KEB

- Offer Profile

- The quality and performance

of KEB solutions is continuously proving itself in the equipment and systems

of our customers. We create movement. And we are also always on the move.

Always with the target in sight: To create the optimum drive and control

technology solution that is tailored to your requirements. Trust is not a

gift, but rather the result of hard word, ambition and reliability - "Made

in Germany".

Product Portfolio

Automation & Controls

- KEB COMBICONTROL C6 - the automation platform

dedicated to dynamic transmission applications in machine and plant

engineering. The KEB product portfolio is scalable and tailored to your

requirements, offering a wide platform for all kind of automation jobs.

Hardware - with the embedded control C6-COMPACT and the IPC-based control series C6-HMI, C6-VISU, C6-ECON and C6-PERFORM KEB offers different controller platforms with scalable processing power for decentralized architecture or central machine control.

Software - KEB offers automation tools for to handle effective control jobs, high-class visualization and cost optimized remote maintenance. KEB COMBICONTROL C6

- KEB COMBICONTROL C6 is the automation platform that

focuses on dynamic and drive-oriented applications with motion control in

the machine and equipment building sector. Scalable and tailored to your

requirements, this control technology, which was designed with embedded and

IPC versions, offers a broad platform for a variety of tasks.

The KEB COMBIVIS studio 6 automation tool is the new software environment, freely programmable pursuant IEC 61131-3.

C6 COMPACT

- C6 COMPACT is a compact control whose functionality and

performance are designed to coordinate and synchronise the motion processes

of multiple axes.

The integrated EtherCAT Master provides a rapid real-time bus system that in combination with computing performance and software functionalities represents a truly powerful and cost-effective system.

Equipped with all possible options, the C6 COMPACT can assume control of your entire system or merely look after the motion processes of your application as a subordinate system with numerous interfaces such as Profibus, CAN, Interbus and Ethernet.

This efficient concept without a superimposed operating system uses the entire computing performance for the application of Soft PLC and motion tasks and allows for cycle times starting at 1 ms. The C6 COMPACT is full of possibilities, and offers a cost-effective system for solving your requirements notwithstanding its flexibility and high performance.

C6 HMI - Embedded Panel PC

- The C6 HMI was designed using the latest graphic and

communication technologies typically found in modern day smart devices such

as tablets and smartphones. As a result, the C6 HMI provides the user a high

quality Human Machine Interface experience while providing the user a

competitive "right-price" edge.

"Right-price" does not mean the C6 HMI wasn’t designed for an industrial environment! The front bezel is aluminum and meets IP66/Nema 4X Indoor ratings. There are no moving parts: no fans, no hard drives. A fanless cooling design and flash mass storage maximize reliability.

C6 VISU

- The C6 VISU series has been prepared for the specific

requirements that apply to visualisation tasks, and it forms the

human-machine interface in a variety of applications.

An attractive design, high-quality materials combined with extensive functionality at a reasonable cost.

In combination with realtime software the IPC serves typical control and motion tasks in smaller machines.

C6 ECON

- The C6 ECON was built with the power for processing

tasks. On-board RAM provides a good balance between cost and visualisation

performance. Designed for economy and built with an Intel chip set, the user

can easily use the C6 ECON as a panel PC for both a Human machine interface

(HMI) and for motion control.

To maximize up-time, the C6 ECON was designed as a fanless system. Data storage is achieved with hardware options such as Compact Flash (CF), hard drives or newer solid-state drives.

C6 PERFORM

- The C6 PERFORM is KEB’s top end of product performance. Based on the Intel® Celeron Dual Core and Core® 2 Duo processors, the user can expect high performance visualisation. With the on-board processing power, the C6 PERFORM can easily be the Human Machine Interface AND the machine motion control.

C6 MONITOR

- The C6 MONITOR series complements the BOX PCs with an

industry monitor for visualisation and operation of the application.

Sizes based on latest technologies complement the program offered by KEB appealing design and various monitor sizes.

