- Offer Profile

- We solve challenges in the field of measurement, control and automation technology

For us here at m-u-t, the exceptional comes as standard. In the areas of spectroscopy/sensor technology, industrial automation, laboratory automation/medical technology and early fire detection, we specialise in bespoke, state of the art designs and serial manufacture characterised by short delivery times.

Industry sensors - Gas Measurement

-

OEM sensors from m-u-t are designed to reliably measure the physical properties of materials such as solids, liquids, gases and plasmas in your production process.

By using m-u-t OEM sensors you can measure properties of solids, e.g. concentration of ingredients, color, contour, and a variety of quality parameters. In liquids, sensors determine identifying features (tracers), optical density, ingredients and color, for example. Contactless measurement and analysis of gases based on UV and NDIR technology (none-dispersive infrared technology) has become the superior test method. With this technology, production processes can be monitored and controlled continuously and in real time. Therefore, customers from various industries are improving their process quality and minimizing waste by using NDIR detectors. Gas sensor applications developed by our engineers, e.g. methane sensors, are individualized complete solutions, calibrated precisely to the specific measuring task.

Our single gas sensor modules are designed to measure gases individually: e.g. oxygen (O2), carbon dioxide (CO2), hydrogen (H2), ozone (O3), ethine (C2H2), ethene (C2H4) and ethane (C2H6), methanol (CH3OH), acetone (C3H6O), ethanol (C2H5OH).

m-u-t multi-gas detectors analyze up to fourteen gases simultaneously and selectively in a single sensor chamber. Up to eight gases, e.g. CO (carbon monoxide), CO2 (carbon dioxide), CxHx (hydrocarbons), are measured optically and are integrated in a unit with up to six other chemical sensors, e.g. H2 (hydrogen) or O2 (oxygen). Besides determining the concentration of target gases, physical parameters such as humidity and temperature are also measured. In addition to the high precision of the measuring results, which are essential for production-critical processes, m-u-t sensors are also completely wear-free, as they do not have any moving parts. Therefore, the sensors are maintenance-free and require no repair.

Components

Ozone (O3) Gas Sensor

- m-u-t develops and manufactures gas sensor modules exactly according your requirements. Several platforms with different concentration ranges and options are available for gaseous ozone (O3) measurement.

1) Type "HR", measuring range 0-20g / Nm3 (1.0Vol%)

2) Type "MR", measuring range 0-1g / Nm3 (510 Vol. ppm)

3) Type "OEM"; measuring range and interfaces exactly according to your requirementsThe measurement principle of the m-u-t ozone gas sensors is based on two-beam non-dispersive UV spectroscopy (NDUV).

m-u-t ozone gas sensors use the latest UV LED technology as light source, thus providing the following advantages for your application:

a) very short warm-up time: fast availability of measurement results

b) very low energy consumption: battery operation possible

c) very compact design: portable applications, easy to integrate

O2 Detector Modul

- m-u-t develops sensor modules to your specifications to exclusively fit your needs.

The following standard modules are also available in stock:

The O2-Detector module is a compact and cost-effective gas analyzer based upon the electro-chemical measurement of oxygen concentration. The O2 sensor can be calibrated for the range of 0 to 10 % or 0 to 25 % oxygen. It features a low power input, a large range of supply voltage and a long lifetime of the electrochemical sensor

CO2 Detector Modul

- m-u-t develops sensor modules to your specifications to exclusively fit your needs.

The following standard modules are also available in stock:The CO2 sensor LC is a microprocessor controlled gas analyzer using non diffractive IR detection (NDIR) for determination of CO2 concentration. This low price CO2 detector is characterized by low power consumption, a wide supply voltage range of 8 V … 15 V and simultaneous integration of current and voltage interface.

A microprocessor controls all necessary functions and performs calculations which allow fast customer specific adaptions by software variations.For our CO2 detector we offer different calibrations for varying concentrations of CO2: 10%, 11%, 30%, and 100%.

IR Multi-Gas Sensor NDIR Module

- Infrared multi gas sensors are based on the principle of non-dispersive infrared spectroscopy (NDIR).

The multi gas sensor

The multi gas sensor uses light of a specific wavelength in the infrared range to illuminate the sample depending on the type of gas to be analyzed. It measures the absorption of light when crossing the sample chamber and indicates the concentration of the gas in the sample chamber. A chemical reaction does not take place in the process, so our multi gas sensors have a long service life and remain stable over the long term.

The measurement of up to three gases in a single sensor considerably reduces cross-sensitivities (which are otherwise commonplace) not only by adeptly selecting the IR wavelengths, but also via algorithmic incorporation of all measurement channels. Three gases can be combined freely depending on the requirements. CO carbon monoxide, CO2 carbon dioxide, CH4 methane, C2H2 acetylene, C2H4 ethylene or C2H6 ethane are available right now.

The measurement precisions that can be achieved depend on the respective gas combination and the measurement ranges, and can be optimized for the application at hand by suitable calibration.

Solutions

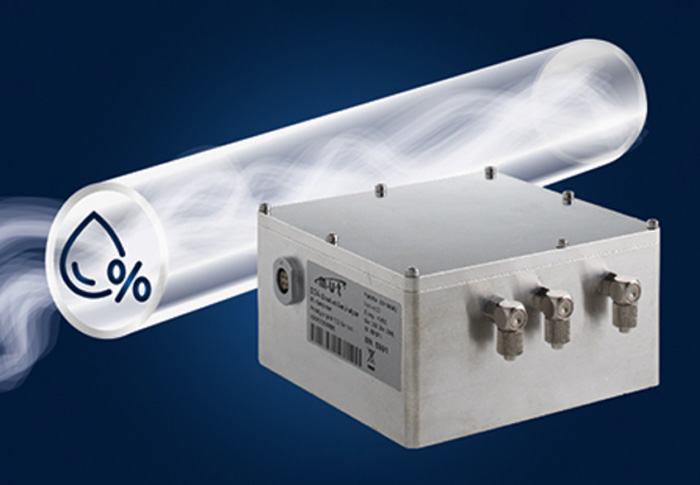

Air humidity and gas measuring module

- For the measurement of the absolute humidity m-u-t develops and manufactures NDIR air humidity measuring devices - exactly suitable for your requirements.

