- Offer Profile

- We offer quality tanks and

system solutions in steel for industry, communities and agriculture.

Your project, from an individual tank to a complete turnkey plant, will be completed with the emphasis firmly on longevity, flexibility and individual adaptability.

Lipp-System

-

In industry, agriculture and communities, the proper storage and processing of solids and liquids places extremely demanding requirements on tanks – especially where problematic or aggressive substances are concerned.

The LIPP-System – the only one of its kind in the world

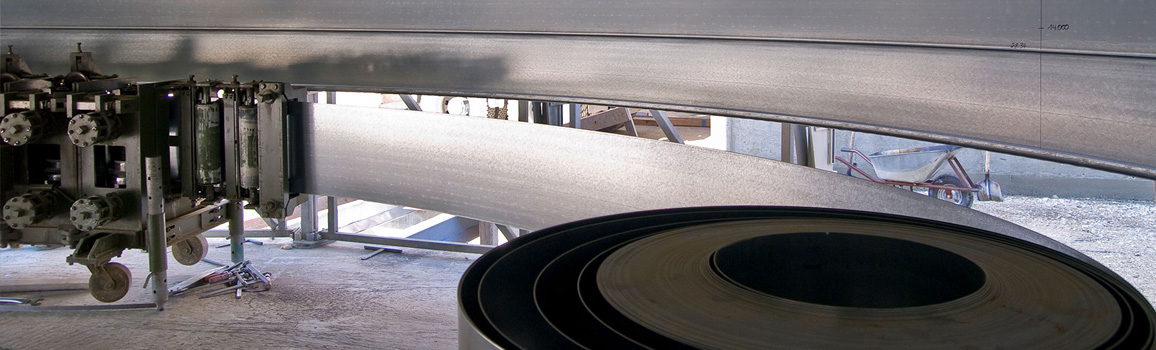

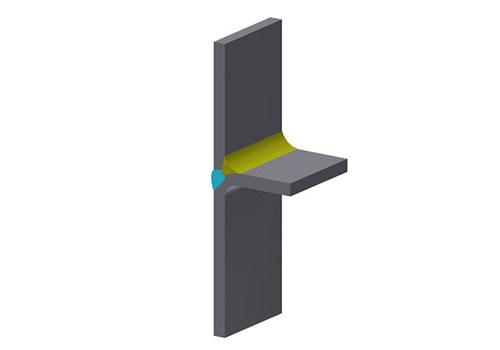

The LIPP-System is based on a simple yet ingenious tank construction principle that is the only one of its kind in the world. Steel coils, machines and accessories are transported to the building site where the tank is then constructed – the process is fast, efficient and flexible in terms of tank height and diameter. A profile is formed from steel strip by means of an automated two-step procedure. During the second step, the profile layers are joined together while the tank continues to grow upwards in a spiral. The steel strip can be tightly joined both using the LIPP Double-Seam System and also the LIPP welding technique, while ensuring stability.The benefits of the LIPP-System

- Consistent quality worldwide

- Automated, efficient construction on site

- Individually customisable solutions

- Minimal installation space required

- High structural stability

- Corrosion-resistant

- Maximum leak-tightness

- Low assembly and investment costs

- Substrate-flexible due to specific choice of materials

- Low maintenance costs

LIPP Double-Seam

-

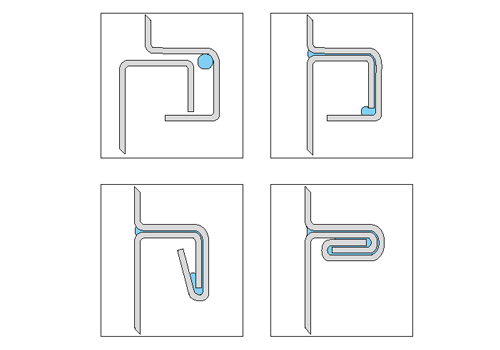

Flexible, safe and proven the world over – the LIPP Double-Seam System

Conventional systems are often unsuitable for the optimum, safe storage of solid or liquid substances and their use can result in premature corrosion, leaks and problems with safety. Flexibility is another important factor. Tanks must be flexible in terms of size and substrate and optimally adaptable to the local conditions.

