- Offer Profile

-

CT-Systems for industry and academic research

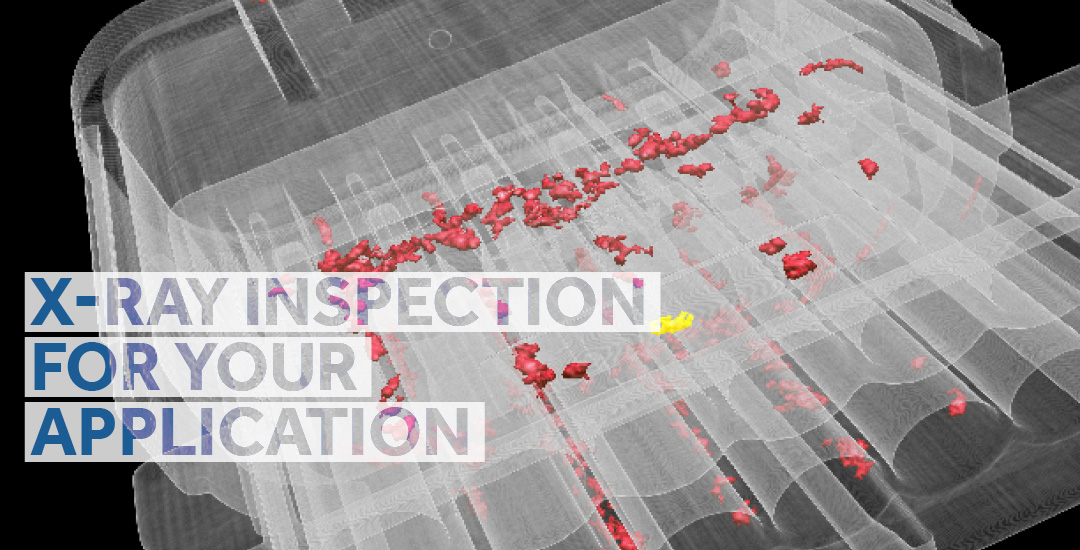

High-resolution X-ray inspection has become a widely used tool for non-destructive testing, failure analysis, and process control in a variety of industrial and scientific areas.

Our CT-Systems are able to inspect any object without destroying it. 3D- and now 4D CT (3D with motion) are up to date analyzing systems.

ProCon X-Ray CT Systems deliver uncompromised Image quality to help you deliver revolutionary and differentiated capabilities across all of your quality control needs.

CT-Systems for industry and academic research

Desktop Systems

CT-PORTABLE

-

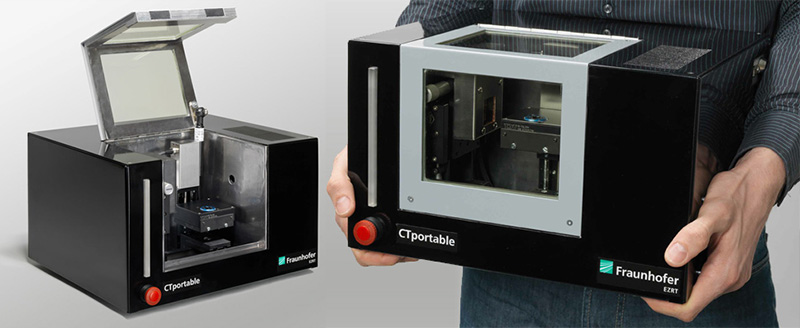

A portable, easy-to-handle CT system

Recently the computed tomography (CT) became more and more important as a non-destructive ins-pection method for the industry. CT provides a fast visualization of a threedimensional volume model of the outer and inner structure of an object that can be interpreted even by laymen. CTportable is especially suitable for demonstration purposes as well as for mobile services or an application in arbitrary laboratories.

