- Offer Profile

-

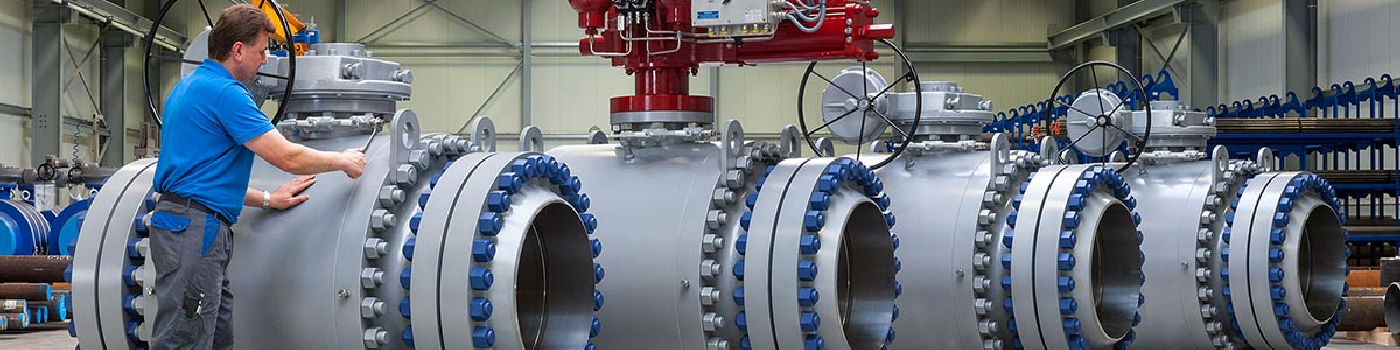

Welcome to BÖHMER –

one of the world’s leading manufacturers of ball valves.From a careful coordination of design, technology and materials we create the optimum ball valve for your application.

For more than 60 years, Böhmer has been synonymous with safety and absolute reliability. Our strength: Ball valves from DN3 to DN 1400 (1/8 – 56 inch) for your individual application.

Böhmer valves are used successfully in all sectors of industry as well as in the oil and gas industry. Likewise in pipelines and district heating networks.

BÖHMER BALL VALVES

-

DURABLE - RELIABLE - SAFE

Böhmer offers a wide product portfolio of ball valves for a wide range of application conditions and purposes.

Our products are suitable for use anywhere where liquid, solid or gaseous media have to be shut off securely. We have specially selected model series constantly available so that we can meet demands appropriately at all times.

SYSTEM LINE

-

QUALITY IN SERIES

It is not easy to fit our product line into a catalogue. The vast number of tested designs and combinations of materials make Böhmer ball valves suitable for many diverse applications. The wide range of our immediately available model series is highly appreciated worldwide. Our products are suitable for use anywhere where liquid, solid or gaseous media have to be shut off securely. We have specially selected model series constantly available so that we can meet demands appropriately at all times.

Our products can be used wherever it is necessary to ensure safely controlled flow of liquid, gaseous or solid substances. Irrespective of whether threaded, flanged or welded, low or high pressure: We meet your demands with the appropriate valve.

FULLY-WELDED BALL VALVES

-

ALL-ROUND DEPENDABILITY

Ball valves are often subjected to extreme conditions, especially when used in pipelines.

To withstand even the highest loads, Böhmer ball valves are therefore welded through the entire cross-section. Thus, weakening of the construction, for example by stress corrosion cracking on the weld seams, is actively counteracted.

Böhmer is one of the few manufacturers that actually welds the weld seams of its fittings over the entire cross-section using a complex process.

Various testing procedures are used to confirm the tightness of the entire ball valve. Furthermore, weld seams undergo visual, magnet particle, ultrasonic and if requested radiographic testing.

And we do not rely only on ourselves. We contract external institutions to confirm the perfection of our products. The weld seams thus comply with the legal regulations for the construction of pipelines, reservoirs, tanks and containers.