The benefits of the LIPP Double-Seam- Edgeless, smooth finish

- Maximum leak-tightness

- Automated, efficient production on site

- Low installation and investment costs

- Minimal installation space required

- High static and dynamic stability

- Available in stainless steel, VERINOX stainless steel or galvanized/black steel

- Substrate-flexible due to specific material selection

- Low maintenance costs

LIPP Welding Technology

-

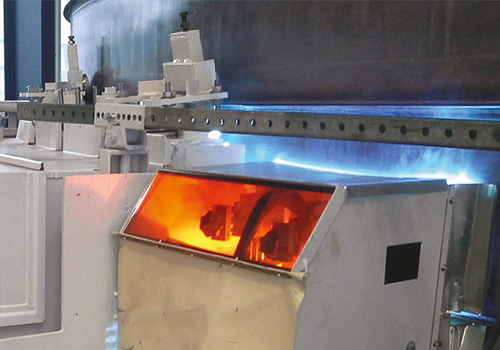

The new automated Lipp welding process will again shake up tank construction

market just as the well-established Lipp double-fold system did decades ago. It

is a perfect combination of the long experience in metal forming and

state-of-the art welding technology.

Key benefits of the LIPP Welding Technology- Automated welding proces, on-site

- Visual weld-monitoring and technical documentation

- Reinforcement ribs for enhanced structural stability and reduced material costs

- High quality and repeatability

- Fast installation

- Choice of different material grades and types

LIPP Materials

-

Lipp offers a range of metallic materials suitable for use with a wide variety of media, from pure water to problematic and aggressive substances. Those materials range from galvanised/black steel through the combination material VERINOX to high-alloy stainless steels. VERINOX stainless steel is a patented, award-winning combination material that offers the properties of high-quality stainless steels, e.g. 1.4301, 1.4571 or 1.4539, at the cost of

galvanized steel and has been in use for more than 20 years. The highest quality and longevity of materials are our top priorities.

LIPP materials at a glance- Stainless steels

- VERINOX stainless steel

- Galvanized steels

- Black steels

LIPP Product Catalogue

-

- Liquid Storage Tanks

- Digesters

- Post-Digesters

- Liquid Manure Tanks

- Gas Accumulators

- Bulk Storage Silos

- Welded Tanks

- Drinking Water Tanks

- Buffer Storage Tanks

- Special Tanks and Silos

- Roofs and Covers

- Sugar Beet Silos

- Tank Refurbishing

- Accessories

Tanks

-

Producers of high-quality tanks for more than 35 years

Since the LIPP Double-Seam System was invented by Xaver Lipp more than 35 years ago, Lipp has been setting the standard for tank construction worldwide. Our tanks are the core business of our family-owned company and represent high quality, longevity and flexibility. LIPP produces a range of tanks suitable for storing solid, liquid and gaseous media which are designed to allow customization based on the customer’s intended application.

LIPP Liquid Storage Tanks

-

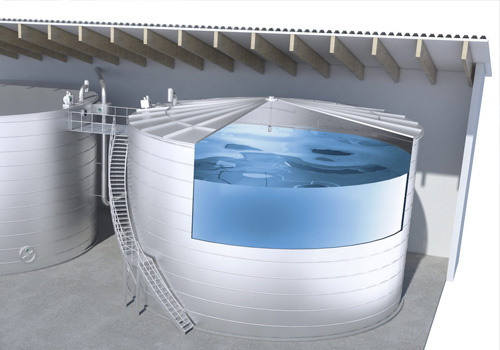

Made from Verinox stainless steel or galvanized steel with volumes ranging from 40 m3 to 10,000 m3

Both industry and communities require professional solutions for plant and tank construction and for the storage and treatment of liquids, as well as flexibility in terms of size, choice of material and equipment.

When constructing liquid storage tanks, the selection of the best material is an important quality factor. Municipal/industrial waste water and sludge or certain processing, intermediate and end products from the chemical, pharmaceutical and food processing industries set high requirements regarding the tank material, for example. LIPP offers a variety of materials, ranging from galvanized steel through the combination material Verinox to high-alloy stainless steels.