The smallest mobile CT system worldwide

With its dimensions of approx. 350 x 300 x 230 mm (l x w x h) the space requirement of the CT system is minimal, moreover the low weight of approx. 20 kg ensures maximum mobility. Thus the CTportable is the smallest and lightest CT system in its market segment at present. These features enable the user to apply the system flexibly at any location without the necessity of transporting the samples or components to a laboratory.Application fields

CTportable is especially suitable for demonstration purposes as well as for mobile services or an application in arbitrary laboratories. The CT system can not only be utilized by universities or research institutions in the fields of e.g. biology, geology and archaeology, but also by the industry, especially for the nondestructive testing for quality assurance in the areas of electrics, plastics, textiles and ceramics. The range of applications also includes rapid prototyping.Features

- High image quality.

- High dynamic range.

- Basis materials analysis, Dual Energy CT.

- Extended field of view function.

- Helical CT for avoiding Feldkamp artifacts.

- Isotropic resolution in all layers.

- Highly accurate dimensional measurement.

- Plug&Play via USB connection.

- Large windows for demonstrations.

- Compact and light design for easy transport.

CT-MINI

-

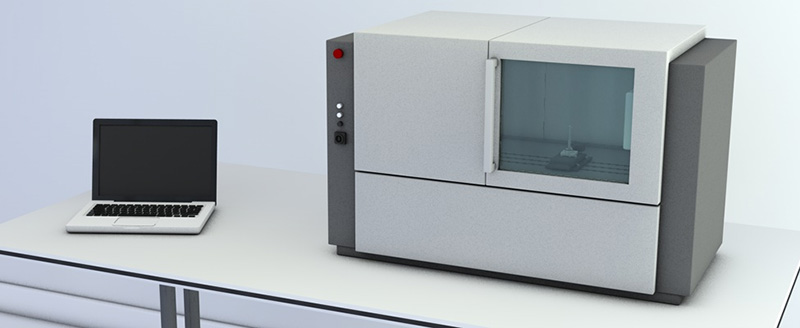

CT-MINI, – the Original- , with minimal space requirement

Inspecting plastics, ceramics, and metals. This 3D-CT, from ProCon X‑Ray GmbH “performs as laboratory micro CT by excellent CT results in real-time”, comment of Norman Schott, our Applications Specialist.

The room-saving CT-MINI can be equipped with micro-focus X-ray tubes from 90 kV up to 130 kV, depending on specific customer requirements. The focus-detector distance can be adjusted to optimize the contrast. The CT-MINI system is ideal for nondestructive testing (NDT), materials analysis, rapid prototyping, and because of its fast on-line reconstruction capable for a production guided process control.

The CT-MINI system is ideal for nondestructive testing (NDT), materials analysis, rapid prototyping, and because of its fast on-line reconstruction capable for a production guided process control.

Features

- Industrial X-ray Computed Tomography (CT).

- 3D volume CT.

- Non-destructive testing (NDT) – 2D and 3D.

- Quality control independent of material.

- Defect recognition (voids, cracks, …).

- Contactless metrology.

- CT reconstruction in real-time.

- Easy operation.

- Radiation safety better than 1 µSv/h.

- Desktop system.

CT-COMPACT

-

CT-COMPACT, the most versatile desktop system for 3D-CT requirements

The space-saving CT-COMPACT can be equipped with micro-focus X-ray tubes capable of operation up to 160 kV, depending on specific customer requirements. The focus-detector distance can be adjusted to optimize the contrast. The CT-COMPACT system is ideal for nondestructive testing, materials analysis, metrology and, rapid prototyping. Due to our cabinet temperature concept the CT-COMPACT holds the certificate of proven measurement uncertainty, by Q‑DAS.

Features:

- Industrial X-ray Computed Tomography (CT).

- 3D volume CT.

- Non-destructive testing (NDT) – 2D and 3D.

- Quality control independent of material.

- Defect recognition (voids, cracks, …).

- CT reconstruction in real-time.

- Easy operation.

- Radiation safety better than 1 µSv/h.

- Desktop system.

