- Offer Profile

- GEA is one of the largest technology suppliers for food processing and a wide range of other industries. The global group focuses on technologies, components and sustainable solutions for sophisticated production processes in diverse end-user markets.

Brewing Systems

- When it comes to brewing technology, GEA is the specialists. With our extensive know-how and vast engineering experience we are uniquely qualified to build brewery plants. Like no other supplier, GEA covers the complete brewing process in the finest detail – from the mill to the valve manifold of the bright beer tanks. This level of attention gives you exceptional security in terms of operation, process design and spare parts.

Beer Mix Solutions

-

The perfect Mix! Beer variations are the latest trend today, as mixed beverages or as new beer specialties. GEA provides comprehensive solutions for the economical production of high-quality beverages.

- ECO-BEVMIX™ for Beer Mix Beverages

- Membrane Unit to Produce FAB

Brewing Carbonating

-

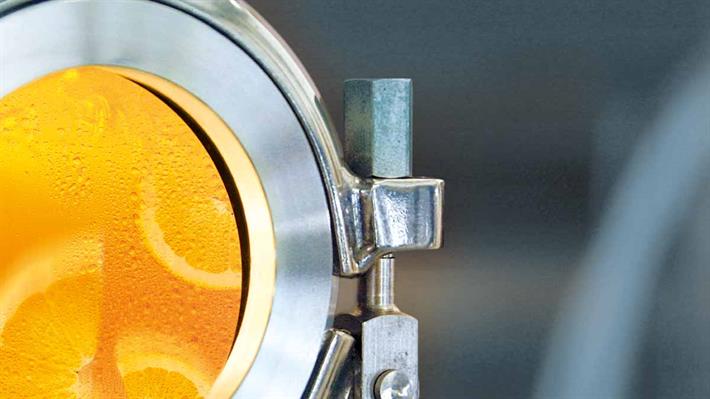

Carbonation plants need to have a very high hygiene status at all times and must be easily cleanable. In our systems we have therefore put special attention on the CO2-injection nozzle and the dissolving section design.

- DICAR-B™ Carbonation System

Brewing Fermentation

-

Brewmasters have only limited possibilities to optimize and speed up fermentation and maturation processes. Pressure and temperature influences lead to considerable changes in the flavor and taste of the finished beer.

- ECO-FERM™ Optimized Beer Fermentation

Brewing Pasteurizer

-

The best way to achieve stable beer quality and full taste is pasteurization or flash pasteurization.

- ECO-FLASH™ Flash Pasteurizer

Craft Brewing

-

From single-step infusion ale recipes to sophisticated multi-step decoction mashing regimes, GEA provides the right technologies and equipment so you can make your beer exactly your way.

- COMPACT-STAR™ Craft Brewhouse

- CRAFT-STAR™ Artisan Brewhouse

- GEA Craft Yeast Propagator

- WORTSTAR™ Craft Wort Aeration

Energy Environmental Products

-

Increasingly, we are all facing rising energy costs, stricter environmental regulations or even taxes on energy or emissions. There are many ways to address the rising costs in the field of energy management and environmental technology.

- Brewhouse 2.0

- Energy Storage System - ESS

Lauter Tuns

-

The performance of a lauter tun depends on many factors. The number of brews per day is not the only decisive criterion. Brew cycle, raw materials, milling method, cutting technique, wort concentration and weak wort management all these aspects play an important role in the lautering process.

- LAUTERSTAR™ Lauter Tun Technology

- MLM – Multifunctional Lautering Management

Mash Tuns

-

As simple as the mashing process looks in principle, it is as complex as its various functions. When designing a mash vessel, all these functions are of considerable importance and must be taken into consideration.

- Mashing

Mills

-

Efficient brewing starts with appropriate milling. The last three decades of practical experience have proven the efficiency of GEAs' steeping conditioned milling concept.