Applications- Waste water tanks

- Sewage sludge tanks

- Process water tanks

- Storage tanks

- Firefighting water tanks

- Mixing and compensation tanks

- Buffer tanks

- Stackable sludge tanks

- Storage containers

- Rainwater reservoirs

- Digesters

- Filtrate water tanks

- Activation tanks

- Percolating filter tanks

- Final sedimentation tanks

- Landfill leachate tanks

- Special tanks on request

LIPP Digester

-

Development of the first Digesters since 1971

Xaver Lipp began speculating about alternative energy sources as early as 1971. As a response to the oil crisis at that point, he began tests on the family farm, where the silos were being used for the first time as reactor tanks. With support from the universities of Weihenstephan and Hohenheim, he succeeded in creating energy from organic materials.

In the 1970s, a digester with a horizontal fermentation process was created, with a paddle agitator and a screw conveyor. At the end of the 1980s, biogas plants were beginning to gain popularity as alternative sources of energy. Lipp customers were able to benefit from the know-how gained over the previous years of development. Further development and optimization of the digester led to the creation of four different digester types, each suitable for a different application.

- LIPP KomBio-Reactor

- LIPP Universal Digester

- LIPP UniCentralmix

- LIPP Eco Digester

LIPP Post-Digesters

-

Flexible post-digesters for increasing biogas yield

Lipp offers three flexible post-digesters for ensuring the effective utilisation of residual gases and improving efficiency which can be tailored to the requirements of each individual biogas plant.

The LIPP Universal post-digester (with digester chamber volumes from 200 to 5000 m3) comes with the high-quality LIPP stainless steel diaphragm cover and is designed for use with an external gas accumulator. It is particularly suitable for the collection of residual gases and for improving efficiency.

The LIPP KomBio post-digester (with digester chamber volumes of up to 2500 m3) provides a tank solution with an integrated gas accumulator. The patented post-digester is substrate-flexible and also protects the gas accumulator from the wind, weather and UV radiation.

The third option is the LIPP Eco post-digester (with digester chamber volumes from 100 to 10,000 m3) which is available with or without a gas accumulator and with a choice of roof constructions.

Key benefits:- Can be integrated in existing plants

- Flexible diameter and height

- Minimal installation space required

- Short installation time

- Durable tanks and covers

- Consistent quality worldwide

- Individually customizable based on customer’s requirements

LIPP Liquid Manure Containers

-

Cost-effective storage of liquid manure

Lipp offers liquid manure containers for farms of any size that not only make promises to provide safe and cost-efficient storage but also keep those promises. Stainless steel may be the material of choice for constructing liquid manure containers but steel is expensive – and that is why Lipp uses Verinox, the material that it developed in-house. A combination of galvanised steel sheet (for the outside of the container) and stainless steel sheet (for the inside of the container), Verinox offers all the benefits of a high-quality material while enabling significant cost savings to be made at the same time.

The LIPP Double-Seam System enables containers to be constructed on site within a short space of time with a diameter that is steplessly variable between 3 and more than 50 metres. Damaged concrete containers can also be easily refurbished (see Container Refurbishing).

Key benefits:- Can be tailored to the customer’s requirements

- Steplessly variable in diameter and height

- On-site production

- Construction without the need for container boarding or scaffolding

- Suitable for expansion

- High quality and a long service life

- Wide range of peripheral accessories

- Consistent quality worldwide

LIPP Gas Accumulators

-

Cost-effective system for the non-pressurized storage of biogas, landfill gas and sewage gas

In biological processes, gas production is not continuous. That is why the utilization of gas (e.g. in a combined heat and power plant) requires an accumulator in order to compensate for fluctuations during gas production and to bridge downtimes for plant repairs and maintenance.

Besides high functional and operating safety, other important criteria for the construction and operation of gas tanks include the economic aspects of investment and maintenance costs.

Lipp developed a system for the non-pressurized (up to max. 5 mbar) storage of dry gas which has been used for over 300 projects worldwide over the past 30 years or more. Sizes from 30 to 5000 m³ are available according to the gas yield in each case.