Standalone-Systems

CT-ALPHA

-

The CT-ALPHA system meets the most stringent demands in CT X-ray

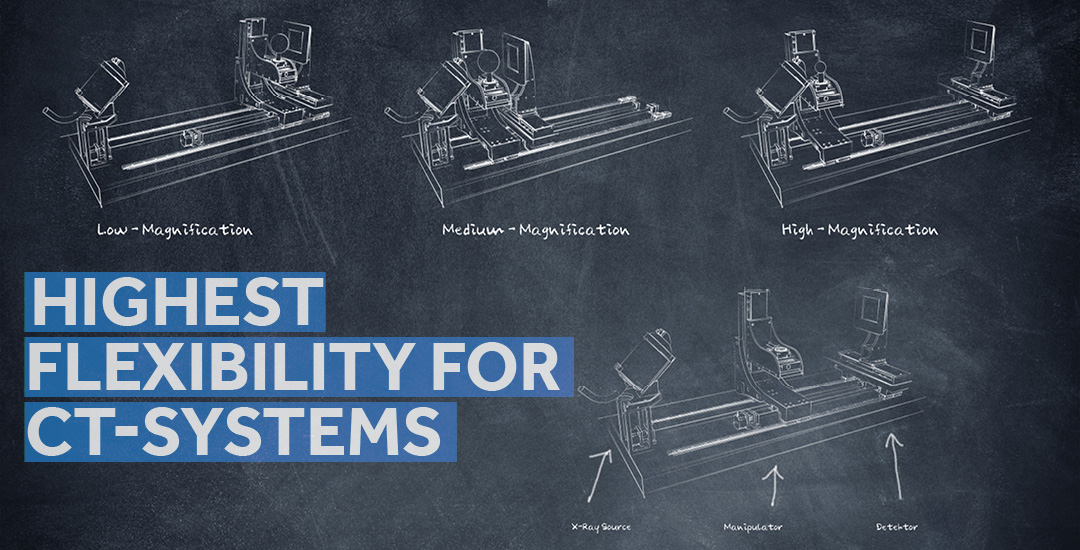

With this Computed Tomography system, ProCon X-ray GmbH offers the highest possible flexibility for individual customer requirements. The CT-ALPHA system is ideal for non-destructive testing, materials investigations and, in particular, dimensional measurements of internal structures, undercuts and free form surfaces.

This space-saving system can be equipped with different X‑ray powers, from 160kV for nanometer resolution through 225 kV, 320 Watts to the highest power of

450 kV, 1500 Watts.The variable focus-detector distance permits maximum contrast. As an option, the CT-ALPHA offers the Helix-Scan technique for longer objects as well as for the best avoidance of volume CT artefacts for optimum results in dimensional

measurement.Very large geometric magnifications permit real-time reconstructions in the submicron range. The CT-ALPHA system is ideal for non-destructive testing, materials investigations and, in particular, dimensional measurements of internal structures, undercuts and free form surfaces.

Features

- Industrial X-ray Computed Tomography (CT).

- 3D volume CT.

- Non-destructive testing (NDT) – 2D and 3D.

- Quality control independent of material.

- Defect recognition (voids, cracks, …).

- CT reconstruction in real-time.

- Easy operation.

- Radiation safety better than 1 µSv/h.

- Helix CT.

CT-Microscopes

CT-ALPHA nanotube

The system is combining the latest state-of-the-art components for highest resolution. Two separate manipulation systems allow a very precise detector and sample positioning. A high-precision air bearing rotary stage delivers a well-defined sample rotation, mounted on top of a linear position system with 3 DOFs. A separate manipulation (2 DOFs) system on top of the rotation stage is installed for automatic adjusting the sample position in the center of the rotation.

Features

- Min. Voxel sampling 50 nm.

- Spatial resolution of 150 nm.

- Photon counting detector.

- Variable field of view.

- Automatic alignment.

- State-of-the-art reconstruction.