- MILLSTAR™ Milling System

Pipe Solutions

-

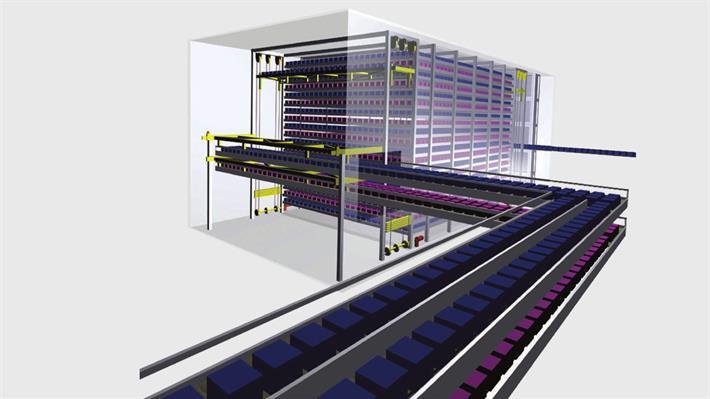

GEA has the right solution for the wide variety of tasks in your brewery, from pipe fence solutions and the manual system ECO-FENCE up to the fully automated ECO-MATRIX piping system. Individual piping concepts, which improve the foam and flavor stability of your beer with minimum life cycle costs.

- ECO-MATRIX™ Piping Solution

- Pipe Fences Piping Solutions

- Swing Bend Panel Solutions

- Valve Blocks Piping Solution

Utilities

-

To realize functional and economical solutions, expertise from both worlds, refrigeration technology and the brewing process, is essential. GEA has decades of experience and our experts have the necessary technological expertise.

- CO2 Recovery

- Refrigeration

- Service next level for Breweries

Wort Treatment Products

-

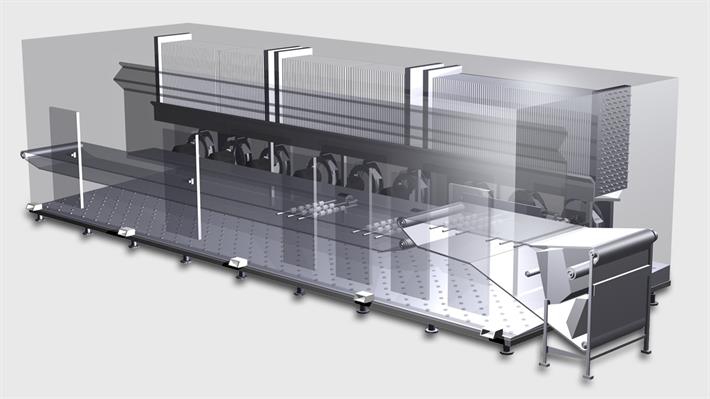

At GEA we understand state-of-the-art wort boiling as an interrelated package comprised of the heating-up process, the actual wort boiling and the wort treatment during cast-out. Only the holistic approach achieves best values in terms of beer quality and in energy efficiency.

- HOPSTAR™ Iso Hop Technology

- Whirlpool

- Wort Boiling with JETSTAR™

- Wort Cooler

- WORTSTAR™ Wort Aeration System

Yeast Handling Products

-

Yeast handling is the core of a brewery. For ideal yeast propagation and thus for a good beer hygienic plant design is essential. Yeast quality is defined particularly by the preservation of yeast viability and by optimized yeast vitality. GEA offers everything for comprehensive yeast management.

- Yeast Pitching

- YEAST-STAR™ Yeast Management

Distillation & Fermentation Systems

- GEA is your single-source supplier of complete systems, lines and plants for a variety of industries, from food to pharmaceutical, from brewing to biotechnology. Our experienced process engineers have the expertise and know-how to develop innovative and efficient process plants for your individual distillation and fermentation applications.

Bioreactors

-

GEA is the process plant specialist for liquid pharma & biotech products. We offer unsurpassed experience in process plant construction, and the collective expertise of the entire GEA, with its unrivalled technological resources worldwide.

- Pharma Bioreactors

- Skids & Units for Pharma Biotech Products

Distillation Equipment

-

Distillation technology is used throughout the chemical, pharmaceutical, food and beverage and environmental technology industries.

- Batch Distillation Plants

- Dehydration and Purification

- Distillation Test Facilities at Karlsruhe R&D Center

- Multiple Effect Distillation Plants

- MVR / TVR heated Distillation Plants

- Process Integration

- Reboiler for Distillation Plants

- Skid Mounted Distillation Units

- Tray and Packing Columns

Fermentation Solutions

-

Fermentation is a process by which yeast and some bacteria convert sugars to compounds such as alcohols and acids. The process is exploited by the bio-industry and the pharmaceutical industry, as well as the beverage and food industries.

- Fermentation Process

Fermenters

-

GEA is your competent partner for the manufacture of individual or multi-stage fermentation systems for the cultivation of micro-organisms and human/animal cells and complete plants for the pharmaceutical industry.

