- Offer Profile

- GEA is one of the largest technology suppliers for food processing and a wide range of other industries. The global group focuses on technologies, components and sustainable solutions for sophisticated production processes in diverse end-user markets.

Automation & Control Systems

- Diversity is one of nature’s key concepts to cope with changing and variable environments. This strategy is also a strength in process automation: different process environments and trades need different solutions and individual adaptations. Whether in the brewing, chemical, dairy or pharmaceutical industries, process control has different requirements and needs individualized solutions.

Analytical, In-Line Control & Measurement Devices

-

Combining process monitoring using online analyzers, together with solid process engineering principles and advanced process modelling techniques will enable processes to be actively controlled in order to compensate for input variations.

- Lighthouse Probe™ - online measurement

- LYOPLUS™ PAT for Pharma Freeze Dryers

- POWDEREYE® for Inline Powder Analysis

- VARINLINE® Level Probe TNS

- VARINLINE® Pocket-free Instruments

- VARINLINE® Pressure Gauges TPIA

- VARINLINE® Sight Glass TXIA

- VARINLINE® Thermometer

Data Capture Systems

-

Data capture and metering systems measure, monitor and ensure traceability of collected milk or similar liquid product from farm to table.

- Data Capture System ZEVODAT-C1™

Machine Control

-

Every plant or machine, which is designed for a reliable long-term operation, requires a control unit that enables the communication between the different system parts. It is one of the most important component that guarantees reliability and efficient operation.

- GEA Grasso Maintenance Monitor (GMM)

- GEA IO - One control for every centrifuge

- GEA Omni™ Control Panel

Process Automation & MES Solutions

-

As system integrators we bring our knowledge from process technology and plant engineering together with software products from market leaders.

- GEARBOXX™ Process Automation

- MLM – Multifunctional Lautering Management

- OTAS® Beverages Process Automation

- OTAS® Dairy Process Automation

- OTAS® Food Process Automation

- OTAS™ Brewery Process Automation

- Poultry, Meat & Seafood Automation

Cleaners & Sterilizers

- In today's processing industries, from food and beverage to personal care, from dairy to pharmaceutical, integrated clean-in-place (CIP) solutions play a key role. GEA supplies both manual and fully automated CIP and sterilize-in-place (SIP) solutions, ensuring reliable process outcomes with minimal downtime. Whether it's liquid, solid or semi-solid, GEA’s extensive range of cleaning and sterilization solutions — from R&D to full-scale production and from standalone equipment and modules to completely integrated processing lines — are an essential requirement for any quality conscious manufacturer. We also recognize the increasing need to handle highly potent and toxic actives, guarantee both operator and product safety, prevent batch-to-batch cross-contamination and protect the environment.

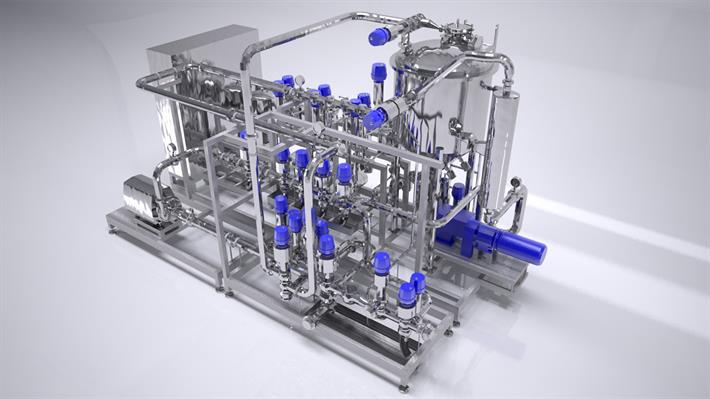

CIP/SIP Solutions

-

Innovative CIP concepts of GEA meet comprehensive high standards. Our experts guarantee product safety at every point of the process. Every upgrade is adapted to individual local conditions and customer requirements and leads to noticeable savings.

- CIP for Pharmaceutical Process Plants

- CIP-STAR™ System Brewhouse

- CIP-STAR™ System Cold Process Area

- Cleaning System DICIP-E™

- Cleaning System DICIP-S™

COP/SOP Solutions

-

In addition to providing complete containment services, GEA also offers multifunctional wash skids that can be moved from one location to another and used to clean different parts of the process. Every plant delivered by GEA has a tailor made CIP, WIP or Wash-Off-Line (WOL) system to suit your application.

- Wash-Off-Line for Pharmaceutical Plants

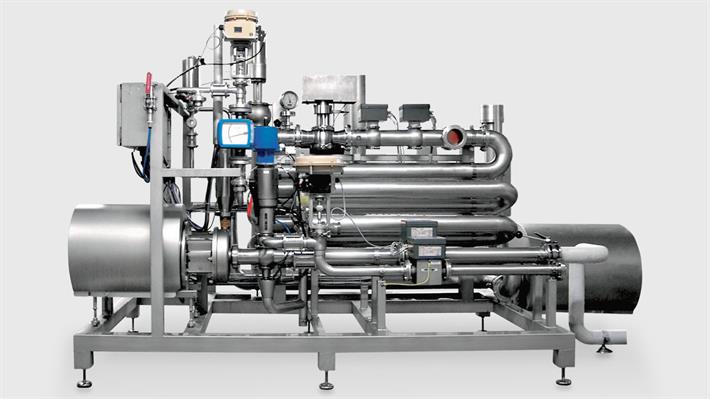

Sterilizers

-

Concentrated food products need to be sterilized before they can be stored, packed or dried.

- Direct Steam Sterilization

Tank Cleaning Equipment

-

Our cleaning devices are designed for todays hygienic standards. They have shown best success in the brewing and beverage industry as well as in the dairy, food, pharmaceutical , fine chemical and personal & health care industries. As a specialist in hygienic and sterile applications, we can offer you economical, flexible and service-oriented solutions.

- Accessories Cleaning Devices

- Controlled Rotating Cleaners

- Free Rotating Cleaners

- Index Cleaners

- Orbital Cleaners

- Retractors

- Static Cleaners

- Verification System

Distillation & Fermentation Systems

- GEA is your single-source supplier of complete systems, lines and plants for a variety of industries, from food to pharmaceutical, from brewing to biotechnology. Our experienced process engineers have the expertise and know-how to develop innovative and efficient process plants for your individual distillation and fermentation applications.

