- Offer Profile

- We are a team of diverse specialists, but all with a sound background in 3D scanning and aerosol development

This unique combination enables us to change and shape the scanning spray industry. We know the needs of complex digitization processes and know how to provide dedicated solutions. We make scanning life easier with our products.

We are continuously developing ourselves and our products and can therefore ideally support challenges and new requirements.

We love the daily exchange with users, scanning manufacturers, service providers and our partners.

AESUB STATE OF THE ART SCANNINGSPRAY

-

AESUB – a new revolutionary scanningspray. Helps to digitize reflecting and transparent surfaces and evaporates after the 3D scanning. No more mess, no more cleaning, easy to apply, thin layer, super quality – state of the art scanningspray!

The idea of AESUB scanningsprays is, to allow faster, more efficient and accurate 3D Scanning processes.

3D Scanning Sprays as Aerosols

-

Vanishing Scanning Sprays

Vanishing scanning sprays form a white, dry to handle coating that evaporates automatically after scanning. There is no need to clean scan objects and components. Laboratories, sensors, environments and users are not contaminated by any pigments.

AESUB blue

-

AESUB blue is a self-vanishing scanning spray developed by scanning experts. The spray evaporates within a few hours, meaning that there is no need for cleaning after scanning. Unlike traditional sprays, AESUB blue does not contain pigments and thus avoids pigment-contamination of sensitive areas, such as laboratories and production sites, equipment and users. You can therefore apply AESUB blue directly, on spot of scanning, without any costly transport to avoid said pigment-contamination in sensitive areas. Overall, AESUB blue greatly increases efficiency and productivity within the digitizing processes.

- Sublimating

- Pigment-free

- White coating

- Scanning time: approx. 1-2 h

- Sublimation time: approx. 4 h

- Layer thickness: 8-15 μm

AESUB violet

-

AESUB violet is a new self-volatilizing scanning spray developed by scanning experts. It eliminates basic application problems of 3D metrology, especially in sensitive areas (laboratories, production, etc.) and protects the equipment from contamination by deposition of pigments. Expensive transports of externally matted measuring objects to the sensor as well as the time-consuming cleaning of the measuring environment and objects after scanning are no longer necessary. With AESUB violet, you achieve a significant increase in efficiency and productivity in the entire digitization process.

- Sublimating

- Pigment-free

- White coating

- Scanning time: approx. 2-6 h

- Sublimation time: approx. 24 h

- Layer thickness: 4-8 μm

AESUB orange

-

AESUB orange is a long-lasting self-volatilizing scanning spray developed by scanning experts. It eliminates basic application problems of 3D metrology, especially in sensitive areas (laboratories, production, etc.) and protects the equipment from contamination by deposition of pigments. Expensive transports of externally matted measuring objects to the sensor as well as the time-consuming cleaning of the measuring environment and objects after scanning are no longer necessary. With AESUB orange, you achieve a significant increase in efficiency and productivity in the entire digitization process.

- Sublimating

- Pigment-free

- White coating

- Scanning time: approx. 4-8 h

- Sublimation time: approx. 12-24 h

- Layer thickness: 2-6 μm

AESUB transparent

-

AESUB transparent is a scan spray that temporarily mattes glossy surfaces with a transparent film. This allows optical scanners to capture not only the surface contours but also the color values of the measured object at the same time. AESUB transparent is vanishing so no cleaning required.

- Sublimating

- Pigment-free

- Transparent coating

- Scanning time: approx. 1-2 h

- Sublimation time: approx. 4 h

- Layer thickness: 15-20 μm

AESUB diamond

-

AESUB diamond is a cutting-edge solution tailored for the jewellery industry. Developed by scanning experts, AESUB diamond is a revolutionary self vanishing scanning spray designed to enhance your scanning experience. Unlike conventional sprays, AESUB diamond is pigment-free, ensuring zero pigment contamination in crucial areas like scanner, equipment, and users. With its unique formulation, AESUB diamond eliminates the need for cleaning after scanning, as it naturally evaporates within abt. 10 minutes. This means you can scan rings and other jewellery items, applying AESUB diamond directly on the spot, without worrying about transporting them to prevent pigment contamination.

- Sublimating

- Pigment-free

- White coating

- Scanning time: approx. 10 min

- Sublimation time: approx. 15-30 min

- Layer thickness: 2 μm

Permanent Scanning Sprays

-

Permanent scanning sprays create a thin and homogeneous coating on the surface of the object. It ensures perfect contrast for the 3D scanning process. AESUB white contains pigments, propellant and solvents and has been optimized in terms of material compatibility. With the improved surface homogeneity and reduced layer thickness, AESUB white sets new standards.

