- Offer Profile

-

We are a leading international provider of innovative, hydraulic drive and control technologies for mobile and stationary hydraulics. Through our extensive technical expertise, we support our customers' projects from the project phase through to series production. We provide valuable support from the planning stage to the production of future-oriented, high-quality and technologically advanced machinery.

Based on our flexible standard components, we can implement innovative solutions for almost any application.

Applications - Valued Worldwide for Pioneering Hydraulics Solutions

-

Working closely with our customers, we also develop tailor-made solutions for specific, machine-related requirements. These solutions often come with design challenges and demand the very highest performance requirements.

We are able to combine our products in various ways and to enhance functionality through appropriate software. This way, subsystem solutions and system solutions are created and subsequently integrated into the overall machine system

Energy

In the energy sector, Bucher Hydraulics develops solutions and products for wind energy as well as hydraulic valves, drive modules, and hydraulic drive systems for high-voltage circuit breaker applications.

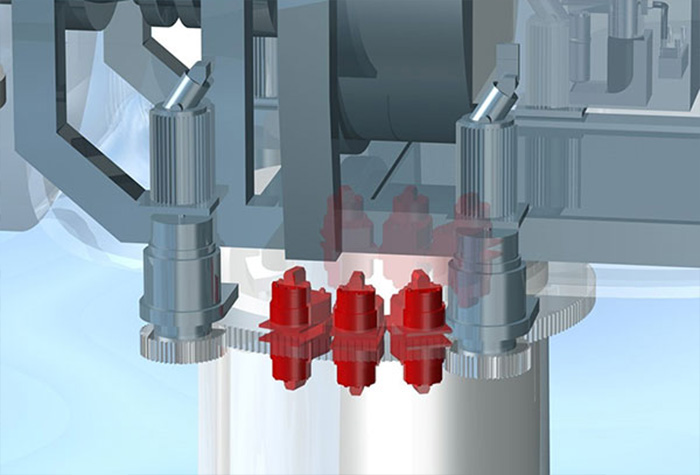

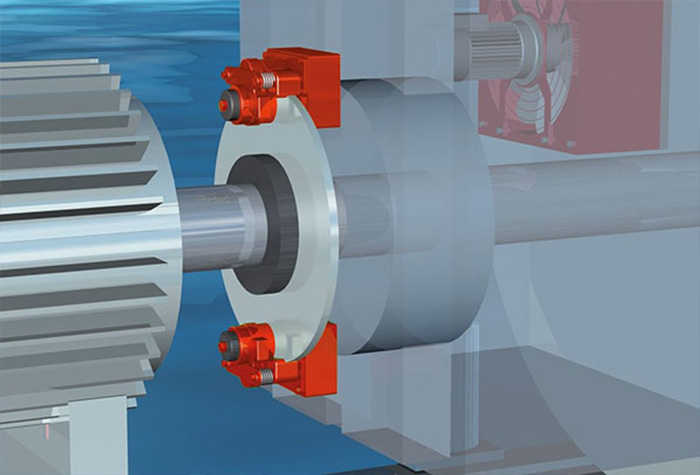

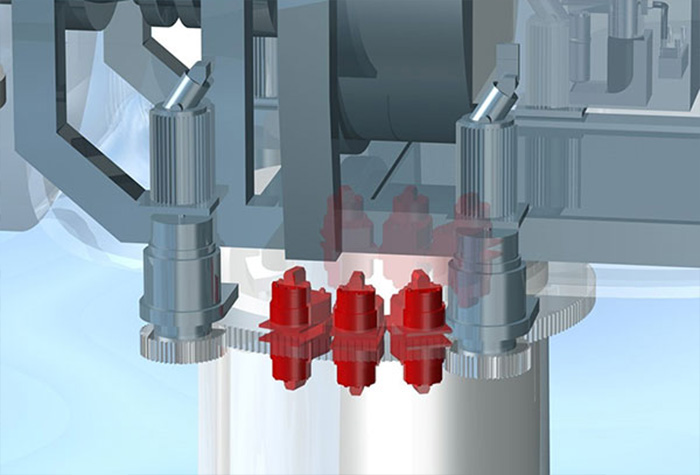

Wind turbines

- Bucher Hydraulics, one of the leading manufacturers of high-quality pumps, valve components, cylinders and compact power units, has been supplying its products to hydraulic system manufacturers for use in wind energy systems for decades. Our in-depth expertise and the high functional reliability of the individual components have been incorporated in wind energy systems around the world.