Bioreactors

-

GEA is the process plant specialist for liquid pharma & biotech products. We offer unsurpassed experience in process plant construction, and the collective expertise of the entire GEA, with its unrivalled technological resources worldwide.

- Pharma Bioreactors

- Skids & Units for Pharma Biotech Products

Distillation Equipment

-

Distillation technology is used throughout the chemical, pharmaceutical, food and beverage and environmental technology industries.

- Batch Distillation Plants

- Dehydration and Purification

- Distillation Test Facilities at Karlsruhe R&D Center

- Multiple Effect Distillation Plants

- MVR / TVR heated Distillation Plants

- Process Integration

- Reboiler for Distillation Plants

- Skid Mounted Distillation Units

- Tray and Packing Columns

Fermentation Solutions

-

Fermentation is a process by which yeast and some bacteria convert sugars to compounds such as alcohols and acids. The process is exploited by the bio-industry and the pharmaceutical industry, as well as the beverage and food industries.

- Fermentation Process

Fermenters

-

GEA is your competent partner for the manufacture of individual or multi-stage fermentation systems for the cultivation of micro-organisms and human/animal cells and complete plants for the pharmaceutical industry.

- Pharma Fermenters

- Skids & Units for Pharma Biotech Products

Process Vessels

-

The handling of high-value pharmaceutical products require the highest possible quality from the vessels used.

- Pharma Preparation & Pressure Vessels

- Pharma Process Vessels

- Storage & Transportation Vessels

Dryers & Particle Processing Plants

- GEA's drying and particle processing plants are applied in the production of a wide range of products - from bulk products to the most advanced powders within food and dairy products, chemicals and pharmaceuticals. Our supply includes plants in all sizes; from small pilot plants for research and product development to the largest industrial installations. Whether you wish to produce a powder, granulate, or an agglomerated product we have the expertise, technology, and equipment to match your needs . Our portfolio also includes the technology in front of or downstream the drying process.

Column Processors

-

The GEA Column Processors are used for cooling, heating and purging of residual moisture and volatile components from free flowing materials including amorphous or crystalline powders and granules.

- Column Dryers

- Contact Column Coolers, Heaters & Dryers

Continuous Processing Lines for Pharma

-

At GEA, we believe that continuous processing improves the quality of pharmaceutical end products: by focusing on quality during the whole product lifecycle, not just tested in quality; and by understanding the capability of your processes, managing sources of variability and decreasing any associated risks.

- ConsiGma™ Continuous Direct Compression

- ConsiGma™ Continuous Tablet Coater

- ConsiGma™ Continuous Tableting Line

- Continuous Processing for Pharma R&D

Extractors

-

With several types of Extractors in the portfolio, GEA is at the forefront when it comes to solids/liquid extraction for instant coffee production and for production of herbal and other extracts in the food industry.

- CONTEX™ Extractor

- FIC® and CARINE™ Extractors

Flash Dryers & Coolers

-

With a history spanning from the Flash dryer's invention in 1928 to the development of unrivaled dispersion equipment and the most efficient integrated systems, no one knows more about Flash drying than GEA.

- Flash Dryer

- Pilot Ring & Flash Dryers

- SWIRL FLUIDIZER™

Fluid Beds

-

Fluid bed technology is a core technology of GEA. We supply several different types of Fluid Bed units for application within food and dairy products, chemicals and pharmaceuticals. All are applied for drying and/or cooling of particles - powders, agglomerates or pellets - and for production of agglomerates and granulates from fine powders.

- CONTACT FLUIDIZER™ Fluid Bed

- FlexStream™ Fluid Bed Processor

- Fluid Bed Dryer (Static)

- Fluid Bed Processing of Pharmaceuticals

- PharmaConnect™ PLUS

- Potash Conditioning System

- SPRAY FLUIDIZER™

- VIBRO-FLUIDIZER™ Fluid Bed

Freeze Dryers

-

Whether it is for food and beverage or pharmaceutical applications, GEAs expertise in freeze drying plants is unrivalled. Building on decades of experience, we supply freeze drying plants that meet the individual industries specific regulations, standards and requirements.

- CONRAD™ Freeze Dryer

- LYOVAC™ Pharma Freeze Dryer

- LYOVAC™ Small-Scale Freeze Dryers

- RAY™ Freeze Dryer

- RAY™ Pilot Plant Freeze Dryer

- SMART LYO™ Pharma Freeze Dryer

Lyophilizers

-

GEA's thorough understanding of the lyophilization process enables them to supply a comprehensive range of products and services, comprising laboratory equipment, pilot plants for research and small-scale production batches, industrial size pharmaceutical production freeze dryers.

- ALUS™ Load & Unload of Lyophilizers

- LYOPLUS™ PAT for Pharma Freeze Dryers

- LYOVAC™ Pharma Freeze Dryer

- LYOVAC™ Small-Scale Freeze Dryers

- SMART LYO™ Pharma Freeze Dryer

Pellet Production Lines

-

The pelletizing process for the production of pharmaceutical pellets - including extrusion and spheronization, production of pellets by powder layering and liquid layering and pelletization via melt and wet granulation processes.

- AirConnect™ Fluid Bed Processor & Coater

- FlexStream™ Fluid Bed Processor

- Fluid Bed R&D Processing of Pharmaceuticals

- Liquid Layering of Pellets by Fluid Bed Processing

- NICA™ Extruder System

- NICA™ Integrated Pelletizing Systems

- NICA™ Spheronizer System

- PharmaConnect™ PLUS

- PharmaConnect™ R&D Processing

- UltimaPro™ Single Pot Processors

R&D Drying Systems

-

GEA's versatile range of R&D drying & particle processing equipment - for advanced powder processing within food and dairy products, chemicals and pharmaceuticals.

- AirConnect™ Fluid Bed Processor & Coater

- Continuous Processing for Pharma R&D

- Fluid Bed R&D Processing of Pharmaceuticals

- FSD Minor™ Spray Dryer

- LYOVAC™ Small-Scale Freeze Dryers

- MOBILE MINOR™ R&D Spray Dryer

- PharmaConnect™ R&D Processing

- Pilot Ring & Flash Dryers

- PRODUCTION MINOR™ Spray Dryer

- SDMICRO™ R&D Spray Dryer

- SMART LYO™ Pharma Freeze Dryer

- UltimaPro™ Single Pot Processors

- VERSATILE-SD™ Spray Dryer

Ring Dryers

-

The collection of GEA Ring Dryers are group of proprietary pneumatic type drying systems which are essentially modified flash dryers with the addition of a various classifying manifold to provide selective recirculation of semi-dry material, lowering exhaust temperatures, increasing efficiency and improving product quality.