Your added value when using our technology:- high level of safety in use, even at remote measuring points, thanks to the long-lasting technology

- low spare part costs as there are no moving parts

- no maintenance and associated maintenance costs

- reduced service costs

Integrated pressure and temperature sensors enable the output of the measurement results in many common units:- as absolute humidity or vapor density (g / Nm³)

- as a mixing ratio (g / kg)

- as vapor pressure (Pa or bar)

- as dew point temperature (° C or K)

- or another unit of humidity suitable for the application

Further advantages through the purely optical process:- higher measurement sensitivity, especially in the end ranges> 90% humidity and less than 10% humidity compared to capacitive sensors

- there are no chemical reactions like with capacitive sensors

- measurement almost free of hysteresis and drift

- high measuring rates possible

- robust long-lasting technology

- resistant to solvents (alcohols) thanks to the optical measuring method

- parallel gas measurement possible (NDIR active gases)

- long-term stable measurements

- reduction of cross-sensitivities as far as possible

Measuring range and measuring speed can be adjusted according to your requirements.

Spectroscopy Measurement

-

OEM spectroscopy solution

Step-by-step, together with you, we will develop the OEM spectroscopy solution exactly tailored to your application: development > prototype > test > series product. In this process, our customers from various industries are always working directly with our engineers. Confidence is a top priority. All customer information and development data remain strictly confidential.Technical solutions

In addition to successful technical solutions, we are pleased that m-u-t customers also report budget compliance and excellent teamwork during joint project work. We believe, the short distance between development and production and the m-u-t project management, which has been continuously improved over many years, are also responsible for this positive experience. Solutions

Measuring Content in Liquids

- Whether you need a simple sensor or a regulating module, we can provide you with optical spectroscopy that enables you to continuously record precise measurement data such as identifying features, optical density, content and colour.

Precise planning

What are the environmental conditions and regulations? Where and how do you want to send the data? Do you need integrated evaluation? By asking these and other questions, we aim to clarify the parameters of your project. So you can be sure that we take every detail into account at the planning stage.

Flexible solutions

Installed into fixed equipment? Built into a vehicle? Or portable as a handheld? We meet your specific needs so you can measure any liquid as required, from water, wine or milk to fuel, disinfectant and antifreeze.

Endless possibilities- Quantitative analysis: measuring concentration of main and secondary ingredients and additives

- Qualitative analysis: identification of variety and specification of material and substance

- Colour measurements: capture of complete colour spectra of raw materials and intermediate and end products

- Analysis at large measuring distances

- Analysis requiring direct contact with material to be measured, e.g. in pipelines

- Sample representations as required by gauge heads and probes

- Immersion probes or flow cells for the analysis of liquids, pastes and other fluids

- Numerous interfaces: e.g. Modbus TCP, EtherCAT, PROFINET, PROFIBUS DP, CAN Bus, OPC UA

- Chemometric prediction models

Photonic Solutions

- Since the foundation of m-u-t in 1995, we have developed optical measurement systems that cover the wavelength range from UV-VIS-NIR-LWIR.

Photonics -- as this field is often called -- stems from the combination of the word ‚photon’ (meaning ‚light quantum’) and the latin suffix –ic (meaning ‚having some characteristics of’). At m-u-t, photonics is synonymous with the field of optoelectronics.

The numerous applications of photonics can be divided up into four general fields:

- Lighting and displays

- Industrial process and quality control

- Information and communication

- Life sciences (including biophotonics)

Our customer specific development products are normally covered by confidentiality clauses.

Talk to m-u-t about developing a product for your specific application!

Automated Measurement

-

Is spectroscopy possible in automated processes?

It is for m-u-t. With our decades of experience in spectroscopic sensor technology, we provide you with solutions that allow you to integrate manual or external laboratory analysis into your equipment.

In order to meet the criteria for automated measurement, we take the following into account when implementing our systems:

1. Sample feeding and sample handling

Whether the sample needs to be fed to the sensor system or vice versa, our mechatronic solutions enable either procedure to be automated.

2. Measuring method

Whether UV/VIS, NIR, RAMAN, LIBS spectroscopy or other methods, we check: which measurement method is the right one to achieve the effect required whether the measurement method is suitable for the usage intended

3. Sensors for the measuring method

Which spectroscopic sensors fit your measurement methodology? We'll procure the optimal solution from the extensive Nynomic portfolio.

4. Data handling

How do you obtain the necessary target data from the data available? We'll create the algorithm for this task and integrate it into the measurement hardware.

5. Data transfer to interface

The measurement hardware delivers the required target data to the automated surrounding system via defined interfaces and interface protocols e.g. via Modbus or RS485. We create these interfaces in accordance with your needs.

Talk to us about the unique requirements of your automated measuring

Serial production

Process Control on UV Lamp

- For fast UV lamp drying processes in CD & DVD production and drying of dyestuffs and colors in the printing industry, it is important that the light source has the right intensity at the correct wavelength. Otherwise either the process takes too long or the material is not completely consolidated.

