SSB Wind Systems

- Offer Profile

- We develop solutions for the

wind energy industry with our customers’ best interest and benefits in mind.

More than 400 employees are active worldwide. As part of the Emerson Electric Co., we will continue to set benchmarks as one of the most recognized suppliers of pitch systems worldwide. Our trademarks are quality and reliability, even under the most extreme conditions.

Product Portfolio

Pitch Systems

- Experience from A to Z instead of according to

books:

Our pitch systems.

We learned the ABC’s of pitch systems more than 20 years ago. From A as in active-stall blade pitching, which we developed in 1992, to Z for Z-axis. We haven’t just participated in the development of pitch systems, we pioneered the electric pitch system and launched it into the market.

The detailed engineering and design of pitch systems in the hub has become a part of our service portfolio, as has the development of new technologies which make pitch systems more efficient and reliable. For example with the new generation of MPC series converters. At SSB Wind Systems, the letter P continues to stand for progress. Our pitch systems

- We learned the ABC’s of pitch systems more than 20

years ago. From A as in active-stall blade pitching, which we developed in

1992,

to Z for Z-axis. We haven’t just participated in the development of pitch systems, we pioneered the electric pitch system and launched it onto the market.

The detailed engineering and design of pitch systems in the hub has become a part of our service portfolio, as has the development of new technologies which make pitch systems more efficient and reliable. For example with the new generation of MPC series converters. At SSB Wind Systems, the letter P continues to stand for progress.

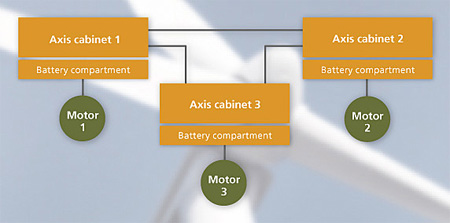

The 3-Box-System

- Features:

- 3 axis cabinets (converter cabinet with integrated battery section)

- 3 motors including encoder, brake and external fan

- 1 cable set (single-sided connections for supply, brake, fan, heater, motor sensor, interlock monitoring)

- 3 sets of limit switches

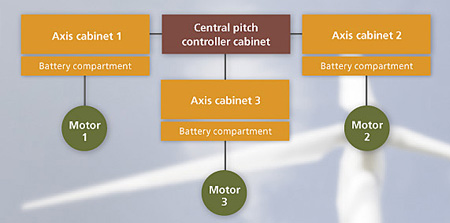

The 4-Box-System

- Features:

- 1 central pitch controller cabinet

- 3 axis cabinets (converter cabinet with integrated battery section)

- 3 motors including encoder, brake and external fan

- 1 cable set (single-sided connections for supply, brake, fan, heater, motor sensor, interlock monitoring)

- 3 sets of limit switches

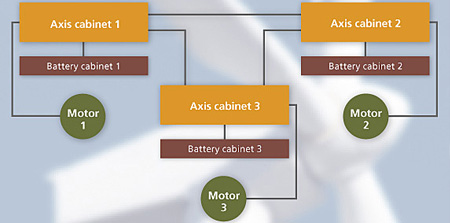

The 6-Box-System

- Features:

- 3 axis cabinets

- 3 battery cabinets (UPS)

- 3 motors including encoder, brake and external fan

- 1 cable set (single-sided connections for supply, brake, fan, heater, motor sensor, interlock monitoring)

- 3 sets of limit switches

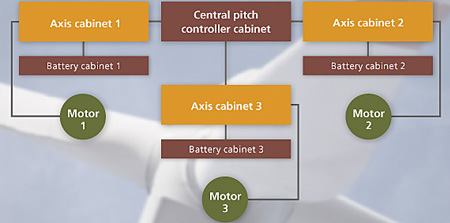

The 7-Box-System

- Features:

- 1 central pitch controller cabinet

- 3 axis cabinets

- 3 battery cabinets (UPS)

- 3 motors including encoder, brake and external fan

- 1 cable set (single-sided connections for supply, brake, fan, heater, motor sensor, interlock monitoring)

- 3 sets of limit switches

Safety Philosophy

- Philosophies generally

sound good. But even the greatest ideas are only worthwhile if they can be

put into practice. The same applies to our safety philosophy:

Every one of our pitch systems is built so that the safety function of each axis operates fully independent of each other. The same goes for the motor control, the emergency power supply, as well as the switch cabinets and wiring systems. With 17,500 pitch systems installed worldwide we have had many opportunities to put these requirements to the test.

Our philosophy: Safety has to be put to the test.

-

- The pitch system must be able to be used as a primary brake without any compromises.

- The turbine must be able to be stopped safely under any operating conditions.

- The minimum requirement is being able to turn a blade to the feathering position to achieve a safe minimum speed (Fail-Safe).

Emergency Power Supply

- In an emergency or during unexpected downtimes, the pitch

system must be capable of returning the rotar blades at a fixed speed to a

safe 90° position. Even during a network failure. This is one of the

directives established by Germanischen Lloyd. For us it’s a given. Of course

the pitch system then requires an uninterrupted power supply (UPS).