A front USB port, and two more on the back with integrated HUB belong to the standard equipment.

C6 REMOTE I/O

- Analog or digital - the acceptance and output of signals in the periphery of a system requires the decentralisation of joining technology and a suitable medium of signal transmission to central intelligence. The KEB REMOTE I/O system is based on the economically optimal Ethernet hardware and transfers the proven characteristics of real-time communication into each element of the input/output level using the EtherCAT protocol standard.

Automation Tools

COMBIVIS studio 6

- KEB COMBIVIS studio 6 combines drive parametrisation,

IEC 61131-3 application development and HMI designer into a flexible tool

that allows for highly efficient and customised application designs in the

automation technology sector.

KEB COMBIVIS studio 6 is the entry-level option for programming pursuant to the international standard IEC 61131-3, which can be used for the independent and future-proof creation of your source code using a flexible selection of programming languages. Benefit from the comfortable „SmartCoding" programming tools for declaration, error diagnostic, debugging and on-line data analysis purposes.

COMBIVIS studio HMI

- KEB COMBIVIS studio HMI is a powerful extension of the

automation platform.

The special feature of this platform is the universality and portability of visualisation projects, which can be used both with WinCE as well as Win32 systems, and also support automatic scaling for different display sizes.

Two run-time versions, BASIC and ADVANCED, are available for the WinCE operating system. The Win32 operating system comes in three versions - BASIC, PRO and ADVANCED - which guarantee an optimum functional scope for any system.

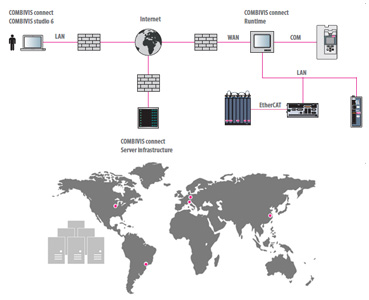

COMBIVIS connect

- KEB COMBIVIS connect is the innovative software solution

for remote access and maintenance of computer based industrial machines with

Windows operating systems (WinCE and Win32 / 64 environment).

- COMBIVIS connect Client: application on the office computer (supervisor)

- COMBIVIS connect Runtime: software component on the remote computer

Frequency inverters

- KEB COMBIVERT - Digital drive technology with 15 years of production experience

The program for controlled and regulated applications for synchronous and asynchronous motor technology in demanding applications up to 900 kW. Innovation and continuity form the foundation for our powerful series, for which logistics and production have been configured so as to ensure the long-term and parallel availability of current and new product generations:

COMBIVERT F5

- Using the "as much as required" principle, we provide

graduated power ranges that offer features and equipment that have been

optimised for each application.

In this context, integrated operation, identical handling and the same tools assist with the practical work for installation, start-up and service processes.

The drive generation KEB COMBIVERT F5 offers the following features:

• F5-Basic

• F5-Compact

• F5-Multi

Power range 0,37 ... 900 kW

COMBIVERT G6

- "High Performance Inverter" stands as synonym for a range

of devices from 0,75 kW up to 30 kW / 400 V whereby all requirements can be

fulfilled for the open-loop operation of three phase motors.

Some highlights of this model range:

• STO-integrated safety according toDIN ISO

13849-1, PLe or rather IEC 62061, SIL3

• Innovative EMC solution by the use of novel core materials for long motor cables up to 100 m for the environments C1 and C2

• Variable support by future-oriented field bus systems like CAN, EtherCAT and projected Profinet

COMBIVERT B6

- The new entry-level inverters with the proven features of

KEB drive controllers!

KEB COMBIVERT B6 - comprises the new entry-class at KEB, available in power ranges

0.37 kW / 0.75 kW / 1.5 kW and 2.2 kW -

1 ph. 230 V AC and

0.74 kW / 1.5 kW / 2.2 kW and 4 kW -

3 ph. 400 V AC

COMBIVERT F6

- KEB COMBIVERT F6-K - Single Axis Drives

KEB COMBIVERT F6-K is controlled and regulated drive technology ready for the networked world - designed 13849-performance level 62061-SIL 3 in a kit, consisting of seven physical sizes with integrated security STO ISO e / IEC. The devices are highly compact designed and optimized for use in single axis applications in machinery and equipment. The entire series uses a power range from 1,5 up to 900 kW in the voltage range 230, 400 and 690 V AC.