- Dewatering Screw Press for Vital Wheat Gluten

- Feed-Type Ring Dryer

- P-Type Ring Dryer

- Pilot Ring & Flash Dryers

- Ring Dryer

Rotary Dryers & Coolers

-

The GEA Rotary Dryer is extensively used throughout the process industries and is highly reliable under the most arduous operating conditions with it often described as the "workhorse of the industry".

- Potash Conditioning System

- Rotary Calciners

- Rotary Coolers

- Rotary Dryers

Single Pot Processors

-

Whether your requirement is for mixing, granulation or drying, at GEA we have a solution for every pharmaceutical processing challenge. UltimaPro Single Pot Processors (One-Pot Processor) offer a choice of mixing, granulation and drying options integrated into one processing vessel. With our help, choose the most appropriate technique for the product.

- UltimaPro™ Single Pot Processors

Spray Coolers

-

GEA has a long history supplying Spray Coolers to producers of melts - oils and fats, glycerines, etc. - all over the world. Our supply includes spray cooling plants for bulk product as well as for advanced special applications.

- GEA Spray Cooler

Spray Dryers

-

No one knows more about spray drying than GEA. Our expertise has been gained over close to a century, in which period we have designed and supplied more than 10,000 GEA drying plants all over the world, and made even more tests for customers.

- Chemical Products

- Food & Dairy Products

- Pharmaceutical Products

- Pilot & small-scale Spray Dryers

Single Pot Processors

-

Whether your requirement is for mixing, granulation or drying, at GEA we have a solution for every pharmaceutical processing challenge. UltimaPro Single Pot Processors (One-Pot Processor) offer a choice of mixing, granulation and drying options integrated into one processing vessel. With our help, choose the most appropriate technique for the product.

- UltimaPro™ Single Pot Processors

Spray Coolers

-

GEA has a long history supplying Spray Coolers to producers of melts - oils and fats, glycerines, etc. - all over the world. Our supply includes spray cooling plants for bulk product as well as for advanced special applications.

- GEA Spray Cooler

Spray Dryers

-

No one knows more about spray drying than GEA. Our expertise has been gained over close to a century, in which period we have designed and supplied more than 10,000 GEA drying plants all over the world, and made even more tests for customers.

- Chemical Products

- Food & Dairy Products

- Pharmaceutical Products

- Pilot & small-scale Spray Dryers

Emission Control Systems

- For over a century, GEA has been a world leader in development, design and installation of emission reduction systems and technologies for customers in the process industries. Our unparalleled innovation and expertise enables us to closely examine your needs, listen to your challenges and explore the most suitable technology to achieve the agreed-upon performance of your emission control solution. Not only does this provide lasting benefits for the environment, but keeps you competitive and compliant, now and for the future.

Gas Cleaning Systems

-

GEA has been pioneering emission control systems since we built our first electrostatic precipitator (ESP) for removing particle-bound pollutants in 1913.

- GEA Baghousefilter

- GEA Cooling Systems

- GEA Cyclone

- GEA Electrostatic Precipitator's (Dry & Wet)

- GEA Energy Recovery Unit

- GEA EP-Absorber

- GEA ORC-Module

- GEA Quench Tower

- GEA SCR Plants

- GEA Scrubber for Exhaust Cleaning

- Spray Dryer Absorber

Scrubbers

-

The operation of gas scrubbers is based on the principle of absorption, i.e. absorbing or dissolving a substance in a liquid.

- Absorption columns

- Aerosol separator systems

- Compact gas scrubbers

- Cooling columns

- Customized multi-stage gas scrubber systems

- Emergency gas scrubbers

- Hot gas quench systems

- Jet scrubbers

- Laboratory gas scrubbers

- Scrubber Test Facilities at Karlsruhe R&D Center

- Special purpose gas scrubber systems

- Spray tower

- Submerged scrubbers

- Venturi scrubbers

Evaporators & Crystallizers

- Evaporation and crystallization plants are required whenever in a process: water or any other solvent has to be removed, concentration has to be increased or volume reduced, valuable and pure crystals have to be produced, by-products or impurities have to be stripped or precipitated. To meet customer specification in density, purity, particle size, operating time, while minimizing investment and operating costs, the GEA highly skilled process engineers design evaporation and crystallization plants with a full range of all applied technologies. For high standards of quality, recrystallization can be applied to improve the purity of final product. GEA's extensive experience in building continuous evaporation and crystallization plants is essential to satisfy customers needs.

Crystallizers

- Crystallizers are often used in the chemical industry to achieve liquid-solid separation and generate high purity products.

Evaporator Configuration

- Evaporation plants are used as a thermal separation technology, for the concentration or separation of liquid solutions, suspensions and emulsions.

Evaporator Type

- To satisfy the wide spectrum of process requirements, GEA designs solutions with all types of evaporators. Each type offers its own benefit, and the most suitable type is selected in each case with consideration of the main process parameters: scaling tendency, product thermal sensitivity, annual operating hours, and accessibility for maintenance. GEA designs smart solutions to clean vapor or recover gas distilling from evaporated liquor.

Freeze Concentrators

- Water removal is the key to concentration of all aqueous products. Various methods are available to remove water from liquid food products. Of all the available methods crystallization provides the highest selectivity toward water removal in that only water is included into the ice crystals.

Filling & Packaging Systems

- From raw bulk materials discharge to filling and packaging finished product in the container of your choice and every process in between GEA can engineer, manufacture and install the most appropriate equipment to suit your product handling requirements. GEA has a tradition specialising in the field of filling and packaging applications, offering a full design, manufacture, installation and start-up service in any part of the world. GEA's core business is the design and manufacture of a range of filling machines and packing lines that are designed to meet the specific needs of our clients.

Aseptic Fillers

-

Volumetric electronic fillers for any kind of drink can be filled, including high and low acid varieties, those with and without pulp, fibers or pieces, and still and carbonated beverages.

Aseptic Filler Fillstar CX EVO

Aseptic Filler Fillstar FX AS

Aseptic Piston Doser PX

IBCfill® Filling System

VARI-DOS-ASEPT

Bag Closers

-

GEA offers a range of bag closing systems to suit most powder packing applications. Flexible bags come in a variety of sizes, types and construction, all of which have different requirements for handling and closing. Our range of hygienic closing and sealing systems has been designed to meet the needs of the world's powdered food, dairy and nutraceutical producers.

