- Offer Profile

-

A strong Partner - with more than 100 years of experience

We move things along

The company Romberger is a family-owned company with over 100 years of tradition.

We are considered as one of the best adresses in the areas of- Bulk freight technology - mill construction

- Conveyor systems

- Drying plants

- Feeding technology for biogas plants

- Special machine manufacturing and

- Environmental technology

Products

-

The Romberger® advantages

- We generously dimension our machines and drives with adequate power reserves

- Our modular design promises high stability, an easy installation and maintenance

- The low conveying speed treats the product gentle and is low wearing

- Low Speed also gives the machine a longer working life

- We adapt our products individually to our customer's request

- We offer a wide range of possible areas of application

- We rely on high quality through precise measurement and fitting accuracy

- We make large spacing available between the shafts

- Our belt bucket elevators operate smooth and low-noise

- You can rely on our outstanding service for life by our Customer Service Department

Belt Conveyors

-

Types:

- flat belt conveyors

- troughed belt conveyors

- troughed belt conveyors with sliding table

- sack belt conveyors

- dosing belt conveyors

- studded belt conveyors

- hopper discharging belts

- plastic belt conveyors

- apron conveyors

Material: all suitable materials; especially sheet steel (also galvanised) or types of stainless steel

Performance: 1 to 500 m3 /h

Conveying angle:

- 0° to 20° for belt conveyors

- 0° to 60° with studded belt

- 0° to 90° for plastic or apron conveyors

Belt:

- belt widths from 100 to 1500 mm

- from solid partners in the supply industry, for almost every customer requirement

Design: sides of sheet steel or structural steel design

Drive: maintenance-free motorised drive pulley, IP 67 or generously designed geared motor

Control and Safety Devices:

- speed monitor

- ripcord emergency cutout

- build-up monitor

- electronic off-track monitoring

Alternative Designs/Accessories:

- self-aligning roller bearings to prevent off-track running

- with belt scale

- with integrated metal locator

- magnetic drum

- quick-change belt stripping system

- belt conveyors, mobile, with rotating centre bearing, reversible, swivel-mounted as gib design with adjustable tilt angle

- telescopic, for smooth alignment with the discharge station

- metal locator

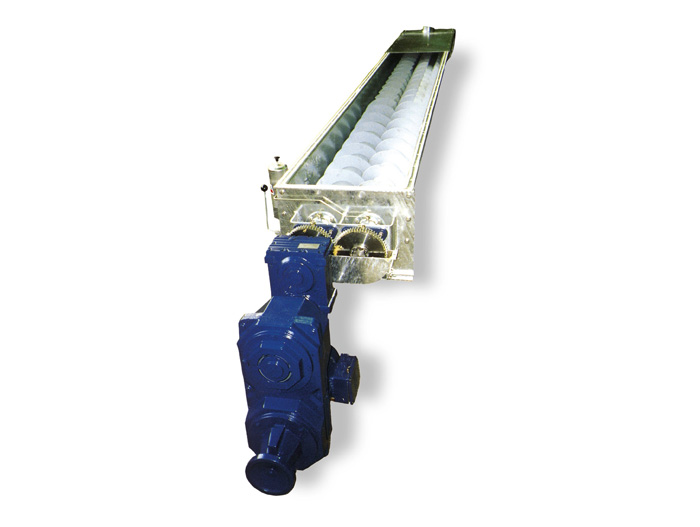

Screw Conveyors

-

Types:

- trough screw

- pipe screw

- paddle screw

- dosing screw

- cooling and heating screw

- double, multiple screw

- spiral screw

Material: all suitable materials; especially sheet steel (also galvanized) or stainless steel

Capacity: 0.1 to 400 m3 /h

Conveying angle: 0° to 90°

Thread:

- Normal thread

- spiral thread without axis

- conical thread

- band thread

- double thread

- paddle thread

Thread diameter: 50 to 800 mm Combinations of the thread designs are possible at any time

Propulsion:

- Generously dimensioned parallel shaft helical geared motor

- as a shaft-mounted gear unit or adapted to any customer requirement

Bearings:

- Drive and end bearings with flanged or pedestal bearings

- for long lengths, intermediate bearings are used or larger dimensioned axles are used

- one-sided flying bearing

Sealing:

- dust-tight

- gas-tight

- odour-tight

- fluid-tight

Chain conveyors

-

Chain conveyors - Tensioning station with offset support and sealing of the shaft inlet, as well as spring pre-stressing for transporting salt in the foodstuffs sector

Types:

- single line chain conveyors

- delivery chute-loading chain conveyors

- multiple line chain conveyors

Material: all suitable materials, especially sheet steel (also galvanised) or types of stainless steel

Performance: standard to 400 m3 /h apart from that no top limit

Conveying angle: to 30° standard to 90° special design

Conveying trough:

- Clearance width: from 160 to 1000 mm

- Length: standard to 100 m with rapidly changeable, hard-wearing T–shaped plastic wear strips and floor panel which can be unscrewed

Drive station:

- generously designed parallel-shaft geared motor as slip-on gear mechanism or adapted to suit any customer requirement

- top-quality bearings and driving sprockets

Chain: from reliable partners in the supply industry, for almost every customer requirement

Inlet and outlet:

- according to customer requirements

- variable in number, position and shape and can be precisely adjusted to fit existing systems

- inlet dosage Control and

Safety Devices:

- shaft speed monitor on the return wheel

- overflow detector

Alternative Designs/Accessories:

- intermediate floor for double-sided transport in the top and bottom halves

- trough bottom made from all possible materials or shapes, e.g. bottom made of special polyurethane, ceramic bottom or slatted sieve plate bottom to separate different fractions

- materials feed-back buckets

- slidegate, pneumatic, with electric motor or as manual version

- version in accordance with ATEX Guidelines

- with offset bearing and shaft seals

Belt bucket elevators

-

Types:

- Bucket belt conveyor

- Double belt bucket elevator

besides: - chain bucket elevators

- Pendulum bucket elevators

Material: all suitable materials; in particular Sheet steel (also galvanised) or stainless steel

Delivery rate: up to 500 m3 /h

Belt width: Standard: 125 mm to 1000 mm

Samplers

-

Installation variations:

- intermediate flange mounting in fall pipe

- direct installation in conveyor

- installation in container

Variations in types of sampling:

- continuous sampling

- clocked sampling

- clocked 24-hour operation with sample carousel

Material:

- ordinary steel

- stainless steel

Surface design:

- coated

- galvanised

- pickled, passivated

- bead-blasted

- polished

- chrome-plated

Parts:

- worm gear pair motor

- screw flight, with or without shaft

- conveyor tube with pick-up dish

- fastening device according to customer application

- bearing in motor and extra flange mounting

- seal on shaft inlet with stuffing box

- with facilities for self-cleaning

Alternative Designs/Accessories:

- quick-tensioning device for straightforward cleaning • sample carousel, standard to 40 sample containers

- adjustment to almost all available sample containers

- choice of sampling from drive side or opposite side

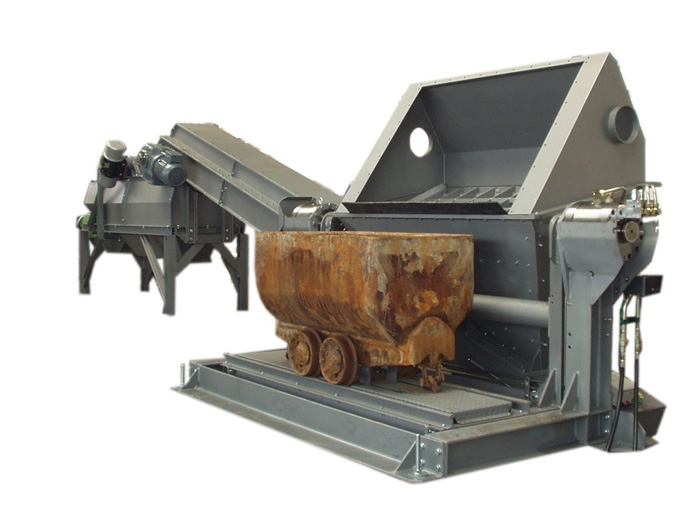

Metering feeders for biogas

-

The right feeding technoogy for your biogas plant:

- Solid stainless steel construction

- Shredding grinder

- 20–300 cbm bunker volume

- Time- or weight-based metering

- Different feeding techniques

- From the top through the ceiling

- Distribution to several fermenters

- Lateral fillingof the high fermenter

- Below the surface of a liquid with screw press

- Communication-enabled controller

- With self-monitoring controller

- Low internal power consumption

- Modular construction

- Weighing system with large display

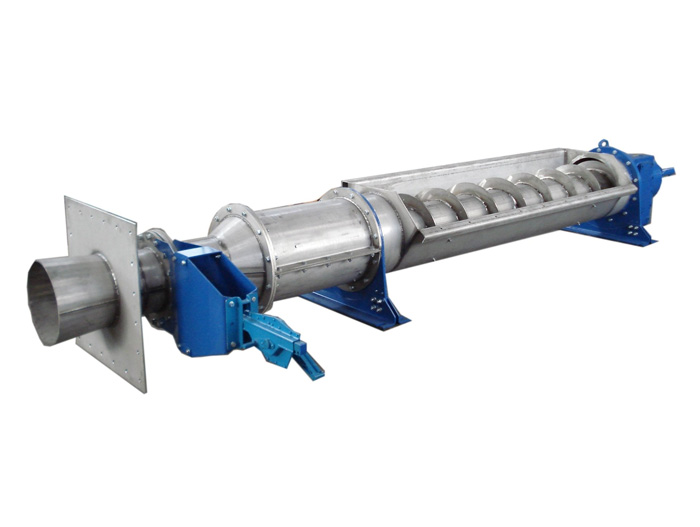

Screw conveyors for biogas plants

-

The right conveying technology for your biogas plant:

- Solid construction, entirely made of stainless steel

- Inclined screw conveyor with bearings at both ends and no intermediate bearings

- Reliable drive unit

- Linear conveying capacity 6- 100 cbm/h

- Mantle pipe with wearing protection and removable half-shells

- Thread diameter 350 or 450 mm

- Suitable for all solid materials

Our options:

- Transport systems for all installation versions

- Direct product transfer without injection

- Accurate adaptation of the transported volume to your system

- Versions for all existing way of feeding possible

- Fermenter screws with feeding hopper

Feeding technology biogas

-

The right feeding technology for your biogas plant:

- Directly through the wall, without long conveying distances

- Solid stainless steel construction

- Reliable drive unit

- Linear transport capacity up to 35 cbm/h

- Hydraulic injection after the feeding process

- Supply to places up to 6 m under water

- Suitable for all solid materials

Accessories:

- Feeding hopper made of stainless steel with feeding rollers up to 10 cbm

- Slide valve with leak detection

- Complete control with radio switch

Drying plants

-

Our patented Romberger® Drying plants are individually designed according to your requirements built, adapted to your drying product and designed for the required capacities.

We take into account all your specifications regarding emission limits and space requirements. To save overall height, the various drying zones can be arranged in two adjacent columns can be accommodated. We install your dryer in the open air or in existing Building in. Later conversions or extensions are possible at any time due to the modular design. Our experience helps you with advice, planning, assembly, instruction, approval, commissioning and lifelong service.Mode of action:

We dry your grain gently and effectively. The Dryer is installed from above in equal layers filled with the product. The grain then slides through the shaft at intervals and gets into an air stream, which is blown through conical air conduction roofs, the grain is fed in and out washes around all sides and removes the moisture.

The grain passes through the different temperature zones in cascade without damage. The warm air temperature of the product humidity always adjusted. In the lower The product is gently re-cooled before it leaves the dryer cooled and evenly dried by our special discharge device.Types: Continuous dryer and circulation dryer in one model.

Product to be dried: corn, all cereals and oilseeds.

Capacity: from 1 to 50 t/h. Other sizes on request.