Servo Technology

- Top of the line products in equipment and machinery building are based on dynamic drives that are increasingly being designed as closed-loop systems. Depending on the physical requirements, these requirements are met by particularly robust and low-maintenance alternating current or brushless synchronous or asynchronous motors. Single axis or multi axis solutions are the ideal solution depending on power range, number of axis and load profile. KEB COMBIVERT offers both!

COMBIVERT S6

- The new servo solution

COMBIVERT S6 is the new integrated servo drive controller in book size format for high dynamic machine solutions up to 5,5kW.

It offers following highlights:- integrated EtherCAT and CAN interface for highspeed connection to control level

- onboard Safety Functionality and an integrated EMI filter class C2 with low leakage current for residual current detectors.

The high overload capacity of 250% for 3s and 200% for 60s is especially designed for high dynamic applications like packaging, food processing, tool machinery, spindles, lift or woodworking applications and special machinery.

Servo Drive KEB COMBIVERT F5 Multi

- Closed-loop drive controller for synchronous and

asynchronous motors up to 900 kW with modular pluggable sensor systems.

Basis for distributed, decentralized control architecture in the drive with internal functionalities such as:- Speed and torque regulation

- Positioning control with train mode

- Synchronous run control, electronic transmission

- Simple positioning, round table positioning, register function

- All drives support the isolated serial interfaces Profibus, CAN, Sercos, InterBus, DeviceNet, Modbus, Ethernet, EtherCAT, Powerlink, Profinet and KEB-HSP5 / DIN 66019-II.

KEB COMBIVERT F6-K

- KEB COMBIVERT F6-K is controlled and regulated drive

technology ready for the networked world - designed 13849-performance level

62061-SIL 3 in a kit, consisting of seven physical sizes with integrated

security STO ISO e / IEC.

The devices are highly compact designed and optimized for use in single axis applications in machinery and equipment. The entire series uses a power range from 1,5 up to 900 kW in the voltage range 230, 400 and 690 V AC.

KEB COMBIVERT H6

- KEB

COMBIVERT H6 is a modular drive system for synchronous- and asynchronous

motors up to 160 kW with DC coupling of links. It implements a universal

system for the simplest applications such as u/f controlled ASM all the way

to sophisticated NC axes.

All axis modules have been designed with an identical compact installation height of 400 mm and 200 mm module depth for space-optimised system integration. Designed for variable centralised cooling concepts based on water or air.

Cooling concepts electronics

- The KEB COMBIVERT F5 modular system provides mechanical solutions for particularly thermal loads with respect to inverters and servo controllers, with the aim of optimising heat removal from the classic control box.

Convection Heat Sink

- ... are particularly compact and the basic version, often with supporting ventilation, for conventional control box installations of IP20 protection type devices.

Push Through Heat Sink

- .... reduce heat in the panel by up to 80%, i.e. forms the basis for compact and tightly sealed cabinets. With the thermal separation of the heat sink and the installation of the devices in a two-part panel, heat is shifted to the outside, which leads to better ambient conditions for the electronic components.

Flat Rear Heat Sinks

- ... create an interface for using existing environments, e.g. thermal connection to the machine or a master heat sink.

Liquid Cooled Heat Sink

- This is a closed cooling system for the design of hermetically sealed enclosures for challenging ambient conditions. Liquid cooled heat sinks guarantee the cooling of large power stages also in conjunction with liquid cooled motors.