- Pharma Fermenters

- Skids & Units for Pharma Biotech Products

Process Vessels

-

The handling of high-value pharmaceutical products require the highest possible quality from the vessels used.

- Pharma Preparation & Pressure Vessels

- Pharma Process Vessels

- Storage & Transportation Vessels

Farm Equipment

- GEA is one of the worlds leading solutions and system providers for livestock farming. From design and planning of barns to daily herd and farm management, we offer a total solutions package to help farmers manage their businesses efficiently and sustainably. GEAs world-class farming technology portfolio includes animal feeding, barn equipment, manure management and the care of youngstock. Our planning specialists have completed many successful projects for cow, sheep, goat and buffalo herds worldwide, so farmers know they are in good hands with GEA.

Animal Health

-

Maintaining optimum animal health is critical to keep your cows producing at their maximum

- Bloat Remedies

- FIL Udder Health Solutions

Automated Feeding

-

Increase milk quality and raise productivity GEA automatic feeding systems can help you to achieve this. As a Total Solutions provider to the agricultural industry we are in a position to provide you with a range of tried and tested systems for automatic feeding, which can be perfectly integrated into your farm and are compatible with one another.

- Automated Feeding MixFeeder with WIC system

- Automatic Feeding Belt Feeder

- Automatic Feeding DairyFeed C 8000

- Automatic Feeding Free Stall Feeder

- GEA FRone - Automated feed pusher: Less work. Greater yields.

- GEA Mix&Carry WIC

Barn Ventilation

-

A good barn climate is a fundamental requirement for a high level of cow comfort. And this pays off. It ensures that milk production yields increase and reduces the costs of energy and ventilation, both in summer and in winter.

- Circulation Fans for Barn Ventilation

- Curtains for Barns & Milking Parlors

- Ridge Ventilation For Barns

Cow Comfort

-

Comfort is key for your cows and for you and your employees on every dairy operation.

- Bedding Conditioner ZorbiSan Plus

- Cow Brush E-Brush & M-Brush

- Cow Drinker & Watering

- Cow Mattress Systems

Cow Routing & Selection

-

Each individual cow and herd has its own requirements. As such, a professional and well-developed system for animal selection is the key to the success on your farm.

- Animal Separation Handling Race

- Animal Sorting AutoSelect

- Animal Sorting iSORTER Remote Sorting System

- GEA One Way Finger Gate

- Lifting Fence

- Separation Fence

Cubicles & Free Stalls

-

GEA puts the important goals first when designing freestall systems to achieve superior stall usage results. The comfortable cubicles allow cows to get up and lay down with ease, reducing stress and injuries. Plus, cow position is optimally controlled so that stalls stay clean, reducing the risk of mastitis.

- 2-D High Neckrail Cubicle

- 2-D Optima Cubicle

- Combi Comfort Cubicle

- Freestall Systems

- GEA DairyBarn B3130 flexible cubicle

- Single Beam Freestall Mounting System

Feed Fences

-

The focus is on calm processes in feeding. A clean and problem-free access to feed and the possibility to separate individual animals to check or treat them after milking where necessary are important aspects of feeding.

- Classic Feed Fences

- Self-locking Feed Fences

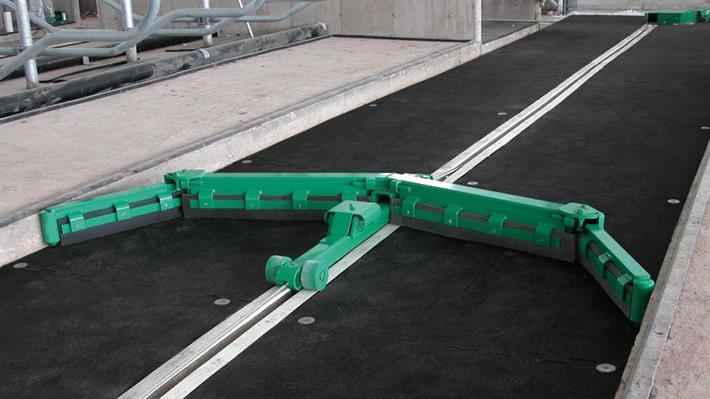

Free Stall Alley Cleaner Systems

-

GEA has always made its mark by developing efficient and long lasting free stall manure cleaner systems. Whatever your barn condition is we have the solution to meet your highest expectations.

