- Offer Profile

- Pioneers in Premium Recycling of Electrical and Electronic Waste

For over 30 years, weeeSwiss has stood for innovative, tailor-made WEEE recycling plants of premium quality. As an industry benchmark, we develop customized solutions for demanding customers worldwide – with a clear goal: to make a functioning circular economy a reality.

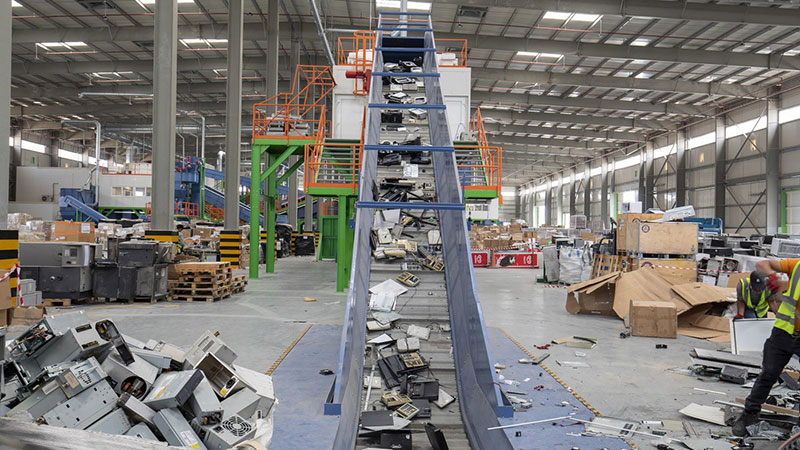

E-waste Processing Plant

-

For over 30 years, weeeSwiss has been developing and implementing customized recycling processes for all types of electrical and electronic waste – successfully operating worldwide.

Our plants are designed to efficiently remove hazardous substances from e-waste and separate it into high-quality materials and raw resources. A particular focus lies on the concentration of precious metals, ensuring that subsequent pyro-, hydro-, and electrometallurgical processes are as efficient as possible.

Input materials

- The process begins with weighing, inspecting, and classifying the input material, followed by allocation to the appropriate processing units.

Hazardous substances are removed both manually and mechanically. A proprietary process developed by weeeSwiss – and continuously improved since 2000 – significantly reduces the amount of manual effort required.

Extracted hazardous substances are safely stored and handed over to certified disposal specialists – always in parallel with the recovery of valuable materials.

Our modular plants allow for precise shredding, achieving the desired grain sizes while ensuring that pollutants can still be removed after shredding.

Ballistic Separator

- A central element of the process is the ballistic separator: In a single step, it separates 2D, 3D, and fine fractions. This allows plastics to be selectively removed immediately after coarse shredding, relieving downstream modules. The material then undergoes further screenings and manual sorting before being shredded again. This enables the extraction of ferrous and non-ferrous metals and, in particular, high-quality plastics.

Maximum Recovery of Valuable Materials

- In the next stage, sensor-based sorting divides the material into further fractions such as printed circuit boards and plastics.

Remaining materials are reprocessed within a closed-loop system – right up to complete liberation in the granulation mill.

Granulation Module 4 plays a key role in releasing precious metal–bearing fractions. Our process is highly energy-efficient and low in wear, reducing heat development within the material. This enables plastics to remain recyclable even after milling.

Our modern dedusting systems not only ensure clean and safe working conditions but also enable the recovery of the finest precious metal particles – another important contribution to resource conservation.

Process Technology and Modules

-

We operate with a modular concept that offers the following benefits:

- Independent control: Each module can be run individually, significantly increasing overall plant availability.

- Targeted routing: Input material does not have to pass through every module; it can be directed only through the stages it actually needs, which cuts production costs.

- Flexible feeding & extraction: Each module can be loaded separately, and material can be removed whenever required, boosting overall efficiency.

Below you will find each module with a concise description.

Module 0 – De-dusting

- Module 0 collects dust from all modules and channels it through ducting to a filtration system that separates dust from air. This keeps both the material and the workplace clean, ensuring high output quality and a healthy working environment.