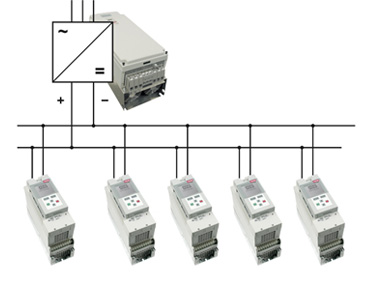

Supply and regenerative units

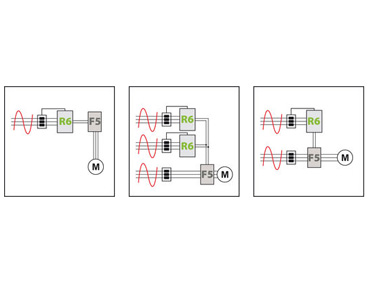

- All moving systems have kinetic energy when in operation. When the motor slows down it acts as a generator and converts the mechanical energy back into electrical energy, which then is shunted into a braking resistor that results in heat. The power supply and line regeneration control R6 provides a solution to balance energy or return energy to the utility grid.

COMBIVERT R6

- The kinetic energy of AC motor drives is often an

unutilized energy source.

The compact new product KEB COMBIVERT R6 is designed for power supply and regenerative operation for inverters and servo systems.

KEB COMBIVERT R6 can be operated at line voltage from 200 - 500 VAC. The design is modular with a compact commutation choke and EMI filter. In conjunction with the KEB COMBILINE harmonic filter solutions a sinusoidal regeneration to the utility grid is achieved.

KEB COMBIVERT R6 has a display to show the energy savings while regenerating to the grid.

COMBIVERT F5-AFE

- Designed for temporary and continuous feedback

operations, COMBIVERT F5-AFE offers the basis for system solutions for

permanent feed and others as applied in trigeneration and block heat and

power plants, biogas facilities and also small wind power facilities.

The production of other types of grids represents another application area; they are also used for test facilities or test stands.

At present, power ranges of 7.5 kW to 250 kW are available based on industrial device hardware.

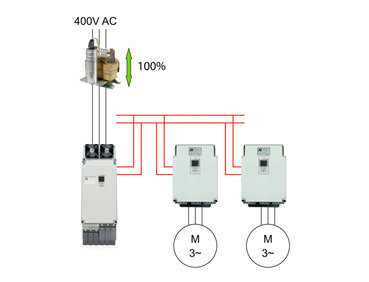

COMBIVERT R5

- The connection of electrical drives makes it possible to

internally balance motor and regenerative energy loads.

KEB COMBIVERT R5 comprises central feed modules for DC-bus coupled frequency inverters and servo drives.

The integrated braking transistor and the central DC fuse reduce the complexity of the system installation.

The centrally supplied machine features lower power consumption and higher resistance in case of line-voltage drops.

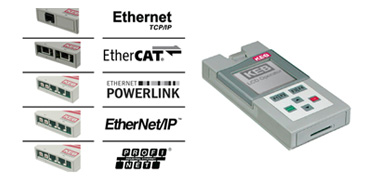

Communication

- We connect drives to controls.

Based on the modular structure of fieldbus operators, all KEB COMBIVERT drive controllers can be operated in all commonly used serial fieldbus systems.

You choose the right networking platform for your application!

Ethernet, EtherCAT, Powerlink, ProfiNET

- Ethernet-based solutions…

use the worldwide expansion of the IT network technology for industrial applications.

It begins with powerful EtherCAT master implementations in the embedded and IPC-based controls, continues with the integrated EtherCAT slave versions in the COMBIVERT H6 multi-axis system, or the current COMBIVERT G6 inverters, and is rounded off with fieldbus solutions for decentralised I/Os with the module KEB Remote I/O system for complete automation.

Ethernet TCP/IP is a cost-effective way of connecting the drive level to the IT level, and allows for easy start-up and diagnostics.

Powerlink and Varan also lend real-time properties to the drives, which are thus made available for highly dynamic applications and motion operation.

The extensive market penetration of Ethernet IP is supported in the US by our local subsidiary KEB America.

Profinet RT and IRT are additional solutions currently serviced by KEB for pluggable operators for COMBIVERT F5, and which are planned with further integrated versions in the future.