- Combiscraper

- Cross Gutter Cleaner Systems

- Flush Valves

- Free Stall Alley Cleaner with Cable

- Free Stall Alley Cleaner with Chain

- Hydraulic Free Stall Alley Cleaner

- Manure Scraper Robot SRone and SRone+

- Manure Scrapers

- Scraper - 16°

- Scraper - Deep Groove System

- Scraper - High Profile

- Scraper - Straight

- Scraper - Under Floor Channel

- Scraper - V-Shape

- Tube Scraper System

Hydraulic Piston Pumps

-

The hydraulic piston pumps offered by GEA have the particularity to transfer dairy manure through underground line up to your main storage or over long distance to treat manure in other facilities.

- Electromix System - Single Piston Pump

- Evacuation line for hydraulic piston pumps

- Futuro - Single Piston Pump

- Magnum - Single Piston Pump

Manure Agitators

-

GEA Agitators are designed to offer high agitation performance in all types of manure storage.

- Articulated PTO Agitator

- Electric Agitator on Pontoon

- Electromix Agitator

- Lagoon Agitator

Manure Loading Pipes

-

Good and efficient feature to ease manure transfer from main storage to liquid manure spreader.

- Articulated Loading Pipe

- Loading Pipe on Tripod

- Loading Pipe on Wheels

Manure Pumps

-

For decades GEA has offered electric and power take-off pumps, a wide range of products designed to agitate and facilitate the evacuation of manure from your reception pit or main storage reservoir.

- Articulated PTO Pumps

- Electric Pumps on Pontoon

- Irrigation Pumps

- Lagoon PTO Pumps

- Maxi-Pump

- Vertical Electric Pumps

- Vertical PTO Pumps

Manure Separators

-

Once viewed as a necessary evil, today an intelligent manure management ensures numerous advantages for the farm and livestock. In addition of being a valuable source of plant nutrients, manure can be treated so that you will see your farm profitability increases through the years. See in these sections different solutions allowing you for liquid recycling or recovering of the fiber contained in manure in order to produce compost or bedding.

- 2-Stage Separator

- Customizable GEA environmental Decanter lines prime for Sludge Dewatering

- Regulator Tank

- Sloped Screen Separator - 4ft X 4ft

- Sloped Screen Separator - 8ft X 8ft

- Vertical Dewaterer

- XPress

Manure Spreading

-

Performance and reliability, its what GEA offering through theirs Liquid Manure Spreader and Tool Bar lines of products.

- Liquid Manure Spreaders

- STR Series Manure Semi-Tanker

- Tool Bars

Youngstock Feeding

-

Today the calves decide themselves: Controlled ad-libitum feeding or feeding on demand promises a growth of up to 1000 g/day (35 oz./ day) in the first weeks of life. This special feeding technique is successful and, therefore, becoming more popular.

- Calf Feeder DairyFeed J C400+, V600+, V640+

- Calf Milk Purification UVPure

- Concentrate Calf Feeder DairyFeed J 1000

- Lamb Feeder DairyFeed J E130 / E150

- Mobile Milk Troley MilkBuggy

Youngstock Housing

-

Successful long-term milk production means extreme care and diligence in the rearing of young cattle. The essential basics for successful rearing of an animal to the adult stage are formed by an initial investment in accommodation and care - from the newly born calf to a sexually mature heifer.

- Calf Pen Systems

- Youngstock Housing Solutions

Filling & Packaging Systems

- From raw bulk materials discharge to filling and packaging finished product in the container of your choice and every process in between GEA can engineer, manufacture and install the most appropriate equipment to suit your product handling requirements. GEA has a tradition specialising in the field of filling and packaging applications, offering a full design, manufacture, installation and start-up service in any part of the world. GEA's core business is the design and manufacture of a range of filling machines and packing lines that are designed to meet the specific needs of our clients.

Aseptic Fillers

-

Volumetric electronic fillers for any kind of drink can be filled, including high and low acid varieties, those with and without pulp, fibers or pieces, and still and carbonated beverages.

Aseptic Filler Fillstar CX EVO

Aseptic Filler Fillstar FX AS

Aseptic Piston Doser PX

IBCfill® Filling System

VARI-DOS-ASEPT

Bag Closers

-

GEA offers a range of bag closing systems to suit most powder packing applications. Flexible bags come in a variety of sizes, types and construction, all of which have different requirements for handling and closing. Our range of hygienic closing and sealing systems has been designed to meet the needs of the world's powdered food, dairy and nutraceutical producers.