In contrast to conventional sprays, AESUB white does not contain any titanium dioxide, which the European Chemicals Agency (ECHA) has classified as carcinogenic when inhaled.

AESUB white

-

AESUB white is a permanent scanning spray developed by scanning experts. It is the result of consistent further development of permanent scanning sprays. The spray applies a homogeneous, thin matting layer onto the surface of the object. It is developed for optimal contrast values in optical scanning applications. AESUB white contains pigments, propellant and solvent and has been optimized with regards to material compatibility. AESUB white sets new standards by optimizing the surface’s homogeneity and reducing layer thickness. Unlike traditional sprays, AESUB white is free of titanium dioxide, associated with cancerogenic incidents through inhalation by the European Chemicals Agency.

- Permanent

- Free of titanium dioxide

- White coating

- Easy to remove

- Layer thickness: 7 μm

3D Scanning Sprays as Liquids

-

Vanishing Scanning Sprays

Vanishing scanning sprays form a white, dry to handle coating that evaporates automatically after scanning. There is no need to clean scan objects and components. Laboratories, sensors, environments and users are not contaminated by any pigments.

AESUB violet

-

AESUB violet is a self-volatilizing scanning spray liquid developed by scanning experts. It eliminates basic application problems of 3D metrology, especially in sensitive areas (laboratories, production, etc.) and protects the equipment from contamination by pigment deposition. Expensive transports of externally matted measuring objects to the sensor as well as the time-consuming cleaning of the measuring environment and objects after scanning are no longer necessary. With AESUB violet, you achieve a significant increase in efficiency and productivity in the entire digitization process.

- Vanishing scanning spray

- Bulk for spray gun

- Perfect for large scale and automated scanning applications

- No cleaning required

- Free of pigments – free of titanium dioxide (TiO2)

- Thin and homogeneous coating

AESUB green

-

AESUB green is a self-volatilizing scanning spray liquid developed by scanning experts. It eliminates basic application problems of 3D metrology, especially in sensitive areas (laboratories, production, etc.) and protects the equipment from contamination by pigment deposition. Expensive transports of externally matted measuring objects to the sensor as well as the time-consuming cleaning of the measuring environment and objects after scanning are no longer necessary. With AESUB green, you achieve a significant increase in efficiency and productivity in the entire digitization process.

- Vanishing scanning spray

- Bulk for spray gun

- Perfect for large scale and automated scanning applications

- No cleaning required

- Free of pigments – free of titanium dioxide (TiO2)

- Thin and homogeneous coating

AESUB yellow

-

AESUB yellow is a self-volatilizing scanning spray liquid developed by scanning experts. It eliminates basic application problems of 3D metrology, especially in sensitive areas (laboratories, production,etc.) and protects the equipment from contamination by pigment deposition. Expensive transports of externally matted measuring objects to the sensor as well as the time-consuming cleaning of the measuring environment and objects after scanning are no longer necessary.

- Air brush solution

- Coating thinkness of less than 1 micron

- Perfect for scanning parts with highest accuracy

- Thin & homogenous coating

- Free of pigments

- No cleaning required

Reference Targets

-

Precise Scanning With Flawless Results

Reference targets are essential for precise scanning no matter if a structured light scanner or a laser scanner is used. We offer a broad portfolio of specially developed reference targets and other accessories for precise scanning with flawless results. They adhere ideally to the AESUB scanningsprays. Together, they form an unbeatable team.

AESUBdots black & white

-

- For structured light scanners

- Strong adhesive effect

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for application on all vanishing AESUB sprays

AESUBdots retro permanent

-

- For laser light scanners

- Strong adhesive effect

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for application on all vanishing AESUB sprays

AESUBdots retro easy remove

-

- For laser light scanners

- Light adhesive effect for easy removal

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for application on all vanishing AESUB sprays

AESUBdots retro infinity

-

- For laser light scanners

- Random order, transparent

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for all vanishing AESUB sprays

AESUBdots high reflective

-

- For laser light scanners

- Light adhesive effect for easy removal

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for application on all vanishing AESUB sprays