Heat utilization for biogas plants

-

RST fermentation substrate drying for biogas plants

- The amount of fermentation substrate is reduced by evaporation of liquid (0.7-1Kg/KW/h)

- As a result, savings in storage capacity and transport logistics of up to 50% can be achieved

- This amount is acknowledged at the fermenter volume capacity

- The system is operated automatically with low maintenance and energy expenditure

- We install the plant into your process with automatic filling and emptying

- Thus, a continuous plant operation with full-year utilization is possible

- The production of manure is possible by increasing the dry matter content up to 50%

- Due to the evaporation of the liquid, the dry matter content of the liquid manure increases up to 12%

- The nutrients per cbm increase accordingly

- By means of the fume scrubber, the ammonia is bound with sulfuric acid. This results in a solid ammonium sulfate bond (ASL), i.e. liquid fertilizer

- In the mixture with ASL, the manure then becomes a complete high quality fertilizer

- The plant is operated dust-free

- The fermentation substrate is reduced to a maximum of 12% dry matter content. As a result, there is no dust

- The plant is operated with an exhaust air purification according to TA-Air, so there is no odor imission

- You can use the complete waste heat

- The machine is KWK-bonus able

The performance varies with the available heat. Only time is affected.

For example: at 600kW/h x 0,7L/kW = approximately 420L/h evaporated liquid.

In an 8000h annual operation this corresponds to approximately 3360cbm liquid that does not need to be stored and transported.Function:

The Romberger fermentation substrate drying plant increases the solids portion in the fermentation substrate by evaporation of liquid. Continuously heated contact plates in a rotating drum are immersed in the substrate. The moistened sheets are then fed into the air stream. The heated air flows through between the sheets and transports the evaporated liquid. By doubling the nutrient content due to the reduction in quantity, high quality manure is produced. In addition, the quantity reduction saves logistical costs, such as the discharge of manure or storage.The following points have to be proven for granting the KWK bonus:

- The fermentation products must be prepared for the purpose of fertilizer production

- The aim of the treatment is a weight reduction to improve the transport and storage capacity and a slurry upgrading

- The plant is connected to a heat network of at least 400m in length

- The plant is energy efficient and needs no more than 1500KWh (therm) to evaporate 1000l of water

- The nitrogen must be less than 30%. The nitrogen contents of the products of an exhaust-gas/exhaust-air purification are subtracted from the difference and are therefore not counted as nitrogen loss.

- The Plant must be notified to the competent authority

- The amount of the fermentation substrate must be detected by a flow meter, the energy requirement via the heat meter

- The TA-Luft must be maintained by means of exhaust air purification with an odor statement in ppm / cbm, and perhaps an odor report

- The system must be coordinated with the responsible environmental expert

Shredder

-

Processing biomass with the Romberger Shredder DLZ

- All substrates are continuously processed

- The Romberger DLZ is always filled steadily

- There is no need for constant switching on and off of the upstream dosing and conveyor system

- With the Romberger DLZ you can shred all solid feedstocks to 100%. Manure, straw, corn silage, grass, sudangras, GPS, potatoes, sugar beet, all vegetable waste, grain maize, new substrates, etc.

- Complex batch operations and peak current loads can be avoided with the Romberger DLZ

- There are no complicated conversions of the existing system needed

- The Romberger DLZ has an output of approx. 12to/h with corn silage at 55KW

- The Romberger DLZ is absolutely immune to impurity and contaminants. What can not be crushed is ejected

Function:

- The constant and steady filling and emptying allows a trouble-free and low in wear plant operation

- Fast rotating impact elements fray the biomass in a few seconds

- Due to the special design of the Romberger DLZ the operation can be carried out continuously

- The crushing degree can be changed by the number of impact elements

The rapidly rotating shredding elements in the machine break up the cell structure of the biomass in seconds, thus creating a homogeneous substrate with a large surface. The Romberger DLZ frays the various input materials instead of cutting them. This increases the surface area of the biomass and provides more attack surface for bacteria, allowing for faster and more efficient decomposition. The frayed substrate has a much better swimming behavior in the fermenter due to the higher fine fraction. This makes it easier to stir. The short structure thereby improves the stirring and pumping behavior.