The given task

The lamps need to be inspected for intensity and wavelength distribution. As soon as they are altered, the intensity needs to be increased. If this does not help, the lamp needs to be replaced. A device for permanent inspection of each lamp is necessary. The process may not be prolonged by the inspection or by replacing the UV lamps too early.

The solution

An OEM version of our TRISTAN UV spectrometer is used to control the spectral distribution and intensity of the UV light. It is fully integrated into the process control system of the production line. Due to the unique design of the integrated processing unit (a 32 bit RISC processor), a separate PC for data transfer is not required. The lamp is operated for the actual lifetime at the needed parameters and at a constant output level. At the end of the lamps lifetime, the operator is notified to change the lamp. The OEM TRISTAN monitors and regulates fully-automatically the UV intensity in the running process. Analysis of the UV spectrum in the range of 250 to 550 nm is performed in up to 3 freely-definable control ranges. Changes to the UV intensity are recognized and the process is steered to optimum at all times by the closed control circuit. The spectrometer in use has a resolution of up to 0.15 nm. This guarantees a stable UV process, a consistently high quality and performance, and at the same time reduces the number of rejects.

At the start of production, the optimum UV power for the respective process is registered with the Teach-In function. The power control is performed directly based on the consolidation and sterilization process, and no longer on the electrical input values. Process control is done automatically by means of special software. Measurements can be started by internal timers or by external triggers. The measurement cycle times of the internal timer can be selected freely in the range of 1 sec to 180 sec. This guarantees exact harmonization with the production cycle. Optical fibers and sensors are re-calibrated with every Teach-In. This ensures precise and reliable values with every measurement. The measuring lens is also protected by shutters. With this system, based on the TRISTAN OEM spectrometer with its fast integration time and easy-to-use software interface, it is possible to raise the quality and shorten the time of industrial drying process in one single step. Moreover, the cost-intensive change rate of UV-lamps can be decreased.

Testing fuel with a gas tag analyser

- If you need a portable measuring device to detect the presence of counterfeit or mixed fuels, m-u-t has developed an amazingly simple solution: the gas tag analyser (GTA).

Complete system for mobile use

Compact in size and striking in performance, this mobile test equipment fits in the boot of any car. Yet it offers everything you need to measure very small amounts of chemical indicators in liquids. So you can easily identify and mark fuels that are stored or transported without a container. No more time-consuming lab analysis.

How the GTA works

Fuels contain very low concentrations of a liquid indicator, which due to its spectral signature is practically copy-proof. Our GTA system determines this indicator and measures its concentration in the liquid. It then indicates whether the fuel is original, mixed or counterfeit. You get accurate results that reflect even the slightest deviation from the original.

The GTA at a glance- Complete spectrometer system

- Multiple laser sources

- Interactive software

- Up to four hours' battery life

- Immediate display of test results

- Mobile device: can be used on the road or at petrol stations

- Reliable results – no chemical expertise required

Early fire detection with infrared detection - fire prevention

-

IGNIS3D early fire detection

IGNIS3D early fire detection checks the monitored area automatically and continuously, monitoring set temperature limits and temperature trends. IGNIS3D early fire detection detects potential hazards up to 1 Kelvin (K) exactly and initiates custom actions: e.g. sends message to central fire alarm system, pre-alignment with fire monitor, starts extinguishing.

IGNIS3D early fire detection is modular and durably designed to be able to adapt to the respective customer requirements. IGNIS3D early fire detection is optimised for use in a wide variety of environmental conditions.

Whether for use in open spaces, half-open storage facilities or for closed indoor applications - IGNIS3D early fire detection is prepared. With over 20 years of experience, m-u-t solidly guarantees the design, delivery and service for your safety. The goal of fire prevention is integrated into your fire protection concept. m-u-t uses long-wave infrared radiation (LWIR) for temperature monitoring as a technological basis.

IGNIS3D early fire detection seamlessly monitors surfaces with infrared detection and warns you before other commercially available systems can. Solutions

Object detection

- Intelligent object detection that avoids false alarms? m-u-t's IGNIS3D detects fire hazards earlier and more accurately than any other infrared system available. Around 25 years of experience have gone into this innovative product.

How does IGNIS3D differ from competitors?

The IGNIS3D system detects small sources of danger even if there are larger but non-hazardous hot objects in the vicinity. As a result, it detects hot spots faster and prevents the spread of fire more efficiently.

How IGNIS3D works- Moving objects are filtered out and don't trigger an alarm

- Dormant permitted objects are specified in a database as geometric objects and don't trigger an alarm

- Includes a standard database that can be enhanced as required

Modular expansion

No matter what your requirements and budget, our modular infrared detection system can expand with your company. Discover how simple effective property protection can be. Ask us for advice on planning. We have been successfully using IGNIS3D for more than twenty years. The system can be tailored to your specific requirements. IGNIS3D at a glance:- Surveillance of large areas

- Precise measurement of all surface temperatures

- Critical conditions reported before danger arises

- Emerging embers detected

- Extinguishing monitor (water cannon): control with projection trajectory calculation

- No false alarms due to moving hot objects

- Unique vehicle detection for large, stationary hot objects

- Panoramic thermography for quick, easy overview

- VdS device approval

Early fire detection with patented 3D IR detection for optimal cooling / "extinguishing"

-

Patented 3D IR detection

The basic module of the IGNIS infrared detection for early fire detection identified a danger. The globally unique 3D module extension for early fire detection determines the precise location information and the individual danger of the glowing nest. This information will be forwarded to a particular deletion server. The danger points are sorted according to the degree of danger and dealt with separately. The extinguishing server is for the simultaneous control of different extinguishing monitors. The number of IGNIS3D infrared detection systems and water cannons is independently from each other. The installation position of the systems can now be freely selected: Your fire protection concept will be ideal.

