Navigation : EXPO21XX > QUALITY & TESTING 21XX >

H26: Reliability and Life Cycle Testing

> Carl Zeiss

Carl Zeiss

Videos

Loading the player ...

- Offer Profile

- ZEISS is an internationally leading technology enterprise operating in the optics and optoelectronics industries.

For its customers, ZEISS develops, produces and distributes highly innovative solutions for industrial metrology and quality assurance, microscopy solutions for the life sciences and materials research, and medical technology solutions for diagnostics and treatment in ophthalmology and microsurgery.

Product Portfolio

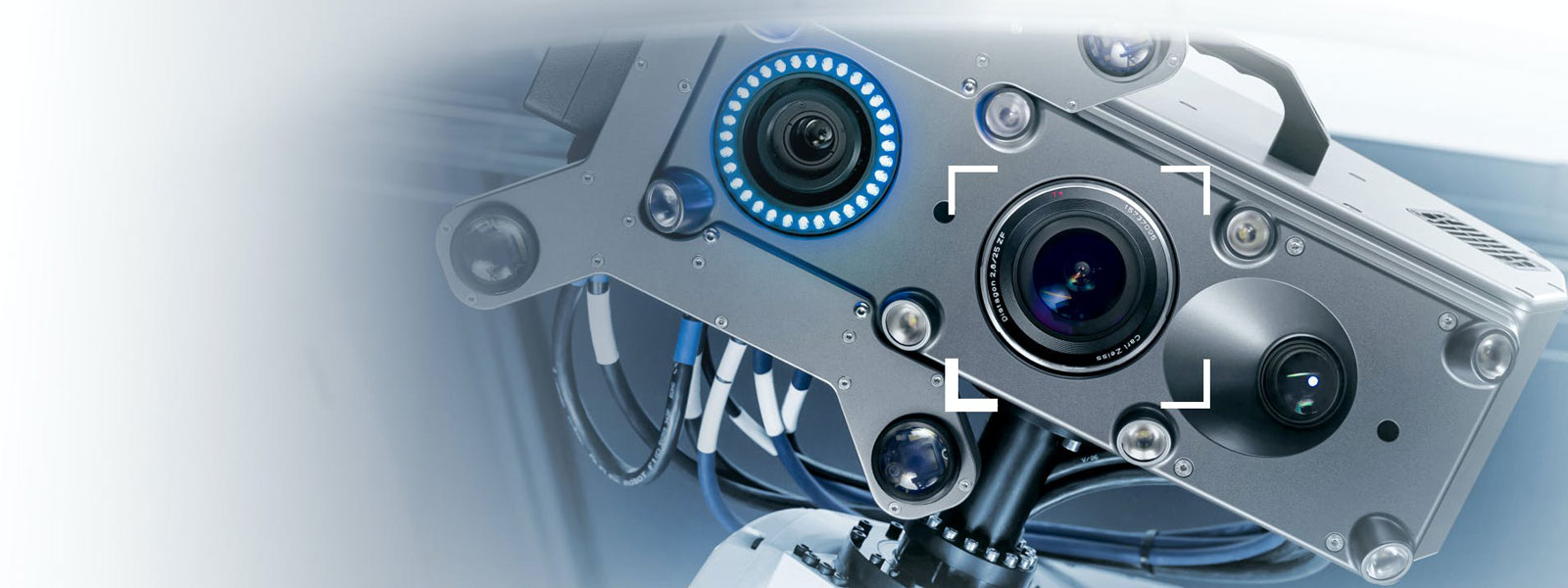

ZEISS Industrial Lenses

- Ensuring reliable results with high performance optics.

Gain valid results and completely new insights.

ZEISS lenses for technical applications are key components in complex production processes (Machine Vision) as well as in optical metrology, medical applications, traffic enforcement, quality assurance, sports and many other applications. Here they prove their outstanding image performance and reliability. Due to the precise manual adjustment of the helical focusing mount our partners will gain much better results than with comparable lenses. ZEISS Ventum 2.8/21

Lightweight industrial lens with E-mount for use with drones.