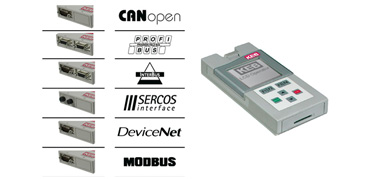

Profibus, CAN, Sercos, InterBus, DeviceNet, Modbus

- Established Fieldbus Connections...

... have long been the "motor" for advanced concepts of systems and machines in conjunction with sensors and actuators in the process chain.

With the modular operator system, KEB supports all recognised standards for the entire bandwidth of inverters and servo systems.

Pluggable functional components make initial equipment and later retrofitting in the field very easy and flexible.

EMC

- As the amount of electronics increases, EMC loading and

EMC compatibility is becoming an increasingly important factor for the

operational reliability of machinery and equipment.

European norms and standards require manufacturers and operators to comply with a set of EMC limitations.

KEB designs, manufactures and supplies a comprehensive programme for limiting noise levels created by the mains and motors, and for optimising operating conditions.

Competent advice and mobile EMC measurement devices support onsite selection and optimisation - i.e. they warrant reliable compliance with statutory requirements in a variety of applications.

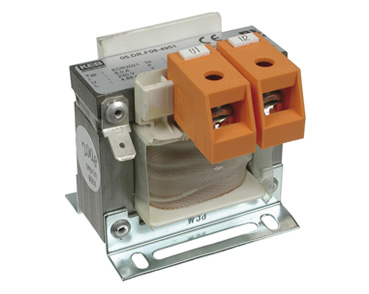

KEB COMBILINE HF Filter

- Variable speed drives with uncontrolled rectifier input

can cause low or high frequency interference on the line that are limited by

the EMC regulations.

Adherence to the standards is ensured with the use of universal EMC filters for individual interference suppression at the drive controller or as a central filter, designed for complete installation in a panel.

KEB COMBILINE interference suppression filters are designed for industrial or residential areas and can be supplied with currents rated up to 1000 A.

Segments: single filter IT line filter, filter for small leakage currents, 3-phase central filter, central filter with neutral (4-phase system), combined input/output filters.

KEB COMBILINE Harmonic Filter

- The low-frequency harmonics resulting from B6 rectifier

switches pose an increasing burden on public grids and must be limited with

expensive and cumbersome compensation facilities.

The KEB COMBILINE harmonic filter is a patented passive component which provides a connection-ready alternative for original equipment or the retrofitting of production facilities. Two models of these compact filters are available:- standard series with THD (total harmonic distortion) smaller than or equal to 8%, PWHD smaller or equal to 15% in power settings 4 - 460 A.

- economy series with THD smaller than or equal to 15%, PWHD smaller or equal to 38%. According to standard EN 12015 (European elevator/escalator norm) in power settings 2 - 63 A.

Larger power settings can be covered with connecting filters in parallel.

Sinusoidal Output Filter

- The cyclical output voltages of frequency inverters

produce additional losses in motor leads and windings which can

significantly affect the reliability and longevity of motor insulation.

KEB COMBILINE sinusoidal output filters limit stresses to admissible limits and provide the required protection of lacquer insulation and end connections particularly for long motor leads and special motors.

The protection offered by sinus filters is particularly important for the retrofitting of already installed older motors with frequency inverters to optimise the efficiency of existing systems.

The sinus filter range includes the following versions:- sinusoidal output filter fmax = 100 Hz

- sinusoidal output filter fmax = 200 Hz

- sinusoidal output filter fmax = 400 Hz

- and customer-specific versions for output frequencies up to 1600 Hz.

Electronic assembly

- With respect to the specific requirements of machine

building, we supply a comprehensive accessories programme that has been 100%

designed for KEB drive controllers.

The free PC tool KEB COMBIVIS provides software that can be used for all devices, and which simplifies handling, diagnostics and optimisation processes.

Power and motor chokes reduce the reactions from the pulse-shaped subsequent loading and additional stress of the motor winding from cyclical output voltage. Both units also represent an effective measure to extend the service life of components in the equipment.