Continuous Heat Sealer/Closer

Continuous Leveler/Sealer/Closer

Impulse Sealers

Static Heat Sealer/Closer

Bag/Sack Powder Fillers

-

Our range of multi-wall bag/sack fillers is designed to pack powdered products at rates of less than 1 tonne/h up to more than 12 tonnes/h with an accuracy better than 10 g (0.35 oz). Our extensive experience with a wide range of powdered products and packaging types means that we can provide a solution to meet the most demanding powder filling requirements.

Automatic Powder Fillers

Inert Gas Packing (Modified Atmosphere Packing/MAP)

Limited Intervention Powder Fillers

Box & Drum Powder Fillers

-

The choice of packaging format is often driven by a consumers needs. GEA understands the requirement for a flexible system to handle a wide range of packaging types. To meet this need, we have developed a range of solutions to handle flexible bags, boxes and drums for powder filling applications.

Automatic Powder Fillers

Inert Gas Packing (Modified Atmosphere Packing/MAP)

Container Decontamination for ESL Filling

-

The choice of container decontamination technology depends largely on the application, the customers requirements and the quality, production pasteurization and cold chain temperature of the raw material.

GEA Whitebloc Filling System ESL

Container Handling Equipment

-

The heart of all fillings systems is the filling machine itself. To make a system requires a lot more. GEA offers complete filling lines which means that we also take care of the complicated task of line integration and control. In order to provide an efficient production line, it is important to consider all parts of the system together. Our experience and our intelligent automation enable us to guarantee the total line performance.

Bag, Box and Drum Container Handling

Convair 2000 Air Conveyors

Loose Package Conveyors

Pack Conveyors

Ventilo Container Dryers

Container Sterilization for Aseptic Filling

-

GEA offers a variety of sterilization technologies for any PET preform, PET/HDPE bottle and/or closure, allowing beverages with different pH values to be filled on the same system.

Aseptic Blow Fill System ABF 1.2

Aseptic Filling Bloc ECOSpin2 Zero

Aseptic Filling Bloc Modulbloc

GEA Whitebloc Filling System Aseptic

ESL Fillers

-

The filling of sensitive beverages in a cold chain distribution demands high levels of hygiene and safety. GEAs range of volumetric electronic fillers has been designed to meet those clean environment requirements.

ESL Filler Fillstar DX

ESL Filler Fillstar FX

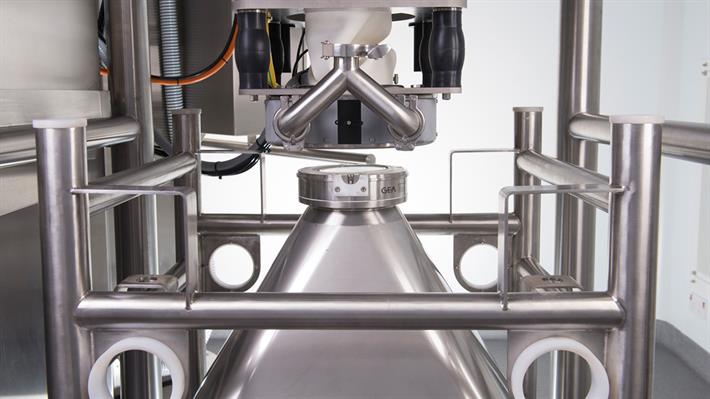

FIBC Powder Fillers

-

GEA offers a range of FIBC (flexible intermediate bulk container) filling systems to suit a wide variety of applications. Our range includes manual and automated solutions that include conveyor or overhead gantry systems for bag handling.

Automatic FIBC Fillers

Inert Gas Packing (Modified Atmosphere Packing/MAP)

Manual FIBC Fillers

Fillers

-

GEA fillers represent the industrys most advanced technology for the filling of liquid products into plastic bottles. They combine flexibility, performance and operational safety for applications throughout the sector.

Filler Fillstar DX

Filler Fillstar LXf

Filler Fillstar LXi

Filler Fillstar PET2

Hot Fill Fillstar HF

Food Packaging Equipment

-

The twentieth century witnessed a major shift in eating habits as processed and packaged foods gained popularity alongside fresh products.

Thermoformers

Vertical form fill sealer

Modified Atmosphere Packing (M.A.P.)

- Customers wishing to preserve the flavor of their powdered food and dairy products can apply our modified atmosphere packing (M.A.P.) technology to their powder handling and packing plants.

Palletizers Depalletizers

-

The GEA range of palletizers and depalletizers covers all beverage, food and home & care applications, all container and secondary packaging configuration and every type of pallet management.

Depalletizer Resolvis

Depalletizer Velox

Layer Preparation System Polaris EVO

Palletizer Agilis

Palletizer Artis EVO

Palletizer Fluens

Palletizer Opera

Robotic Isles Omnia

Quality Control Equipment

- A critical part of any powder packing plant is the QA/QC procedure. GEA offers standardized solutions to process filled bags through a powder packing line whilst performing important quality control operations.

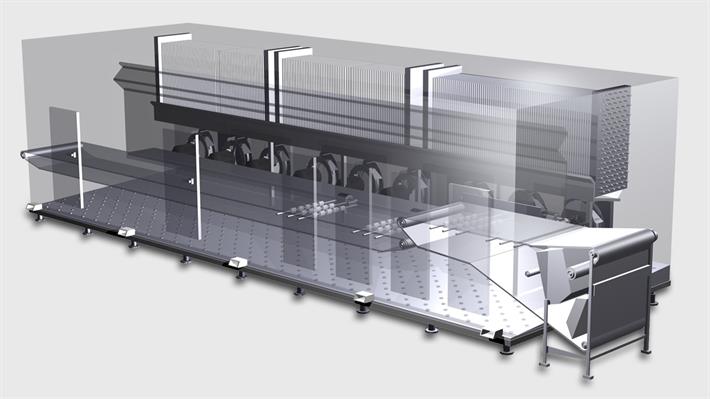

Thermoforming

-

PowerPak is an innovative thermoformer concept for the highest horizontal packaging standards, complex applications and high output demands. This machine combines unsurpassed top performance with outstanding cost-saving potential thanks to low machine downtimes. An additional advantage for you with GEA: the PowerPak is tailored exactly to your needs by means of configurable functional modules so you achieve your personal peak performance.