- The ZEISS Ventum® 2.8/21 offers outstanding optical quality in a compact and rugged aluminum housing. The extremely fast, fixed-focal-length lens for Sony's E-Mount was primarily developed for use with drones. Lenses used for this purpose must be as small and light as possible, yet still offer outstanding image quality. Thanks to its compact design and the use of a fixed-focus setting, the weight of the ZEISS Ventum® 2.8/21 has been reduced by 50% compared to the Interlock Compact 2.8/21. This reduction in weight allows drones to fly longer, resulting in greater efficiency.

The lens is equipped with the E-Mount and is compatible with large area-scan and line-scan sensors with an image circle of up to 43 mm and a pixel size starting at 2.8 µm. The aperture can be adjusted on the lens by 1/3 f-stops from F2.8 to F22. The locking and torque of the aperture ring are designed to prevent accidental adjustment due to vibrations or the movement of the drone through the air.

Zeiss Ventum and Drones

- Drones are important tools in modern surveillance applications, and will become increasingly common in the future. The ZEISS Ventum 2.8/21 offers unmatched data quality for applications such as cartography, creating three-dimensional models, inspections, surveys or monitoring project progress from the air.

The lens also provides reliable data in stationary applications such as the large-scale monitoring of events, power plants, open-cast mining, landfills or construction sites.

DATALens Type Focal Length Max. Aperture Min. Free Working Distance Min. object distance Filter Thread Camera Mount Ventum 2.8/21 21 mm 2.8 - Fixed to 15m M52 x 0.75 E-Mount

Stress Test

ZEISS lenses need to operate perfectly in extreme conditions, withstanding everything from scorching heat and bitter cold to sandstorms and severe vibrations. The video shows how ZEISS researchers systematically submit lenses to extreme stresses in order to arrive at findings that can help in future lens design and development. The video explains how a lens with fixing screws was tested regarding following norms:- DIN ISO 9022

- DIN EN 60068-1: 1988-06

- DIN EN 60068-2 Part 64: 2009-04

- MIL-Std 810G

Rugged and Lightweight Housing

- The high-quality aluminum housing is extremely rugged and both dust and weather-resistant (IP64). It is designed to prevent the ingress of even ultra-fine dust and is resistant to rain or splash water on all sides. As a result, the ZEISS Ventum 2.8/21 is ideal for outdoor use in extreme environmental conditions. Rain, fine sand, extreme temperatures, and high humidity are no problem for the wide-angle lens. In addition, eliminating electronic communication between the camera and lens saves weight and energy, allowing operators to perform even longer inspection flights.

The fixed focus close to the hyperfocal distance produces a large depth of field. This allows the pilot to fly the drone to different heights without having to worry about readjusting the focus. In addition, eliminating variable focus levels simplifies downstream data processing. Adjusting the aperture setting makes it possible to precisely adjust the depth of field in order to inspect closer objects in detail. Nevertheless, the focus of the image processing system remains unchanged. In the case of drones, this ensures that the stabilizer balances the drone consistently.

Exceptional image quality

- The ZEISS Ventum 2.8/21 stands out as an extreme wide-angle lens with exceptional optical imaging correction. The lens offers unmatched levels of contrast, resolution, and color fidelity across the entire imaging area. This saves time and computing power during post-processing and also provides to more accurate data when calculating 3D models.

ZEISS T* Coating

The ZEISS T* coating was applied to every surface of the optical elements in the ZEISS Ventum 2.8/21. It prevents reflections and guarantees exceptional image quality, even under difficult lighting conditions.

ZEISS Dimension Lenses

High precision for greater efficiency.

- The new ZEISS Dimension® family meets the highest demands for industrial applications. The lenses developed for use with a C-mount are designed for image sensors up to a size of 4/3” and offer exceptional image quality in a compact, lightweight and rugged aluminum housing. The ZEISS Dimension® family consists of six focal lengths ranging from 8 to 50 millimeters. Almost all ZEISS Dimension lenses have the same outer diameter for reliable planning when mounting them in production facilities.