AESUBdots retro medical

-

- For laser light scanners

- For medical use

- Coiled on roll

- Tear perforation every 20 – 30 cm

AESUBdice

-

- For up to 11 retro-reflective 6 mm targets and even more 3 mm targets

- With magnet or thread

- For quick attachment and easier scan preparation

AESUBdomes

-

- For up to 19 targets of 6 or 3 mm diameter

- high retro-reflective or retro-reflective

- With magnet and M4-thread and for use of putty

- For quick attachment and easier scan preparation

AESUBdots retro magnetic

-

- For 3D scanners with laser light

- Reusable

- Magnetic retro-reflective targets in various diameters

- For quick attachment and easier scan preparation

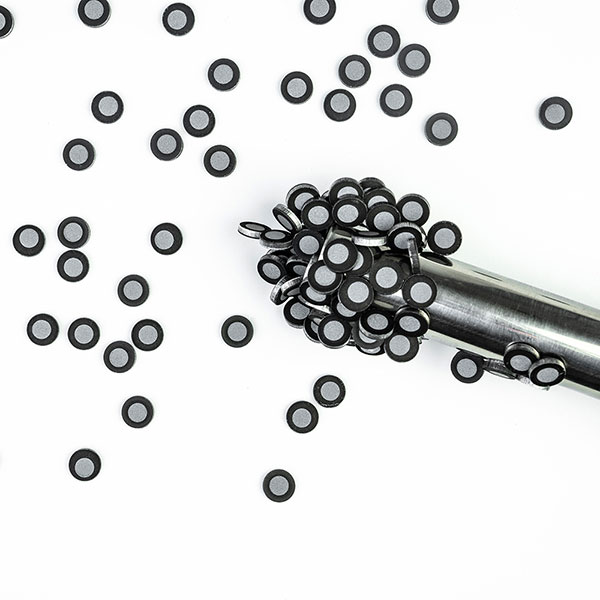

AESUBdots CONFETTI SET

-

- Retro-reflective reference targets for laser scanners

- Easy, simple, and fast to collect with a magnet

- Reusable

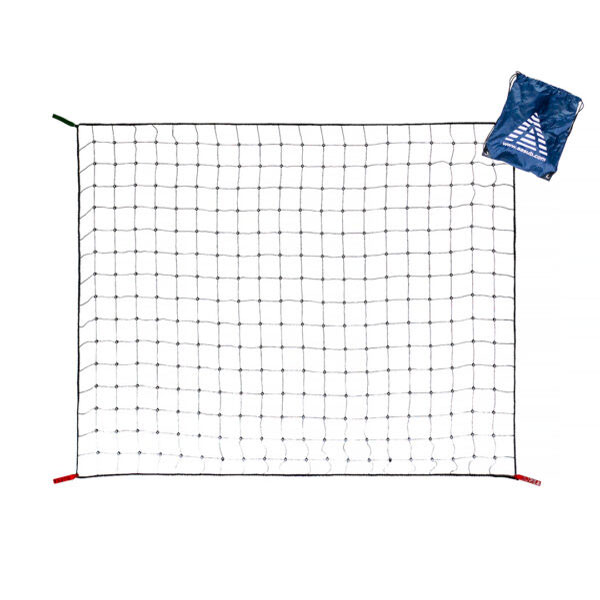

AESUB target net

-

- Retro-reflective reference points for immediate application on medium-sized or large components

- Magnet on each point base

- Reusable

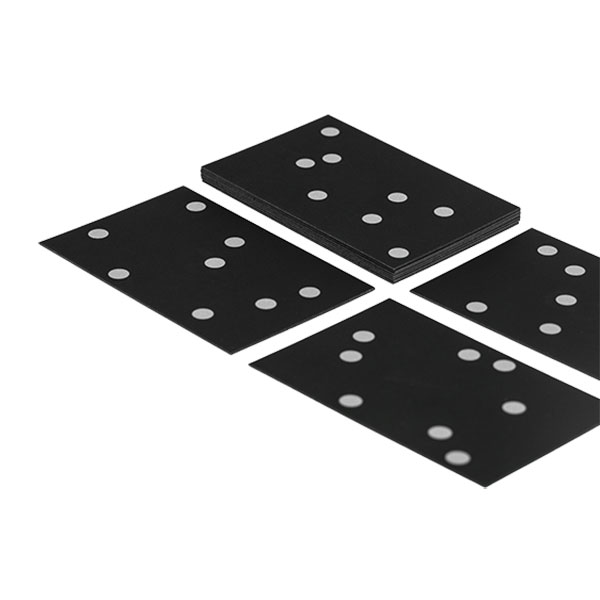

AESUB code.cards

-

- High retro-reflective reference targets for laser light

- 10 code.cards with individual pattern in a set

- Reusable

AESUBdots applicator gun

-

- Automated positioning of reference points

- Universal compatibility: Suitable for retro-reflective and AESUBdots black & white