Module 1 - Goods-In / Sorting Cabin

- Quality assurance and transparent material flow start here, with accurate weighing on arrival. Hazardous and valuable components are removed from the stream.

Module 1.1 – Toners & Cartridges

- Material is fed to the shredder, where cartridges are safely opened during the shredding process. System inertisation reliably prevents explosions. After shredding, toner powder is extracted and the remaining material is passed on to Module 3.

Module 2 – Pre-shredding & Separation

- After initial removal of hazardous or disruptive items, large and small appliances are processed in Module 2. The material is gently shredded and then optimally conditioned by a ballistic separator. Batteries and capacitors can be removed mechanically or manually, and plastics can be selectively processed. These steps greatly simplify the removal of hazardous substances. Early separation of plastics in Module 2 also relieves downstream modules and improves end‑product quality.

Module 2.1 – Plastic Separation

- The 2-D material discharged from the ballistic separator is first precisely size-reduced. In the subsequent separation stage, ferrous metals, non-ferrous metals and other metallic constituents are efficiently removed, leaving a high-grade, single-polymer plastic fraction.

Module 3 – Post-shredding & Mechanical Separation

- Material from Module 2 is further shredded so that iron can be recovered using magnetic separators, screens, air classifiers and manual sorting – producing iron of the highest steel‑mill quality.

Module 3.1 – Extraction of Valuable Materials

- Material from Modules 2 and 3 is accurately separated using non‑ferrous separators and sensor‑based systems, delivering non‑ferrous metals, mixed plastics and/or printed circuit boards in top quality. Plastics are then sent to Module 5 for further plastic‑to‑plastic separation.

Module 4 – Balling

- Precious‑metal‑bearing material from all modules is crushed in an impact mill and formed into balls. After several passes the material is completely processed. Subsequent screening prepares it perfectly for metal‑plastic separation on the downstream machines, allowing targeted concentration of precious‑metal fractions.

Module 5 - Plastic / Plastic Separation

- Flame‑retardant and target plastics are separated by precise sensor technology, recovering ABS, PS, PP and PE at superior quality. This new, highly efficient, dry mechanical process represents the future of plastic recycling from e‑waste.

Module 6 – Refrigerators & Air-conditioners

- Stage 1 drills into the cooling circuit and removes oils and climate‑relevant gases, which are safely collected. Stage 2 shreds the remaining material, followed by state‑of‑the‑art separation of iron, non‑ferrous metals and plastics, including PUR foam. The entire system is fully enclosed to safely capture harmful gases.

Module 7 – Printed Circuit Boards

- PCBs are first shredded; iron and non‑ferrous metals are then removed by magnetic and eddy‑current separators. A mill further reduces the material for the next separation stage. Screens prepare the material for an air separator that removes plastics from non‑ferrous metals. Finally, an electrostatic system precisely separates precious metals from dust.

Module 8 – Cables

- Cables are cut into smaller pieces in a pre‑shredder, then further reduced in a granulator and mill. Subsequent steps efficiently separate copper, plastics, dust and ferrous metals.

Module 9 - LCD Screens, PV Panels & Lamps

- LCD screens and lamps are fed via two separate inlets. Shredders and drums process the material, followed by additional separation stages to recover iron, non‑ferrous metals, plastics and mercury. The fully automated PV‑panel line precisely separates the junction box, aluminium frame and glass from the solar element, enabling up to 95 % of the materials to be returned to the recycling loop.

Module 10 - Lithium-ion Battery Recycling

- Batteries are completely discharged and then continuously shredded under inert conditions using our patented process, leaving as little reactive mass as possible in the shredder. All material is transferred directly to the separation phase, where the electrolyte is removed and black mass is separated and cleaned.

Module 11 – Dust Precious-Metal Concentration

- Dust containing precious metals is treated in a specialised system that first removes capacitor foils and other coarse components. Subsequent screening and separation stages then selectively concentrate the valuable metals present.

Module 12 – Precious-Metal Extraction Plant

- Precious‑metal concentrates are further processed in Module 12. Hydrometallurgical recovery extracts precious metals from the non‑metallic fraction.