Continuous Heat Sealer/Closer

Continuous Leveler/Sealer/Closer

Impulse Sealers

Static Heat Sealer/Closer

Bag/Sack Powder Fillers

-

Our range of multi-wall bag/sack fillers is designed to pack powdered products at rates of less than 1 tonne/h up to more than 12 tonnes/h with an accuracy better than 10 g (0.35 oz). Our extensive experience with a wide range of powdered products and packaging types means that we can provide a solution to meet the most demanding powder filling requirements.

Automatic Powder Fillers

Inert Gas Packing (Modified Atmosphere Packing/MAP)

Limited Intervention Powder Fillers

Box & Drum Powder Fillers

-

The choice of packaging format is often driven by a consumers needs. GEA understands the requirement for a flexible system to handle a wide range of packaging types. To meet this need, we have developed a range of solutions to handle flexible bags, boxes and drums for powder filling applications.

Automatic Powder Fillers

Inert Gas Packing (Modified Atmosphere Packing/MAP)

Container Decontamination for ESL Filling

-

The choice of container decontamination technology depends largely on the application, the customers requirements and the quality, production pasteurization and cold chain temperature of the raw material.

GEA Whitebloc Filling System ESL

Container Handling Equipment

-

The heart of all fillings systems is the filling machine itself. To make a system requires a lot more. GEA offers complete filling lines which means that we also take care of the complicated task of line integration and control. In order to provide an efficient production line, it is important to consider all parts of the system together. Our experience and our intelligent automation enable us to guarantee the total line performance.

Bag, Box and Drum Container Handling

Convair 2000 Air Conveyors

Loose Package Conveyors

Pack Conveyors

Ventilo Container Dryers

Container Sterilization for Aseptic Filling

-

GEA offers a variety of sterilization technologies for any PET preform, PET/HDPE bottle and/or closure, allowing beverages with different pH values to be filled on the same system.

Aseptic Blow Fill System ABF 1.2

Aseptic Filling Bloc ECOSpin2 Zero

Aseptic Filling Bloc Modulbloc

GEA Whitebloc Filling System Aseptic

ESL Fillers

-

The filling of sensitive beverages in a cold chain distribution demands high levels of hygiene and safety. GEAs range of volumetric electronic fillers has been designed to meet those clean environment requirements.

ESL Filler Fillstar DX

ESL Filler Fillstar FX

FIBC Powder Fillers

-

GEA offers a range of FIBC (flexible intermediate bulk container) filling systems to suit a wide variety of applications. Our range includes manual and automated solutions that include conveyor or overhead gantry systems for bag handling.

Automatic FIBC Fillers

Inert Gas Packing (Modified Atmosphere Packing/MAP)

Manual FIBC Fillers

Fillers

-

GEA fillers represent the industrys most advanced technology for the filling of liquid products into plastic bottles. They combine flexibility, performance and operational safety for applications throughout the sector.

Filler Fillstar DX

Filler Fillstar LXf

Filler Fillstar LXi

Filler Fillstar PET2

Hot Fill Fillstar HF

Food Packaging Equipment

-

The twentieth century witnessed a major shift in eating habits as processed and packaged foods gained popularity alongside fresh products.

Thermoformers

Vertical form fill sealer

Modified Atmosphere Packing (M.A.P.)

- Customers wishing to preserve the flavor of their powdered food and dairy products can apply our modified atmosphere packing (M.A.P.) technology to their powder handling and packing plants.

Palletizers Depalletizers

-

The GEA range of palletizers and depalletizers covers all beverage, food and home & care applications, all container and secondary packaging configuration and every type of pallet management.

Depalletizer Resolvis

Depalletizer Velox

Layer Preparation System Polaris EVO

Palletizer Agilis

Palletizer Artis EVO

Palletizer Fluens

Palletizer Opera

Robotic Isles Omnia

Quality Control Equipment

- A critical part of any powder packing plant is the QA/QC procedure. GEA offers standardized solutions to process filled bags through a powder packing line whilst performing important quality control operations.

Thermoforming

-

PowerPak is an innovative thermoformer concept for the highest horizontal packaging standards, complex applications and high output demands. This machine combines unsurpassed top performance with outstanding cost-saving potential thanks to low machine downtimes. An additional advantage for you with GEA: the PowerPak is tailored exactly to your needs by means of configurable functional modules so you achieve your personal peak performance.