The braking resistors, which are designed for different duty cycles, economically convert short-term energy peaks from regenerative loads into heat.

KEB Software

- KEB COMBIVIS is the universal and effective tool for all

former and current KEB drives.

The new version KEB COMBIVIS 6 in .net-based structure is ready for the needs of the future and supports the controls and drive controllers as of generation 5.

KEB COMBIVIS 6 is factory-tested with operating systems Windows 2000, XP, Vista and Windows 7, and has been designed as a free too for the complete administration of all device adjustments, amongst others:- display and adjustment of all parameters up to 8 parameter sets

- display of units and monitoring of operating data

- configuration of customer-specific parameters in the "CP level"

- analysis of communication between drive and control

The established KEB COMBIVIS 5 version continues to support all former device series such as Type KEB COMBIVERT 56 / F0 / F1 / F2 / F4/S4 and all current generation KEB COMBIVERT F5 / G6 / B6 devices.

It can be run on all PCs with serial interface and systems software Windows 95, 98, NT, XP, Vista and Windows 7.

KEB COMBILINE Mains Input and Motor Chokes

- The B6 rectifier input circuit in the input of variable

speed drives causes current ripples that strain the DC-bus capacitors in the

inverter and generate harmonic distortions in the utility grid.

The power choke (50/60 Hz) flattens the charging current and reduces harmonics - both are important factors for the reliability and lifetime of the machine.

The modulated output voltage of the inverter creates additional stress for the insulation and can result in functional problems in the device in the case of long motor leads.

KEB COMBILINE power chokes flatten the output currents, reduce the strain on the insulation and are available for output frequencies...50 Hz, ...100 Hz and ...200 Hz.

Braking Resistors

- The DC-bus capacitors of inverters can only partially

absorb regenerative energy and must be guided from the system to the

outside. KEB COMBIVERT are available with internal brake transistors (GTR7),

which transmit "excess" energy to external resistors.

The OHM-A and OHM-B resistors offer high pulse capacity at a small installation space and- feature thermal monitoring through break contacts (series feature)

- work without additional noise during braking

- universal ancillary components Ohm-A and Ohm-B for high pulse performance and

- compact substructure module for absorbing smaller pulse energies.

Magnet Technology

- For more than 40 years, we have used electro-magnetic

forces for starting, stopping, holding and positioning motion axes in

machines and systems.

Electromagnetic clutches will create locking connections both today and in the future. A wide variety of electromagnetic brakes brings dynamic motion axes into a secure holding position.

In addition to universal standard solutions, we also offer an experienced team of application engineers and modern design and calculation tools for a customised adaption to your application.

Spring Applied Brake KEB COMBISTOP

- KEB COMBISTOP are electro-magnetically operated two-part

spring-set brakes for dry operations, whose brake force is generated by

springs and cancelled by electromagnetic forces. The proven spring applied

brake is used in applications where rotating masses must be slowed down or

shafts need to be held in position.

Our standard program consists of:- Minibrake KEB COMBISTOP M

- Holding brakes for dynamic applications KEB COMBISTOP N

- Holding brakes for static applications KEB COMBISTOP H

- Holding brakes for protection class IP 66 KEB COMBISTOP P

- Holding brakes for mounting of tachometers KEB COMBISTOP T

- Double brakes for theatres, lifts and elevators KEB COMBISTOP D

- Elevator brakes D8 KEB COMBISTOP L

KEB COMBIPERM Permanent Magnet Brakes and Clutches

- KEB Combiperm P1 brakes provide power-off brake

engagement with electromagnetic release. KEB P1 brakes are designed using

rare earth magnets which allow for very high torque densities in small

diameters.

P1 permanent magnet brakes have zero backlash and operate across a wide range of operating temperatures and voltages — this makes them ideal for the most precise and demanding applications.

KEB COMBINORM

- KEB COMBINORM offers a complete program of brakes,

clutches and combinations as installation and mounting components for

applications in machines and systems. The torque range is 0.5 up to 500 Nm.