Input und Output

- In our state-of-the-art sorting plants, we process a wide variety of discarded devices, including computers, smartphones, household appliances, and much more. These devices contain valuable raw materials, but also harmful substances that must be carefully separated. Using advanced sorting processes, we recover valuable materials such as metals, plastics, and rare earth elements from this input, which can then be reused in new products. Our facilities are capable of processing the entire range of WEEE categories. Below you’ll find a detailed overview of the different input materials and the output resources recovered from them.

Input

IT and Telecommunications Equipment

-

- Centralized data processing (mainframes, minicomputers, printer units)

- Personal data processing (personal computers, laptops, notebooks)

- Printing and copying equipment

- End-user devices and systems (electric and electronic typewriters, calculators, fax machines, telephones, mobile phones, answering machines)

Small Household Appliances

-

- Floor care (vacuum cleaners and other large appliances)

- Other small household appliances (carpet sweepers, sewing, knitting, weaving equipment, irons, toasters, fryers, coffee machines, small kitchen devices, etc.)

- Various small household appliances (hair clippers, hair dryers, shavers, massage devices, etc.)

- Clocks and watches

- Screens, monitors – LCD and LED TV panels

Large Household Appliances

-

- Large devices – washing machines, dryers, dishwashers, cookers, electric stoves

- Medium-sized devices – microwaves, electric hotplates, electric heaters

- Other devices – electric fans

Refrigerators and Air Conditioners

-

- Refrigerators

- Freezers

- Air conditioners

Output

The recovered resources

-

- Ferrous scrap in various sizes / CrNi

- Non-ferrous metal fraction

- Brass

- Copper

- Copper-iron (“meatballs”)

- Large electric motors

- Cables

- Aluminum (medium-sized and granulate)