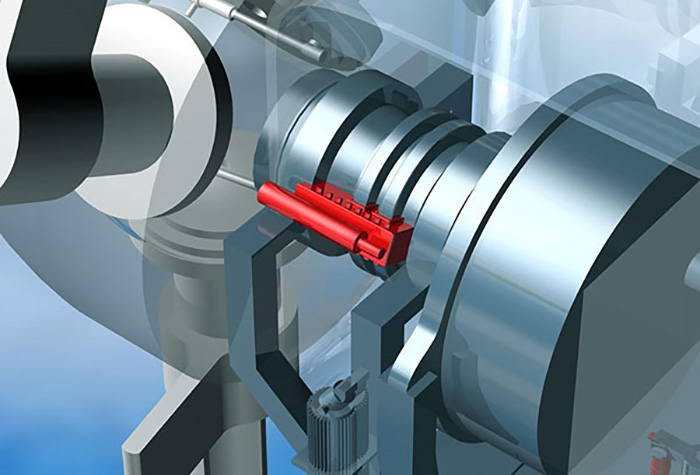

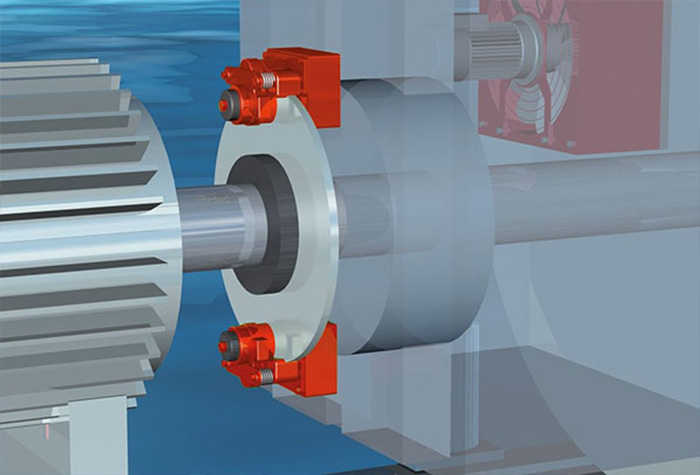

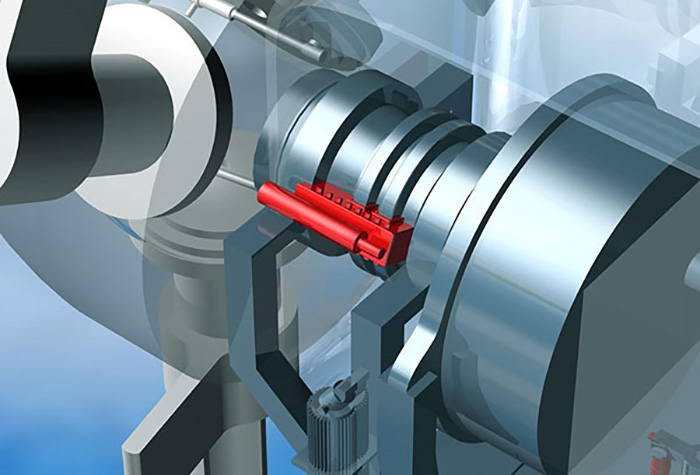

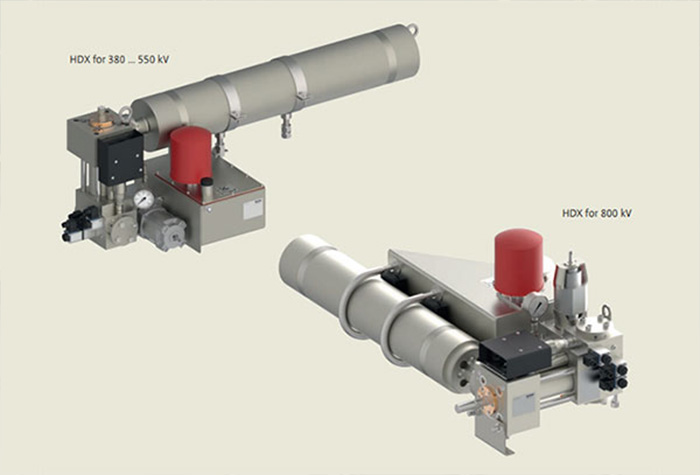

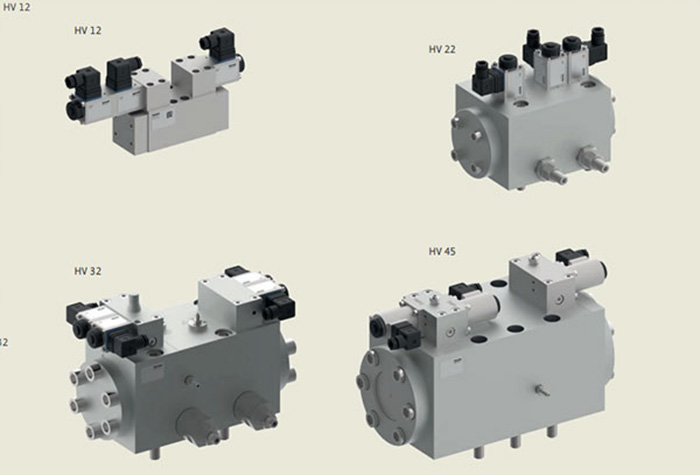

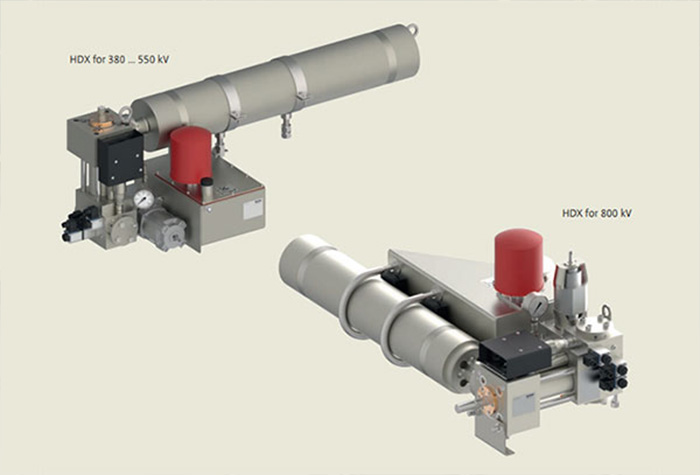

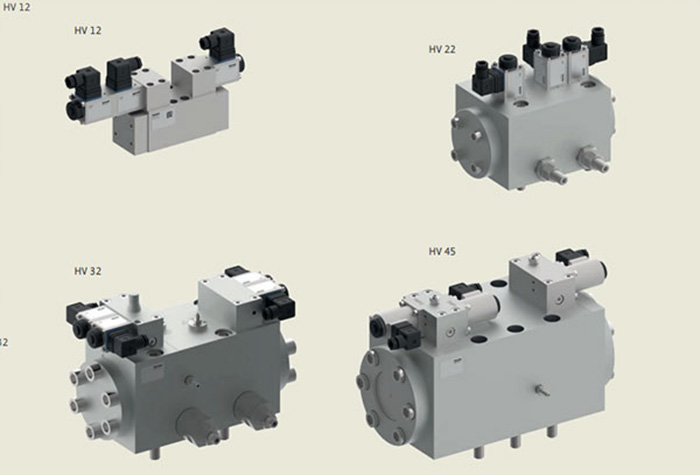

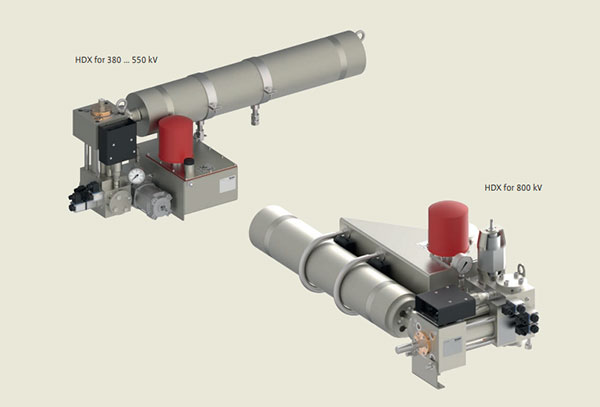

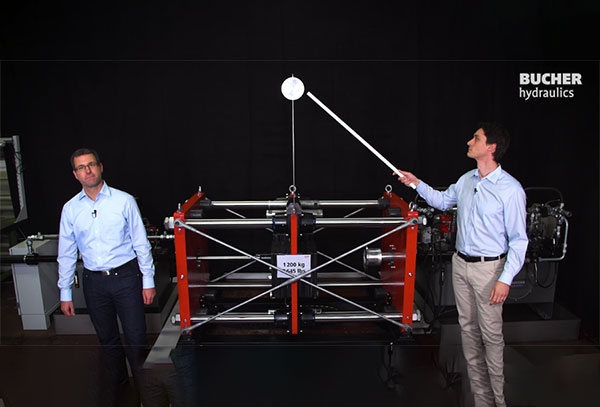

Hydraulic Drives for High-voltage Switch Gear

-

As the only independent supplier, we offer a wide range of customized hydraulic solutions for high-voltage circuit breaker applications to 1,200 kV. Bucher Hydraulics solutions are based on well proven technology, which has been in operation in high-voltage circuit breakers for 50 years all over the world.

For 50 years, Bucher Hydraulics has been developing and manufacturing:

- hydraulic valves

- drive modules

- hydraulic drive systems

for high-voltage circuit breaker applications.