- Sizes: DN 3 DN 1400 1/8 56 Inch

- Pressures: PN 10 to PN 800 ANSI Class 150 to 2500

- Temperatures: -180° to +650° C -292° to +1200° F

FEATURE OF OUR FULLY-WELDED BALL VALVES

Reliable

-

We spend a great deal of time and money and make considerable effort to ensure that the weld seams can withstand extreme conditions. That is the reason why our full-welded ball valves operate reliably even under high pressure. The precision design and manufacturing of all components enables safe operation at all times

Resistant

-

Our fully-welded ball valves offer almost no surfaces liable to corrosion. Water, dust and sand cannot penetrate the ball valve and can therefore not settle in any cracks. Corrosive influences from the outside are thus actively reduced and the service life of our ball valves is increased significantly.

Fire-Safe

-

Fire-Safe ball valves have been specially designed for use in critical areas. Thanks to the special design and the particularly resistant materials, Böhmer Fire-Safe ball valves retain their full functional reliability even at temperatures above +650 ° C.

Economical

-

In addition to their robust design in respect to internal and external influences, our ball valves provide considerable savings potential for transporting, installing and servicing ball valves. Our ball valves are thus an economical solution, especially in the long term.

Certified

-

All welding seams are carried out by our trained welding specialists and checked by our welding engineers. Our company is process-tested according to DIN EN ISO 3834-3729 and AD-HP 2/1 (TÜV)

Product Catalogue

-

Our regular customers are demanding and therefore appreciate our fi rst-class service. They have relied on the quality and reliability of BÖHMER ball valves for decades. We are proud to be recognized as one of the leading valve manufacturers.

DN 25 - 400, ANSI Class 150 | PN 16

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2; ASTM A106/P235 GH-TC1; P250 GH

- Ball: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 450 - 1400, ANSI Class 150 | PN 16

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2; P250 GH

- Ball: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 25 - 400, ANSI Class 300 | PN 25/40

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2; ASTM A106/P235 GH-TC1; P250 GH

- Ball: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 450 - 1400, ANSI Class 300 | PN 25/40

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2

- Ball: ASTM A350 LF2; ASTM A105; ASTM A182; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTMA350 LF2; ASTM A105; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 25 - 400, ANSI Class 600 | PN 100

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2

- Ball: ASTM A350 LF2; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 450 - 1400, ANSI Class 600 | PN 100

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTMA 350 LF2; ASTM A694

- Ball: ASTM A350 LF2; ASTMA694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; HNBR

DN 25 - 400, ANSI Class 900 | PN 160

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2; ASTM A694

- Ball: ASTM A350 LF2; ASTM A182; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A694; ASTM A182; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 450 - 1200, ANSI Class 900 | PN 160

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2; ASTM A694

- Ball: ASTM A350 LF2; ASTM A182; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A694; ASTM A182; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; HNBR

DN 25 - 900, ANSI Class 1500 / PN 250

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2; ASTM A694

- Ball: ASTM A350 LF2; ASTM A182; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A694; ASTM A182; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE;PTFE-filled; HNBR

DN 25 - 300, ANSI Class 2500 / PN 420

-

Standard Materials:

- Body: TSTE 355N/P355 NL1; ASTM A350 LF2; ASTM A694

- Ball: ASTM A350 LF2; ASTM A182; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A694; ASTM A182; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; HNBR

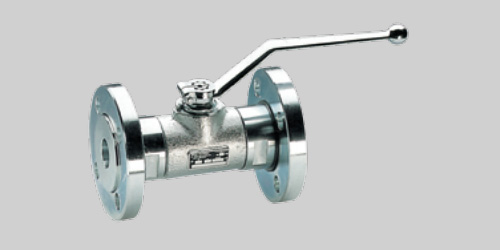

SPLIT-BODY BALL VALVES

-

EXPERTS FOR AGRESSIVE FLUIDS

Split body ball valves up to a nominal diameter of 56 inch are a integral component part of the Böhmer product line. Ball valves of this design are well suited for extremely abrasive and corrosive fluids.

Böhmer ball valves with two-piece or three-piece bodies are designed for easy maintenance thanks to their continually improved design. Components or complete shutdown units can be replaced easily and efficiently.

- Sizes: DN 3 DN 1400 1/8 56 Inch

- Pressures: PN 10 to PN 800 ANSI Class 150 to 2500

- Temperatures: -180° to +650° C -292° to +1200° F

FEATURES OF OUR SPLIT-BODY BALL VALVES

Easy to maintain

-

Böhmer split body ball valves were designed for fast and uncomplicated maintenance. High-precision production makes it possible to replace components without any difficulty. Even complete units can be replaced efficiently and economically.