GEA OxyCheck

Medical PowerPak

TiroLabel and TiroPrint

Food Processing Systems

- GEA is one of the multifaceted suppliers of secondary food processing and packaging equipment in the world: manufacturing machines for the preparation, marination, further processing, freezing, slicing and packaging of meat, poultry, fish, seafood, cheese and other foods such as sugar-based products and vegetables. The extensive product range covers everything from individual, stand-alone machines to complete processing lines.

Bakery Equipment

-

GEA offers complete solutions for processing and manufacturing cakes, pies, cookies, croissants, crackers and snacks, together with selected solutions for pizzas and bread.

Baking Tunnel Ovens

Cup Denesters

Depanners

Depositors

Dough feeding systems

Freezing and cooling systems

Handling systems

Pie Making Systems

Piston Filling Injectors

Rotary molder

Sheeting lines

Cheese Making Equipment

-

A full supply of cheese making technology - from milk processing through to packaging - makes GEA a competent provider of cheese plants. GEA is your partner in design, engineering and manufacturing of complete production systems for soft/fresh-, semi-hard and hard cheeses.

Cheese Making Vats

Curd Drainage, Maturation & Feeding

Hardening and Brining Vats

Molding and Pressing Machines

Salt Dosage System & Hot Water Heaters

Steam Stretching machines – Continuous Type

Stretching Machines - Steam

Stretching Machines - Water

Further Food Processing Equipment

-

GEA is one of the multifaceted suppliers of secondary food processing and packaging equipment in the world: manufacturing machines for the preparation, marination, further processing, slicing and packaging of meat, poultry, fish, seafood, cheese and other foods such as sugar-based products and vegetables.

Buttermaking Machine

Coaters

Cooking, Roasting, Grilling and Smoking Equipment

Formers

Fryers and oil treatment

Poultry, Meat & Seafood Automation

Marination Equipment

-

Marinating meat is one of the oldest food preparation techniques. Todays innovative processes from GEA offer far more than increased shelf life. They add value in terms of enhanced flavor, more appetizing color, higher yield and an appealing bite.

Brine Preparation Equipment

Defrosting & Tumbling

Emulsifying Equipment

Injecting Equipment

Massaging & Tumbling Equipment

Tenderizing Equipment

Preparation Equipment

-

Efficient particle reduction, mixing and emulsifying of raw materials to boost quality, improve yield and add value. Whether you need a single machine or a fully automated preparation line, GEA has all the ingredients to help you lead in a world of changing tastes

Cutting Equipment

Defrosting & Mixing Equipment

Fat Analyzing Equipment

Grinding Equipment

Mixing Equipment

Slicing & Loading

-

The appearance of a sliced packaged product contributes to consumers buying decisions. So the more attractive and appetizing a product is, the more it stands out on crowded supermarket shelves. GEA slicers arrange sliced products in a variety of visually appealing, space-saving and consumer-friendly ways.

Slicers

Freezers

- GEA Freezers: State-of-the-art freezing technology. GEA Freezers fulfils customer needs from initial contact to long after installation. Our widely respected design and manufacturing teams produce a broad range of energy efficient freezing and cooling systems. GEA customizes systems based on extensive experience with a large breadth of products and processes.

Belts

-

Through unique robustness and interlocking design, GEA Q-belt ensures a more reliable stacking system. Our enhanced patented interlocking system ensures robust, more stable stacking and minimize friction between tiers of long belts.

GEA Q-belt

Carton Freezers

-

GEA carton freezers can freeze or chill your food products in cartons, plastic totes or shrink-wrap.

GEA I-VRT

Spiral Freezers

-

GEA Spiral Freezers and Chillers are the most hygienic spiral freezers on the market today.

CALLIFREEZE® control system

GEA A-Tec

GEA S-Tec

GEA Static Pressure Control System

Tunnel Freezers

-

GEA Tunnel Freezers and Chillers: State-of-the-art freezing and chilling tunnel technology.

GEA A-series

GEA AY-series

GEA HVF-series Impingement Freezers

GEA S-series

Milking Systems

- GEA is one of the worlds leading manufacturers and suppliers of integrated milking solutions. From the smallest bucket milking installation to a variety of milking parlors, from automated milking systems like our innovative Mlone milking robot to the first continuous fully automatic milking rotary DairyProQ, we provide equipment to suit all herd sizes and dairy farmers needs. Our unrivalled milking portfolio is complemented by a range of hygiene products to ensure a spotless environment for the cows and the highest milk quality. All our components are designed to be animal friendly and guarantee optimum yields. GEAs milking technology expertise is part of a total solutions package that is helping farmers to manage their businesses efficiently and sustainably.