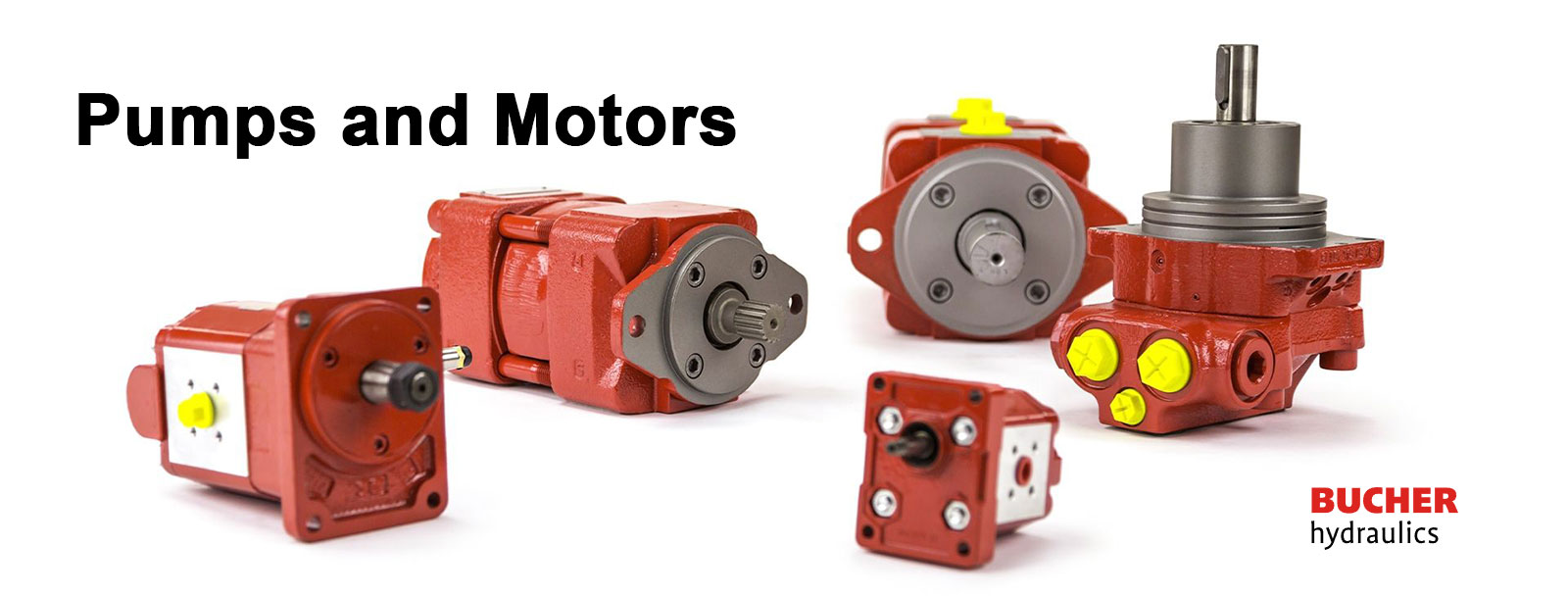

Pumps and Motors

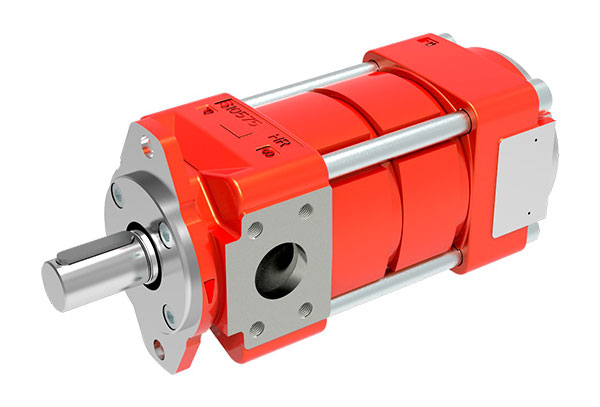

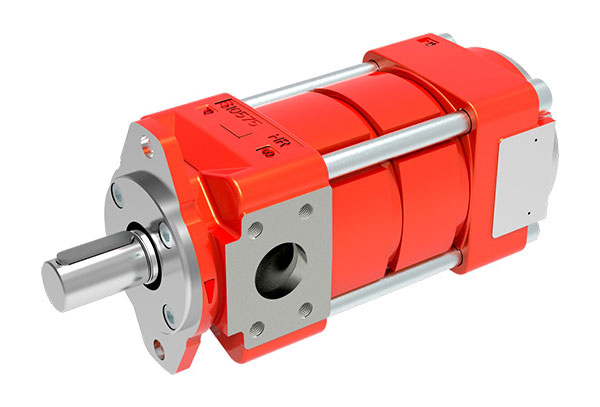

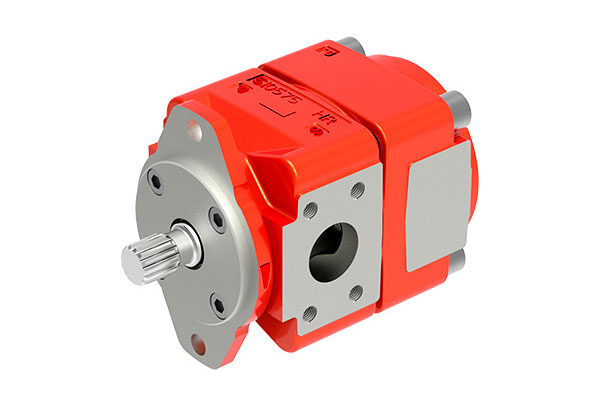

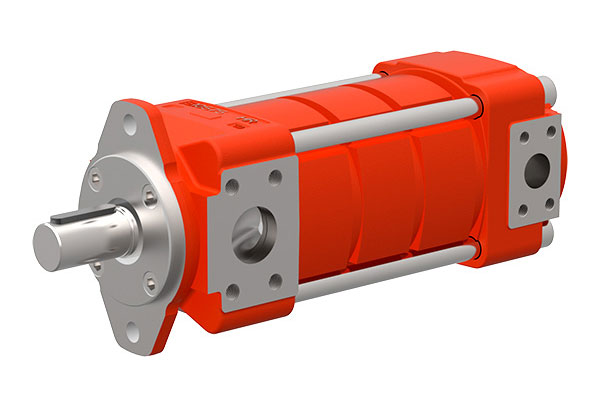

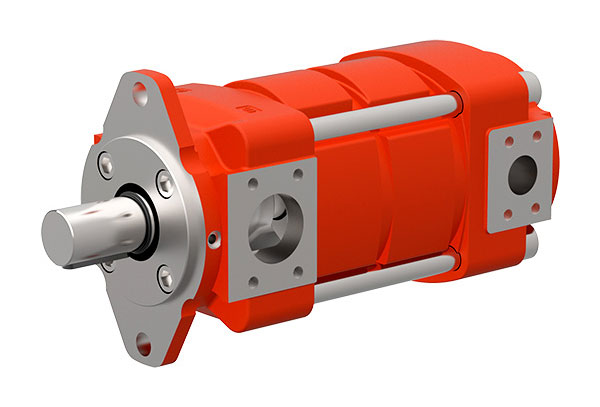

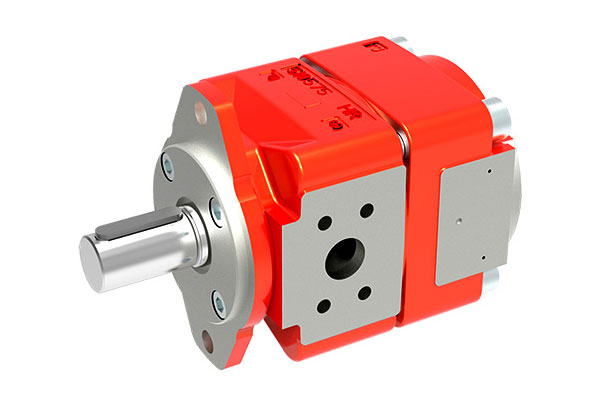

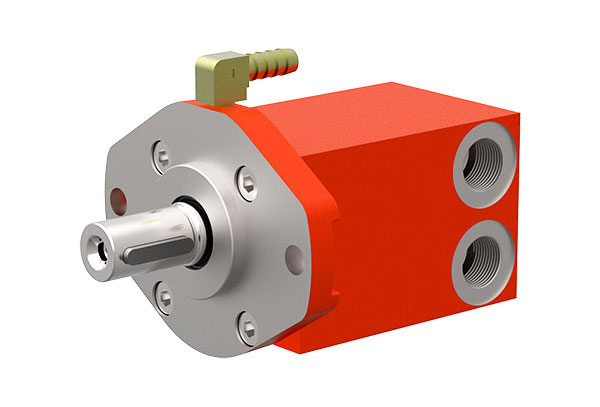

External Gear Pumps, Series AP

-

The product range of Bucher Hydraulics includes single pumps 05-100-212-212HP-250HP-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves.

External Gear Pumps Series Wuxi - CBKA Gear Pumps

-

The CBKA gear pump consists of a gear pair supported by two aluminum bearing blocks, a housing, front cover and rear cover. The axis clearance can be automatically compensated by the bearing blocks. The CBKA pumps' features are high mechanical a-nd volumetric efficiency, low noise level as well as low weigh/power ratio.

QX Internal Gear pumps

-

Pump all-rounders up to 400 bar

The QX series is the 5th generation of Bucher's internal gear pumps and has proven itself for decades in the mobile and industrial hydraulics markets. Many aspects of the design have been enhanced, and it is characterized by a simple layout with relatively few components. It is exceptionally compact and robust. As a direct result of the special gear profile that Bucher uses, QX pumps achieve extremely low levels of pulsation and noise emission, even at high pressures and speeds. Thanks to the wide range of variants, QX pumps can be used for virtually all applications.

QXEH Internal Gear Pumps

-

Highly dynamic variable-speed pump operation

The QXEH series has been specially developed for pumping duties in highly dynamic servo drives with a reversing function. Using the pinion-shaft technology, high pressures up to 280 bar are developed in a single stage. QXEH pumps are therefore particularly well suited for a wide range of applications in industrial hydraulics where there are high demands on power density, energy efficiency and machine productivity. At the same time, they ensure maximum operational reliability coupled with minimal flow- and pressure-pulsations even during operation with highly dynamic load cycles.

QXEHX Internal Gear Pump

-

Highly dynamic pump operation with very high speeds