Following models also available:- Electromagnetic Actuated Brake KEB COMBINORM B:

The KEB COMBINORM brake is the most economical solution for slowing down and holding loads for flange- and shaft-mounted installation in equipment and systems. - Electromagnetic Actuated Clutch KEB COMBINORM C:

The KEB COMBINORM clutch uses the force of an electro magnet focused on two pole faces for the locking connection of shafts and connected loads.

A locking design with tooth rotors and anchoring pieces makes it possible to transfer maximum torque in small installation spaces.

We have the ability to customize KEB COMBINORM for your structural and electrical requirements.

- Electromagnetic Actuated Brake KEB COMBINORM B:

KEB COMBIBOX Clutch/Brake Modules

- KEB COMBIBOX is an integral clutch-brake combination for

start – stop applications in the enclosure, which allows for wear

adjustments without having to dismount the unit thanks to the patented

adjustment of the air gap.

The following models are available:

• COMBIBOX Type 10

• COMBIBOX Type 09

• COMBIBOX Type 06

COMBITRON Rectifiers and Switches

- for the supply and control of KEB COMBINORM series

electromagnetic clutches and brakes.

The product program includes half and full wave rectifiers for AC or DC side switching as well as rapid switches for optimized starting and stopping. All products are designed according to the low voltage directive 73/231/EWG.

The following models are available:

• COMBITRON 92

• COMBITRON 94

• COMBITRON 91

• COMBITRON 98

Motors and gears

- Optimal interaction between motor and electronic drive is the foundation of excellent machine functionality. Servo motors are the ideal drives for dynamic applications with low inertias and high peak torques. Asynchronous motors are preferred in applications with high external load inertias must be safely controlled (in relation to the motor shaft in the control). The addition of a sensor system that is right for the application and the mechanical adjustment of torque and speed characteristics through the transmissions of the systems results in all-in-one solutions for a variety of different requirements in machine and equipment building (optionally also available with brakes). Ready-made connections provide pre-tested, connection-ready systems with easy installation for quick start-up.

AC Motors

- TORQUE LINE asynchronous motors are specially designed

for closed-loop operation with KEB COMBIVERT F5 – Multi. These systems offer

an economical alternative for demanding applications with speeds as low as 0

rpm.

Features:- B3 or B5 motor design

- External ventilation IP 55 (optional)

- Thermal winding cover 3 PTC resistor

- Incremental encoder 2500 ppr / RS 422, 5V DC, 12 pole connector

- Spring-set brake KEB COMBISTOP (optional)

KEB Synchronous Servo Motors

- KEB synchronous servo motors are permanent magnet,

electronically commutated synchronous motors - Made in Germany - for

applications with demanding requirements for quality and positioning

accuracy with minimum installation volume and weight.

TA series made by KEB in Schneeberg

TA Series - 5 installation sizes which are optimised and configured for direct mounting of combigear, helical bevel, helical worm and shaft-mounted helical systems with nominal torque of 0.8 to 80 Nm.

KEB DYNAMIC LINE

The series for machine building in new design with short mechanics, either with a smooth or finned surface and high torque characteristics with nominal torque of 0.2 to 70 Nm.

Inline helical gears

- KEB COMBIGEAR G and ZG Helical Geared Motors...

...are available in 2 series and 10 sizes from 0.12 to 45 kW with a 2- and 3-level assembly and drive torques up to 13,000Nm as flange- or foot-mounted versions. A refined speed gradient to a minimum of 1.2 rpm provides optimum torque adjustments on the output side.

The universal installation position, life cycle lubrication and minimal backlash ensure long-lasting use. IEC mounting flanges are used to adapt any number of special motors to special requirements.

Directly mounted servo motors provide dynamic solutions with especially high effectiveness and compact design forms.

All KEB COMBIGEAR can be combined with spring-set brakes, tachometer – and feedback systems and forced ventilation cooling fans (optional).