Precision and ease of operation are key factors that make the ZEISS Dimension family stand out. With the help of the innovative adjustment mechanism*, it is easy to compensate for tolerances at the camera mount. In addition to the C-mount’s stable screw connection, locking screws on the focus and aperture rings guarantee a high degree of stability and ensure that the settings remain in the correct position.

DATALens Type Focal Length Max. Aperture Min. Free Working Distance Min. Working Distance (Sensor to Object) Filter Thread Camera Mount* Dimension 2.8/8 8 mm 2.8 102.1 mm 180.6 mm M72 x 0.75 C-Mount* Dimension 2/12 12 mm 2.0 101.0 mm 180.4 mm M43 x 0.75 C-Mount* Dimension 2/25 18 mm 2.0 91.1 mm 170.5 mm M43 x 0.75 C-Mount*

Stress Test

ZEISS lenses need to operate perfectly in extreme conditions, withstanding everything from scorching heat and bitter cold to sandstorms and severe vibrations. The video shows how ZEISS researchers systematically submit lenses to extreme stresses in order to arrive at findings that can help in future lens design and development. The video explains how a lens with fixing screws was tested regarding following norms:- DIN ISO 9022

- DIN EN 60068-1: 1988-06

- DIN EN 60068-2 Part 64: 2009-04

- MIL-Std 810G

Exceptional image quality

- Thanks to ZEISS Dimension lenses’ outstanding image quality, even the smallest structures are clearly resolved. This reduces the demands placed on downstream image processing and makes shorter production times possible. In addition, the lenses’ extremely high image resolution is what makes certain measurements and the ability to collect some data possible at all.

Correct flange focal distance tolerances

- Precision is crucial in industrial applications. For maximum image sharpness, the lens and camera must work perfectly together. The smallest deviations in the flange focal distance can have negative effects on imaging performance. This is why the ZEISS Dimension lens family is equipped with the innovative adjustment mechanism*. The benefit of this system is that it allows the back focus distance to be corrected by up to +/- 0.2 millimeters without having to disassemble parts of the lens.

ZEISS T* coating for high-contrast images without reflections

- The ZEISS Dimension lenses feature all ZEISS T* coating. The careful selection of the layers deposited on the lenses ensures both the high and uniform transmission of light from the visible spectral range to the near-infrared wavelength range.

For sensors up to the 4/3” format

ZEISS Dimension lenses can be used with all common sensor formats that are offered in combination with the C-mount. The range of compatible formats extends up to 4/3” sensors. All ZEISS Dimension lenses make it possible to fully exploit the resolving power of sensors with a pixel size of up to two microns. They stand out due to their high speed with a maximum aperture of f/2, or f/2.8 at 8 mm. This not only brings advantages in low light – the lenses’ high speed makes short exposure times possible, resulting in faster processes.

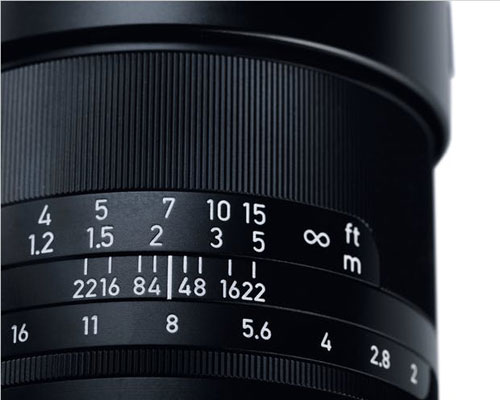

Scales can be read from any position

- The mounting position of lenses on cameras in industrial applications can vary greatly. This often leads to scales being in inconvenient positions that are difficult to see during operation. To ensure optimum legibility at all times, the azimuth alignment of the scales can be corrected. Doing so is as easy as loosening three screws, moving the scales into the desired position and retightening the screws.