The QXEHX series is the successor to the QXEH series, and brings new advantages with it. In addition to optimized hydrodynamic lubrication, the speed range has now been extended up to 5000 rpm. With increased power density and improved operational reliability, this surpasses even the benefits offered by the QXEH series. This makes QXEHX pumps particularly suitable for downsizing the entire drive train, e.g. in injection molding and die casting machines, while at the same time achieving a long service life.

QXV Internal Gear Pumps

-

Pumps Low-viscosity fluids

The QXV series has been developed for use with low-viscosity fluids. QXV pumps have proven particularly successful in applications for pumping kerosene, automotive fuels, paraffin, brake fluids and many other low-viscosity fluids. When required, a multi-stage pressure build-up can be employed to achieve high pressures of up to 250 bar with a viscosity close to 1 mm2/s, and with high efficiencies at the same time.

QXP Internal Gear Pumps

-

Metering function in polyurethane production

The QXP series has been specially developed for metering and conveying the fluids used in polyurethane production. Thanks to the hydrodynamic and hydrostatic bearing support for the ring gear, the pump can be operated with low, as well as with very high, viscosities, and at low speeds. QXP pumps are therefore particularly suitable for variable-speed drives with exacting requirements for precision metering. In addition, the enlarged sealing surfaces enable high efficiencies to be achieved.

QXM Internal Gear Unit

-

Highly dynamic variable-speed multi-quadrant applications

The QXEM series is intended for operation as both a pump and a motor. A symmetrical design makes these units specially suitable for highly dynamic variable-speed multi-quadrant operation. In the industrial hydraulics field, they are therefore particularly appropriate for applications with highly cyclical loading. Thanks to the pinion-shaft technology, pressures up to 250 bar are built up in a single-stage. The direction of rotation can also be reversed in milliseconds, while maximum operational reliability is ensured at all times thanks to optimized hydrodynamic lubrication.

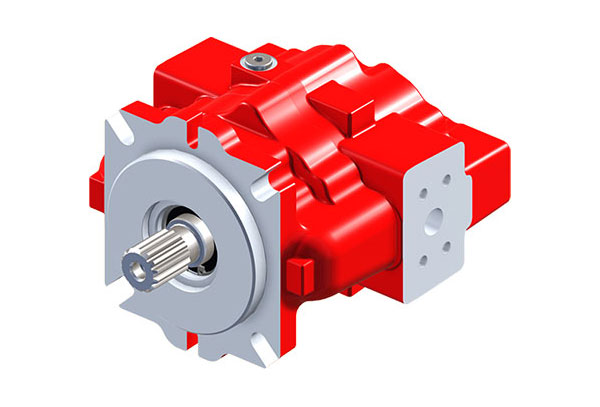

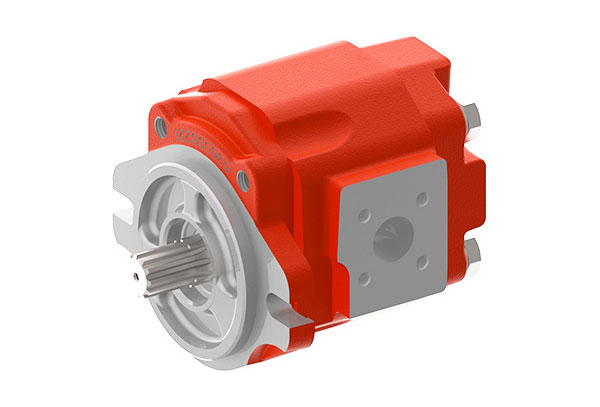

Axial Piston Pumps AX

-

AX is the innovative piston pump series, designed and industrialized to match newest requirements of electric machines with variable speed drives. The AX piston pump is available in different sizes with displacement ranges form 18 to 122 cc and with single, two or four quadrant operation. Various combinations with tandem pumps are possible as well.