- Ideal in combination with AESUBdots

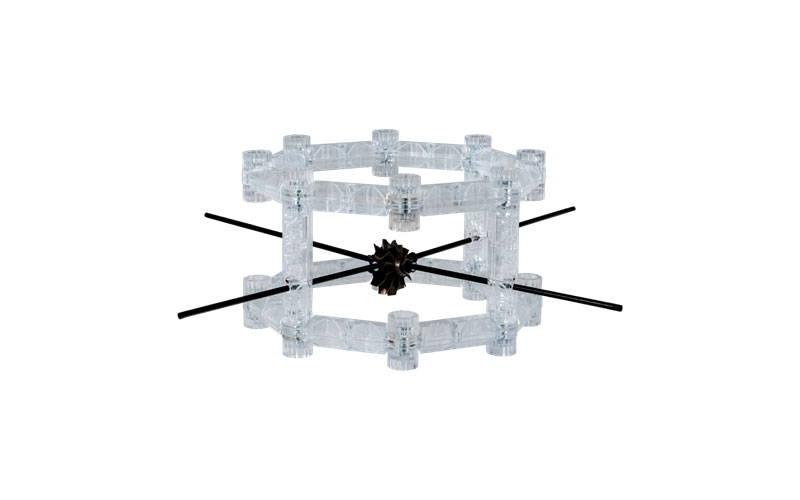

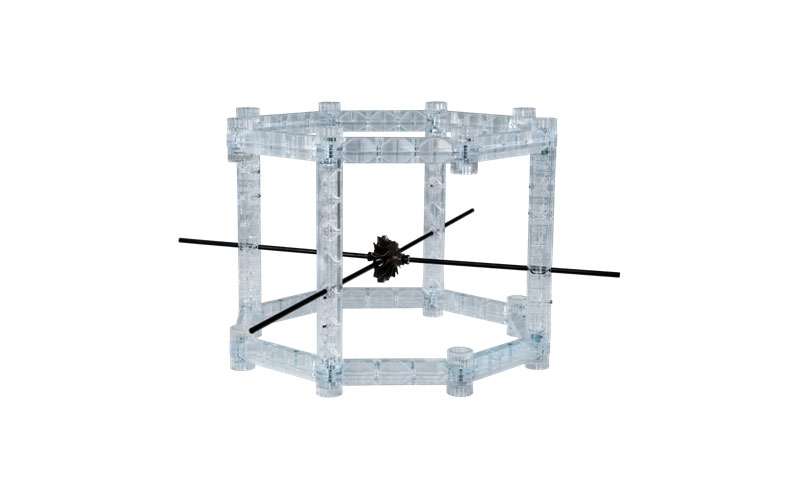

AESUBframe

-

- Carbon fibre enforced printed synthetic material

- Modular assembly

- Extrem lightweight and stiff structure

- Ideal in combination with our AESUBdots

AESUBframe

-

Reference frame for precise digitisation

The AESUBframe was developed for the rapid digitisation of small and medium-sized objects. It ensures that these are precisely and consistently aligned in space in order to obtain accurate 3D data during scanning. Fixing the object in the frame minimises measurement errors. With the help of that efficient tool, the position and orientation of the scanner can be defined relative to the object during the scanning process. This enables the individual scans to be merged later into a complete 3D model. Using the AESUBframe saves time and resources, as less post-processing is required.

AESUBdots and AESUBdice can also be attached to the frame as reliable reference points. It is suitable for use both in the measurement laboratory and at the customer’s premises.

Ideal for, among other things:

- Component series

- Small parts in production

- Stamped parts

- Milled parts

- Medical components

AESUBframe 200 mm

-

- For small parts

- Transparent plastic

- Modular assembly

- Extrem lightweight and stiff structure

- Ideal in combination with AESUBdots

AESUBframe 300 mm

-

- For midsize parts

- Transparent plastic

- Modular assembly

- Extrem lightweight and stiff structure

- Ideal in combination with AESUBdots

Accessories

AESUBdots black&white

-

- For structured light scanners

- Strong adhesive effect

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for application on all vanishing AESUB sprays

AESUBdots retro

-

- For laser light scanners

- Strong adhesive effect

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for application on all vanishing AESUB sprays