Locking screws for aperture and focus

To ensure maximum image quality, eliminating interference from external vibrations is extremely important. This is why ZEISS Dimension lenses are equipped with three locking screws each on the aperture and focus ring. They prevent the lens settings from shifting unintentionally as a result of vibrations. All ZEISS Dimension lenses have been extensively tested for reliable performance under permanent mechanical stress and meet the stringent requirements of DIN ISO 9022.

ZEISS Interlock Lenses

Professional lenses with optimized locking screws.

- All Interlock® lenses from ZEISS offer extraordinary image quality with high contrast for technical and industrial applications. They feature an improved fixture for focus and aperture as well as a full metal housing for robustness. The lenses impress with their high image quality and precise manual focus. They are available with standard F-Mount and standard M42x1 Mount (45,5 mm Flange Focal Distance) for even more stability.

In the F-Mount version the aperture can be adjusted continuously by taking advantage of the de-click function, allowing precise exposure setting. The Interlock® familiy cover linescan sensors up to 43 mm (4k to 8k) or full frame area sensor with 24 x 36 mm (up to 42 Mpixel).

The ZEISS Interlock family consits of eleven focal lengths range from 15 mm to 135 mm. With additional focal lengths and improved fixations they complete the lenses of the ZEISS Classic family.

DATALens Type Focal Length Max. Aperture Min. Free Working Distance Min. Working Distance (Sensor to Object) Filter Thread Camera Mount* Interlock 2.8/15 15 mm 2,8 90 mm 250 mm M95 x 1.00 F-Mount, M42 Interlock 2.8/18 18 mm 2,8 200 mm 300 mm M82 x 0.75 F-Mount, M42 Interlock 2.8/21 21 mm 2,8 90 mm 250 mm M82 x 0.75 F-Mount, M42

Stress Test

ZEISS lenses need to operate perfectly in extreme conditions, withstanding everything from scorching heat and bitter cold to sandstorms and severe vibrations. The video shows how ZEISS researchers systematically submit lenses to extreme stresses in order to arrive at findings that can help in future lens design and development. The video explains how a lens with fixing screws was tested regarding following norms:- DIN EN 60068-1: 1988-06

- DIN EN 60068-2 Part 64: 2009-04

- MIL-Std 810G

High-quality metal housing

-

Noticeable quality and high value stability qualify ZEISS lenses for decades of intense use. The high-quality craftsmanship of the all-metal mount, the metal housing and the aperture ring as well as the robust front bayonet ensure reliable results.

Heavy-duty fixtures for focus and aperture

ZEISS Interlock lenses are equipped with special screws to fix focus and aperture to get stable and reliable measuring results even in rough industrial conditions. Both the locking screws and the stable design make the lens inured to vibrations, improve measuring repeatability and avoid machine downtime.