- 500 bar maximum pressure

- Silent working

- Low levels of vibration and pulsation

- No minimum speed limits

- Highest overall efficiency in the market, up to 96% total

- Very high mechanical efficiency

- Very high starting torque at 0 rpm, up to 99% nominal value

- Low heating generation

- Compact design, high power density

- Robust and long life

- Machine optimization or downsizing (installed power, battery capacity or cooling system)

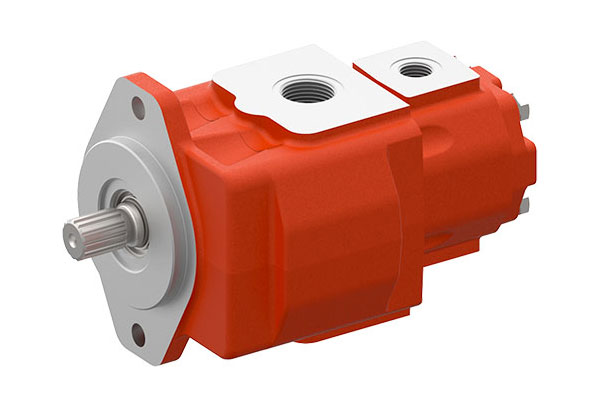

Motors

External Gear Motors APM

-

The essential components of series APM212 external gear motors are an aluminium alloy body and two gearwheels supported by plain bearings. The front flange can be the SAE standard, or the British or German OEM patterns. Particular attention has been focussed on the design of the shaft seal, which is often affected by back-pressures.

- High overall efficiency thanks to optimised hydraulic compensation

- Optimum quality/price ratio

- Customised models can be built for specific applications

- Low maintenance requirements, even in heavy-duty operating conditions

- Various components and accessories are available for radial/axial loads, integral anti-cavitation valve, etc.

Internal Gear Unit QXM-HS

-

The QXM-HS (High Speed) internal-gear motor was developed specifically for use at extremely high speeds. Its first-rate efficiency and extremely low noise levels also make a significant contribution to reducing the costs of both energy and anti-noise measures.

Thanks to the special motor flange, adapted for such applications, and the integral ports for auxiliary functions, the motor can be used in many applications without needing any further modification.

- Particularly suitable for high speeds

- Very low hydraulic and mechanical losses

- Can carry high external radial loads

- Low noise levels

- Cost-savings in system design, assembly and maintenance

Internal Gear Unit QXM-Mobil

-

The QXM-Mobil internal gear motor was specifically developed for use in mobile applications. Its outstanding efficiency and extremely low noise levels also make a significant contribution to reducing the costs of both energy and anti-noise measures. The QXM design principle, featuring an integral outboard bearing, ensures top-class protection against leakage at the shaft seal.

- Excellent torque characteristics even at high speed

- Sealing concept for ultra-high protection against external leakage

- Easy start, no "stick-slip-effect"

- Integral outboard bearing can carry high external loads

Valves and Manifold Block Solutions

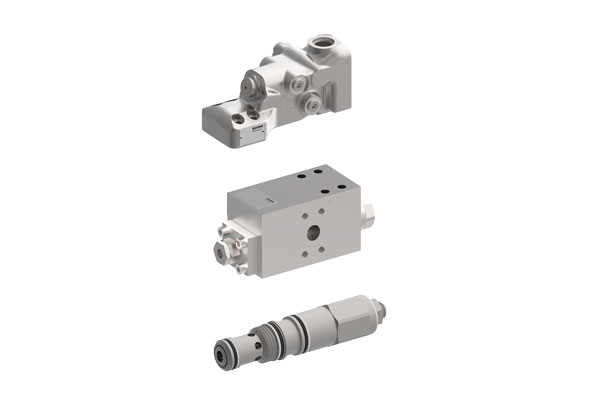

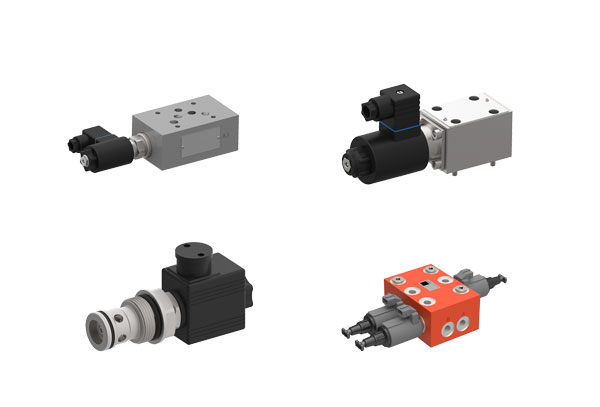

Pressure Functions

Load Holding Valves

Lock valves

Flow Valves

Directional Spool Valves

Directional Seat Valves

Cylinders

-

- Locking Cylinders

- Steering Cylinders

- Brake Cylinders

- Spring Actuators

- Lift/tilt Cylinders

- Gripper Cylinders

- Cylinder for Quick Hitches

- Counterbalances

- Dosing Units

- Cylinders for Tool Changers

- Push-out Cylinders

- Hydraulic Backstop Cylinders

- Steering Lock Cylinders

- Stabiliser Cylinders

- And More

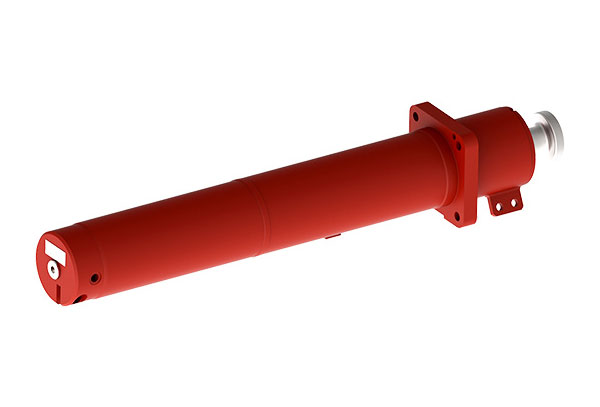

Boom Cylinders

-

Boom cylinders are used for moving the boom and stick. These cylinders are the largest in our product range. They are up to 3500 mm in length when extended and weigh almost 600 kg.

- Very reliable anti-leakage features

- Consistent, temperature-independent, material-friendly damping

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

- Heavy-duty design with smooth radius transitions

- Can be used for high bearing load

Swing-axle Cylinders

-

Swing-axle cylinders are used for locking the swing axle in mobile construction machines. Our swing-axle cylinders feature a strong and stable design with integral lock valves. Thanks to this compact design, complex routing of hydraulic lines is unnecessary. The cylinder can be controlled with just one line.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

- Cylinder can be controlled with just one line

- Wide range of variants available, enabling a rapid response to your requirements

Stabiliser Cylinders

-

Stabiliser cylinders are safety-related components that are subjected to enormous loads. Our cylinders fulfil the exacting requirements relating to functionality, compact design, long service life and, of course, safety-related design.

- Very reliable anti-leakage features

- Consistent, temperature-independent, material-friendly damping

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

Dozer-blade Cylinders

-

The dozer blade is an attachment on mobile excavators. The dozer blade is also used as a support to improve the stability of the excavator. Two hydraulic cylinders bring the blade into the support position. Integral check valves provide leak-free shut-off and offer pipe rupture protection. In a similar manner, when the dozer blade is in the raised position a check valve prevents it from sinking.