AESUBframe

-

- Carbon fibre enforced printed synthetic material

- Modular assembly

- Extrem lightweight and stiff structure

- Ideal in combination with our AESUBdots

AESUB spray gun

-

- For large objects

- Innovative spray control

- Optimized spray nozzle

- Perfect for AESUB green

AESUB yellow airbrush

-

- For small objects

- Innovative spray control

- Optimized spray nozzle

- Perfect for AESUB yellow

AESUBdots retro

-

- For laser light scanners

- Strong adhesive effect

- Coiled on roll

- Tear perforation every 20 – 30 cm

- Perfect for all vanishing AESUB sprays

Fields of application

-

Learn all about the application areas of AESUB Scanning Sprays by means of numerous examples

Even with state-of-the-art scanners, it is necessary to apply matting spray in several application cases:

Transparent parts

- As we are dealing with optical technologies, light needs to be projected on and/or reflected off the surface back into the detector of the scanner. In case of a transparent surface, however, the light will go through the surface instead of being reflected by the same. In consequence, the scanner is not able to capture the surface structure.

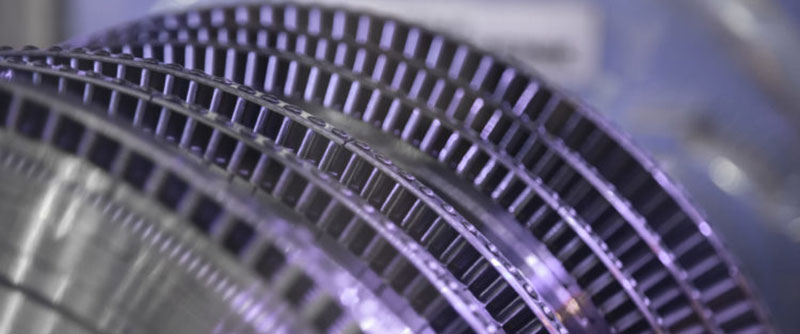

Reflective parts

- In case of reflective parts, such as a mirror, the light beams will be reflected in a focused way instead of in a diffused way. This means that the chance of a beam hitting the reflector of the scanner is greatly reduced and the scanner will only capture a fraction of the reflected light beams.

Deep Pocket

- When the object to be scanned has deep pockets, the scanner receives a reflection from the walls of the pocket onto the bottom. This causes disturbance in the pattern of the light manifesting in the scan as “artefacts” or bad data.

High quality and accuracy

- When quality and accuracy are important, you might want to apply spray to remove as much as possible all the causes like colour differences, differences in reflection, texture, etc. The use of spray creates a matt, white coat reducing reflection and other inhomogeneities and thus provides perfect scanning condition.

References

AESUB and small objects

-

Jewellery Scan with Shining3D

Shiny, reflective surfaces such as jewelleries are difficult to scan. Shining 3D demonstrates how easy 3D scanning a silver bracelet can be when using the AutoScan Inspec with AESUB 3D scanning spray for 3D digitalization. AESUB for more shining ideas!

AESUB meets Hexagon

-

AESUB meets Hexagon Manufacturing Intelligence

Hexagon Manufacturing Intelligence meets AESUB 3D Scanningsprays – no mess, no cleaning, improved efficiency and perfect scan results.

AESUB takes off

-

3D Scan of a Cessna 441

Apply the vanishing AESUB green to large surfaces with a spray gun to obtain perfect conditions for optical 3D measurements. In this application, our partners from INVIZION scanned a Cessna 441 aircraft with a SCANTECH handheld scanner using our new AESUB green.

AESUB improves the service business

-

AESUB meets a3Ds

Artur Skuratowicz from A3Ds GmbH gives insights into how his scanning-service business has changed since the introduction of AESUB scanningsprays. 3D scanning of transparent, reflective and deep pocket objects using 3D Scanningspray for 3D digitalization without any intensive post cleaning. It´s magic!

AESUB and Artec Scanners

-

AESUB meets Laserscanning Europe

Oliver Niemann, 3D scanning expert at Laserscanning Europe GmbH, presents the advantages of the vanishing AESUB blue scanningspray together with the Artec 3D Spider for 3D digitalization.

Technology deep dive

-

Test report - AESUB blue Scanningspray

Check out this testreport on AESUB vanishing 3D Scanningsprays for 3D scanning and thus 3D digitalization. It’s the answer to challenging parts (shiny, dark, or transparent surfaces) that can’t be cleaned. It leaves no mess and disappears after scanning.