This is accomplished with batteries or ultracapacitors. And because we never make compromises when it comes to safety, we offer both technologies and recommend the optimal system for your WTG type. Ranging from voltages of 144 V, 216 V, 288 V … you need only remember one figure: 100 %. That is the only acceptable safety standard when it comes to your WTG.

There’s always a way to get things going again: Emergency Power Supply.

-

Fast and robust: Our ultracapacitors Simple and efficient: Our batteries - Short recharging time

- Very long service life (10 years+)

- Insensitive to temperature

- Rated voltage of 2,5 – 2,7 V

- Series connection at high voltages: e.g., 60 2,5 V capacitors = 144 V

- Optimized chargers and overvoltage module for reliable function over many years

- High energy density

- Low production costs

- Simple charging

- Rated voltage 12 V / 7.2 Ah

- Series connection at high voltages: e.g., 18 12 V batteries = 216 V

- Integrated voltage monitoring

- Temperature monitoring by PT100 relay

Converters

- There’s more to be found behind the acronym MPC than just MULTI Pitch

CONTROLLER. We also offer DGNR and DCTransD converters, the latter even

featuring a controlled emergency shutdown. That said, we are committed to

offering the latest converter technology for optimal reliability. Hence the

development of the MPC Series. Their quality is a result of our own

development and production expertise. And that eight times over.

The MPC Series is in fact an entire family of converters. And similar to any family, it includes converters big and small. That means four AC variants with an output from 20 A to 75 A. Add to that four DC variants with an output from 30 A to 125 A.

Perfect voltage at lofty heights: Our MPC Series.

-

The application features of the MPC Series: The technical features of the MPC Series: - MULTI Pitch CONTROLLER with actual speed value feedback

- Positioning control can be activated

- Actual speed value generation via sine/cosine signals

- Speed control in closed-loop and open-loop mode

- High-priority emergency operation in feathering position as an open loop

- Heavy-duty for activation of a defined current/time profile

- 4 AC variants (20 A, 35 A, 55 A, 75 A)

- 4 DC variants (30 A, 60 A, 75 A, 125 A)

- Integrated positioning card for signal conditioning and analysis

- BatteryPitchProfile and BatteryBrakeChopper

- Usable from -40 °F to +158 °F

- Interfaces: USB, 2 x RS485, CANopen (others possible via Busmaster)

- Additional inputs: 12 digital, 4 analog

- Additional outputs: 8 digital

Pitch Drives

- Always doing the same thing can be very exciting. This is the experience made by our engineers who are always challenged with something new – every one of our pitch drives is unique. Every motor, whether AC or DC is individual in size, design and performance parameters. We orient ourselves in accordance to your needs, your WTG type, the location and resulting demands on the motors.

We treat AC and DC motors exactly the same: Individually.

-

Happy for a change:

Our AC Motors.Consistently reliable:

Our DC Motors.- Absolute value encoder, tachometer, parking brake as standard

- Separately driven ventilation

- Specific protection classes for onshore and offshore

- Special paint finishes for offshore use

- Integrated anti-condensation heater

- From inline to compound motors

Integrated anti-condensation heater - Absolute value encoder, tachometer and parking brake as standard

- Separately driven ventilation

- Specific protection classes for onshore and offshore

- Special paint finishes for offshore use

Axis and central controller cabinets

- The one swears by overall product design, the other is satisfied by the accessories. We make no such compromises. Rather we focus on a total solution, and that means not limiting ourselves to the construction and producing of switch and control cabinets according to your demands. We also provide you with equally high quality accessories by, for example, installing all the cables ourselves. That means that every cabinet is completed according to your demands and the technical specifications of your WTG.

There is more in it for you: Our axis and central controller cabinets.

With no ifs or buts: Our

central controller cabinets.With all the frills: Our axis cabinets. - Head Officer overvoltage protection

- Mains filter

- Mains monitor

- Power distribution for the 3 axis

- Charger

- Including an individual support for your WTG

- Control section with converter

- Battery charger

- Battery voltage monitoring

- Contactors

- Power distribution

- Overvoltage protection

- 24 V control voltage

- Battery switch

- Battery section with batteries

(total voltage e.g. 144, 216 or 288 V DC)

Switch and Control Cabinets

- Every switch and control cabinet is equipped with something very unique: The special requirements demanded by a customer for a highly individual WTG. There’s good reason why we are always striving to set new standards in planning, development and production. At the end of the day, there is always a particularly high standard which has to be reached: Yours.

Top and Tower Boxes

- The soul of a wind turbine is contained in the top and

tower boxes regardless whether at its base or in the nacelle. This is where

all information converges, is processed and results in the optimal

positioning of your WTG vis-a-vis the wind. There could be no greater need

for extreme reliability and safety than here.