GEA OxyCheck

Medical PowerPak

TiroLabel and TiroPrint

Freezers

- GEA Freezers: State-of-the-art freezing technology. GEA Freezers fulfils customer needs from initial contact to long after installation. Our widely respected design and manufacturing teams produce a broad range of energy efficient freezing and cooling systems. GEA customizes systems based on extensive experience with a large breadth of products and processes.

Belts

-

Through unique robustness and interlocking design, GEA Q-belt ensures a more reliable stacking system. Our enhanced patented interlocking system ensures robust, more stable stacking and minimize friction between tiers of long belts.

GEA Q-belt

Carton Freezers

-

GEA carton freezers can freeze or chill your food products in cartons, plastic totes or shrink-wrap.

GEA I-VRT

Spiral Freezers

-

GEA Spiral Freezers and Chillers are the most hygienic spiral freezers on the market today.

CALLIFREEZE® control system

GEA A-Tec

GEA S-Tec

GEA Static Pressure Control System

Tunnel Freezers

-

GEA Tunnel Freezers and Chillers: State-of-the-art freezing and chilling tunnel technology.

GEA A-series

GEA AY-series

GEA HVF-series Impingement Freezers

GEA S-series

Granulators

- Every Granulation and Drying plant from GEA is a unique union of proven technology and individual solutions. Whether the granulation line is for batch or continuous production, we supply plants for cGMP production configured to meet the customers specific requirements. Our granulation and drying plants and process expertise is based on experience and R&D. With plants installed around the world and literally thousands of tests performed, we have established a solid base of expertise related to the needs of the pharmaceutical, nutraceutical and food industries.

Continuous Granulation Lines

-

Continuous Processing is becoming more and more important in the pharmaceutical industry. GEA takes the lead in introducing this innovative technology with ConsiGma - continuous high-shear granulation and drying lines.

ConsiGma™ Continuous Tableting Line

Continuous Processing for Pharma R&D

Fluid Bed Processors

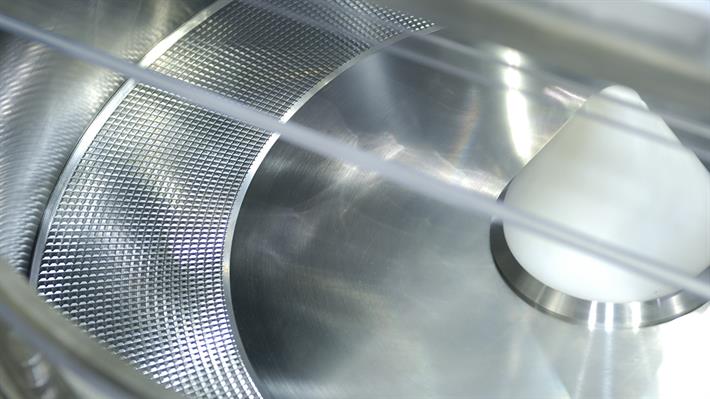

-

For more than 50 years, GEA has supplied fluid bed processors for blending, granulating, drying, pelletizing and coating for the pharmaceutical industry. This includes small capacity systems designed for R&D as well as industrial size plants for batch production of pharmaceutical compounds under cGMP conditions.

AirConnect™ Fluid Bed Processor & Coater

FlexStream™ Fluid Bed Processor

Fluid Bed Processing of Pharmaceuticals

PharmaConnect™ PLUS

High Shear Granulators

-

Our High Shear Granulator plants and granulation process expertise is based on experience and R&D. With plants installed around the world and literally thousands of tests performed, we have established a solid base of expertise related to the needs of the pharmaceutical manufacturing industry.

Gral™ High Shear Granulators

PMA™ High Shear Processor

UltimaPro™ Single Pot Processors

Integrated Granulation Lines

-

Current good manufacturing practices increasingly require that product is fully contained during processing to protect both operators and the environment. Integrated process systems not only offer containment, but also provide improved productivity through automation, increased yield and efficient cleaning procedures.

Integrated Granulators & Dryers

PharmaConnect™ PLUS

R&D Granulation Lines

-

Granulation lines for research and development, takes the process from dispensed raw materials to finished tablet. Our systems clearly demonstrates the flexibility that can be achieved throughout the process including high shear granulation, pelletizing and blending, etc.

AirConnect™ Fluid Bed Processor & Coater

Continuous Processing for Pharma R&D

Fluid Bed R&D Processing of Pharmaceuticals

PharmaConnect™ PLUS

PharmaConnect™ R&D Processing

Homogenizers

- The equipment needed by the homogenizer includes all the components able to micronize the particles of the fluid and to obtain a homogenous and stable emulsion of the product. Industrial and laboratory high pressure homogenizers are positive displacement pumps equipped with the compression block and the homogenizing valve able to process a wide range of applications and to enhance the organoleptic characteristics and the stability of the product.