- Very reliable anti-leakage features

- Consistent, temperature-independent, material-friendly damping

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

Suspension Cylinders

-

Suspension cylinders are used for hydro-pneumatic chassis suspension on mobile cranes. The extending piston rod is an area that is exposed to many demands, and it is protected by a gaiter.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

Counterweight Cylinders

-

Counterweight cylinders are used to hold the counterweight on mobile cranes. Appropriate process planning ensures the safety standard for this cylinder during manufacturing and assembly.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

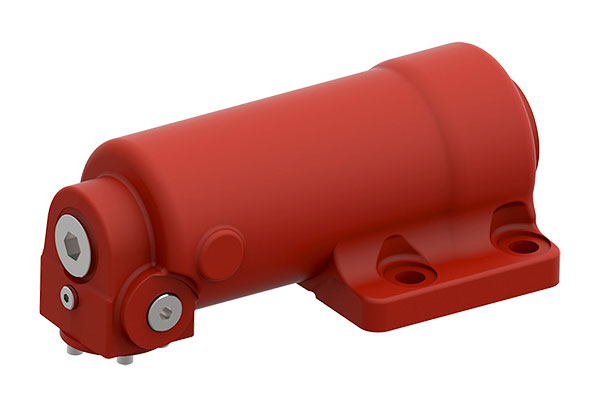

Locking Cylinders

-

Locking or bolting cylinders are safety devices on cranes. They are used to bolt the boom extension or the main boom. The necessary bolts are integrated in the design of our cylinders.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

Steering Cylinders

-

Our steering cylinders are used in the hydraulic steering system of various vehicles such as cargo/material handlers, for example. Thanks to our efficient manufacturing, you get an inexpensive, long-lasting product.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

Brake Cylinders

-

Our brake cylinders are used in the hydraulic brakes of various vehicles, for example as wheel brake cylinders.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

Spring Actuators

-

Our spring actuators are mainly used in parking and service brake systems in a very wide variety of vehicle types. The active work is done by the integral compression spring and the brake is released hydraulically or pneumatically. The compression springs used are fatigue resistant and treated to ensure optimum corrosion protection.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

Lift/tilt Cylinders

-

Lift and tilt cylinders are used to move the bucket in wheel loaders. These cylinders are subjected to high dynamic loads and therefore need to be designed and built for extremely heavy-duty service.

- Very reliable anti-leakage features

- Consistent, temperature-independent, material-friendly damping

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

- Heavy-duty design with smooth radius transitions

Gripper Cylinders

-

Our gripper cylinders are used in two- and multi-tine grabs for material handlers. These cylinders feature the robust and fail-safe design that the harsh application requires. The piston rods used are induction hardened and, where needed, the cylinders are equipped with cushions.

- Very reliable anti-leakage features

- Consistent, temperature-independent, material-friendly damping

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

Cylinder for Quick Hitches

-

Quick-hitch cylinders are incorporated in the steelwork of the attachment-change devices on wheel loaders. They bolt and unbolt the attachment. The heavy-duty design ensures a long service life

- Very reliable anti-leakage features

- Robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

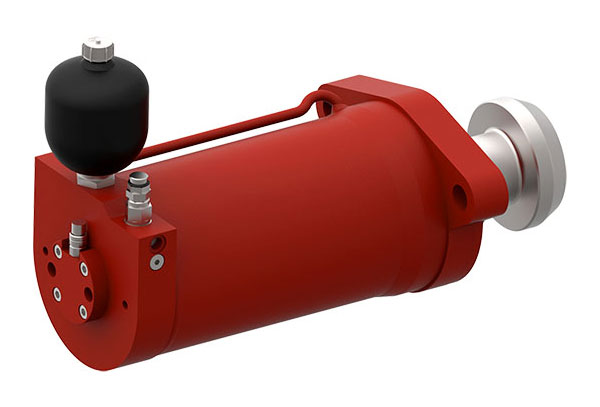

Counterbalances

-

Hydraulic counterbalances are used in industrial robots. The job of the closed system is to counteract the axis load-moment sufficiently that the axis drive is not statically overloaded and can provide maximum torque for the acceleration of the axis. The function of the closed gas volume in the diaphragm accumulator is comparable to that of a mechanical spring.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Long bearing life

- Good cost-effectiveness for the customer

Steering Lock Cylinders

-

Steering lock cylinders are special designs for locking steered axles on construction machines. Our products range from spring actuators with pneumatic override to steering rods with hydraulic unlock for mobile cranes.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

Cylinders for Tool Changers

-

Our tool-changer cylinders are used in modern CNC machine tools. A long service life is essential for this application.

- Very reliable anti-leakage features

- Consistent, temperature-independent, material-friendly damping

- Visually appealing and robust construction

- For use under the harshest conditions

- Good cost-effectiveness for the customer

Stabilizer Cylinders

-

Mobile cranes are usually brought into their working position with four ground stabiliser cylinders. It is important to provide the greatest possible stability. The cylinders must be designed for high loads and shear forces. As is fitting for this application, we use high-strength materials and take care to ensure the greatest precision. The stability of the cylinder is ensured by incorporating leak-free lock valves in the head of the cylinder.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

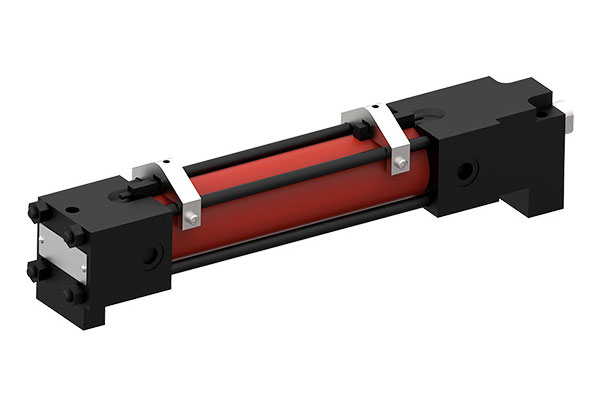

Hydraulic Backstop Cylinders

-

Hydraulic backstop cylinders are used on lattice boom cranes as a hydraulic means for preventing the boom from toppling backwards. In the final position of the jib (almost vertical), the cylinder is forcibly in-stroked and thereby builds up the necessary pressure to push the jib back again. They are therefore Category A safety components. A cylinder failure would result in the crane overturning. To accommodate the enormous mechanical forces, our hydro-storage cylinders are manufactured exclusively from high-strength steels.