Rugged

-

Our ball valves are designed for maximum load capacity. Thanks to the ingenious construction, which reliably absorbs the tensile and compressive forces in the housing, our bolted ball valves are suitable for use in applications like transport pipelines. The use of sturdy materials guarantees a long service life, even when using heavy wearing fluids or aggressive media.

Flexible

-

Split ball valves from Böhmer are available with numerous options, such as trunnion mounted balls, spring-loaded seat rings or Double Block and Bleed function. The Valves can be equipped for a wide variety of applications and high pressure levels. Also retrofits to qualify already installed taps for changing conditions of use are possible.

Product Catalogue

- The standards that our ball valves now fulfill are the highest on the market. But we go a step further. Our team of highly qualified engineers and designers takes special care to further develop our ball valves with maximum quality of design and material as well as cost-effectiveness.

DN 25 - 350, ANSI Class 150 | PN 16

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH; ASTM A216 WCB/GS C25

- Ball: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 400 - 900, ANSI Class 150 | PN 16

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH

- Ball: ASTM A350 LF2; ASTM A105; ASTM A182 ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A105; ASTM A182 ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; HNBR

DN 25 - 350, ANSI Class 300 | PN 25/40

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH; ASTM A216 WCB/GS C25

- Ball: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 400 - 900, ANSI Class 300 | PN 25/40

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH

- Ball: ASTM A350 LF2; ASTM A105; ASTM A182 ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A105; ASTM A182 ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; HNBR

DN 25 - 350, ANSI Class 600 | PN 100

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH; ASTM A694

- Ball: ASTM A350 LF2; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 400 - 900, ANSI Class 600 | PN 100

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH; ASTM A694

- Ball: ASTM A350 LF2; ASTM A105; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A105; ASTM A694; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; HNBR

DN 25 - 350, ANSI Class 900 | PN 160

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH

- Ball: ASTM A350 LF2; ASTM A105; ASTM A182; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A105; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBRStandard Materials:

DN 400 - 900, ANSI Class 900 | PN 160

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH; ASTM A694

- Ball: ASTM A350 LF2; ASTM A105; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A105; ASTM A694; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; HNBR

DN 25 - 150, ANSI Class 1500 / PN 250

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH

- Ball: ASTM A350 LF2; ASTM A182; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; PTFE-filled; HNBR

DN 200 - 400, ANSI Class 1500 / PN 250

-

Standard Materials:

- Body: ASTM A350 LF2; TSTE 355/P355 NL1; ASTM A105; P250 GH; ASTM A694

- Ball: ASTM A350 LF2; ASTM A182; ASTM A694; ENP or hard chrome; stainless steel on request

- Seat Rings: ASTM A350 LF2; ASTM A182; ASTM A694; ENP or hard chrome; stainless steel on request

- O-Rings: FPM; EPDM; NBR; HNBR

- Seat Insert: FPM; PTFE; HNBR

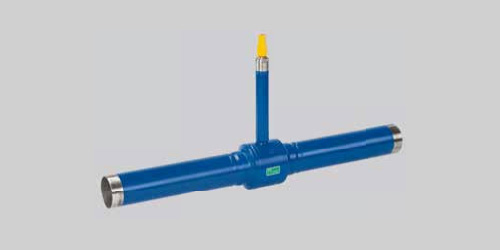

BURIED BALL VALVES

-

HIDDEN CHAMPIONS

In urban areas, densely populated industrial parks and at all places where every square meter counts and where media in underground pipe systems must be reliably shut off, our buried ball valves are in use.

Buried pipes are complex in construction and are also subject to strict regulations to protect the environment. Therefore, it must be ensured that all components remain emission-free and reliable over long periods of time. Böhmer ball valves are manufactured with experience, great know-how and high quality standards. Thanks to these ingredients, Böhmer ball valves are ideal for use in underground pipelines.

Our valves are characterized by absolute freedom from leaks, extreme longevity and low maintenance requirements. This is ensured, among other things, by the construction with fully welded seams and redundant sealing systems, which ensure that corrosive influences remain outside and the medium stays inside.