Extinguishing measures can also be carried out by other detectors or the operating personnel. They are treated in such a way that they cannot be experienced by the IGNIS3D or are explicitly excluded from fully automatic viewing.

Worldwide visibility and patented - 3D measuring detection- Adaptation to changing storage heights and filling heights

- Danger position - the greatest danger is always cooled first

- The position of the extinguishing window is automatically set depending on the distance: optimal cooling through external coolant application

- Trajectory parabola calculation - no test required

- A danger can be approached simultaneously by all available water cannons

- Automatic assignment of water cannons to the hazard

- Most precise temperature measurement even with heavy dust exposure

Serial production

IGNIS3D infrared detection for early fire detection

-

If you need accurate infrared measurement technology for early fire detection, m-u-t's patented Ignis3D infrared detection with distance measurement is the answer. It enables embers to be accurately detected and dealt with using the latest 3D spatial data.

The advantages of distance measurement at a glance

How does Ignis3D outperform competing systems?

Conventional systems record the area once at the time of installation. The disadvantage with this is that if, for example, the fill heights of a room change, the system may not be able to locate the source of a fire.

Ignis3D scans the environment automatically and continuously, so the 3D coordinates are never more than two minutes old. In the event of an alarm, this is a considerable advantage, as the data enables accurate extinguishing. Ignis3D is the only system on the market that can do this.

What is the distance used for?

Temperature measurement The VdS loss prevention council stipulates accuracy of 5K for temperature measurement. Only Ignis3D meets this standard every time even in dusty environments and at variable distances. Under these circumstances, conventional solutions can cause deviations of more than 25K.

Cooling

The system applies coolant to the same surface from any distance, and the projectile trajectory is always accurate thanks to precise calculation. The number of Ignis3D detectors doesn't have to be the same as the number of sprinklers, and their mounting locations can be different too.- Precise temperature measurement even in dusty environments

- Accurate detection of embers

- Calculation of projectile trajectory

- Standard size for efficient cooling

- Flexible installation and optimal adaptation to spatial conditions

IGNIS3D VdS recognition

- First infrared fire detection system with laser

distance measurement and VdS recognition.

The IGNIS3D IR camera units have been certified by the VdS under recognition number G 220008.

IGNIS3D fulfils more than the requirements of the VdS 3189 directive for the design and installation of IR camera units for temperature monitoring in fire protection. Instead of static 3D space detection, hotspots that move on the optical axis of the infrared camera are also measured precisely. Thanks to the unique dynamic 3D measurement, hotspots can also be evaluated and prioritized in their potential danger.

The aim of VdS directive 3189 is: Due to local and operational characteristics, it may be useful to use IR camera units in addition to fire detection in accordance with VdS 2095 or DIN VDE 0833-2, in particular for the temperature monitoring of surfaces. This way, temperature abnormalities, e.g. in the form of temperature gradients, can be reacted to at an early stage in the monitoring area of the IR camera unit.

The following functions are performed by an IR camera unit IGNIS3D:- Early detection and localisation of areas with elevated temperature, such as hotspots, hot surfaces

- Monitoring of surfaces by measuring current temperatures, temperature curve or temporal changes in temperature

- Support of firefighting management and optional mobile and/or stationary firefighting

Please contact our project engineers to discuss the exact procedure with you.

Early fire detection technology with infrared detection

- Early fire detection with IGNIS3D measures the surface temperature of the property being monitored so it can detect the increase of heat long before a critical temperature is reached.

Early fire detection based on this principle has crucial system advantages over all other detector technologies:

Visualisation of the temperature increase

Invisible LWIR radiation is made visible by using calibrated microbolometer technology. Each radiation value has a temperature value and a colour associated with it. In this way, the surface temperature distribution becomes visible and can be captured with a view to its immediate assessment.

Non-contact measurement over long distances

LWIR thermal image-based early fire detection can be used over several hundred meters. Every pixel of the sensor corresponds to a temperature of the observed image. Using this information, the unit can be used to identify potential sources of fire and fire prevention measures.

‘Clear view’ in smoke and haze

In the wavelength range of LWIR radiation of 8-12μm, in many situations where there is smoke or haze, aerosols are transparent. In contrast to normal surveillance cameras or the human eye, which have much shorter wavelengths, an LWIR camera can ‘see through smoke’, so to speak. This technology provides valuable support for firefighters in case of fire.

Railway Technology

-

Measure, control, operate and

display in rail vehicles

An experienced OEM partner for your rail technology: you have found it with m-u-t. For around 20 years we have been supplying more than 100,000 products to operators and manufacturers of rail vehicles and their suppliers - worldwide. Gladly to you too!

From a single source: product development, series production and support

We provide you with customer-specific electronic products that meet the regulatory requirements for rail transport - for example DIN EN 50155 and DIN EN 45545. Of course, we also supply the necessary software.

Save costs with m-u-t technology

At m-u-t, efficiency is not just an empty phrase, it is part of everyday life. We have been at home in the field of measurement and control technology for decades. This will give you our new technologies faster and more cost-effectively. Convince yourself of our innovative spirit for optical measurement technology and highly integrated electronics in weight-saving plastic housings. Specification finding, product development, verification, qualification and validation? Series production and life cycle support? We cover all of this under one roof. In this way, you benefit from a compact solution with high competitive advantages.

Sustainable life cycle management

The useful life of a rail vehicle is at least 30 years - and we support you with our product service over the entire period. Together with you, we implement a life cycle strategy that is precisely tailored to your needs.