Use of previously unused substrates:

Another important aspect that has so far received little attention is, in addition to increasing the yield of biogas through the pulping process, the Romberger DLZ generates the possibility of using materials that are currently difficult or not biogas capable, such as manure, grass, straw, landscaping or biowaste. Also new crops can be introduced and are safely controlled by the Romberger DLZ.

Special machinery

-

You can purchase all our standard conveyors in a modified version, for example in

- pharmacy design

- food-grade design

- or in a gas-tight version

- and much more!

We also adapt all our standard products to your specific requirements. We develop, plan and construct an individual design of our products according to your requirements.

We also build custom machines according to customer requirements. We take over all necessary activities of development, planning, construction and production

References

Drying and silo plant - Agricultural Warehouse Erhardt GmbH

-

The company Romberger planned and built a complete drying and grain silo plant for Erhardt GmbH in Feldkirchen.

- Grain silo plant with 8x 1500to and 6x 480to = total capacity of 14880to

- Conveyor technology Acceptance: 2x 150to/h

- Conveyor technology Loading: 150to/h

- Performance conveyor system for drying plant: 70to/h

- Output of the drying plant: 12to/h corn or 40t/h grain

Performance of Romberger:

- Planning of the system according to customer requirements

- Complete delivery of the system except for concrete and hall construction

- Production and delivery of the complete conveyor technology

- Production and delivery of the drying plant

- Complete installation of the entire system

- Electricity distribution including low-voltage main distribution

- Electrical installation with wiring

- Control cabinet with PLC, system communication via Profi and ASI bus

- Operation of the complete system via a visualization system

- Complete silo temperature monitoring with logging

- Grain aeration and cooling

Silo plant

-

The company Romberger planned and built a grain silo plant for ProAgrar Logistik GmbH & Co KG in Zeil am Main.

- Silo plant with 9x2550to = total capacity of 22960to

- Conveyor technology Acceptance: 250to/h

- Conveyor technology Loading: 200to/h

Performance of Romberger:

- Planning of the system according to customer requirements

- Complete delivery of the system except for concrete and hall construction

- Production and delivery of the complete conveyor technology

- Complete installation of the entire system

- Electricity distribution including low-voltage main distribution

- Electrical installation with wiring

- Control cabinet with PLC, system communication via Profi and ASI bus

- Operation of the complete system via a visualization system

- Complete silo temperature monitoring with logging

- Grain aeration and cooling

Drying and silo plant

-

The company Romberger planned and built a grain silo and drying plant for the Baden Agrarhandel GmbH in Friesenheim.

- Silo facility 10x 716to, 2x 78to (loading silo) and 1x 117to (small grain silo) = total capacity of 7433to

- Conveyor technology Acceptance: 2x 150to/h

- Conveyor technology Loading: 150to/h

- Performance conveyor system for drying plant: 70to/h

Performance of Romberger:

- Planning of the system according to customer requirements

- Complete delivery of the system except for concrete and hall construction

- Production and delivery of the complete conveyor technology

- Production and delivery of the drying plant

- Complete installation of the entire system

- Electricity distribution including low-voltage main distribution

- Electrical installation with wiring

- Control cabinet with PLC, system communication via Profi and ASI bus

- Operation of the complete system via a visualization system

- Complete silo temperature monitoring with logging

- Grain aeration and cooling

Extension silo plant Parsberg

-

The company Romberger planned and built the extension of a grain silo plant for the Raiffeisenbank Parsberg-Velburg eG in Parsberg.

- Extension of the grain silo facility by 4x 262to and 4x 1200to = total capacity of 10.300to

Conveyor technology Acceptance: 150to/h

Conveyor technology Loading: 150to/h

Performance of Romberger:

- Planning of the extension of the system according to customer requirements

- Complete delivery of the system except for concrete and hall construction

- Production and delivery of the complete conveyor technology

- Complete installation of the entire system

- Electricity distribution including low-voltage main distribution

- Electrical installation with wiring

- Control cabinet with PLC, system communication via Profi and ASI bus

- Operation of the complete system via a visualization system

- Complete silo temperature monitoring with logging

- Grain aeration and cooling

- Extension of the grain silo facility by 4x 262to and 4x 1200to = total capacity of 10.300to