-less pumps for the petrochemical industry, pumps with CIP option (cleaning in place), pumps with minimal surface roughness for the pharmaceutical and food industry and high pressure pumps for dynamic applications etc. Our pumps have proven their quality and efficiency for over 80 years in the following industries:

Chemical industry

- To meet the needs of the chemical industry we offer in addition to our conventional pump range, special and custom pumps built out of special materials with high performance coating, heating and cooling jacket.

Petrochemistry

- We offer self-priming rotary lobe pumps with heating or cooling jacket and seals such as ATEX, “TA-Luft” or API compliant to deliver crude oil and all types of bitumen including those containing solids.

Pharmaceutical industry

- To respond to the requirements of the pharmaceutical industry we have designed pumps with reduced surface roughness down to 4μ, CIP (cleaning in place) cleaning connections and aseptic connections.

Bitumen industry

- We offer special low-speed rotary lobe pumps with heating jacket to deliver bitumen and filled bitumen with barium ferrite under working temperatures up to 450°C. Those pumps operate with low-wear and are long lasting due to low revolution speed and special covering.

Automotive industry

- We build pumps to deliver solid emulsion and drilling liquids containing aluminium swarf and chips as well as wax, glue, paintings and modern paintings containing solid color pigments and nanoparticles in accordance with the requirements of the automotive industry.

Regenerative energy

- Our T-REX pump range is designed to meet the requirements of the power and regenerative energy sector. They deliver oil or acids and their design makes them highly durable. Our pumps are used in biogas plants to deliver biomass.

Shipping and offshore industry

- We offer maritime-grade rotary lobe pumps for offshore

applications to deliver heavy oil and machine lube oil.

We offer rotary lobe pumps to load and unload liquide chemicals, oil and bitumen filled with solids.

Building industry

- Our pumps deliver primary materials, protective agents, white cement, glue, silicone, waste water and filled bitumen for the building industry. We offer pumps for high temperature applications with heating jackets.

Food and candies industry

- Our stainless steel CIP rotary lobe pump range is FDA compliant and particulary suitable for the meet and animal feed industry. We offer special pistons avoiding caramelization for sugar based products as chocolate. Our high volume pumps with low-revolution speed can pump liquids with shear sensitive solids as strawberries and nuts while holding clipping under 5%.

Fiber industry

- We offer pumps with high systemic pressure and high dosing precision (optional with heating jacket) to deliver synthetic fibers, finishing agent, pigments loaded paints and dyestuffs.

Delivering solids

- Our rotary lobe pumps are specially designed to pump liquids with high concentration of solid particles or abrasive products as well as cuttings with cooling lubricant.

Metallurgy

- Rotary lobe pumps with heating jacket dispatch furan resins and refractory finishings in foundries, mercury, gallium, zinc alloy and stibium alloy up to 450°C.