Your advantages: Your products are continuously available over the long term. Let us replace electronic components that are discontinued at an early stage and adapt the products to new regulatory requirements in good time. In this way you avoid unwanted delivery bottlenecks and provide your customers with your products seamlessly. Solutions

Rail-compliant product development

- Are you looking for an OEM partner for rail-compliant product development and serial manufacture? For around 20 years, m-u-t's rail technology division has specialised in sensor and control technology and operating and display elements for rail vehicles.

Over 100,000 products and systems every year

Our productivity is almost endless. Every year, our experienced teams develop and manufacture more than 100,000 products and systems in-house. The result: cutting-edge technology in accordance with current requirements (e.g. DIN EN 50155, DIN EN 50121 or DIN EN 50128).

A sample from our portfolio- Operating and display elements for train staff and passengers

- Sensors e.g. for temperature, fill levels, proximity and light

- Control units with various interfaces and software/network protocols

- Control panels with wireless PCB technology

Benefits

Our product development team works hand in hand with our manufacturing staff. From the point of view of manufacturing and cost, we develop and approve products in an optimised manner right from the word go. Everything is undertaken by us in-house to meet stringent quality criteria and deadlines.

Time and cost efficiency

Cost-effectively manufactured, to tight deadlines – this applies to all our solutions, from serially manufactured products in small quantities to customised OEM components. With our innovation management processes, you benefit from shorter development and manufacturing phases and lower investment costs.

Network protocols

- If you need special network protocols implemented for your railway technology control systems, m-u-t can provide you with railway-compliant hardware with protocol translators. So you benefit from smooth communication in trains via ethernet, CAN or other interfaces. For this purpose, we provide rail-compliant hardware with protocol translators.

We offer the following implemented protocols:- IPTCom (Bombardier IPTCom)

- Simple IPTCom (PD data only)

- TComm (Siemens protocol)

- TRDP (based on TCNopen)

- Hitachi TRDP (based on TCNopen)

- Expert 2 (Siemens protocol)

- UDP

- CANopen

- SCN Smart Cabin Network

- Others protocols available on request

Allow us to implement your network protocols with precision.

Serial production

Illuminated display

- You need large and reliable illuminated displays for your railway technology?

m-u-t's WA46 series provides a flexible solution:- Large illuminated display area of 46x46 mm

- Uniformly illuminated with flat, long-life LED module

- 24V power supply as per DIN EN 50155

Fully customisable

Different colours, customised designs our illuminated displays are available in a wide range of options. You can choose from different symbol foils, and multiple displays and acoustic feedback signals can be configured with ease. Thanks to the integrated fade effect, the display symbol can disappear when switched off.

For a harmonious look and feel, the design of the WA46 series matches the buttons of the WT40 series.

For fast delivery of your customised illuminated displays.

Tank level indicator

- If you need a flexible tank level indicator for rail vehicles, m-u-t's TLI – a technology platform for sand tanks, wiping water tanks, fresh water tanks, waste water tanks and fuel tanks – is ideal. The display can also be used as a battery charge indicator.

TLI platform benefits

With its input voltage of 24 V/DC and robust stainless steel construction, it's suitable for a variety of common applications, even on vehicle exteriors. Standard threshold switches can be connected, as can resistance transmitters (0-5 V) and sensors with current signal (4-20 mA). Compliant with DIN EN 50155 and numerous other standards, it meets the requirements for electronic equipment on rail vehicles.

The following functions are factory-programmable- Labelling and function of the 17 LEDs

- Time constants for signal smoothing in the event of tank content surge

For fast delivery of your required tank level indicators.

Switchboards with controls

- More flexible, safer, more cost-efficient – such are the benefits of m-u-t's own PCB technology compared to conventional strand wiring. With our many years of experience in the construction of switchboards for train systems, we have developed an innovative solution that is feasible for medium quantities.

Benefits of switchboards with controls- No time-consuming wiring tests required

- Serial manufacture reduces unit costs

- Considerable space savings in installation rooms

- Increased product quality and reliability

- Easy integration into your system thanks to codable plug-in connections

Use our efficient PCB technology for your specific requirements.

Pre-wired control panels

- If you're looking for an efficient alternative to manually wired control panels, our many years' experience in panel building for train systems form the basis for our reliable and high-quality pre-wired panels.

How they work

We use PCB (printed circuit board) technology in accordance with rail vehicle standards and guidelines. It replaces loose strands with printed circuit board technology for electronics. Even for medium quantities, this design is more efficient than conventional techniques.Use our pre-wired control panels for your specific requirements.

Benefits of pre-wired control panels- Savings in installation space and weight

- No mismatched or missing wires

- No costs for troubleshooting, inspections or reworking

- Integrated passive components can be pre-assembled: e.g. relays, connectors, diodes, switches and LEDs

- Required equipment markings and any texts and symbols can be printed accurately on the PCBs free of charge, thus doing away with the need for lots of small labels

- Any system can be used, from decentralised control of individual components to centralised train control

Modularer Logic Controller

- If you need a flexible, modular controller for DIN rail mounting, m-u-t has developed the ideal product platform: the modular logic controller (MLC) compliant with DIN EN 50155, DIN EN 50121-3-2 and DIN EN 45545. It's easily adaptable and expandable according to your requirements.

What makes it so flexible?- Up to 15 different I/O modules are available with digital and analogue inputs and outputs. Combinable in any way for use with rail vehicles

- Central unit upgradable with SD memory cards and PC104 interface cards for different vehicle and 'train-bus' interfaces

- Operating and display unit rotatable in 90° increments

- Membrane keypad and vacuum fluorescence display usable in temperatures down to -40°C

- Multi-dimensional installation of system possible

- With the Multiprog© programming system, the MLC can be created in up to five different programming languages

- Other programming available (e.g. logi.CAD, CODESYS)

Can be tailored to your individual needs.