- Very reliable anti-leakage features

- Visually appealing and robust construction

- For use under the harshest conditions

- Low-temperature service

- Good cost-effectiveness for the customer

Power Units

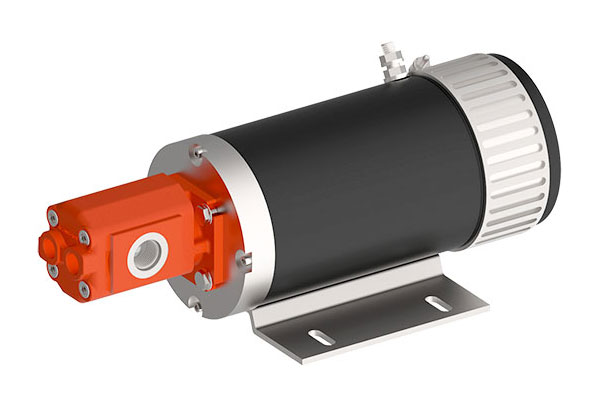

Electro-Pumps ET

-

Bucher Hydraulics electro-pumps series ET are equipped with modern external gear pumps - AP05, AP100 and AP212 series together with efficient DC or AC electro-motors. These electro-pumps offer high volumetric efficiency and mechanical characteristics, good balancing and therefore reduced noise and vibration.

In Bucher Hydraulics ET project development, simplified architectures and reduced dimensions were the main goals to be achieved. For this purpose the housings of these pumps can be equipped with valves and hydraulics circuits.

- Low noise emission

- Wide range of displacements and electric motor powers

- Hydraulic circuit simplification.

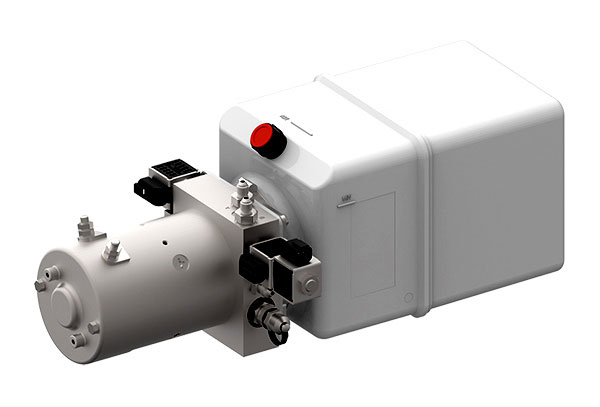

Hydraulic Power Packs, Series UP

-

These units feature a high degree of accuracy and have a wide application range. Bucher Hydraulics power packs are designed according an integrated modular system of valves for the various functions.

This highlights the equipment’s compact nature, the foundation of its high performance level.

The basic components of the power packs are:

- a manifold block with cavities for various types of valves

- a very quiet, high-efficiency gear pump

- an electric motor (DC or AC)

- a reservoir (plastic or steel)

- several optional accessories

Hydraulic Power Packs, M-Series

-

DC power units have a lot of features and include:

- Compact designs

- Integrated and manifolded valve circuits

- Flow: 0.40 - 8.0 GPM (1,5 - 30 l/min)

- Pressures to 4000 psi (280 bar)

We manufacture AC hydraulic power units for commercial and industrial applications. We offer a wide range of motors, reservoirs, manifolds and valve options. In addition to our standard products we are willing and capable of manufacturing AC Power Units to your exact specifications.

Hydraulic Power Packs, Series MT&T

-

We design and manufacture series MT & T AC hydraulic power units for industrial and commercial applications. These power units can be configured to create common circuits or systems that incorporate specialized and custom manifold designs.

- Flow rates from 0.25 gpm to 15 gpm, pressures to 4000 psi

- Electric motors from 0.5 Hp to 20 Hp in several voltages and frequencies

- Pressure balanced, pressure compensated, and fixed clearance pump options

- Single acting, double acting, and multi-station circuit options

- D03 & D05 directional valves and stack mount control modules

- Conduit box, DIN style, and other coil options

- Air / oil and water / oil type heat exchangers

- Return line and pressure filter options

Application Power Packs, Series YBZ

Smart Power Packs

-

EU regulations for road vehicles are becoming increasingly stringent. To reduce CO2 emissions, mechanical V-belts or power take-offs may not exist on future commercial vehicles. Energy-efficient electrohydraulic systems provide an alternative. The hydraulics specialist Bucher Hydraulics offers just such a solution with its latest range of Smart PowerPacks.

The Smart PowerPack "L" is a modular system for the power range of 15 - 60 kW and voltages above 400 VDC. In addition to power electronics in various sizes, the modular system also includes several pump series from Bucher Hydraulics, offering great flexibility to meet a wide range of applications. Options also include a closed cooling system for the power electronics

Bucher Hydraulics’ Smart PowerPack S (SPP S) is an intelligent electrified power unit. This PowerPack offers greater controls and efficiencies over traditionally gas-powered hydraulic systems.The SPP S is equipped with an electronically variable pressure-balanced hydraulic pump, a single power input connection, and an integrated Negative Bypass Control cartridge valve.With these technologies, a global footprint, and Bucher’s one-of-a-kind service, everything is in place to develop the right solution for your needs.

Electronics

-

The use of electric drives continually opens up opportunities for future-oriented, ecological and economical vehicle concepts. Bucher Hydraulics Mobile Drives has been developing and producing energy-efficient and environmentally friendly drive technology for electric and hybrid vehicles since 1995.

Power Electronics

Analog Electronic Control Systems

-

Proportional Amplifier ELSK 103

- With one power output and two ON / OFF outputs

- To drive one proportional valve and one ON / OFF directional valve

- To drive two proportional solenoids and one ON / OFF directional valve

- 1-channel for proportional valves with one solenoid

- With one control signal input andone power output

Proportional Amplifier ELSK 106- With one power output, switch ON / OFF and ramp

- To drive one proportional solenoid, installed for example in instrument panel

Digital Electronic Control Systems

-

Modern vehicles and mobile machines require powerful control electronics, to cope with all kinds of demands.

We at Bucher Hydraulics have made it our business to provide the right controller for every system requirement. You have the possibility to choose from our wide product range "EBM, ELMR & EBH", if your desired configuration is not shown, please contact our sales team.

In cooperation, we will work out the perfect component and system solution.

Input Devices Electrical

-

Modern vehicles and mobile machines require powerful electronic components, to meet all kinds of requirements.

At Bucher Hydraulics, we have made it our business to always be able to provide the right to provide the right input device (joystick) for every system requirement. You have the possibility to choose from our wide product range "FGE, FSE & FCE", if your desired configuration is not shown, please contact our sales team.

In cooperation, we will work out the perfect component and system solution.