Animal Hygiene

-

Get maximum care and udder health for maximum milk yields with GEA animal hygiene products. Our product range extends from udder hygiene and hoof hygiene to bedding conditioners. Our service specialists will be glad to assist you in customizing your products. This is the only way to ensure optimal animal health!

Animal Foot Care

Antibacterial Solutions

Bedding Conditioner ZorbiSan Plus

FIL Udder Health Solutions

FutureCow® Prep System

Udder Hygiene Products

Animal Marking

-

Animal markers are one of the most effective and easy to use herd management tools. Our tail paint and markers are specifically designed with fluorescent pigments for quick identification for various applications. We have a wide range of animal markers from products specifically formulated to stay on the udder to foam mark which helps to clearly identify cows that need to be drafted.

Multi-purpose Animal Markers

Tail Paint

Automated Milking Systems

-

Welcome to GEAs sophisticated selection of automated milking technology.

DairyProQ

GEA DairyMilk M6850 cell count sensor

GEA DairyRobot R9500 Robotic Milking System

Cooling Tanks

-

Whether your herd is large or small: GEA will provide you with the most suitable milk cooling tanks and vats for all your needs, fitted with the latest cooling and control equipment.

Cooling Tank Koolway

Cooling Tank TCool

Cooling Tank VCool

Cooling Tanks iStore Vertical / Horizontal

Milk Cooling Vat PCool

Cow Crowd Gates

-

Cow crowd gates ensure that cows quickly enter the milking stall and also reduce personnel requirements down to a minimum. This simplifies your work and, at the same time, increases the throughput for higher yields with less effort.

Cow Crowd Gate CowMander

Cow Crowd Gate Global

Cow Crowd Gate ProMotion

Equipment & Facility Hygiene

-

The product range from GEA is tailor-made for all requirements of equipment and facility hygiene. Our experienced hygiene specialists can give you advice and customize your hygiene program. Only with optimum hygiene standards humans and animals are comfortable during the production process.

CIP Cleaning for Dairy Farms

FIL Specialty Cleaners

Manual Detergents

Quantum Dairy Hygiene

Special Hygiene Products

Water Treatment Solutions

Heat Detection & Health Management

-

Give yourself more time and automate tasks with herd management solutions from GEA. Many aspects of daily herd monitoring can be automated and all relevant information can be readily available - assuring you that important decisions are implemented at just the right time.

CowScout Heat Detection & Health Management

CowView Localization,Health & Fertility Management

Herd Management Software DairyPlan C21

Rescounter III Heat Detection

Herd Management Software

-

Making the right decisions every day is a prerequisite for successful farm management.

Herd Management Software DairyPlan C21

iDENTITY Herd Overview Software

Liners & Tubing

-

As the interface between the animal and the milking machine, liners and hose must fulfill strict hygiene regulations. In order to withstand the high levels of mechanical stress and chemical exposure our liners and hoses are subjected to a comprehensive range of field tests and quality tests beginning during the initial development phases and continuing onward to the dairy farm.

GEA Milking Liner Overview

iDAIRYWARE Milking Rubberware

iFLEX Milking Liners

Milking Equipment

-

Milking parlor components increase the efficiency of your farm. As a system provider, GEA has developed a series of high-performance products which can be combined as required and which increase your yield.

Milk Handling Equipment

Milking Cluster

Milking Control Units

Milking Hygiene

Milking Parlor Accessories

Pulsation

System for Small Herds: Bucket Milking

Vacuum

Milking Parlors

-

At GEA you can find milking centres which can be easily adjusted to the demands of your farm. The solutions we present offer you a number of advantages.

Herringbone Parlours

Milking Parlor Auto Tandem

Rotary Milking Systems

Side-by-Side Parlours

Pre-cooling & Instant cooling

-

With a high performance pre-cooling system you can save energy and the load on the reduce condensing unit. You can immediately stop bacterial growth and reach the highest quality standards.

KoolWay® Chillers

Snap Chilling

Scales

-

In general, the closer a cows gets to its ideal weight, the more efficient the milking procedure becomes. As a system provider, we present you with optimal and professional solutions for weighing your cows.

Animal Scale TaxaTron 5000

iNTELWEIGH Walk Over Weigh System