Light reflector button

- If you need a button for contactless activation of your toilet flush or water tap, m-u-t has developed a special solution: the LBHP light reflector button.

What makes it so practical?- Vandal-proof and not affected by glare or daylight

- Thanks to its integrated IR interface, can be programmed and checked wirelessly once installed

- Integrated switching transistor enables direct connection of other components such as a solenoid valve for a water tap

- Compliant with DIN EN 50155 and other standards. Meets requirements for electronic equipment on rail vehicles

The LBHP light reflector button is available for immediate delivery.

Agricultural Industry

- Welcome to the Future of Spectroscopy! Thanks to more than 20 years of experience in the field of optical measurement systems we at m-u-t are the experts for NIR sensor technology.

Agriculture is in our Blood

It is easy to answer why we are the perfect development partner for you: We live agriculture. Thanks to our experience, we are one of the most renowned NIR sensor suppliers and developers. Early on, the importance of accurate analysis and detection of ingredients in organic fertilizers, crops, soil or milk has driven us to advance development in the field of optical measurement technology. Today, m-u-t is therefore able to offer fully developed solution concepts and products that meet your requirements. Above all, our measurement technology stands for the future of agriculture in harmony with nature.

With NIRS technology, we actively protect the environment. Based on nutrient measurements in the crop, we enable farmers and contractors to optimize cultivation planning and gain precise knowledge about nutrient cycles.

With the analysis of farm manure and liquid manure, we help farmers to fertilize their land precisely and in an environmentally friendly way - for needs-based fertilization in compliance with all legal requirements and optimal use of the valuable fertilizer. Other areas of application for our measurement technology can be found, for example, on mixer feeders, in soil cultivation or the transport of agricultural goods. We enable the exact analysis of the ration, the nutrient requirement or the transported, valuable ingredients - and thus make both an ecological and an economic contribution. Solutions

NIRS

- Near-infrared spectroscopy (NIRS) describes a physical-optical analysis method based on spectroscopy in the range of short-wave infrared light. The method originally comes from the medical sector but has also been used in agriculture for many years. For analysis, the medium (e.g. liquid manure) is irradiated with near infrared light - the human eye cannot perceive this. With the help of reflection, the NIRS sensor is able to detect the ingredients based on the difference between irradiated and reflected light.

Your advantages at one glance:- Innovative procedure with a wide range of analysis options

- Easy and fast analyses with high degree of accuracy

- Sustainable optical analysis option

- Calibration databases for highly accurate results

Grain Analysis

- Even after the harvest, NIRS technology is crucial for the successful marketing and use of grain.

Your advantages at one glance:- Successful marketing

- Simple evaluations

- Adjusted storage

- Considerable time saving

Feeding Technology

- Adapted feeding is the key to success in animal husbandry. Varying nutrient contents in silages or different grain batches complicate the exact calculation of a ration.

Precise Rations

The NIRS sensor - installed in the feed mixer - ensures that farmers have precise knowledge of the energy content of their mixed ration.

Your advantages at one glance:- Adapted feeding

- Increase in feed intake

- Increase in milk yield

- Reduction of feed waste

- Healthier animals

- Consistent TM content of the feed

Milk Analysis

- The analysis of milk ingredients is a time-consuming process - usually it requires pre-treatment.

The Plus in Safety

Using an NIRS sensor during the milking process enables the analysis of quality-relevant ingredients directly in the raw milk. Contaminants can also be identified. Due to the sample frequency, very high accuracy can be achieved. The data is directly available - long waiting times are avoided. Thus, milk producers get a plus in safety.

Your advantages at one glance:- Significant time saving

- Analysis during the milking process

- Especially high precision

- Extra safety (traceability)

Soil Sensor Technology

- More Efficiency in Crop Production

For optimum harvest results, farmers and contractors can combine their ISOBUS sowing technology with a soil sensor. Soil sensors based on NIRS technology are the key to optimal harvest results. Knowledge of the nutrient content of the soil and the different soil conditions allows adjusted sowing rates - the seed drill varies the seed quantity and seed rate according to the respective values. The complicated use of application maps is no longer necessary.

Your advantages at one glance:- Maximum harvest results thanks to adjusted sowing rates

- No complicated use of application cards necessary

- Increased efficiency

- Adapted soil cultivation

- Reduced fuel costs

Data Management

- What is the best technology without the appropriate software? Our NIRS sensors allow you to use a wide variety of systems. Open data interfaces as well as certification according to the ISOBUS standard enable data transfer to various agricultural software systems and field mapping systems for generating application maps.

There is nothing more flexible

Already today, our m-u-t system provides an interface to CCI, ISOBUS Task Controller, DKE agrirouter and IoT. Other systems can be easily controlled via ISOBUS. Thus, customers can not only use their NIRS sensor for analysis, but also send it to the field file and create yield, fertilization and spray maps.

Your advantages at one glance:- Open data interface

- Combinable with all ISOBUS systems

- Brand independent

- Creation of yield, fertilization and spraying maps

Serial production

Fertilization

- Liquid Manure Application

- Accurate & Sustainable

In contrast to mineral fertilizers, farm fertilizers offer many advantages. Using them is more sustainable because all nutrients contained are part of the nutrient cycle anyway.Your advantages at one glance:

- Based on our calibration database, your data is especially precise

- Inhomogeneous liquid manure causes any problems for the measurement

- Real-time data - no more annoying waiting for laboratory results

- Sensors can be mounted anywhere where farm manure flows past - completely flexible

Fertilization 2.0

- Demand-oriented Liquid Manure Application

Would you like to do more? If our NIRS sensor is combined with the appropriate plant or soil sensor, liquid manure application is possible not only on a nutrient-oriented basis, but even on a demand-oriented basis. This means that farmers and contractors can easily meet increased requirements - that is fertilization 2.0.