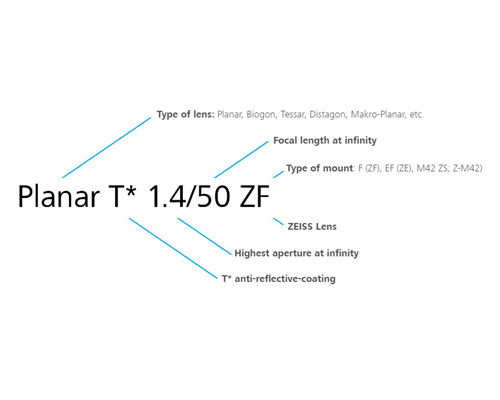

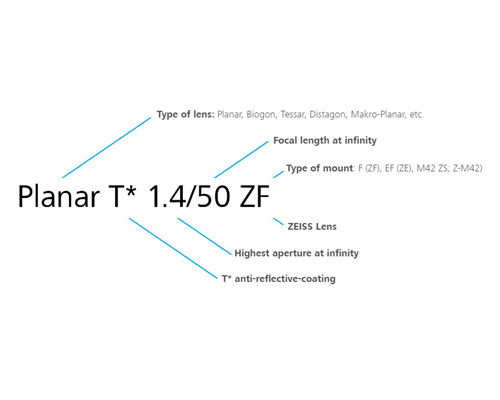

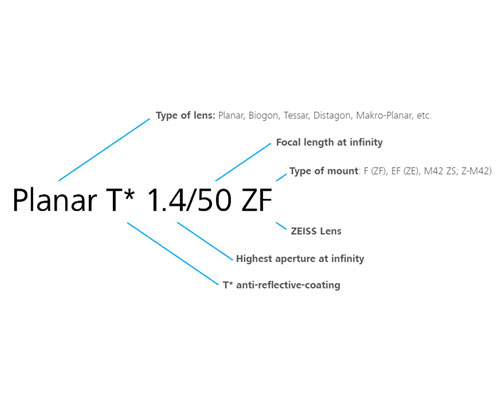

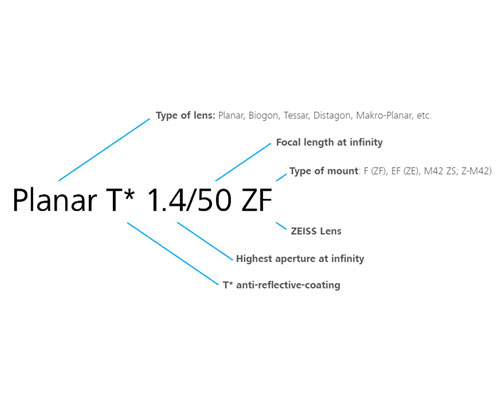

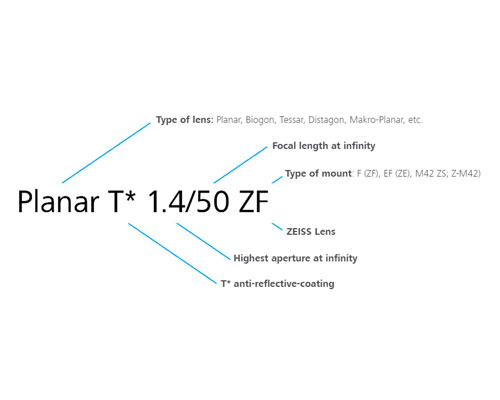

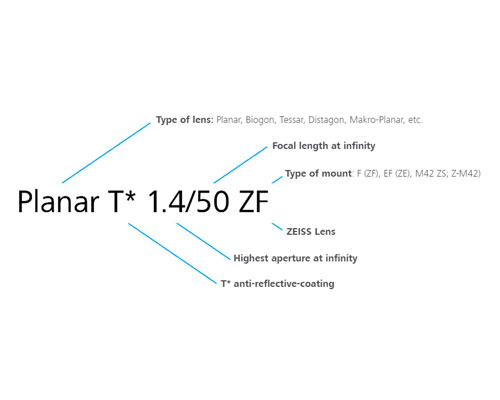

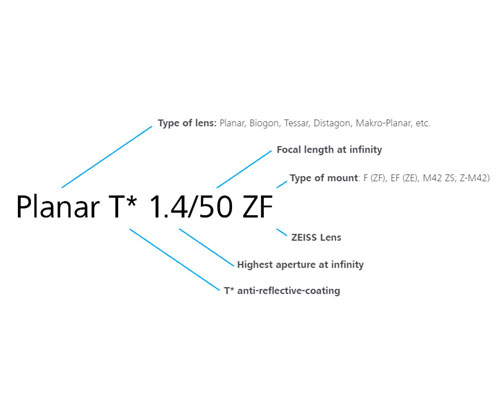

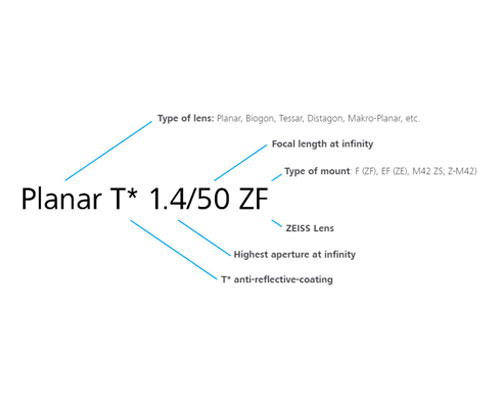

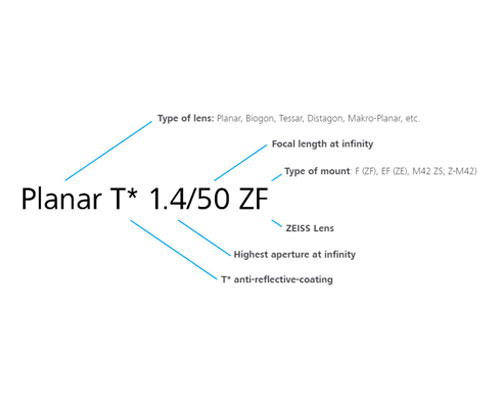

ZEISS T* anti-reflective coating

The optical elements of ZEISS lenses feature T* anti-reflective coating on all surfaces and an optical design that guarantees images of superior brilliance at all times, even in unfavourable lighting conditions. The first coating techniques were employed by ZEISS as long ago as in the 1930s.

High image quality

- The excellent image performance of the ZEISS Interlock lenses is sharply focused on the requirements of current and future high-performance digital cameras. Thanks to the low level of stray light allowed by the lens design, high-contrast images are also possible with increasing high dynamic ranges of the sensors (HDR). The minimization of coma, astigmatism and spherical aberrations enables constantly high resolution over the entire image field. The optics are designed to ensure full utilization of the performance provided by high-resolution camera systems.

ZEISS Interlock Compact Lenses

Compact lenses for large image circles

- The Interlock® Compact lens family impresses with its high and unwavering image quality and precise manual focus. Their low weight, compactness and robust full-metal housing make the lenses suitable for rough industrial use. The lens family features a short M42x1 mount (18 mm FFD) and superior fixture screws that allow exact locking of aperture and focus.

They fit to line scan cameras with sensors of 43 mm (4k – 8k) and area scan cameras with full frame sensors of 36 x 24 mm (up to 42 Mpixel). The outstanding difference of ZEISS Interlock Compact lenses against traditional F-Mount types is the M42x1 mount with a very short flange focal distance (FFD) of only 18,0 mm.