Helical bevel gears

- KEB COMBIGEAR K Helical Bevel Geared Motors

...in power ranges 0.12 to 45 kW form 8 mechanical parameters that create a powerful basis for applications with the highest efficiency for lateral output.

The gear unit sizes, which can be combined with asynchronous and synchronous motors, feature a stiff mounting of shaft or hollow shaft, therefore transmit extensive radial forces even during alternating stresses in repetitive and reverse systems, and allow for output torque of up to 12,000 Nm for the different sizes.

Flat gears

- KEB COMBIGEAR F Shaft Mounted Helical Geared Motors

Seven installation sizes can be combined with power ranges from 1.5 to 45 kW, and provide an ideal connection to the machine and hence robust and long-lasting drives due to their space-saving construction and simple slide-on mounting.

Combined with asynchronous or synchronous motors, output torque up to 8,900 Nm and a minimum output speed of 1.3 rpm is possible, covering a wide range of application requirements.

Worm gears

- KEB COMBIGEAR S Helical Worm Geared Motors...

...in the power range 0.12…11kW represent the “better standard drive" for machines and systems due to their superior economic efficiency.

Lifetime lubrication, universal mounting construction and varied output options (solid shaft, hollow shaft) make this geared motor extremely adaptable.

Planetary gears

- KEB SERVOGEAR AL Planetary Gear

The KEB planetary gears are available in four sizes with output torques in the range of 5 … 2,000 Nm offering low backlash operation.

With the advantages of planetary gears, including high torsional/axial stiffness, low backlash, efficiency greater than 95%, thermal length compensation and compact design, the gearbox is well suited for dynamic servomotor applications.

The mechanical connection to the motor is an “assembly and service friendly" clamp connection that allows for the replacement of individual components during service, and is also ready for the DYNAMIC LINE motor series.

Windenergy

- Always innovative, KEB is at the forefront supplying

components into the wind turbine industry. Whether you need drive solutions

or brake solutions, KEB can offer the right solution for your application.

Drive Solutions- KEB sells over 150,000 industrial drives and controls annually. Through the years, KEB has built a reputation for supplying the best possible solution for specific applications. This philosophy has led to the development of a revolutionary pitch drive system and powerful yaw drive solution…

- A pitch drive is used to adjust the rotor blades and regulate the power transmitted to the mechanical system. A more responsive pitch system allows the turbine to better react to constantly changing conditions. This puts less stress on the mechanical system and ultimately provides a better performing, longer-lasting wind turbine.

- Here are a few examples why KEB’s pitch drive system is superior:

- Small footprint – Innovative heatsink allows for smaller cabinet and cost savings.

- Rugged design – Wide temperature ranges, special shock resistant features, ect.

- Dynamic response – Latest control technology provides the best pitch response.

- Powerful programming environment – Programmed in accordance to IEC 61131-3.

- Flexible communication – RS232 serial(user defined), ModbusTCP, option cards: Profibus, CANopen supported

- Integral RFI filter – Robust electrical system

- Precise Position Control – Flexible feedback interfaces; Including absolute SSI

- Single source – System components are optimized to operate together

- Integrated safety features – e.g. switchover to encoderless operation in case of encoder loss.

- Features as required – Braking resistor, fieldbus communications, 24VDC supply, battery monitoring, ect.

- For decades, KEB has been the leader in supplying electro-mechanical spring-set brakes. Building on this success, KEB has developed robust and innovative solutions which the wind turbine application demands.

- Here are a few examples why KEB’s pitch brake solutions are superior:

- Low Maintenance – No bleeding of the lines or failed tubing/fittings commonly associated with hydraulic brakes.

- Clean Solution – No potential fluid leaks. This makes KEB ideal for offshore applications.

- Easily Assembled – Flexible mounting configurations as required.

- “Fail-safe” Design – Redundant springs provide true power-off braking

- Rugged IP65 Protection – Designed to withstand the harshest environments

- Features as required – Service hand release, microswitch indicator, special power/control connectors, and many more…