The quality of our products is backed up by all necessary certificates and the fulfillment of all standards. In this way, we simultaneously protect the environment and the interests of our customers with our products.

- Sizes: DN 3 DN 1400 1/8 56 Inch

- Pressures: PN 10 to PN 800 ANSI Class 150 to 2500

- Temperatures: -180° to +650° C -292° to +1200° F

Options

- Vent / Drain-connections

- Test connections

- Position indicators

- Actuators

- Sealant injection pipes

- Pressure-relieving extensions

FEATURES OF OUR BURIED BALL VALVES

Reliable

-

We spend a great deal of time and money and make considerable effort to ensure that the weld seams can withstand extreme conditions. That is the reason why our full-welded ball valves operate reliably even under high pressure. The precision design and manufacturing of all components enables safe operation at all times.

Resistant

-

Our fully-welded ball valves offer almost no surfaces liable to corrosion. Water, dust and sand cannot penetrate the ball valve and can therefore not settle in any cracks. Corrosive influences from the outside are thus actively reduced and the service life of our ball valves is increased significantly.

Certified

-

All welding seams are carried out by our trained welding specialists and checked by our welding engineers. Our company is process-tested according to DIN EN ISO 3834-3729 and AD-HP 2/1 (TÜV)

Product Catalogue

-

Our regular customers are demanding and therefore appreciate our fi rst-class service. They have relied on the quality and reliability of BÖHMER ball valves for decades. We are proud to be recognized as one of the leading valve manufacturers.

BBF/KSF-V-HE, DN 20-125, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-V-HE, DN 150-300, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-V-HE, DN 350-1200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: up to DN 400: Stainless Steel

from DN 450: Steel, chemically nickel plated (ENP) - Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-R-HE, DN 25-150, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-R-HE, DN 200-400, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-R, DN 450-1200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: up to DN 500: Stainless Steel from DN 600: Steel, chemicallynickel plated (ENP)

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/ELF/ESF-V-HE, DN 25-80, PN 25

-

Standard materials:

- Body: Stainless Steel 1.4581

- Weld end: Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/EMG/ESF-V-HE, DN 25-50, PN 40

-

Standard materials:

- Body: Stainless Steel 1.4581

- Weld end: Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- Sealing plug: Stainless Steel

- operating temperature: up to +150 °C

BBF/KSF-V-HE, DN 20-200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-R-HE, DN 20-200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-V-HE, DN 20-100, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-V-HS, DN 10-200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-V-HS, DN 150-1200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: up to DN 400: Stainless Steel from DN 450: Steel, chemically nickel plated (ENP)

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-R-HS, DN 15-250, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-R-HS, DN 200-1200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: up to DN 500: Stainless Steel from DN 600: Steel, chemically nickel plated (ENP)

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/FSK-V-HS, DN 32-200, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/FSK-V-HS, DN 150-1000, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: up to DN 400: Stainless Steel from DN 450: Steel, chemically nickel plated (ENP)

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/FSK-R-HS, DN 32-250, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/FSK-R-HS, DN 200-1000, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: up to DN 500: Stainless Steel from DN 600: Steel, chemically nickel plated (ENP)

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/FSL-V-HS, DN 10-100, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBDF/FSL/KSF-V-HS | BBF/FSK/KSF-V-HS, DN 15-150, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/FSL/KSF-R-HS | BBF/FSK/KSF-R-HS, DN 25-50, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSG/KSF-V-HS, DN16-50, PN 25

-

Standard materials:

- Body: Forged Steel / Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- Sealing cap: brass

- operating temperature: up to +150 °C

BBF/KSG-V-HS, DN 10-50, PN 25

-

Standard materials:

- Body: Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BBF/KSF-V-HS, DN 20-100, PN 25

-

Standard materials:

- Body: Steel

- Ball: Stainless Steel

- Stem: Stainless Steel

- Ball seals: PTFE

- Stem seals: EPDM

- operating temperature: up to +150 °C

BURIED BALL VALVES

-

HIDDEN CHAMPIONS

In urban areas, densely populated industrial parks and at all places where every square meter counts and where media in underground pipe systems must be reliably shut off, our buried ball valves are in use.