- Heavy metals with precious metals

- Heavy metals

- Plastics in various sizes

- Dust with and without precious metals

- Printed circuit boards (PCB) of various grades

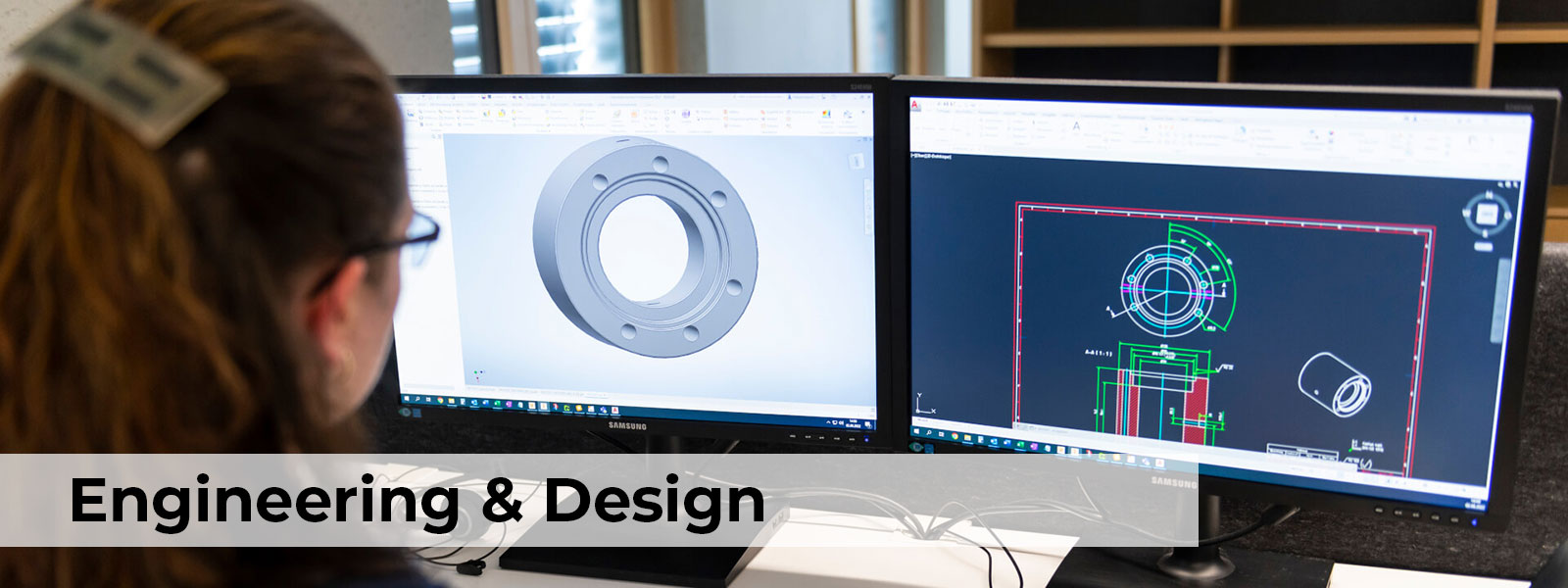

Engineering & Design

- Since 1992, we have been developing innovative e-waste recycling plants for a wide range of applications worldwide. Our systems cover the entire spectrum of e-waste – from printed circuit boards, cables, small and large household appliances, refrigerators, and toner cartridges to plastics recycling, photovoltaic modules, LCD/LED components, and battery recycling.

Operator-Friendliness and Cost-Effectiveness

- Our plants are designed for maximum efficiency and ease of maintenance. Backed by decades of operating experience, they are particularly user-friendly and stand out with low operating costs. Customers benefit long-term from solutions that clearly outperform competing products. Another key focus is the concentration of precious metals – a decisive advantage thanks to high returns from smelters, achieved through carefully optimized process technology and innovative shredding solutions.

Stronger Together

- As part of STADLER Anlagenbau GmbH, we develop our plants alongside first-class engineers with extensive experience in building large-scale systems. Together, we set new standards for sustainable and high-performance recycling solutions.

EPC Services and Turnkey Sorting Plants

- International customers place high and diverse demands on processing concepts.

weeeSwiss brings extensive experience: we have planned numerous plants, developed innovative systems and machinery, successfully commissioned them, and continue to support them with first-class service.

EPC Services – Everything from a Single Source

-

EPC stands for Engineering, Procurement, and Construction. As an EPC contractor, weeeSwiss takes full responsibility for coordinating all planning, procurement, and construction activities. We ensure your project is delivered on time, on budget, and according to your specifications.

Our customers expect high-performance recycling plants – and weeeSwiss delivers customized solutions. While many installations are based on our standardized modular concepts, others benefit from our individual, tailor-made plant solutions.

Turnkey Sorting Plants

-

Together with you, we define your technical and market-related requirements as well as your expectations in detail. On this basis, we develop a well-thought-out concept that meets your needs – leveraging our experience, proven process solutions, and insights from comparable markets.

Once the concept is finalized, we take care of the entire implementation: from planning and procurement through manufacturing and construction to commissioning your plant. In addition, we train your staff and technical personnel to ensure the highest standards in quality, safety, and production. Throughout the process, we always keep your budget, timeline, and performance requirements firmly in view.

weeeServices

-

The success of a WEEE recycling plant depends not only on technology but also on a holistic and perfectly coordinated service approach. weeeSwiss supports you far beyond the construction phase – with expert consulting at every stage of the project and customized solutions for maximum efficiency.

Through high-quality start-up and ramp-up services, we ensure the optimal performance of your plant, while our experienced after-sales team is always by your side. As an industry pioneer, we also provide knowledge transfer and purchase agreements for your output fractions, ensuring long-term profitability and sustainable success.

Project Phases

- Maximum Value for Our Customers

At weeeSwiss, workplace safety, low emissions, environmental protection, and employee satisfaction and motivation are at the core of our philosophy. Our goal is to provide you with the greatest possible benefits:

- Economical plant systems and processing modules

- Flexibility for changing materials and fractions

- Rapid results and profitable lifecycle performance

- High plant availability with low maintenance requirements

- Cost efficiency – low investment (CAPEX) and operating costs (OPEX)

- Maximum value creation through high recovery rates and yields

With weeeSwiss, you choose sustainable, efficient, and future-proof solutions for your recycling processes.

Start- & Ramp-Up

-

An optimal start for your recycling plant! Through precise testing during the start-up phase and a gradual increase in performance during ramp-up, we ensure smooth commissioning and maximum efficiency.