The Interlock® Compact lens family from ZEISS consists of five focal lengths from 21 mm to 85 mm and are key components in complex production processes (Machine Vision) as well as in optical metrology, medical applications, traffic enforcement, quality assurance, sports and many other applications.

DATALens Type Focal Length Max. Aperture Min. Free Working Distance Min. Working Distance (Sensor to Object) Filter Thread Camera Mount* Interlock Compact 2.8/21 21 mm 2,8 160 mm 250 mm M52 x 0.75 M42 Mount / 18 mm FFD* Interlock Compact 2.4/25 25 mm 2.4 160 mm 250 mm M52 x 0.75 M42 Mount / 18 mm FFD* Interlock Compact 2/35 35 mm 2.0 230 mm 300 mm M52 x 0.75 M42 Mount / 18 mm FFD*

Stress Test

ZEISS lenses need to operate perfectly in extreme conditions, withstanding everything from scorching heat and bitter cold to sandstorms and severe vibrations. The video shows how ZEISS researchers systematically submit lenses to extreme stresses in order to arrive at findings that can help in future lens design and development. The video explains how a lens with fixing screws was tested regarding following norms:- DIN ISO 9022

- DIN EN 60068-1: 1988-06

- DIN EN 60068-2 Part 64: 2009-04

- MIL-Std 810G

Advantages of the Interlock Compact Lenses

- Higher stability against shocks and vibrations since the center of gravity is closer to the sensor

- Higher stability between lens and camera because M42-mount

- Less volume consumed

- Higher precision when the aperture is set

- Optics can be designed more symmetrical which leads to higher performance, lower distorsion etc.

High-quality metal housing

- Noticeable quality and high value stability qualify ZEISS lenses for decades of intense use. The high-quality craftsmanship of the all-metal mount, the metal housing and the aperture ring as well as the robust front bayonet ensure reliable results.