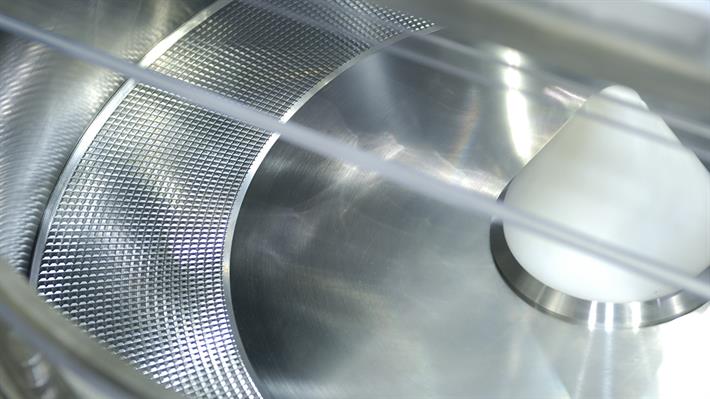

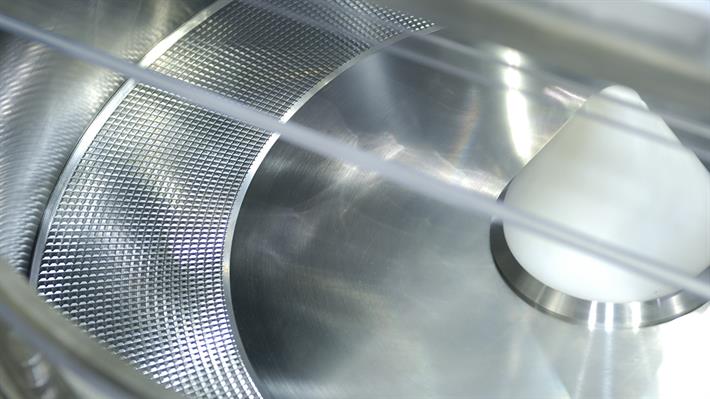

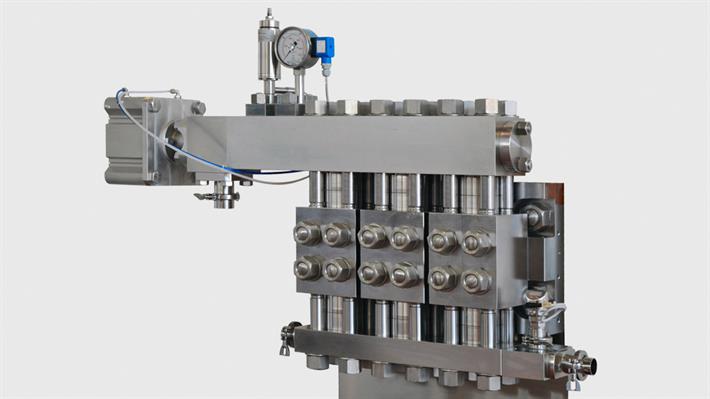

Homogenizer Compression Block

-

GEA compression heads are the homogenizer pulsing core since they activate the homogenization process pumping the product at high pressure until it flows inside the homogenizing valve.

Homogenizer Compression Block NiSoCLEAN

Homogenizer Compression Block OpenXFLO™

Homogenizer Compression Block Standard

Homogenizer Compression Block VHP

Homogenizing Peripheral Devices

-

GEA offers a wide range of accessory components for the homogenizers to expand the additional services of the homogenization technology and the flexibility of use. In this respect, the peripheral devices reflect the green vision of the company as designed to minimize the user consumptions of the machines.

NiSoPURE - Improving your aseptic dairy & food production

O.P.S. Oil Purification System

SLRV-PO Over Pressure Safety Valve

Homogenizing Valves

-

Homogenizing valve is one of the most important elements of GEA homogenizers to make happen the homogenization products effectively.

GEA NiSoX-Valve

Homogenizing NanoVALVE

Homogenizing NanoVALVE HP

Homogenizing Re+VALVE

Homogenizing Standard Valve

Industrial Homogenizers

-

GEA Industrial homogenizers are machines made by two essential elements: a compression block, which allows to pump the product in high pressure and a homogenizing valve, able to micronize dispersed particles down to the order of micrometers and nanometers, depending on products characteristics and the desired results.

GEA Ariete Homogenizer 5400

Homogenizers Ariete Series

Homogenizers One Series

Laboratory Homogenizers

-

GEA laboratory homogenizers, small and compact, allow to test the homogenization effects on the product and evaluate which are the best process parameters.

Homogenizers Pilot Plant

Homogenizers Table-top

Skid-Mounted Homogenizers

-

For some time, GEA has set the standard for very high pressure (VHP) homogenizer units for pharmaceutical and biotechnology applications. Our scope of supply ranges from benchtop laboratory machines through to the in-house design and manufacturing of pilot-scale and production skid-mounted systems for cell lysis and particle size reduction applications.

Homogenizers Plug & Play Pharma Skid

Membrane Filtration Systems

- Cross-flow membrane filtration is the technology of choice for many industrial processes that require the separation or concentration of products without the application of heat. There are applications throughout the food, dairy, pharmaceutical, biotechnology and starch and sweetener industries in which membrane filtration excels. Benefits compared with other methods of separation include: accurate separation of multiple streams; reduced risk of damage especially for heat-sensitive products; no loss of nutritional value or clinical efficacy; reduced energy consumption; reduced waste disposal costs; higher yields; and greater flexibility for new product development. GEA is a world leader for the custom design and building of these large filtration systems with reference sites worldwide.

Membrane Pilot Plants

-

GEA offers a range of self-contained pilot plants for product testing and process development. These are available for use at the GEA facility in Hudson, Wisconsin or can be hired for on-site testing.

Membrane Filtration Pilot Plant C

Membrane Filtration Pilot Plant G

Membrane Filtration Pilot Plant L

Membrane Filtration Pilot Plant P

Membrane Filtration Pilot Plant R

Membrane Filtration Pilot Plant T

Membrane Filtration Pilot Plant U

Membrane Test Facilities at Karlsruhe R&D Center

Pilot Testing and Application Development

Membrane Plants & Solutions

-

GEA membrane filtration systems are used throughout industry. In many applications they have taken over from the more traditional technologies of centrifugal separation, evaporation and coagulation to provide significant benefits in terms of efficiency, product quality and sustainability.

Beer Recovery Unit

CIP Recovery Unit

Clearamic BeerFiltration

COLDSAN™ - Cold Sanitation of Cheese Brine

Condensate Polisher

Custom-Designed Filtration Plants

De-Alcoholization Membrane Unit

Membrane Unit to Produce FAB

Replacement membranes

-

Filter membranes are critical components in dairies. It is essential, therefore that they are maintained well and replaced when necessary to maintain plant performance and product quality. GEA has a comprehensive suite of service programs designed for dairies large and small. They include the monitoring and replacement of membranes and dedicated service technicians who have the experience and know-how to keep plants running efficiently round the clock.

Ceramic Membrane

Service Is Key to Membrane Separation

Spiral Membranes

Stainless Steel Membrane

Mixers & Blenders

- GEA's extensive process knowledge and continuous research delivers the most efficient mixers and blenders. We offer a wide range of technical solutions and process options to ensure the efficient mixing and blending of liquids, powders and granules for a broad scope of industries and applications. Our range of high-performance mixers and wide range of capacity options means you can choose a machine that exactly matches your processing requirements. From food, beverage and dairy applications to chemical, personal care and pharmaceutical ones, whether batch or continuous, GEA not only understands mixing technology, we also have a unique understanding and know-how of the entire process, based on many years of experience and hundreds of successful installations.

Continuous Blenders

-

For liquid component production processes, GEA's efficient in-line blending systems provide the solution you need!