- Start-Up – Precision from the Very Beginning

- Ramp-Up – Efficient Performance Increase

After Sales

- Ensuring Long-Term High Performance

Only with excellent service can you ensure high material quality, maximum throughput, and optimal plant performance. Our experts support your team with maintenance, overhauls, and component replacements. We provide the right spare parts and ensure your plant is always up to date.

As part of the STADLER Group, weeeSwiss customers benefit from world-class service, fast response times, and the highest customer satisfaction.

- Regular Inspections

- Training

- Spare Parts

- Service Contracts

- Production Support

Offtake Agreements

-

To support the sale of output fractions from WEEE recycling plants, weeeSwiss offers customized offtake agreements. Thanks to our in-depth market knowledge and global network of smelters and specialized recyclers, we ensure the best possible market prices for your materials.

Digital Solutions with STADLERconnect

-

Our digital platform STADLERconnect combines machine and material data to systematically enhance the performance of your e-waste plant. Based on real-time information and AI-powered analytics, the platform provides tailored solutions to improve efficiency and reliability throughout operations.

- Digital Maintenance

- Automation & Material Analysis

weeeCoach

-

For Successful WEEE Projects

From the first idea to successful operation, a WEEE project goes through several demanding stages.

Our services for your project’s success

With weeeCoach, weeeSwiss provides competent and tailored support – from the pre-sales phase and implementation to after-sales service. We assist you at every stage of your project to ensure your plant operates efficiently, sustainably, and economically.- Operational Optimization – Improve efficiency and performance

- Business Development– Open up new markets and opportunities

- Management Economics– Economic assessment and decision-making support

- Business Case– Comprehensive profitability analyses for your project

- Know-how Transfer– Knowledge and skills development for your team

- Production Training– Hands-on training for your staff

Operational Optimization

- You have a goal – we deliver the solution.

With experience from the design, commissioning, and operation of more than 15 large WEEE recycling plants – as well as numerous smaller projects – weeeSwiss develops customized processes and selects the right machines to achieve your specific objectives.

Business Development

- Solid planning is the key to every successful project

weeeSwiss has more than 30 years of experience in developing, implementing, and operating e-waste recycling plants around the world. During this time, we have successfully completed many large-scale projects – always with the goal of providing our customers with the most economically and ecologically efficient plant technology.

Our mission is to pave the way for your success — with minimal risk and maximum cost efficiency. That’s why we offer feasibility studies, business plans, and support with permitting procedures. We analyze market conditions and align each project precisely with the proven needs of the target markets.

Management Economics

- Holistic Operations for Maximum Efficiency and Value Creation

The economic success of an e-waste recycling facility depends not only on technology, but also on efficient management and clearly defined structures. weeeSwiss supports operators in aligning all economic and organizational aspects – ensuring stable, profitable, and future-proof plant management.

- Structured Plant Management

- Digital Support through Software Solutions

Business Case

- Step by Step to a Profitable E-Waste-Recycling Business Model

To build a robust business plan, we work hand in hand with our customers to analyse and develop the following core elements:

- Market data:

• Volumes of electrical and electronic equipment (EEE) placed on the market

• Amounts of waste electrical and electronic equipment (WEEE) generated - Regulatory framework:

• Applicable legal requirements for e-waste processing

• Operating permits required from local authorities for an e-waste recycling plant

• Availability of grants, financial incentives or tax relief - Site analysis:

• Selection of the optimum location

• Forecast of expected WEEE volumes

- Market data:

Know-how Transfer

- Customized Training Programs for Sustainable Recycling Success

Operating a recycling plant successfully and efficiently requires more than just technology – it needs well-trained personnel.

That’s why weeeSwiss has developed tailor-made training formats over many years, based on the principle of hands-on know-how transfer.

Our goal: to turn your employees into professional recyclers in the shortest possible time.

Production Training

- Practical Know-how for Sustainable Success

To ensure smooth and efficient operation of a recycling plant, weeeSwiss provides comprehensive on-site production training.

Our training modules combine theoretical knowledge with hands-on practice and are designed for both technical staff and management teams.