Heavy-duty fixtures for focus and aperture

- ZEISS Interlock Compact lenses are equipped with special screws to fix focus and aperture to get stable and reliable measuring results even in rough industrial conditions. Both the locking screws and the stable design make the lens inured to vibrations, improve measuring repeatability and avoid machine downtime.

ZEISS T* anti-reflective coating

- The optical elements of ZEISS lenses feature T* anti-reflective coating on all surfaces and an optical design that guarantees images of superior brilliance at all times, even in unfavourable lighting conditions. The first coating techniques were employed by ZEISS as long ago as in the 1930s.

Precise manual focus

- Manually focusing a lens means controlling the image result from your fingertips. A good ergonomic design makes all the difference. ZEISS lenses stand out with their large rotation angle which enables precise focusing. Changes are immediately visible in the viewfinder. The high-quality focusing mechanism moves smoothly without play, thus also supporting the intuitive interaction with the focal plane. The precise engraving in meter and feet, and the depth of focus scale provide additional support for manually focusing.

ZEISS Otus Lenses

Uncompromising image quality.

- ZEISS Otus Lenses offer the possibility to image fast at low light with practically no aberrations. The lenses operate at f/1.4 without any compromises in performance. At f/1.4 you will hardly see any color fringes even when using 3,5 µm pixels. These lenses will provide you with build quality and extremly smooth rotation angle for the very best usability. All these features make the ZEISS Otus lenses absolutely unique and set new standards.

All ZEISS Otus lenses cover linescan sensors up to 43 mm (12k) or full frame area sensor with 24 x 36 mm (71 or more Mpixel) and are available with standard F-Mount. The ZEISS Otus family consits of four focal lengths range from 28 mm to 100 mm and are key components in complex production processes (Machine Vision) as well as in optical metrology, medical applications, traffic enforcement, quality assurance, sports and many other applications. Here they prove their outstanding image performance and reliability.

DATALens Type Focal Length Max. Aperture Min. Free Working Distance Min. Working Distance (Sensor to Object) Filter Thread Camera Mount* Otus 1.4/28 28 mm 1.4 150 mm 300 mm M95 x 1.00 F-Mount*, EF-Mount* Otus 1.4/55 55 mm 1.4 330 mm 500 mm M77 x 0.75 F-Mount*, EF-Mount* Otus 1.4/85 85 mm 1.4 650 mm 800 mm M77 x 0.75 F-Mount*, EF-Mount*

Stress Test

ZEISS lenses need to operate perfectly in extreme conditions, withstanding everything from scorching heat and bitter cold to sandstorms and severe vibrations. The video shows how ZEISS researchers systematically submit lenses to extreme stresses in order to arrive at findings that can help in future lens design and development. The video explains how a lens with fixing screws was tested regarding following norms:- DIN ISO 9022

- DIN EN 60068-1: 1988-06

- DIN EN 60068-2 Part 64: 2009-04

- MIL-Std 810G

Long-lasting product with protection against environmental influences

- The all-metal housing makes every adjustment a haptic experience. The dynamic, precise barrel design sets new trends in the world of camera lenses. However, the ZEISS Otus Lenses will impress you not only due to their visual and haptic excellence, but also thanks to their inner qualities. Special seals for protection against dust and splashes guarantee the system's functional reliability even in environmentally difficult situations.

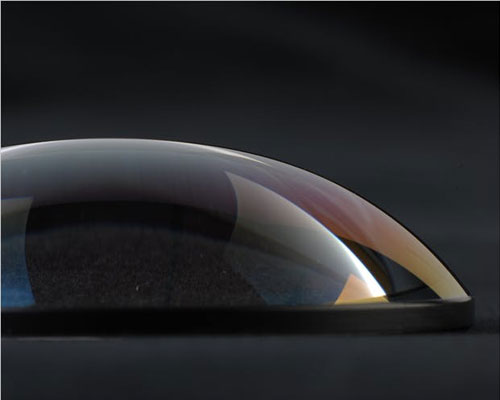

Aspherical design

- The aspherical lens design ensures consistent imaging performance throughout the entire focusing range as well as sharpness to the periphery of the image. The asphere's more complex surface profile can reduce or eliminate spherical aberration and also reduce other optical aberrations compared to a simple lens.