DICON™ Continuous Blenders for Beverage

DICON™ Continuous Blenders for Dairy

DICON™ Continuous Blenders for HPC & Chemicals

High Shear Mixers

-

GEA offers a comprehensive range of advanced processing components that guarantee efficient and successful mixing and a high quality end-product.

Gral™ High Shear Granulators

High Shear Batch Mixer

High Shear In-Line Mixer

PMA™ High Shear Processor

IBC Blenders

-

GEA's wide range of container blenders offers the most flexible and highest quality blending solutions available today.

IBC Blenders

Jet Mixers

-

Liquid jet mixers are ejectors (jet pumps) to mix and circulate liquids. They are simple and reliable, having no moving parts and are hardly subject to any wear.

Liquid jet mixer

Liquid Mixers

-

Mixing is a vital process in the production of a diverse range of products in a wide range of industries. Based on our extensive experience and technological know-how, GEA offers a variety of batch, continuous and in-house custom designed mixing solutions for unique applications that meet specific customer needs.

Batch Mixing Systems

DIMA™ & DI-BATCH™ Batch Mixers

Tailor Made Mixing Systems

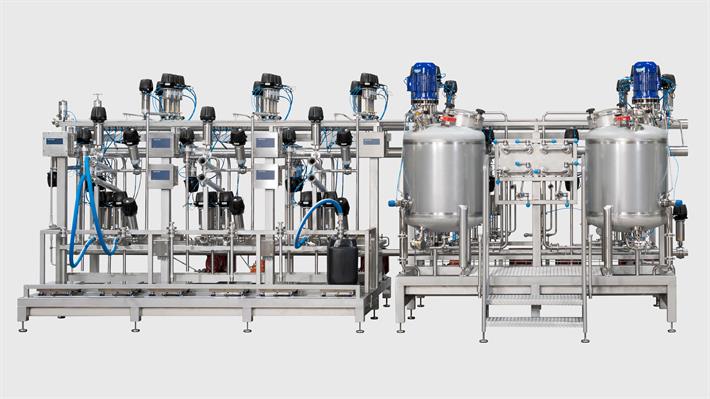

Mixing & Formulation Systems

-

GEA is your knowledgeable partner for the selection and integration of highly purified media production plant and the implementation of storage and CIP/SIP distribution systems within Pharma Liquid Dosage.

Pharma Preparation & Pressure Vessels

Pharma Process Vessels

Storage & Transportation Vessels

Mixing/Carbonating Systems

-

The GEA beverage mixer is designed for the highly accurate continuous blending and carbonation of beverages.

DIMIX™ Mixer/Carbonators

Post Hoist Blenders

-

GEA's blending technology is further extended with our range of post hoist blenders. All of the features and benefits of the pedestal container (IBC) blenders are repeated with the post hoist range, with the added benefits that the IBC can be elevated post-blending to allowing for direct discharge into a downstream process or vessel.

IBC Blenders

R&D Mixers

-

GEA suppliers a range of R&D and small-scale mixers and blenders for the Pharma & Nutraceutical industries.

PharmaConnect™ R&D Processing

Product Handling Systems

- GEA's intermediate bulk containers and powder handling solutions are dedicated to the specific and demanding needs of the worldwide dairy, food and pharmaceutical industries. An experienced team of designers can address your specific application requirements. Whether it's for special tablet handling equipment, spiral hoppers, pinch valves, keg inverters, sack slitters or dispensing hoppers, or solid deceleration devices, please involve us at an early stage in your project so we can help you to select the most appropriate and efficient design solutions.

Contained Materials Handling Systems

-

Contained Materials Handling solutions for Primary and Secondary Pharmaceuticals and Healthcare. With extensive experience within the generics sector, supply a wide range of technologies and equipment that improve and enhance the efficiency and performance of Oral Solid Dosage production.

BUCK® Containment Valves

Contained Powder Sampling

Hicoflex® Disposable Containment System

IBC Blenders

IBC Post Hoists

IBC Systems for the Pharma Industry

Dosing & Feeding

-

GEA supplies a market-leading range of powder handling, feeding and dosing solutions. Our volumetric and gravimetric powder feeding systems guarantee highly accurate processing in critical applications such as minor/major ingredient preparation, pre-mixing, recipe handling, blending and packing.

Screw Conveyors

Vibrating Conveyors

Vibration Feeder

Vibration Spiral Elevator

Vibration Table

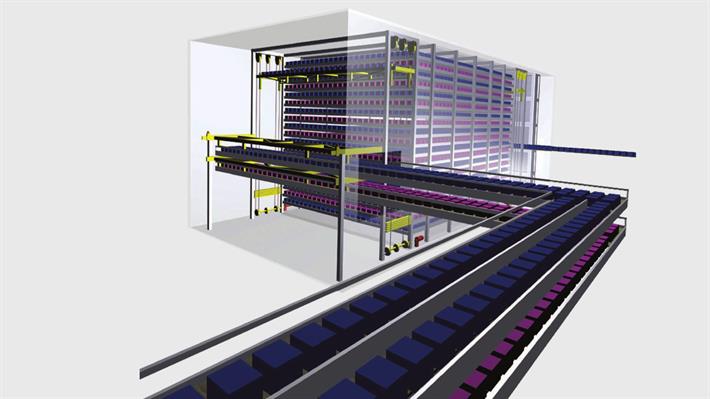

Loading / Unloading systems

-

The design, development and production of loading and unloading systems for applications in numerous industries is a core competence of GEA. Whatever the product or process, standard or tailor-made solutions, both manually operated and fully automated, can be built and delivered to meet the individual needs of our customers.

ALUS™ Load & Unload of Lyophilizers

Grain Handling Systems

IBC Post Hoists

Pneumatic Conveying

-

GEA has been manufacturing pneumatic conveying Systems for more than 40 years and has the experience to select the best system for each product and application.

Pressure Conveying - Dense Phase

Pressure Conveying - Lean Phase

Vacuum Conveying - Dense Phase

Vacuum Conveying - Lean Phase

Powder Handling Components

- GEA is your single-source supplier of powder handling, filling and packing solutions. Whether purchasing an individual machine or a fully integrated system, our clients benefit from our understanding of the exacting requirements of the powder processing industries. We know that our customers demand high standards of quality, reliability and hygiene, so everything we do is done with these requirements in mind.

Powder Samplers

-

GEA offers a range of powder sampling systems to suit the most demanding quality assurance processes in food and dairy plants. Our samplers are able to handle a wide range of containers including bags, bottles, jars and large blow molded containers as required to suit your testing and handling requirements.