LIPP Bulk Storage Silos

-

Guaranteed optimum storage for a wide variety of materials

The storage of bulk materials needs to be not only cost-effective but also safe, and systems should be easy to integrate in production processes.

LIPP Double-Seam technology and welded LIPP tanks have proven to be particularly suitable for bulk storage applications in industry and agriculture. LIPP silos provide a high level of stability and total leak-tightness and protect bulk materials from moisture. The smooth internal walls of the silos are a benefit that pays dividends when storing special media.

Silos for storing grain and other foodstuffs

Grain, soya and other foodstuffs are precious commodities and a major asset in agriculture and they need to be stored particularly carefully. With the tried and tested Lipp Double-Seam System, Lipp silos offer major benefits in terms of design and leak-tightness.

The container roof consists of a substructure comprising galvanized steel profile beams with a fibre-reinforced plastic tarpaulin stretched across them. It will give many years of use thanks to its UV stability. The material to be stored is therefore optimally protected against the effects of weathering. At the same time, the roof surface serves as a pressure relief disc in the event of dust explosions and prevents heavy parts from flying around, enabling damage to be rectified cost-effectively and within the shortest possible time.

Applications:- All kinds of bulk materials

- Grain

- Soya

- Silage fodder

- Woodchips

- Pellets

- Clinker brick

- Cement

Welded Tanks

-

In steel and stainless steel from 50 – 10,000 m3

LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high-alloy stainless steels. The automated process meets the highest quality standards.

LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes.

Key benefits- Solutions for a wide variety of applications and requirements

- Optimum quality thanks to automated welding process

- Material savings and additional stability thanks to circumferential profile

- Short construction times thanks to mechanized and automated production

- On-site production, indoors or in the open air

- Production by qualified technical personnel

LIPP Drinking Water Tanks

-

Made from stainless steel

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high-alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 2000 m3.

In addition, on-site production “off the production line” enables construction to be completed within the shortest possible time.

Project realization is carried out by qualified production and installation personnel. Only high-quality system components (fittings, measuring and control technology, etc.) are used as accessories.

Key benefits- Optimum quality thanks to automated welding process

- Material savings and additional stability thanks to circumferential profile

- Short construction times thanks to mechanized production

- Easy to maintain and clean

- Low investment and maintenance costs

- Can be set up indoors or in the open air

- Turnkey complete solution or components

LIPP Thermal Storage Tanks

-

For the intermediate storage of renewable energies – from 200 to 2,000 m³

The LIPP® thermal storage tank is the tailored thermal storage solution for renewable energies with an effective volume ranging from 200 to 2,000 m3 which is suitable for individual customisation.

Expedient thermal storage is a prerequisite for the effective utilisation of heat from biogas plants, biomass cogeneration plants, solar plants or other heat sources. The flexible-capacity LIPP® buffer storage tank provides the ideal solution for this application. The tanks are fabricated on site using the tried and tested LIPP® Double-Seam System and the stainless steel VERINOX®.

Insulation can be tailored to the intended application in order to produce large-volume, above-ground storage tanks with an individually customised interior. The tanks are designed for non-pressurised operation with an operating temperature of up to 95 °C and are suitable for use with heating water. No additional nitrogen system necessary.

Key benefits:- Tank-inside and interior fittings in stainless steel

- No ongoing operating costs

- Incl. safety systems

- Long durability

- Low-maintenance

- Tailored to individual requirements

- Infinitely variable in diameter and height

- Same quality worldwide

LIPP Thermal Storage Tanks Large Volume

-

Solution to effectively store excessive heat from biogas plants – from 2,000 to 6,000 m³

The LIPP® Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources.

The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal MAW-welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only.

The large-volume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions.

The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. No additional nitrogen system necessary.

Key benefits:- No ongoing operating costs

- Long durability

- Low-maintenance

- Tailored to individual requirements

- Infinitely variable in diameter

and height - Same quality worldwide

- Only horizontal welds

LIPP Special Tanks and Silos

-

On-site production flexibility with continuously variable dimensions

Special circumstances and requirements often call for containers which cannot be produced using standard solutions. This is where special tanks and silos which can be adjusted to suit prevailing conditions and provide individual solutions are required.