A standard configuration from SSB Wind Systems is one that sets standards. Either with custom designed housing, SPS, vibration sensors or other components. Each optimally coordinated with one another. By the way. When you are not only looking for the optimal, but also the perfect solution: Every top and tower box can be enhanced with a variety of options such as touchscreens, etc.

Brimming with ideas: Our Top and Tower Boxes

-

Our standard configuration The options - PLC for control of the pitch system, generator, converter, yaw motors, rotor speed sensor, anemometer / wind vane, temperatures

- Vibration sensors

- Grid monitor

- Fuses

- Lightning protection system

- PLC systems of various manufacturers

- Display options:

- Standard monitor

- Touchscreen

- Laptop interface - Add-on modules:

For the reception and analysis of signals which come from the anemometer, wind vanes and vibration switches - Climate packages:

- CCV cold weather equipment for operation from -40 °F to +104 °F

- HCV hot weather equipment for operation from +14 °F to +131 °F

Operating and Testing Boxes

- Even in unexpected situations, there should be nothing unexpected when it comes to safety and reliability. Rather you should be able to take them for granted. For example, when it comes to the assembly or start-up operations of a WTG. The mobile boxes from SSB Wind Systems help you keep control of all relevant functions throughout this initial phase. Completely independent from axis and control cabinets or the complete nacelle for that matter. Big ideas find a way to fit into even the smallest boxes.

Happiness knows no bounds: Our mobile boxes

-

Our mobile

hub simulation box.Our mobile

pitch drive control box.Our mobile hub simulation box makes it possible to service and test the hub independently from the nacelle. In addition to the actual operating of the hub, its functions include safety function testing and ideal positioning. All you need is a laptop which can access hub functions using simulation software. The software includes a control system and the simulation of the interface to the slipring. The laptop is connected to this interface.

Included in delivery:- Box

- Simulation software, incl. control system and interface to the slipring

Our mobile pitch drive control box enables the setting of the rotor blades during assembly or start-up operations without connecting the axis or control cabinet. In this way, each blade can be tested under controlled speed conditions. The drive is located directly over the rotar blade motor. The connection to the pitch drive control box is made using an extension cable which is plugged in to the motor plug.

Included in delivery:- Box with pitch controller and parameter set

- 400 V connection cable

- Extension cord for connection to the motor supply cable

Custom Solutions

- SSB Wind Systems are in the habit of expecting

particularly good performances. But occasionally these have to be even

better than usual. Our engineers understand this. And they always find a

way. For example, with a solution for your wind park management system. Or

with cabinets or grid integration of your wind park, always meeting the

individual requirements established by the grid operator.

Regardless of the custom solution needed for your WTG, wind park or fleet, we can develop and implement it. Something very special is transformed in something you can take for granted.

Service and Product Care

- Front, top and center:

Our services for your pitch system.

Not only do we design and build complete pitch systems, we also service them. This makes us a competent service partner whom you can count on for assistance at any time – throughout and beyond the warranty period. We understand our service as a real added value that far exceeds the technical performance of any pitch system.

Our own service teams are an integral part of our service department. But they are also flexible and apply their many years of experience to the servicing of pitch systems for your customer’s wind turbines. They also have the know-how to identify the best possible upgrades necessary for improving your pitch system’s performance. This might be a special battery charging process or an individual solution developed by our engineers on your request. Our Services

- Should you ever need support for any SSB Wind Systems

product, we will be happy to assist you.

High levels of performance and reliability are a feature of our product range but, occasionally, failures do occur. When this happens, help is at hand from our service center. Our center staff has extensive product knowledge and will provide a prompt, professional service on your needs.

Our start-up operations service

- Triple redundancy: That is a key safety element of

every SSB Wind Systems pitch system. It is also the minimum requirement for

our handling of the system for your start-up operations. You’ll see: The way

to a perfect pitch system is not long, just consequent. Our goal is not just

that your system runs: We want it to run three times better than normal

First step:

We ensure that things run really well on-site..

Second step:

We ensure that things run even better on-site.

Third step:

We ensure that your WTG runs perfectly on-site.

A smart approach: Our training.

- The experience of developing each pitch system in close cooperation with our customers has taught us the value of sharing our know-how. This continues long after the development phase. For example, by request we will train the service engineers and fitters at your production facilitieson how to optimally implement the pitch system in the hub of your WTG or on an individually determined subject. The training can also be carried out directly at the WTG site itself.

Need a spare part? We've got just what you need.

- That’s exactly how it should be. We offer spare parts

supply for the entire 20-year lifecycle of a WTG for all systems supplied by

us. So that you don’t have to wait that long for your spare parts, we have a

large number of parts, upgrades, and even complete retrofits in stock.

You can rest assured that even the most hard to get components such as converters, controllers or battery packs are available immediately – when necessary, even by express mail directly to your desk. Naturally, we make curbside deliveries of items such as a complete spare cabinet. We’ll even produce it from scratch when necesary with all the necessary interfaces and functions compatible with your WTG. Nothing less really than you should expect.