How does the interaction work?

The plant sensor measures the chlorophyll content of the plants and thus analyzes how much nitrogen the crop needs. The optimum amount of fertilizer can then be calculated on the basis of previously defined minimum and maximum values for N, P and K. The NIRS sensor in the slurry tank also records the nutrient values of the organic fertilizer. With ISOBUS it is thus possible to apply exactly the amount of fertilizer that the crop requires. This precision can be exceeded even further if soil maps are stored, which indicate the yield potential and the nitrogen replenishment. This is the future of fertilization.Your advantages at one glance:

- Combined with plant or soil sensors for even more precision

- Demand-oriented fertilization

Harvesting Technology

- Harvesting is one of the most important and decisive times of the year for agricultural producers.

Arable farms aim for the best prices for their products

Arable farms aim for the best prices for their products and, with the subsequent soil cultivation and fertilization, lay the foundation for the following harvest. Processing farms use the harvest to create the fodder basis for a whole year. So, what if sensors would help to produce the optimal silage, provide the basis for successful price negotiations or ensure precise nutrient removal? With NIRS, this is already possible today. NIRS technology provides great advantages not only in liquid manure spreading, but also during harvesting.

Laboratory automation and medical technology

- Are you looking for an OEM partner with decades of experience in laboratory automation and medical technology? Then you have come to the right place at m-u-t. We develop and manufacture a wide range of individual solutions for you - so efficiently that you save time and money.

What m-u-t mark up as OEM partner

Certified quality

All products are manufactured at the Wedel location according to our established quality system - certified according to ISO 13485 and ISO 9001. Regular audits ensure that we are continuously improving and that these guidelines are adhered to in the long term.

Fast and cost-effective

State-of-the-art quality has to be tedious and expensive to produce? Not at all! Thanks to modern methods from lean management, we can supply you worldwide particularly quickly and inexpensively.

More effectiveness in medical diagnostic

s Current world events show how important the quality of optical measurement technology is - from the increasing number of nosocomial infections to the risk of pandemics. With our products you contribute to solving these challenges. Let us make medical diagnostics more effective and efficient - so that patients receive the right therapy faster.

Robust against extreme conditions

Whether large temperature fluctuations, high mechanical requirements or contact with a wide range of chemicals, such as agents for cleaning and disinfecting medical instruments: Our highly qualified engineers develop products that impress with their above-average process speed and reliability even under extreme conditions. Please contact us about your individual customer solution. Components

Gripper systems handling of blood sample tubes

- Our gripper systems can help you set up and place blood sample tubes accurately. We provide you with durable precision solutions for laboratory automation, developed and manufactured in accordance with your specifications.

TPU for placing

With our tube placing unit (TPU), blood sample tubes can be placed accurately in racks, pucks or cars. For this purpose it is equipped with a Z-axis and rotary movement. It grips the tubes straight so that the bottom of the tube finds the opening of the rack. The integrated barcode scanner enables placement with the barcode aligned. In order not to obstruct the measurement of barcode, fill level or HIL status, the TPU grips the tube high up.

TRU for raising

Our TRU (tube raising unit) lifts blood sample tubes from a horizontal to a vertical position with the cap facing upwards. It doesn't matter whether the tube is placed with the cap on the left or on the right side under the gripper. The TRU can then transfer the upright tube to a second gripper (such as the TPU) or place it directly in a puck, rack or car using integrated Z-axis movement. Our gripper systems can be flexibly adapted to your product.

Separation of blood sample tubes with step conveyor

- Are you looking for a reliable step conveyor for the separation of blood sample tubes? Our patented OEM module has already proven itself in hundreds of large laboratories worldwide.

Our step conveyor features the following benefits:- Fast separation of up to 3,500 tubes per hour

- Teflon-coated: tubes with rubber caps can also be fully processed

- Optimised angles in the hopper area: even the last tube in the hopper is reliably processed

- High level of safety: mechanical construction avoids jamming and other dangers

- Easy to clean if a tube is not closed properly

If you need help in integrating the module into your system, as your OEM partner we'll be happy to help.

De-cappers and re-cappers

-

Tube suction with tried-and-tested de-capper

If you need to have caps suctioned at high speed and with high force, our de-capper has proven its worth for many years in numerous large laboratories worldwide. The risk of cross-contamination is low.Our de-cappers and re-cappers can be adapted to suit your product.

Sealing open tubes

To seal open tubes before storage, we have developed two concepts: - With a combination of de-capper and re-capper, the sample container can be resealed with the original cap straight after pipetting.

- Alternatively, a balloon capper can reseal the tube with a hollow stopper safely and at low cost.

MEMS-based spectral sensors

- Do you need your sensors to measure quickly and reliably even in the most demanding environments? Our sister company Spectral Engines provides MEMS-based spectral sensors that use the patented Fabry-Perot interferometer.

Excellent sensitivity, low cost

The sensors operate in the true near-infrared spectral range from 1100 to 2450 nanometres, thus improving sensitivity and specificity in material sensor applications. So you get excellent performance that is significantly more cost-effective than a spectrometer.

Stable performance guaranteedWith a wide range of features, the sensors guarantee stable performance in even the most demanding industrial and consumer applications:

- Two light sources

- NIR sensor

- Read-out and drive electronics

- Integrated intelligence

Spectrometers

-

You need a spectrometer with

above-average performance?