Universal Power Amplifiers

-

EVM-UIH-…

- Universal power amplifier for proportional valves

- Various voltage and current signals

- Compact housing for top hat rail mounting

- Adjustment via potentiometer (MIN, MAX, RAMP and PWM frequency)

- Universal power amplifier with USB interface for proportional valves

- Analog or digital inputs

- Compact housing for top hat rail mounting

- Simple and application-oriented parameterization via PS1 software

- Universal power amplifier for proportional valves in a plug housing according to DIN EN 175 301-803-A

- Can also be used as a soft-switch amplifier (smooth switching on and off)

- Free scaling of the input signal

- Programmable via USB/LIN bus using PS1 software, or via integrated pushbuttons and a selector switch (functionally reduced against the USB/LIN bus)

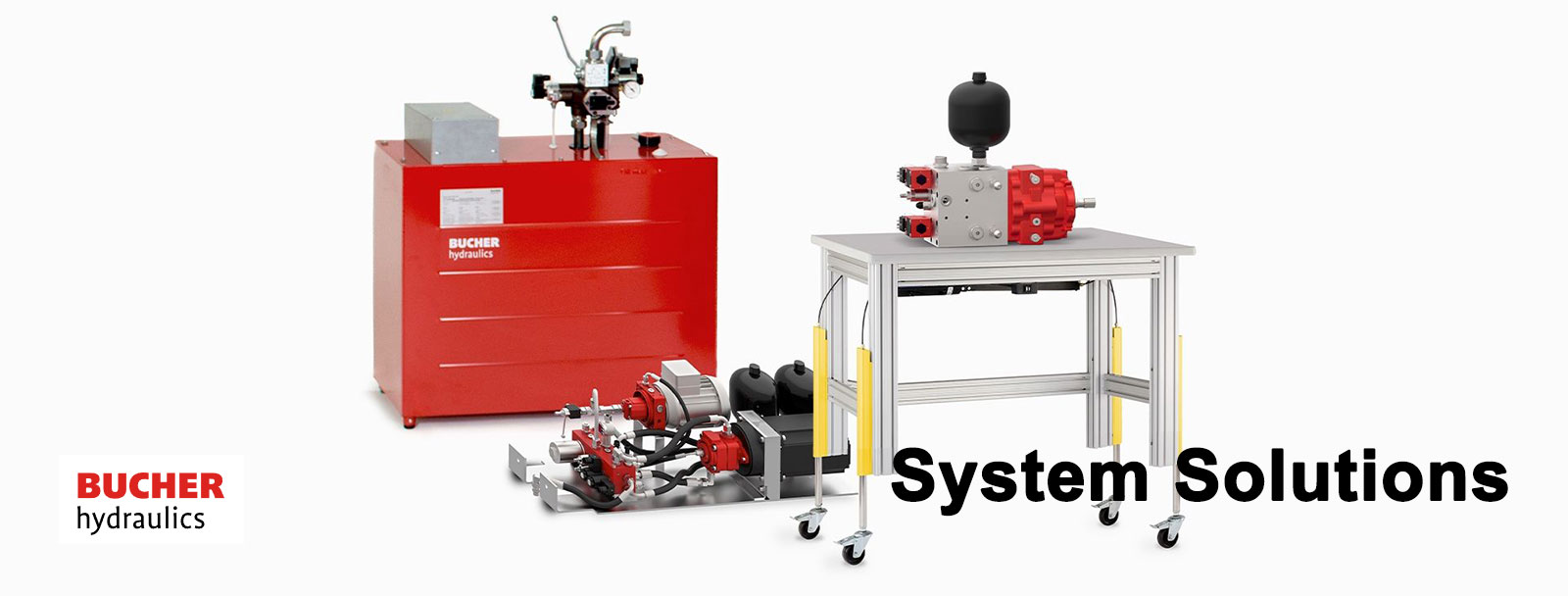

System Solutions

-

We are able to combine our products in various ways and to enhance functionality through appropriate software.

Subsystem solutions are created by selecting individual components from the product portfolio and then integrating them into the overall machine system.

Elevator Hydraulics

-

Hydraulic elevator drive systems from Bucher Hydraulics have enjoyed success over decades for various reasons: flexibility in the design phase, simple assembly, low-maintenance technology, long service life and the latest valve technology.

Safety- Emergency evacuation procedures are very simple and completely safe

- Secure use in earthquake zones

- Safety during service and repair work, since there is no moving counterweight

Dyna-Lift®

-

Ergonomic and height-adjustable work benches are fast becoming standard in the industry. Dyna-Lift® from Bucher Hydraulics offers a variety of applications and can be adapted to customer-specific requirements.

Dyna-Lift® Benefits- OEM and Retrofit Kits Install Quickly

- Improve Productivity

- Increase Comfort

- Comply with ADA & OSHA guidelines

- Smooth and Quiet Operation

- Units Shipped Fully Charged and Ready To Install

Hydraulic Drives for High-voltage Switch Gear

-

As the only independent supplier, we offer a wide range of customized hydraulic solutions for high-voltage circuit breaker applications to 1,200 kV. Bucher Hydraulics solutions are based on well proven technology, which has been in operation in high-voltage circuit breakers for 50 years all over the world.

For 50 years, Bucher Hydraulics has been developing and manufacturing:

- hydraulic valves

- drive modules

- hydraulic drive systems

for high-voltage circuit breaker applications.

Servo-Hydraulic Axes - Helax

-

Closed servo-hydraulic axes combine the advantages of an electric servo drive with those of a robust, powerful and efficient hydraulic transmission.

- "Plug-and-Run": Simple and fast commissioning

- "Power on Demand": Up to 70% energy savings

- High performance and wear resistance

- Elimination of the classic central hydraulic unit

- Low noise operation

- Flexible, modular design enables cost-effective adaptation to customer requirements

- Optional software / intelligence on subsystem control

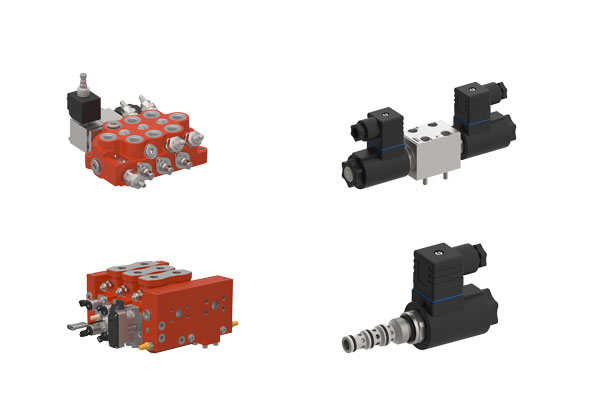

Manifold Blocks

-

System manifold blocks

In Systems Engineering, project methods are used to design client-specific solutions in the form of manifold control blocks. These are mainly used in mobile equipment for agriculture and municipal services, in road-building and construction machines, as well as in renewable energy systems such as wind turbines or solar power plants. The manifold blocks, in steel or aluminium design, offer maximum functionality in a very small space.

Monoblock designsValve combinations in monoblock construction consist of a single, heavy-duty, cast body that is designed for high working pressures. Thanks to the wide selections of spools, types of operators, types of hand levers, and auxiliary valves such as secondary pressure relief, anti-cavitation make-up, pressure control, flow control and check, these are particularly suited for use in complex applications where small installation dimensions are vitally important.

Specific applications

- Description

Custom Solutions

-

Custom solutions are often based on new developments and require close cooperation between the development department and the customer. This calls for direct contact between the customer and the Competence Center.

PistenBully Example: Expert Hydraulics

The red snow groomers from Kässbohrer are a familiar sight in ski resorts. Under the hood are nine of our LCV series valves.

Our proportional, ultra-responsive hydraulic control system in the PistenBully implements the driver's commands quickly and accurately, no matter how heavy the load of snow in front of the plow blade. Development covered the entire hydraulic system, consisting of a 12-way plow blade, rear cutter, winch and fan control.

Drivers and service technicians set the requirements for the development of this new subsystem. The PistenBully 600 shows just what it is capable of in very demanding, extreme weather conditions.