ZEISS T* anti-reflective coating

The optical elements of ZEISS lenses feature T* anti-reflective coating on all surfaces and an optical design that guarantees images of superior brilliance at all times, even in unfavourable lighting conditions. The first coating techniques were employed by ZEISS as long ago as in the 1930s.

Virtually distortion-free optics

- Dramatic perspectives and a view from extraordinary image angles – ZEISS lenses open up new composition possibilities. Distortion would disrupt the composition because straight lines, whose image does not go through the image center, would be reproduced with a curved shape. This annoying effect is accordingly and largely compensated through elaborate optical designs at all focal lengths.

The ultimate in image contrast

Aberrations caused by extreme differences between shadows and highlights are particularly obvious in images captured at night. Thanks to the outstanding correction of lateral chromatic aberration, the floodlit facade is reproduced with absolute perfection.

ZEISS Classic Lenses

Proven optical design in a sturdy metal housing.

- The ZEISS Classis lens family offers extraordinary image quality with high contrast for technical and industrial applications in addition to a precise fixture for focus and aperture. The outer design is characterized by a full-metal housing as well as a focus ring, which allows precise manual focusing.

The lenses cover linescan sensors up to 43 mm (4k to 8k) or full frame area sensors with 24 x 36 mm (up to 42 Mpixel). They are available with F-Mount and M42x1-Mount (45,5 mm Flange Focal Distance) for more stability. The lens family consists of five lenses from 25 mm to 85 mm. This range is completed by the lenses of the ZEISS Interlock family.

ZEISS lenses for technical applications are key components in complex production processes (Machine Vision) as well as in optical metrology, medical applications, traffic enforcement, quality assurance, sports and many other applications. Here they prove their outstanding image performance and reliability. Due to the precise manual adjustment of the helical focusing mount you will gain much better results than with comparable lenses.

DATALens Type Focal Length Max. Aperture Min. Free Working Distance Min. Working Distance (Sensor to Object) Filter Thread Camera Mount* Distagon T* 2.8/25 25 mm 2.8 60 mm 170 mm M58 x 0.75 F-Mount*, M42** Distagon T* 2/28 28 mm 2.0 120 mm 240 mm M58 x 0.75 F-Mount*, M42** Distagon T* 2/35 35 mm 2.0 180 mm 300 mm M58 x 0.75 F-Mount*, M42**

Stress Test

ZEISS lenses need to operate perfectly in extreme conditions, withstanding everything from scorching heat and bitter cold to sandstorms and severe vibrations. The video shows how ZEISS researchers systematically submit lenses to extreme stresses in order to arrive at findings that can help in future lens design and development. The video explains how a lens with fixing screws was tested regarding following norms:- DIN ISO 9022

- DIN EN 60068-1: 1988-06

- DIN EN 60068-2 Part 64: 2009-04

- MIL-Std 810G

High-quality metal housing

- Noticeable quality and high value stability qualify ZEISS lenses for decades of intense use. The high-quality craftsmanship of the all-metal mount, the metal housing and the aperture ring as well as the robust front bayonet ensure reliable results.

Fixing srews for focus and aperture

ZEISS Classic lenses are equipped with small screws to fix focus and aperture to get stable and reliable measuring results even in rough industrial conditions. Both the locking screws and the stable design make the lens inured to vibrations, improve measuring repeatability and avoid machine downtime.

ZEISS T* anti-reflective coating

The optical elements of ZEISS lenses feature T* anti-reflective coating on all surfaces and an optical design that guarantees images of superior brilliance at all times, even in unfavourable lighting conditions. The first coating techniques were employed by ZEISS as long ago as in the 1930s.

High Speed Lenses

Good optical quality captured in low light always begin with a fast lens for a system or a camera. Because, a fast, high-performance lens captures as much light as possible. And a lens with a large maximum aperture leads to the best results when shooting in unfavourable light.