Buried pipes are complex in construction and are also subject to strict regulations to protect the environment. Therefore, it must be ensured that all components remain emission-free and reliable over long periods of time. Böhmer ball valves are manufactured with experience, great know-how and high quality standards. Thanks to these ingredients, Böhmer ball valves are ideal for use in underground pipelines.

Our valves are characterized by absolute freedom from leaks, extreme longevity and low maintenance requirements. This is ensured, among other things, by the construction with fully welded seams and redundant sealing systems, which ensure that corrosive influences remain outside and the medium stays inside.

The quality of our products is backed up by all necessary certificates and the fulfillment of all standards. In this way, we simultaneously protect the environment and the interests of our customers with our products.

SUBSEA BALL VALVES

-

MAXIMUM SAFETY – EVEN IN DEEP SEA

Underwater pipelines run at the bottom of the sea and allow a constant transport of oil and gas from the production site to the industry. The direct connection and the saving of transhipment (for example in tankers) reduces time and costs.

The temperature and pressure conditions at the seafloor as well as the increased requirements for the protection of the sea are particular challenges for pipes and fittings.

Fully welded Subsea ball valves from Böhmer are characterized by their high load capacity, freedom from leakage and maintenance-free operation. Thanks to the fully welded seams and the robust construction, they withstand extreme tensile forces. The built-in materials make them insensitive to corrosion. Thanks to these features, Böhmer ball valves are among the few valves with API6D and API6DSS certification.

For your application we deliver the ball valves with welding ends or flanges. The ball valves can be selectively switched by means of a T-lever, ROV compatible gearboxes or hydraulically.

MULTI-WAY BALL VALVES

-

VERSATILE IN EVERY WAY

Multi-way ball valves from Böhmer, with three or four passages up to DN 100, are versatile in the truest sense of the word.

Our valves are used for a variety of purposes. In shipping, for example, they ensure the smooth switching of alternative fuels. At the production of fine chemicals, on the other hand, our ball valves are used within the production lines of the pharmaceutical industry or cosmetics industry. The precise end stops of the Böhmer multi-way ball valves guarantee a safe shut-off or a clear switching between the different passes.

The design of the balls and the tried-and-tested sealing technology prevent uncontrolled mixing of the connected media. We offer a wide range of multi-way ball valves with T, L, and X drilled balls, various material and seal configurations as well as with threads or flange connections.

APPLICATIONS

-

EVERYWHERE YOU NEED US

Ball valves from Böhmer can be found around the globe and in almost every branch of industry.

The performance of our ball valves can best be summarized as follows: Our ball valves of DN 3 DN 1400 are used wherever rapid and safe shut-off is required. We have the right solution for almost any medium: Whether gases or liquids, suspensions or pure solids our team of experts ensures that you have a tailor-made and proven solution.

-

District Energy

-

Böhmer ball valves prove their reliability in daily operation in aboveground and underground district heating networks, as well as in transfer stations.

Subsea

-

For subsea applications, we manufacture valves according to the specifications and permits of our customers and also according to API 6D SS.

Natural Gas

-

Böhmer ball valves are also used in gas stores where safety is particularly important, e.g. in SAE safety shut down units

Pipelines

-

Böhmer ball valves ensure safe operation of transportation and distribution pipelines for gas and oil all over the world.

Petrochemical

-

Our ball valves operate reliably in pipelines (ethylene, propylene, propane, and butane) but also in the control of cracking processes

On- & Offshore

-

Böhmer products are in use on onshore and offshore platforms throughout the world.

Ship & Shipyards

-

Our products are used extensively in freighter and tanker pipelines. But Böhmer ball valves are also used in shipyards, for example, at terminals for welding equipment.

construction vehicles

-

Böhmer ball valves ensure reliable functioning of hydraulic and pneumatic machine components in construction and industry.

vehicle construction

-

Böhmer ball valves are used in the production lines and paint shops of vehicle manufacturers worldwide.

Power plants

-

Böhmer ball valves are in operation in all relevant sectors (gas, oil, district heating/steam, special gasses and fluid solid substances)

Crude oil

-

Due to their high safety and pressure resistance, our products are ideal for the extraction and transport of crude oil.

Solids

-

Böhmer is the specialist for hardship cases, such as the passage of overburden, viscous concrete, powdery materials, granules or pellets