The LIPP System offers a variety of possible solutions to a wide range of problems in the form of welded or folded designs. Steplessly adjustable diameters and heights enable tank dimensions to be individually adapted to the prevailing conditions. In addition, on-site installation only requires a minimal amount of space, for example enabling containers to be constructed in buildings or other situations where there is limited space available. Tank-in-tank solutions can also be realized using the LIPP System.

Key benefits:- Can be tailored to the customer’s requirements

- Steplessly variable in diameter and height

- On-site production

- Minimal installation space required

- Flexible choice of materials

- High quality and long service life

- Wide range of peripheral accessories

LIPP Roofs and Covers

-

For covering liquid, solid or gaseous media

There are many factors to be taken into account in order to ensure that the medium to be stored is properly covered. To guarantee that the right type of cover is chosen, aspects such as structural requirements, container type, plant concept and the medium to be stored need to be considered.

Lipp offers a wide range of roofs and covers which can be tailored and adjusted to each application. They include both roofs developed by Lipp and also solutions designed by our partners. There are also simple foil roofs to choose from for gas storage facilities as well as single-skin, double-skin or double diaphragm roofs. The LIPP stainless steel diaphragm roof also offers a particularly high-quality solution for the storage of volatile or explosive substances while the versatile LIPP segment roof completes the range of covers.

Roofs and covers at a glance:- Foil roofs

- Single-skin roofs

- Double-skin roofs

- Double diaphragm roofs

- LIPP stainless steel diaphragm roof

- LIPP segment roof

LIPP Betavator Sugar Beet Silo

-

For storing biomass to be used for energy production or animal feed

The open intermediate storage of substrates means energy losses and that is why LIPP developed airtight storage tanks for preserving suitable substrates so that they could then be automatically pumped into the digester for further digestion all year round. As a result, these airtight containers turn energy losses into energy gains, i.e. a higher gas yield, and also prevent unpleasant odour emissions.

The LIPP Betavator sugar beet silo is suitable for the optimal year-round storage (siloing) of sugar beets and other root crops which produce high biogas yields per hectare of cultivated land. After mashing, the beets are pumped directly into the gastight LIPP Betavator sugar beet silo where the high-quality sugar beet silage is preserved.

The LIPP Ligavator was developed for the liquid preservation of wet maize and grain. The substrate is mixed via a filling auger and then pumped into the Ligavator. As a result, the operator is saved the laborious task of feeding the digester or the preliminary tank and the energy in the substrate is preserved.

Key benefits:- Compact and space-saving

- High functional safety

- Reduced retention time in the digester

- Reduced energy losses during storage

- Low-maintenance and durable

- Automatic feeding

- Storage losses as a result of oxidation are avoided

Container Refurbishing

-

System for the cost-effective refurbishing or volume expansion of containers or tanks

Changing conditions, material wear, a change to the filling medium – these are just a few of the factors that lead to the replacement of containers used in industry or at municipal sewage treatment plants. Quantities change and existing containers become too small – these are also problems that frequently arise.

In such cases, the mobile machine technology from Lipp using the LIPP Double-Seam System or the LIPP welding technique offers a solution that is as simple as it is cost-effective, while being extraordinarily stable. Containers can be installed on site in any size required and can be placed in an existing steel or reinforced concrete basin using a mobile crane. The existing container volume is utilised, eliminating the need for expensive demolition work.

There is also a range of materials to choose from for the container itself so that it can be optimally matched to the intended application. Verinox, the combination material developed by Lipp consisting of galvanised steel (for the outside of steel containers) and stainless steel (for the inside of containers), is characterised in particular by the excellent cost-benefit ratio that it offers.

Key benefits:- Utilisation of the existing container volume

- High stability, leak-tightness and safety

- Continuous adaptation to existing container sizes

- Can be combined with a broad range of accessories

- Low investment and maintenance costs

- Short assembly times

LIPP Accessories

-

Wide range for technical equipment

Whether grain silos, biogas systems or liquid manure containers, Lipp places the greatest importance on quality, safety, a long service life and cost efficiency over its entire product portfolio – including accessories.