Contained Powder Sampling

Powder Sampler (PAS)

Vacuum Powder Sampler

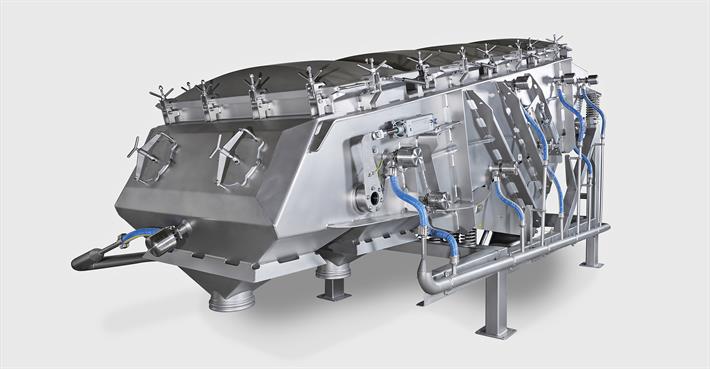

Powder Sifters

-

GEA offers the widest range of sifting systems for powdered products, including rotary, vibratory and circular systems designed to suit a variety of product types and duties.

Sifters for Powders

Powder Storage

-

GEA supplies a wide range of bulk storage solutions for both raw materials and finished goods, including internal/ external stainless steel bulk silos, hoppers and IBC containers.

Powder Silos

Samplers

-

Monitoring of the product quality or determination of the ingredients of the liquids is often only possible in a laboratory procedure. For this, regular samples have to be taken from the liquid (sampling) to ensure the binding traceability.

Samplers for Liquid Processing

Small-scale R&D Handling Systems

-

Contained product transfer for R&D and small-scale applications.

BUCK® Containment Valves

Hicoflex® Disposable Containment System

Tablet Presses

- GEA's strong drive to innovate and improve the compaction process, is reflected in the unique and patented features present throughout our tablet press range. We present our unique design and process features, all of which bring considerable benefits to our customers.

Continuous Direct Compression Line

-

The ConsiGma DC for direct compression is the latest expansion of GEA's continuous portfolio for cost effective, compact, high yield manufacturing systems. It offers a robust and flexible manufacturing method for a wide range of products.

ConsiGma™ Continuous Direct Compression

ConsiGma™ Continuous Tablet Coater

Continuous Tableting Lines

-

At GEA we believe that continuous processing improves the quality of pharmaceutical end products: by focusing on quality during the whole product life-cycle, not just tested in quality; and by understanding the capability of your processes, managing sources of variability and decreasing any associated risks.

ConsiGma™ Continuous Direct Compression

ConsiGma™ Continuous Tablet Coater

ConsiGma™ Continuous Tableting Line

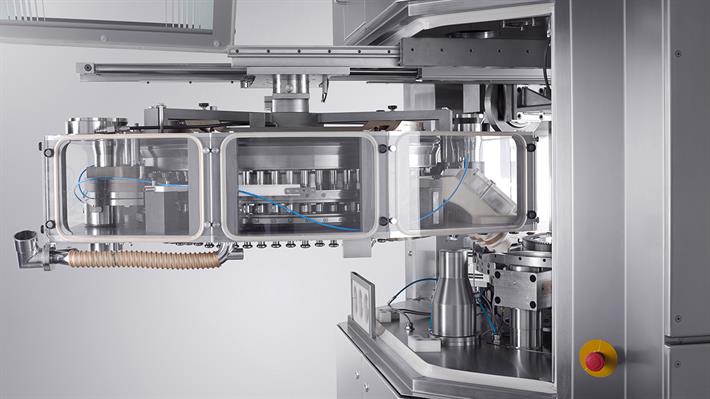

Pharma Tablet Presses

-

Manual to automatic rotary tablet press for research, pilot-scale and full production, presses for normal, clean-room, contained and highly contained environments and presses for the production of single and bi-layer tablets.

MODUL™ D Tablet Press

MODUL™ P Tablet Press

MODUL™ Q Tablet Press

MODUL™ S Tablet Press

MODUL™ Tablet Press Technology

PERFORMA™ Lite Tablet Press

PERFORMA™ P Tablet Press

R&D Tablet Presses

-

Formulation & Small-Scale Production - increased versatility - increased safety - increased productivity - increased flexibility

MODUL™ P Tablet Press

Rotary Presses for Industrial Applications

-

With 100 years of experience, GEA has developed a unique expertise in designing, manufacturing and servicing the widest available range of industrial rotary presses.

PERFORMA™ Lite Tablet Press

R0/2 Tablet Press

R233 Tablet Press

R253 Tablet Press

R353 Tablet Press

R5 Tablet Press

R55 Tablet Press

R57 Tablet Press

Tablet Coaters

-

Presenting a paradigm shift in tablet coating, this new type of coater subjects tablets to a cascading tablet movement that enables greater fluid application rates (higher coating build-rates) than traditional coating pans.

AirConnect™ Fluid Bed Processor & Coater

ConsiGma™ Continuous Tablet Coater

FlexStream™ Fluid Bed Processor

Fluid Bed R&D Processing of Pharmaceuticals

PharmaConnect™ PLUS

Visual Inspection Systems

-

Our Viswill product range for the pharma industry includes inspection systems for both tablets and capsules. All Viswill visual inspection technology is distinguished by high accuracy, high speed and operational efficiency.

Visual Inspection System for Capsules

Visual Inspection System for Tablets

Vacuum Systems

- Vacuum technology is used extensively in the chemical, pharmaceutical, food and oil refining industries and also to remove dissolved gases from water and other liquids. Where industrial processes use the vapor from the product instead of steam, GEA provides completely closed systems that are both ecologically and economically efficient.

Ejector Systems

-

Ejectors, are devices for the conveyance, compression or mixing of gases, vapors, liquids or solids in which a gaseous or liquid medium serves as the motive force. They are "pumps without moving parts".

Ejector Test facilities at Karlsruhe R & D Center

Ejectors

Variable - Flow Ejectors

Vacuum System

-

Vacuum systems are based on jet pump technology. They essentially consist of combinations of jet pumps and condensers.

Combined Steam Jet and LRVP Systems

Dry condensing vacuum systems

High Corrosive Resistant Vacuum Systems

Multi-stage steam jet vacuum pumps

Product Driven Steam Jet Vacuum Systems