Then the ones provided by our sister company Avantes are the perfect basis for

measurement and analysis. You can get precise measurements for chemical composition,

quantification, colour and radiometry in the ultraviolet, visible or near-infrared wavelength ran

Example: CompactLine spectrometers

Slightly bigger than a pack of cards, very powerful and easy to integrate, these are our most cost-effective mini-spectrometers. They are well suited to a range of medical applications. They can be used to assess the haemolytic or icteric status of a blood sample even if the sample tube is covered with labels.

One of the leading developers

Avantes has over 25 years' experience in fibreoptic spectroscopy. With an installed base of more than 20,000 systems, our sister company is one of the leading innovators in the development of fibreoptic spectroscopy instruments and systems. These solutions can be used as a base technology for spectroscopy and material characterisation.

Control and software

- Do you need a control platform that's tailored to your needs? With decades of experience in measurement and control technology, m-u-t will find the right solution for you, whether from our existing portfolio or developed especially to meet your unique requirements.

Modular platform for high flexibility

Versatile, centralised and modular – our modular control platform for laboratory automation makes everyday work easier. It's based on National Instruments hardware with various interfaces possible (CanOpen, Ethernet, etc.) and programmed with Labview.Simple function updates and adaptation for new instruments make it the perfect platform to handle typical applications in laboratory automation in both small and medium quantities.

Precise control of DIN rail mounting

With our modular logic controller (MLC), you get modular control for DIN rail mounting. It consists of a central unit and up to 15 I/O modules that can be combined in any way, containing digital and analogue inputs and outputs. In this way, simple applications can be realised without the need for work-arounds. The programming is done with Multiprog© as per IEC 61131 in up to five different programming languages.With its modular design and generous expansion reserve, the MLC can be easily adapted to different requirements.

Gas sensors for combined air humidity and gas measurement

- Do you need your air or gas humidity sensors to react faster than capacitive sensors? Do you need more precise measurements at high or low humidity? m-u-t has a bespoke solution: NDIR air humidity measuring devices combined with gas sensors. With this purely optical method, you can measure absolute humidity over a wide range.

High flexibility

Measuring range and measuring speed an be easily adapted to meet your requirements. The pressure and temperature sensors allow measurements to be outputted in different units.

Benefits include:- Virtually hysteresis- and drift-free measurement

- High measuring rates achievable

- Robust, durable technology

- Resistant to solvents (alcohols)

- Parallel gas measurement available (NDIR-active gases)

- Long-term stable measurements

- Extensive reduction of cross-sensitivities

- Long-life, maintenance-free measuring cell with no moving parts

Serial production

Bulk input module for total laboratory automation (TLA)

- Do you need a module for the bulk input of blood sample tubes for laboratory automation?

Take advantage of our innovative solution

You can reduce staff required in laboratories and accelerate process flows. For large IVD manufacturers, we have developed a bulk input module for TLA systems that performs the following:- Bulk separation of blood sample tubes

- Scanning of tube parameters, e.g. tube geometry and barcode information

- Positioning of tubes with barcode aligned on customer's track system

Development and production under one roof

As your partner, m-u-t will not only work alongside you but deliver quickly. We have a profound understanding of your requirements and potential. We cover the entire spectrum of development and manufacture in-house:- Technical design

- Creation of control system (electronics and software)

- Comprehensive product documentation for customer's regulatory requirements (e.g. CE certification)

- Serial manufacture of module at our premises

Input-output modul

-

If you need an input-output module for a clinical diagnostics analysis device, then make m-u-t your partner.

Then m-u-t is exactly the right contact for you

Our module feeds the open tubes to and from the analysis devices used by our OEM customers. You can feed the racks into the device in several ways: either in standardised trays, via a connection to a TLA system, or via a separate feed for emergency tubes.

Developed and manufactured under one roof

With m-u-t, you'll have a partner at your side who understands the technical processes involved in the input-output module.

We cover the entire spectrum of development and manufacture in-house:- Technical design

- Creation of control system (electronics and software)

- Comprehensive product documentation for customer's regulatory requirements (e.g. CE certification)

- Serial manufacture of module at our premises

Adapters for instrument reprocessing

- Are you a manufacturer of flexible endoscopes or cleaning and disinfection devices (RDG-E)?

m-u-t develops and manufactures the relevant adapters

And so that you can be sure that our products will be available long-term, we take care of the entire product lifecycle up to obsolescence management.

Treatment of chronic wounds - the most modern medical technology made by m-u-t

- Do you have an innovative idea and quickly need the right device as a series product for it?

All under one roof

The cause of this product success? With our innovative spirit, we don't leave any technical detail to chance! In close cooperation with a customer, m-u-t has developed a direct current pulse generator for the treatment of chronic wounds. Together with hydroactive wound dressings, it supports and accelerates wound healing processes - especially in treatment-resistant and stagnant chronic wounds; state-of-the-art medical technology from m-u-t.

From development to production, we are responsible for the entire creation process under one roof:- mechanical construction

- creation of the control (electronics and software)

- comprehensive product documentation for the customer's regulatory requirements (e.g. CE certification)

- series production of the module at the Wedel site

Process control in instrument reprocessing

- Looking for ways to retrace instrument reprocessing? As an experienced OEM partner in medical technology, m-u-t has developed a self-contained smart system.

Heard and demanded from a single source

Your advantage with m-u-t: Innovative spirit paired with production methods!

What makes the system so effective?

At its core, the control system monitors and documents every reprocessing step. RFID antennas identify the instruments in the cleaning system's rinsing chamber. For this purpose, we have developed RFID transponders that are suitable for all commercially available flexible endoscopes.

Developed and manufactured from a single source:- Technical construction

- Creation of control system (electronics and software)

- Comprehensive product documentation to meet customer's regulatory requirements (e.g. CE certification)

- Serial manufacture of module at our premises in Northern Germany