The whole is more than the sum of its parts. That is especially true for Lipp container solutions and systems as special attention is paid to all parts – including accessories – to ensure quality, safety, longevity and cost efficiency.

A broad range of technical accessories is available for all containers. Some are produced in-house and some are purchased via partners or carefully selected suppliers with whom Lipp has established long-term relationships based on trust.

Accessories:- Container bottoms

- Container insulation

- Pumping and stirring technology

- Overflow gutters

- Container heating

- Steps, platforms and operating bridges

- Overpressure and underpressure protection devices

- Pipeline construction

- Sensors

System Solutions

-

System solutions for industry, municipalities and agriculture

As well as individual containers, Lipp offers system solutions for industrial, municipal and agricultural applications and in particular for biogas production.

In addition to expertise in planning and design, the focus lies in particular on the development and marketing of system components for the following applications:

- Anaerobic and aerobic treatment of industrial and municipal waste waters

- Sewage sludge digestion

- Gas storage

- Biogas production from industrial (waste-to-energy) or agricultural residues (e. g. food and slaughterhouse waste, animal waste) and renewable raw materials of all kinds

- Drinking water

- Process water

Industry

-

Equipment and container systems for various industries

Based on decades of experience in plant and tank construction, Lipp has proved a reliable partner for planners and end users in various industries and areas of application.

In addition to solutions for industrial waste water treatment, for example for the food and beverage industry, and the production of biogas from industrial waste, Lipp also has successfully implemented numerous process vessels and the storage of special liquids, gases and bulk goods.

Lipp’s core expertise was acquired in plant construction in many different projects at home and abroad, and is being constantly expanded. The knowledge and process expertise gained are a crucial advantage in the planning, design and installation of equipment and container systems. One of the biggest advantages, in addition to the durability and low maintenance costs of the system components, is the same high quality standard, regardless of whether a project is planned in Africa, America, Asia or Central Europe. This high quality standard is guaranteed by the on-site machine production with self-developed special machines and highly qualified technicians, as well as the self-manufactured materials and components.- Biogas production

- Waste water

- Process water

- Heat accumulator

Municipality

-

Municipal system solutions

Lipp tanks and system solutions for municipal water supply and waste water management have been equally highly valued by operators as well as planners for decades.

For Local Authorities Lipp offers system solutions for the following applications:

Sludge – sewage sludge digesters

Waste water treatment – waste water tanks

Storage of drinking water – drinking water tanks

Storage of dry gas – gas holders

Sludge Treatment – sludge piling containers / thickeners

- Sewage sludge

- Waste water

- Drinking water

- Gas storage

Agriculture

-

Professional storage, reuse or disposal

Modern agriculture is faced with a great many tasks today – including the proper storage, reuse or disposal of a broad range of different media, from crop yields to bulk materials, liquid manure or vegetable and animal waste.

Flexibility in planning and tendering

Special situations require special solutions. This is particularly true for the agricultural sector. It must be possible to realise the systems quickly and flexibly, and to ensure quality and safety with a simultaneously high level of efficiency.

Lipp traditionally completely fulfils these criteria. Based in the rural area of the Swabian East Jura region, Lipp has been especially close to agriculture for the past 50 years and knows all the aspects when it comes to special requirements.

- Biogas

- Slurry storage

- Cereal storage

- Silage

Anaerobic Digestion & Biogas

-

Biogas for industry, municipalities and agriculture

In addition to tank construction, Lipp built the first biogas plant in Germany in the 70’s. Furthermore, Lipp was one of the first companies to develop and sell small biogas plants in the early 80’s.

By steady advancements in production technology and the materials used, as well as extensive experience in process engineering Lipp has installed in collaboration with its partners, hundreds of biogas plants in Germany and worldwide. The majority of these projects are still in operation and ensure proof of the high quality and the technical and economic performance of Lipp’s system solutions.

Lipp provide system solutions for biogas production in the following areas:- anaerobic wastewater treatment plants

- waste fermentation plants

- sewage sludge digestion

- agricultural biogas plants